Advanced Yttrium Oxide Ceramic (Y₂O₃) for Melting, Coating, Plasma, and Optical Systems

As a China yttrium oxide ceramic manufacturer and supplier with 20+ years of experience, ADCERAX provides high-purity yttrium oxide ceramic crucibles, Y₂O₃ transparent ceramics, and related components for high-temperature melting, plasma systems, thin-film coating, and optical applications. We support full customization, including complex shapes, tight tolerances, and specified purity levels. Through integrated manufacturing, engineering support, and flexible batch production, we help customers minimize project risk and achieve stable performance in demanding industrial environments.

📲 Contact us today to discuss your specifications and start your next Y₂O₃ ceramic project with confidence.

What Is Yttrium Oxide Ceramic?

Yttrium oxide ceramic (Y₂O₃) is a type of advanced oxide ceramic made by shaping and sintering high-purity yttrium oxide into stable solid components. It is widely recognized in industrial and research fields for its role in producing yttrium oxide ceramic crucibles, Y₂O₃ transparent ceramic parts, sputtering target blanks, and other engineered ceramic structures.

Yttrium Oxide Ceramic (Y₂O₃) Advantages

Y₂O₃ ceramic remains stable when exposed to titanium, TiAl alloys, and vapor-phase environments, helping users maintain alloy purity, minimize process interruptions, and keep melting or coating systems running consistently without unexpected material reactions.

Although Y₂O₃ is a premium ceramic, its process compatibility and predictable behavior reduce part replacements, equipment downtime, and scrap losses—providing a more controlled cost structure for production and R&D operations.

Yttrium oxide ceramic interacts minimally with reactive metals and specialty coatings, helping users achieve cleaner alloy compositions, smoother coating layers, and higher repeatability in precision optical or PVD applications.

Y₂O₃ ceramics can be produced as crucibles, windows, liners, shields, and sputtering-target blanks in custom shapes, step features, precise tolerances, and surfaces suited to furnace, coating, or optical system designs.

Properties of Yttrium Oxide Ceramics

Yttrium oxide ceramic (Y₂O₃) offers high thermal stability, strong chemical inertness, and excellent compatibility with reactive metals such as titanium and TiAl alloys. Its clean processing behavior, corrosion resistance, and stable dielectric performance make it suitable for high-temperature melting, vacuum environments, thin-film coating systems, and advanced optical applications.

Yttrium Oxide Ceramic (Y₂O₃)– Technical Sheet

| Category | Property | Value |

|---|---|---|

| Chemical & Physical | Main Composition | 99% Y₂O₃ |

| Color | White | |

| Density | 4.9 g/cm³ | |

| Hardness (Mohs) | 6 | |

| Mechanical | Flexural Strength | 130 MPa |

| Compressive Strength | 508 MPa | |

| Thermal | Thermal Expansion Coefficient (25°C → 400°C) | 7.2 × 10⁻⁶ /°C |

| Long-Term Service Temperature | 800°C | |

| Thermal Conductivity (25°C) | 1.71 W/m·K | |

| Electrical | Dielectric Strength (5 mm) | 10 kV/mm |

| Volume Resistivity | > 10¹³ Ω·cm | |

| Dielectric Loss (25°C @ MHz) | Not specified | |

| Dielectric Constant (25°C @ MHz) | Not specified |

This chart displays the typical properties of yttrium oxide ceramic (Y₂O₃) materials used in our standard products. Please note: Customized parts may have adjusted characteristics depending on production methods, with specific parameters determined by the stabilizer type and formula chosen for your application.

Key Properties of Y₂O₃ Ceramics

Y₂O₃ ceramic maintains stability under sustained high-temperature conditions, making it suitable for alloy melting, vacuum furnaces, and plasma environments in industry.

The material shows minimal interaction with titanium, TiAl, and other reactive alloys, helping protect melt purity and reducing contamination in critical metallurgical processes.

Yttrium oxide ceramic resists corrosion from molten metals, halides, and aggressive atmospheres, supporting long-term performance in demanding chemical and coating systems.

Y₂O₃ ceramic has a stable structure that reduces particle shedding, contributing to cleaner environments for coating, thin-film, and precision optical applications.

Its high dielectric strength and volume resistivity enable use in plasma processing, insulation components, and high-frequency applications.

Y₂O₃ components maintain shape and dimensional accuracy through repeated heating cycles, supporting reliable operation in industrial and R&D equipment.

Yttrium Oxide Ceramic Component Families

ADCERAX supplies a full range of yttrium oxide ceramic components, including Y₂O₃ crucibles, liners, trays, shields, and transparent Y₂O₃ ceramic parts for high-temperature melting, vacuum processing, coating systems, and optical assemblies. Both standard sizes and fully customized geometries can be manufactured according to drawings, tolerances, or specific purity requirements.

Transparent Y₂O₃ covers are used in optical ports, IR windows, and high-temperature viewing areas that require clear, stable transmission during operation.

- Delivers stable optical clarity at high temperatures

- Resists chemical attack and particle generation

- Supports custom sizes for specialized equipment

Yttrium oxide crucibles are used in titanium alloy melting, vacuum furnaces, and high-purity material processing where clean, stable high-temperature performance is required.

- Minimizes contamination in reactive-metal processes

- Maintains dimensional stability under extreme heat

- Supports custom shapes and tight-tolerance designs

Y₂O₃ sputtering targets are used in PVD systems, thin-film deposition, and optical coating processes that require clean, stable material delivery.

- Enables uniform film formation with high material purity

- Supports consistent coating performance with low contamination

- Offers custom sizes and bonding options for various PVD setups

🔥Reduce contamination and stabilize your process—choose engineered yttrium oxide ceramic.

ADCERAX Y₂O₃ ceramic parts deliver dependable behavior in reactive-metal, vacuum, and coating environments, helping you maintain cleaner results and smoother production. 👉 Tell us your needs for a custom Y₂O₃ design.

Where Yttrium Oxide Ceramic (Y₂O₃) Is Used?

Yttrium oxide ceramic (Y₂O₃) is applied in high-temperature and plasma environments across vacuum coating systems, PVD/CVD equipment, halogen-based plasma etching tools, optical and infrared window assemblies, alloy-melting crucibles, and components requiring chemical stability in reactive-gas atmospheres.

Vacuum Metallurgy & Alloy Melting

🔹Advantages

Excellent chemical inertness prevents alloy contamination during melting

High thermal stability supports continuous operation at extreme temperatures

Long service life reduces crucible replacement frequency

Suitable for clean-melt processes where purity is critical

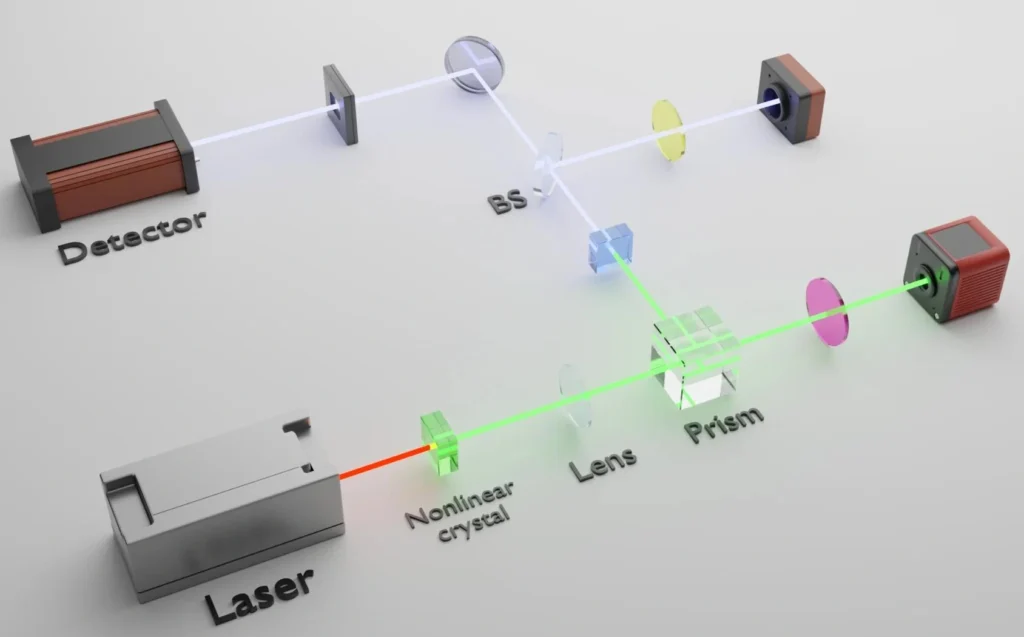

Optical & IR/Laser Systems

🔹Advantages

Optical transparency from visible to mid-IR wavelengths

Withstands heat, dust, and chemical exposure

Maintains mechanical strength even in aggressive conditions

Enables long-term optical stability in harsh environments

Plasma Processing & High-Energy Environments

🔹Advantages:

Exceptional plasma erosion resistance

Low volatility ensures reduced contamination and stable chamber performance

Suitable for prolonged high-energy exposure

Minimizes downtime caused by frequent part replacement

Research, Laboratory, Material Testing

🔹Advantages:

High purity ensures consistent experimental results

Resistant to thermal shock and reactive atmospheres

Supports custom micro-structures and small-batch prototyping

Ideal for precision testing and controlled environments

PVD / Thin-Film Deposition

🔹Advantages:

Low sputter erosion and low particle generation for stable film quality

High purity supports contamination-sensitive coating environments

Strong resistance to plasma and reactive gases

Excellent dimensional stability for precision chamber components

Custom Y₂O₃ Ceramic Parts and Engineering Support

We specialize in custom yttrium oxide (Y₂O₃) ceramic parts based on customer drawings, samples, or application requirements. Dimensions, wall thicknesses, stepped profiles, and complex geometries can be tailored to fit specific operating conditions. Custom Y₂O₃ components typically require 3–9 weeks depending on design complexity, purity grade, and finishing specifications.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

china yttrium oxide ceramic manufacturer

ADCERAX is a China yttrium oxide (Y₂O₃) ceramic factory providing consistent quality, stable lead times, and responsive technical support for high-temperature, vacuum, and thin-film processing applications. Our factory-direct model helps industrial buyers reduce procurement cost, improve supply stability, and maintain reliable performance in demanding operating environments.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

ADCERAX provides integrated manufacturing for yttrium oxide ceramic components, delivering stable quality, controlled lead times, and engineering support. As a china yttrium oxide ceramic manufacturer, we help industrial users obtain reliable Y₂O₃ parts for high-temperature, vacuum, and thin-film applications.

-

Precision Machining & Dimensional Consistency:

Yttrium oxide ceramic parts are processed with accurate dimensions, consistent wall thickness, and clean surfaces suited for melting systems, vacuum furnaces, and coating platforms. Our capabilities support customers seeking high quality china yttrium oxide ceramic for engineered components. -

Batch Stability & Performance Control:

Each batch is inspected for purity, density accuracy, and dimensional stability to ensure predictable behaviour under high-temperature and reactive-metal conditions. As a yttrium oxide ceramic factory, we maintain strict process control to provide consistent and repeatable performance. -

Customization & Engineering Support:

We offer drawing-based customization for complex shapes, stepped profiles, thin-wall sections, and optical-grade surfaces. With experience as a yttrium oxide ceramic manufacturer in china, our engineering team supports application matching for furnaces, coating systems, plasma processes, and research environments.

ADCERAX produces yttrium oxide (Y₂O₃) ceramics with controlled formulation, precision machining, and strict dimensional consistency. Our Y₂O₃ components offer excellent chemical inertness, stable behavior in high-temperature and vacuum environments, and reliable compatibility with alloy-melting, plasma-facing, and thin-film processing systems—supporting consistent performance in demanding industrial applications.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Capability Item | Typical Value / Description | ||

| Purity & Material Stability | High-purity Y₂O₃ ensures chemical inertness, minimal contamination risk, and reliable behavior in high-temperature and vacuum systems. | ||

| Precision Geometry & Surface Quality | Tight tolerances (±0.05–0.15 mm) and clean surfaces help achieve stable system sealing, optical clarity, and accurate component alignment. | ||

| Customization Capability | Supports complex shapes, optical surfaces, thin sections, and deep cavities required for coating tools, plasma chambers, and furnace designs. | ||

| High-Temperature & Vacuum Reliability | Y₂O₃ maintains dimensional accuracy under extreme heat, plasma exposure, and reactive gases, reducing failure rates. | ||

| Consistent Batch Quality | Every batch is verified for density uniformity and high-temperature behavior to ensure predictable performance in critical processes. | ||

FAQs About Yttrium Oxide Ceramic

Most industrial systems require ≥99.9% purity to ensure chemical inertness, low vapor pressure, and minimal contamination in plasma, PVD, or CVD equipment. Higher purity reduces oxygen outgassing and improves long-term stability.

Y₂O₃ is widely selected for environments involving halogen-based plasmas, vacuum systems, and reactive gases because it maintains lower evaporation rates, higher chemical stability, and longer service life than Al₂O₃ or ZrO₂. This performance edge makes it a preferred choice for engineers evaluating high-purity yttrium oxide ceramic for sale.

| Property / Behavior | Y₂O₃ (Yttrium Oxide) | Al₂O₃ (Alumina) | ZrO₂ (Zirconia) |

|---|---|---|---|

| Halogen-Plasma Resistance | Excellent — lowest erosion and particle generation | Poor — heavy erosion in F/Cl plasma | Moderate — corrodes slower than Al₂O₃ but still reacts over time |

| Evaporation Rate in High Vacuum | Very low | Moderate | High — tends to evaporate at elevated temperatures |

| Chemical Stability | Highly stable, minimal reaction with fluorine/chlorine | Reacts readily with halogen species | Shows partial reaction and phase degradation |

| Thermal Stability at High Temperature | Excellent, maintains structure and purity | Good | Good but susceptible to phase transformation |

| Particle Generation Risk | Very low | High | Medium |

| Lifetime in Plasma Tools | Longest | Shortest | Medium |

| Typical Use Suitability | Plasma chambers, PVD/CVD, vacuum optics | General ceramics, low-demand parts | Structural ceramics, moderate plasma exposure |

Yes. Y₂O₃ ceramics are highly suited for molten-metal and alloy-melting environments because they remain chemically inert, resist wetting, and maintain structural stability at extreme temperatures. These characteristics make Y₂O₃ a preferred material for crucibles, liners, and contact surfaces where clean melt quality and long service life are essential—one of the key reasons engineers often work with a specialized yttrium oxide ceramic supplier when sourcing high-purity components.

Yes. With controlled grain growth, full densification, and fine polishing, Y₂O₃ can be produced as transparent ceramics for laser systems, IR windows, and high-energy optical components.

Y₂O₃ maintains dimensional stability even under rapid heating and cooling, provided that thermal gradients are controlled. It outperforms Al₂O₃ and quartz in non-wetting and chemical stability.

It shows extremely low reactivity with molten alloys, fluorine-based plasmas, chlorine gases, and high-temperature oxygen environments—making it ideal for crucibles and plasma chambers.

Yes. Y₂O₃ ceramics handle repeated thermal cycling well because their microstructure suppresses thermal stress and minimizes risk of crack initiation. This stability is essential for components exposed to rapid heating and cooling in vacuum furnaces, plasma tools, and alloy-melting systems—one of the reasons many industrial buyers work directly with a china yttrium oxide ceramic manufacturer to ensure consistent sintering quality.

Define your working temperature, atmosphere, purity level, dimensional tolerances, and expected service life. A professional yttrium oxide ceramic wholesale partner such as ADCERAX can review your drawings, assess your operating conditions, and recommend the most suitable Y₂O₃ grade for your application.

Wholesale Y₂O₃ ceramics at competitive pricing are typically available from large-scale producers in China, where raw-material stability and mature sintering lines help reduce cost without compromising purity. Buyers looking for consistent quality, custom dimensions, or batch-level engineering often choose suppliers like ADCERAX, which provides wholesale cheap price yttrium oxide ceramic with technical support, drawing review, and flexible order quantities for industrial projects.

Yes. ADCERAX offers wholesale pricing for yttrium oxide ceramic components, supporting both small pilot runs and large-volume orders. Pricing is based on purity level, part geometry, machining complexity, and batch size. Our team can evaluate your drawings and provide a competitive quotation tailored to your production needs.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

info@adcerax.com

Telephone: +(86) 0731-74427743

WhatsApp: +(86) 19311583352

Within 24 hours