Silicon Nitride (Si₃N₄) Balls— High-Speed, Wear-Resistant Solutions for Bearings & Motors

ADCERAX is a China-based manufacturer specializing in silicon nitride balls (Si₃N₄) for high-speed bearings, motors, and chemical processing equipment. With a professional engineering team and in-house facilities for sintering, polishing, and precision inspection, we supply Si₃N₄ ceramic balls that deliver exceptional hardness, low density, and long-term wear resistance. Available in G5–G20 grades and diameters from 2 mm to 25 mm+, our products meet demanding tolerance and roundness requirements for hybrid bearing applications.

👉Send your size and grade requirements today—our team will prepare a tailored quotation within 24 hours.

What are Silicon Nitride Ceramic Balls?

Silicon nitride (Si₃N₄) balls are sintered from high-purity powders into dense, fine-grained ceramics. A typical microstructure contains elongated β-Si₃N₄ grains interlocked in a glassy boundary phase, delivering high fracture toughness compared with many technical ceramics.

Silicon Nitride Balls Composition

Silicon nitride (Si₃N₄) is a non-oxide ceramic composed primarily of silicon (Si) and nitrogen (N) elements. In finished ceramic balls, the composition typically includes:

- Si₃N₄ phase (main crystalline component) – over 90–95 wt%, forming either α-Si₃N₄ or β-Si₃N₄ structures.

- Sintering additives (4–8 wt%) such as yttrium oxide (Y₂O₃), aluminum oxide (Al₂O₃), or magnesium oxide (MgO), which promote densification and form a thin amorphous grain boundary phase.

- Trace residual phases (<1 wt%), mainly silica (SiO₂) and glassy oxynitride from the sintering atmosphere.

How are Silicon Nitride Balls Made?

Silicon nitride (Si₃N₄) balls are produced through a multi-stage precision process combining ceramic powder engineering, controlled sintering, and fine polishing. Each step determines the final roundness, density, and surface integrity required for high-speed bearing performance.

Selection and blending of high-purity Si₃N₄ powder with Y₂O₃ and Al₂O₃ additives to ensure fine, uniform composition and stable sintering performance.

Compacting the prepared powder into spherical blanks through isostatic or precision pressing, maintaining uniform density before firing.

Densification under 1650–1800 °C in nitrogen atmosphere, followed by Hot Isostatic Pressing (HIP) to remove pores and achieve >99% theoretical density.

Multi-stage diamond grinding and lapping process to reach precise diameter tolerance, smooth surface finish, and bearing-grade roundness.

Ultrasonic cleaning removes all residues; each ball is sorted by size, grade, and surface integrity to ensure uniform batch quality.

Final roundness, hardness, and density inspection using optical and ultrasonic systems, then vacuum or tray-packed for safe international shipment.

Why Silicon Nitride Balls Outperform Steel and Zirconia Balls?

Silicon nitride (Si₃N₄) ceramic balls deliver superior strength, heat resistance, and corrosion protection compared to traditional steel or zirconia balls. Their unique balance of light weight, hardness, and insulation makes them the preferred choice for high-speed bearings, motors, and precision mechanical assemblies.

Silicon Nitride Ceramic Balls vs. Steel & Zirconia Balls

| Property | Silicon Nitride (Si₃N₄) | Steel Balls | Zirconia (ZrO₂) |

| Density (g/cm³) | ~3.2 (lightweight) | ~7.8 (heavy) | ~6.0 |

| Hardness (HV) | 1400–1700 | 700–800 | 1100–1200 |

| Flexural Strength (MPa) | 600–800 | 2000+ (brittle under heat) | 500–700 |

| Thermal Conductivity (W/m·K) | 20–30 | 50+ | 2–3 |

| Thermal Expansion (×10⁻⁶/K) | 3.2 | 12 | 10 |

| Electrical Conductivity | Insulating | Conductive | Insulating |

| Corrosion Resistance | Excellent | Poor | Good |

| Temperature Limit (°C) | Up to 1200 | Below 300 | ~600 |

| Weight Efficiency | 60% lighter than steel | — | 30% lighter |

| Cost Level | Medium | Low | High |

Si₃N₄ vs. Steel Balls:

Precision silicon nitride balls operate cooler and resist electrical erosion, lasting 3–5× longer in electric motors and precision bearings. Steel balls suffer from oxidation, corrosion, and magnetic losses under high temperature or humidity.Si₃N₄ vs. Zirconia Balls:

While zirconia offers good corrosion resistance, it is heavier and less thermally stable. Si₃N₄ balls maintain strength and roundness under high temperature and provide better dynamic balance for high-speed rotation.Best Choice for Industrial Users:

For EV motors, machine spindles, turbochargers, and precision tools, silicon nitride balls provide the best strength-to-weight ratio, enabling higher rotation speed, lower friction, and longer lifetime with minimal maintenance.

Silicon Nitride (Si3N4) Balls Properties

Silicon nitride (Si₃N₄) balls combine low density, ultra-high hardness, and superior thermal stability, ensuring smooth performance under extreme speed, temperature, and load. They provide excellent electrical insulation and corrosion resistance for hybrid bearings, precision motors, and demanding industrial systems.

Silicon Nitride Ceramic Ball Technical Sheet

| Si3N4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

| Density (g/cm3) | 3.2 | 3.3 | 3.25 |

| Flexture strength (MPa) | 700 | 900 | 600~800 |

| Young Modulus (GPa) | 300 | 300 | 300~320 |

| Poisson’s ratio | 0.25 | 0.28 | 0.25 |

| Compressive strength (MPa) | 2500 | 3000 | 2500 |

| Hardness (GPa) | 15 | 16 | 15 |

| Fracture toughness (MPa*m1/2) | 5~7 | 6~8 | 6~7 |

| Maximum working temperature (℃) | 1100 | 1300 | 1100 |

| Thermal conductivity (W/m*K) | 20 | 25 | 80~100 |

| Thermal expansion coefficient (/℃) | 3*10-6 | 3.1*10-6 | 3*10-6 |

| Thermal shock resistance (ΔT ℃) | 550 | 800 | / |

Advantages of Silicon Nitride Balls

Engineered β-Si₃N₄ microstructure provides superior mechanical strength and impact resistance, ensuring stable performance in high-speed and high-load bearing systems.

Operates reliably up to 1200 °C with low thermal expansion and complete electrical insulation—ideal for high-voltage and high-temperature environments.

Hardness above 1500 HV and chemical inertness make Si₃N₄ balls non-reactive to lubricants, fuels, and molten metals, extending service life in corrosive or dry-running conditions.

At only 40% the density of steel, Si₃N₄ ceramic balls minimize centrifugal force, reduce bearing friction and vibration, and enable longer maintenance intervals.

Silicon Nitride (Si3N4) Ceramic Ball Products

ADCERAX manufactures and supplies silicon nitride balls (Si₃N₄) in multiple grades, diameters, and tolerances. Available for both standard and custom specifications, each ball is precisely ground and polished to meet international quality standards, ensuring dimensional uniformity and surface consistency for diverse industrial requirements.

Silicon nitride bearing balls are made from high-purity ceramic with fine grains to ensure lasting strength and precision. Each ball is carefully ground and polished for smooth rolling, consistent hardness, and accurate dimensions, suitable for long-term use in precision bearings.

- Precisely graded for G3–G10 precision levels

- Uniform density and surface finish

- Available in custom sizes and grades

Silicon nitride grinding beads feature uniform density, smooth surfaces, and exceptional hardness for consistent dispersion and milling performance. They maintain stability during high-speed mixing and abrasion processes, ensuring efficient grinding and extended media life.

- High hardness and uniform wear rate

- Stable in high-speed, high-temperature milling

- Smooth surface minimizes contamination

🚀Precision Si₃N₄ Balls — Zero Rust. Zero Downtime. Maximum Life.

Each precision silicon nitride ball is engineered for high-speed bearings and demanding environments, providing unmatched stability, insulation, and durability. ADCERAX ensures consistent quality and fast worldwide delivery.

What Are Silicon Nitride Balls Used For?

Silicon nitride balls are widely used in high-speed bearings, EV drive systems, chemical pumps, and precision instruments, offering lightweight strength, high temperature resistance, and long-term dimensional stability across demanding industrial and scientific applications.

High-Speed Bearings & Spindles

Applications: Silicon nitride balls are widely used in high-speed motors, precision machine tool spindles, and aerospace shaft systems.

🧩 Key Advantages:

- High-Speed Stability: With a density of only 3.2 g/cm³ (40% lighter than steel), Si₃N₄ balls reduce centrifugal force by over 30% at 100,000 rpm, minimizing vibration and heat generation.

- Precision Roundness: Achieves G3–G5 grade sphericity with surface roughness Ra ≤ 0.02 µm, ensuring ultra-smooth rotation and consistent dynamic balance in spindles.

- Thermal Performance: Maintains hardness above 1400 HV and dimensional accuracy at > 1000 °C, preventing expansion-induced runout in high-speed machining.

🔹Problem Solved:

A precision CNC spindle manufacturer replaced steel balls with ADCERAX Si₃N₄ balls, achieving a 45% increase in rotational speed (from 80,000 rpm to 116,000 rpm) while reducing bearing temperature rise by 18 °C. This upgrade extended bearing service life from 8 months to over 14 months, cutting maintenance downtime by 40% and improving spindle energy efficiency across continuous production lines.

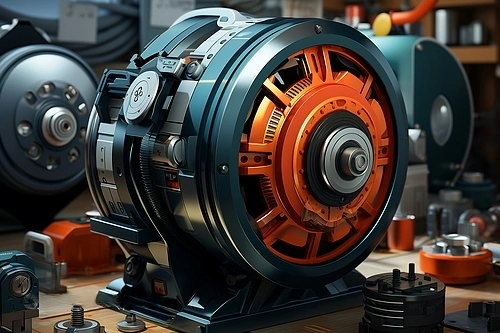

EV & Hybrid Drive Systems

Applications: Si3N4 balls are applied in electric motor bearings, transmission gearboxes, and inverters.

🧩 Key Advantages:

- Electrical Insulation for Motor Bearings: Si₃N₄ balls feature a resistivity of >10¹² Ω·cm, effectively preventing electric pitting and current leakage in high-voltage traction motors.

- Lightweight for Efficiency: With a density of 3.2 g/cm³, they reduce bearing load and friction torque by 25–30%, improving EV drivetrain energy efficiency.

- High-Speed Durability: Maintain structural integrity at >100,000 rpm and withstand continuous temperatures up to 800 °C, ideal for inverter-driven high-speed e-axles.

🔹Problem Solved:

- A leading electric vehicle OEM adopted ADCERAX silicon nitride balls in their hybrid drive motor bearings to eliminate electrical arcing and grease carbonization. Testing across 1,200-hour continuous operation showed zero electric pitting, 28% lower friction torque, and 35% longer service life compared with coated steel bearings, ensuring stable motor output and lower warranty failure rates in mass production.

Pumps & Compressors

Applications: Si3N4 balls are used in chemical equipment, vacuum pumps, and magnetic drive pumps.

🧩 Key Advantages:

- Corrosion Resistance Under Harsh Media

Si₃N₄ bearings maintain full mechanical strength after 1,000+ hours of exposure to acids, alkalis, and salt solutions, far outperforming stainless steel bearings. - Self-Lubricating Operation

Their ultra-smooth surface (Ra ≤ 0.02 µm) allows stable, oil-free rotation in corrosive or deionized liquid systems, preventing contamination and leakage. - Dimensional Stability at High Temperature

Withstand continuous service up to 800 °C, maintaining tight clearances under fluctuating thermal and chemical loads.

🔹Problem Solved:

- A European chemical pump manufacturer replaced stainless steel balls with ADCERAX silicon nitride balls in their magnetic drive pump line. After 2,000 hours of continuous operation under acidic and high-temperature conditions, the failure rate dropped by over 60%, while bearing friction torque was reduced by 22%. The upgrade extended pump maintenance intervals from 6 to 10 months, significantly improving uptime and reducing total operational costs.

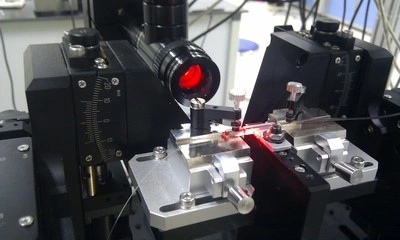

Precision Instruments & Measurement Systems

Applications: Silicon nitride ceramic balls are used in scientific instruments, testing devices, and medical precision motion components.

🧩 Key Advantages:

- Ultra-High Sphericity: Each Si₃N₄ ball achieves G3 precision grade with roundness deviation below 0.08 µm, ensuring accurate motion control in metrology equipment.

- Exceptional Surface Finish: Polished to Ra ≤ 0.015 µm, providing frictionless contact and minimizing noise in optical and positioning assemblies.

- Dimensional Stability in Temperature Variations: Thermal expansion coefficient of 2.8 × 10⁻⁶/K, maintaining measurement repeatability across temperature shifts.

🔹Problem Solved:

A Japanese precision metrology company integrated ADCERAX silicon nitride balls into its probe assemblies for CMM (Coordinate Measuring Machines). Compared with steel probes, measurement repeatability improved by 35%, while surface wear decreased by over 50% after 5,000 test cycles. The adoption resulted in more stable dimensional readings and reduced recalibration frequency, enhancing throughput in high-precision inspection lines.

Custom Silicon Nitride Ceramic Balls Manufacturer

ADCERAX specializes in custom silicon nitride balls (Si₃N₄) engineered to meet your drawings and precision requirements. We support non-standard diameters, specific G-grades (G5–G20), special clearances, and custom surface finishes for hybrid or full-ceramic bearing applications. Each Si₃N₄ ceramic ball is precision-ground, inspected, and sorted to verified tolerances, ensuring stable performance and consistent batch quality.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

ADCERAX – Precision Silicon Nitride Balls Supplier

ADCERAX operates as a dedicated Si₃N₄ ceramic ball factory and global exporter from China, delivering high-precision silicon nitride balls for bearing assemblies, electric motors, and advanced mechanical components. Our facility integrates automated forming, hot isostatic pressing, and precision polishing, ensuring stable batch quality and tight dimensional control.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

ADCERAX integrates Si₃N₄ ceramic ball production, precision grinding, automated inspection, and export packaging into a unified process. We provide custom-sized silicon nitride balls, precision grades (G5–G20), and tailored surface finishes — from prototype runs to large-scale supply.

-

Precision Machining & Dimensional Control:

Each Si₃N₄ ball is CNC-ground and lapped to achieve uniform roundness, verified tolerance, and a mirror-like surface finish. Controlled density and sphericity ensure stable rotation, low friction, and extended lifespan in hybrid or full-ceramic bearings. -

Batch Consistency & Quality Verification:

Every batch undergoes automated inspection for hardness, microstructure uniformity, and density stability. Strict quality control guarantees consistent performance under high-speed, high-temperature, and corrosive environments, reducing rejection rates for global OEM buyers. -

Customization & Engineering Support:

We offer custom silicon nitride balls based on your drawings or specifications, including non-standard diameters, special grades, and coating or lubrication options. ADCERAX’s engineering team supports clients with material selection, precision sorting, and export-ready packaging, ensuring reliable performance and fast international delivery.

ADCERAX specializes in manufacturing silicon nitride (Si₃N₄) balls using advanced forming, high-temperature sintering, and precision grinding technologies. Each ball is engineered for uniform density, accurate roundness, and superior surface finish, ensuring stable performance in high-speed and corrosive environments. As a professional Si₃N₄ ceramic ball manufacturer, ADCERAX guarantees tight dimensional control, low friction, and consistent batch quality for demanding industrial and bearing applications.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Capability Item | Typical Value / Description | ||

| Material Grades | Hot-pressed or gas-pressure sintered Si₃N₄ ceramic balls with fine and dense microstructure. Hardness >1500 HV, fracture toughness > 6 MPa·m½, and density ≈ 3.2 g/cm³ — ideal for high-speed, wear-resistant, and corrosive bearing environments. | ||

| Precision Machining | CNC grinding and lapping achieve diameter tolerances within ±0.002 mm and roundness ≤ 0.1 µm. Mirror surface finish up to Ra ≤ 0.02 µm ensures low friction and stable rotation in hybrid and full-ceramic bearings. | ||

| Forming & Shaping | Isostatic pressing and precision pre-sintering allow for custom sizes and grades (G5–G20). Tailored geometry supports non-standard diameters and specific bearing configurations. | ||

| Flatness & Dimensional Control | Controlled sintering eliminates porosity and guarantees uniform density and sphericity for balanced rotation under high speed and load conditions. | ||

| Surface Finishing | Final lapping and ultrasonic cleaning deliver a defect-free surface with uniform gloss and no contamination. Each batch is sorted by grade and inspected for surface integrity and size uniformity. | ||

FAQ

Si₃N₄ ceramic balls are significantly lighter, harder, and more chemically stable than steel balls — they generate less heat, resist corrosion, and remain dimensionally stable at temperatures exceeding 1,000 °C, while steel balls deform or oxidize under similar conditions, leading to higher friction and shorter bearing life.

The most common Si₃N₄ ceramic ball grades are G3, G5, G10, and G20, which define precision levels for roundness, surface finish, and dimensional tolerance.

At ADCERAX, all silicon nitride balls are produced and sorted by grade according to ISO 3290 / ABMA standards — for example, G5 Si₃N₄ balls achieve ≤0.13 µm roundness and ultra-smooth Ra ≤0.02 µm surfaces for high-speed bearings, while G10–G20 grades are optimized for industrial and general mechanical use where cost efficiency and long service life are both important.

The hardness ranges between 1,400–1,700 HV, while the density is around 3.2 g/cm³ — much lower than steel. This makes Si₃N₄ ceramic balls ideal for lightweight, high-speed mechanical assemblies.

Yes, ADCERAX specializes in custom silicon nitride balls tailored to your engineering drawings and application needs. We can produce non-standard diameters from 1 mm to 50 mm, with grades from G3 to G20, customized surface finish, roundness, and tolerance (±0.002 mm). Our in-house tooling and sintering facilities allow flexible MOQs, prototype support, and consistent quality for precision bearings, pumps, and motion systems — ensuring every batch meets your exact technical and export requirements.

Yes. ADCERAX is both a Si₃N₄ ceramic balls manufacturer and an exporter, integrating production, quality testing, and global shipping. We serve clients in the U.S. UK, Germany, Japan, and other industrial countries.

We supply standard sizes such as 3.969 mm, 12 mm, and 15 mm Si₃N₄ balls, and can also produce special sizes upon request. Each silicon nitride ball is graded according to diameter tolerance and sphericity.

You can get a discount silicon nitride balls price by ordering in bulk or establishing long-term supply cooperation with ADCERAX. We offer preferential rates for high-volume, repeat, or OEM orders, ensuring cost efficiency without compromising Si₃N₄ ball quality or delivery speed.

Yes, ADCERAX is a professional silicon nitride balls exporter supplying high-precision Si₃N₄ ceramic balls to the UK and other industrial markets. Our factory in China ensures stable quality, fast delivery, and full export documentation for global shipments.

ADCERAX is a silicon nitride ceramic balls manufacturer and supplier with over 20 years of experience in precision ceramic production. Our factory integrates material preparation, hot-press sintering, and precision grinding to ensure high strength, low density, and stable quality. With in-house engineering support, flexible customization, and fast global delivery, ADCERAX provides dependable Si₃N₄ ceramic ball solutions for demanding industrial applications.

Silicon nitride balls are lighter, harder, and more heat-resistant, ideal for high-speed and electrical insulation applications, while tungsten carbide balls are denser and better suited for heavy-load, impact, or abrasive environments. In precision bearings, Si₃N₄ balls reduce centrifugal force and wear, extending service life compared to tungsten carbide.

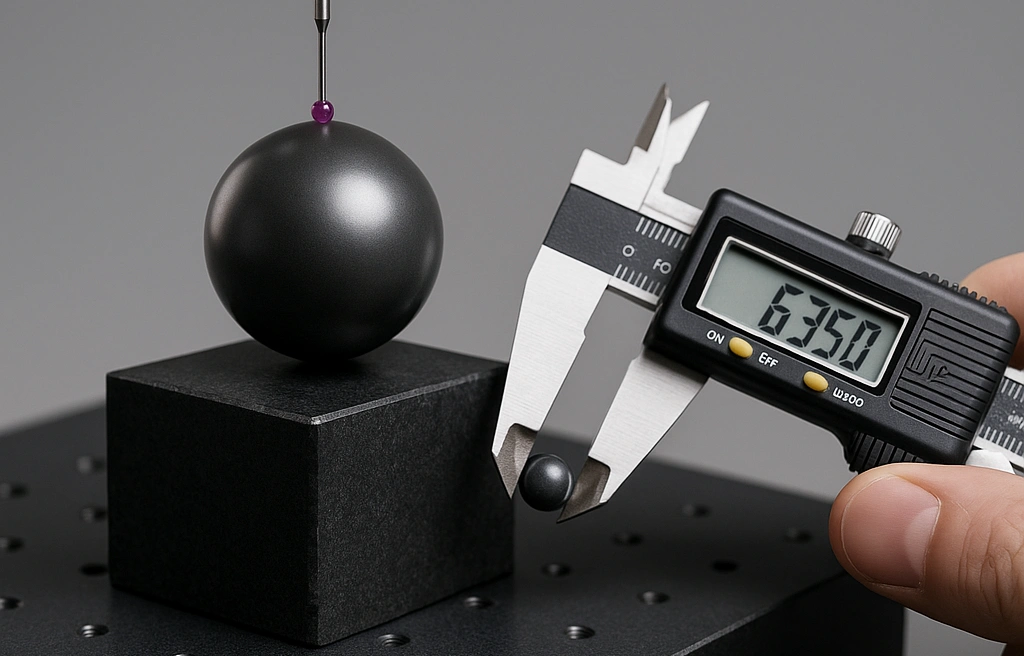

Visual & dimension check: Inspect for chips or cracks and verify diameter/roundness with a micrometer or CMM.

Density/porosity check: Use Archimedes method to confirm expected density and low open porosity.

Non-destructive inspection: Run ultrasonic C-scan or X-ray CT to detect internal flaws.

Quick QC fracture estimate: Perform Vickers indentation and measure crack lengths for a fast toughness indication.

Reference fracture toughness: Test companion specimens with SEVNB (or equivalent) for accurate K_IC when certification is required.

Application test (recommended): Conduct rolling contact fatigue or bearing rig tests to measure cycles-to-failure under real load conditions.

Practical tip: For bearing applications prioritize rolling contact fatigue results and NDT for lot acceptance; use indentation checks for routine QC.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours