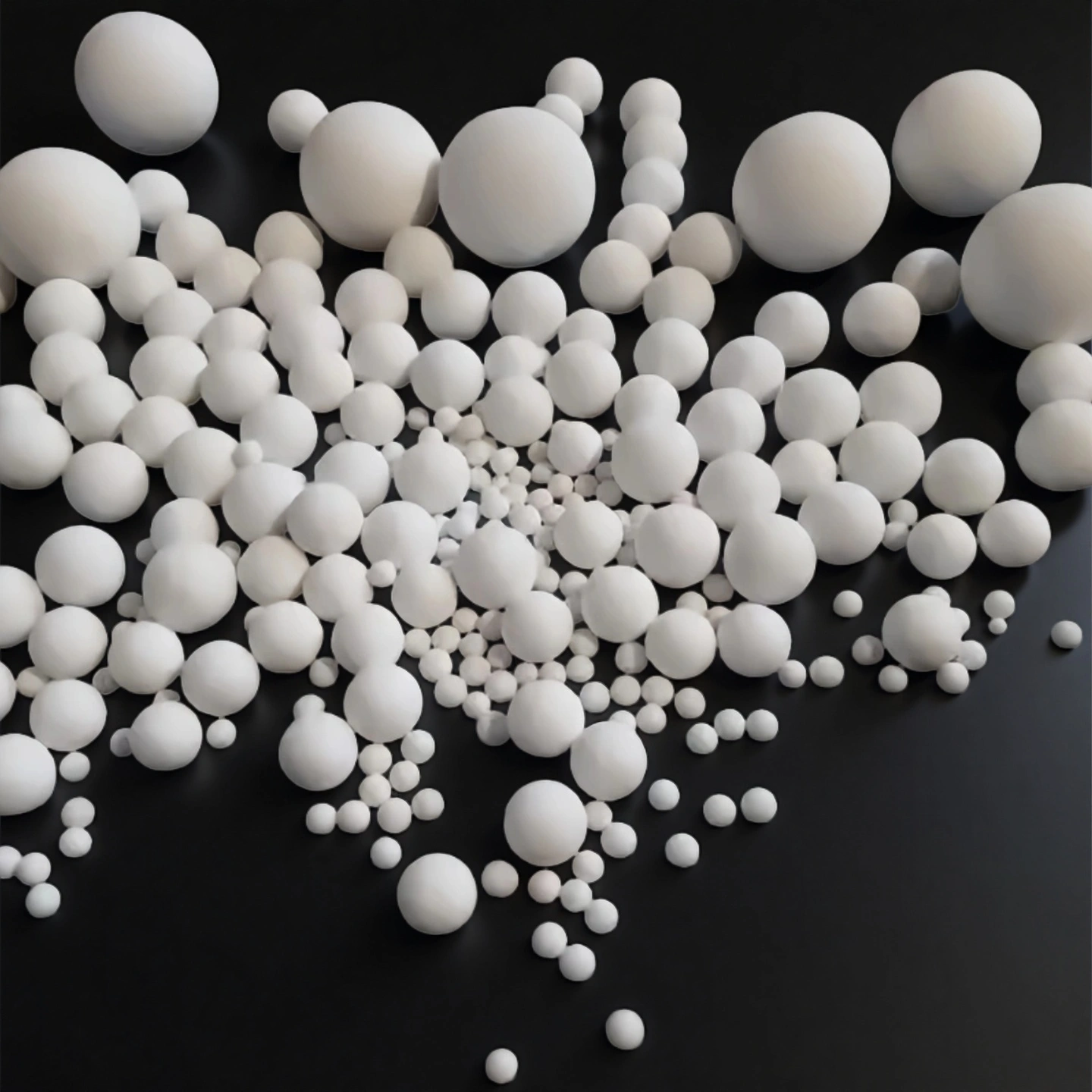

Alumina beads are small, precision-formed ceramic spheres made primarily from aluminum oxide (Al₂O₃). They are engineered for industrial duties where mechanical strength, thermal stability, and chemical resistance are essential—most commonly as adsorbents/dryers, catalyst carriers/support media, and grinding/polishing media.

Alumina Ceramic Beads Advantages

- Optimized Sphericity & Uniform Size – Precisely controlled bead geometry ensures consistent packing density and predictable pressure drop in adsorption and catalytic reactors.

- Low Attrition Rate – Engineered manufacturing minimizes dust generation, which reduces contamination in reactors and extends catalyst bed operating cycles.

- Versatile Form Options – Available in multi-bore, inert, or activated designs, allowing engineers to match bead structures with specific gas/liquid flow requirements.

- Enhanced Regeneration Performance – Activated alumina beads maintain adsorption capacity over multiple thermal regeneration cycles, reducing replacement frequency and operating costs.

- Customizable Distribution & Bed Support – Beads can be supplied in graded size layers (small-to-large stacking) to improve flow uniformity and protect fragile catalysts from pressure surges.

Al2O3 Ceramic Beads Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

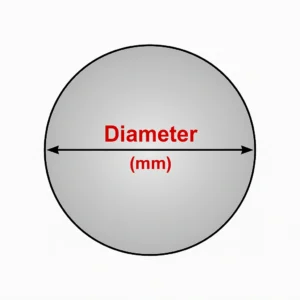

Alumina Beads Specifications

Type 1: Activated alumina beads

*More sizes and specifications about Activated alumina beads ![]() click here

click here

Type 2: Inert alumina (support) beads

*More sizes and specifications about Inert alumina (support) beads ![]() click here

click here

Type 3: wear resistant alumina grinding beads

*More sizes and specifications about wear resistant alumina grinding beads ![]() click here

click here

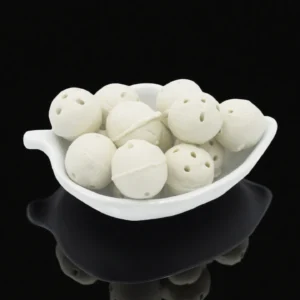

Type 4: alumina ceramic multi bores beads

*More sizes and specifications about alumina ceramic multi bores beads ![]() click here

click here

Type 5: insulator alumina beads

*More sizes and specifications about insulator alumina beads ![]() click here

click here

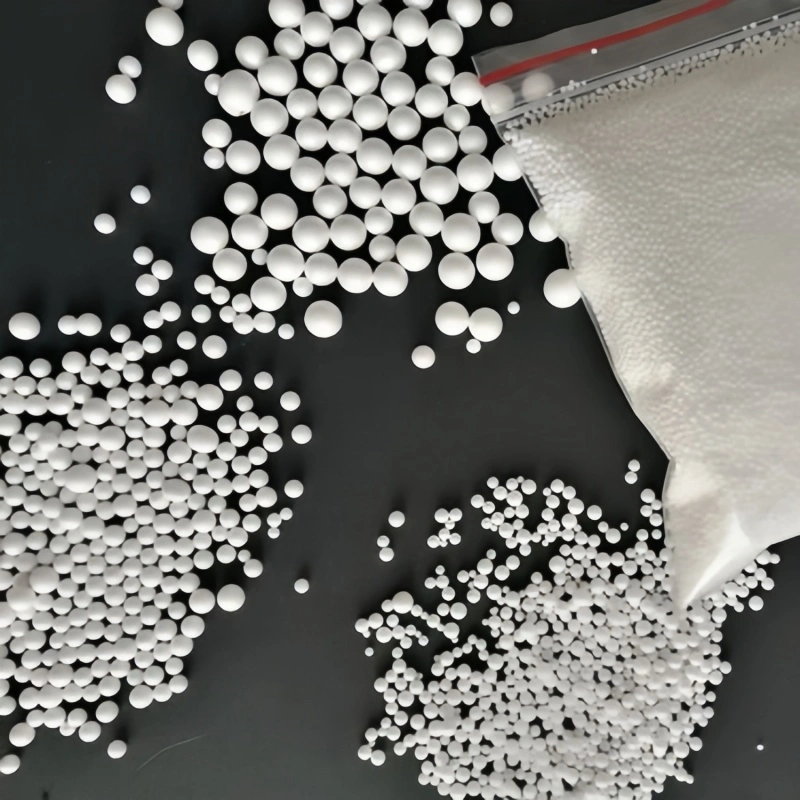

Alumina Ceramic Bead Packaging

- High alumina beads are packaged in 25 kg heavy-duty plastic bags, which are then placed inside 1-ton jumbo bags with inner waterproof liners. The jumbo bags are palletized and shrink-wrapped for secure, moisture-free international transport.