Alumina Ring – High Purity Insulating & Sealing Solutions

ADCERAX is a trusted China manufacturer of alumina ceramic rings, supplying both standard and custom sizes directly from our factory. We focus on delivering high quality with engineering support at a competitive cost. Our alumina rings are widely used for furnace insulation, pump sealing, and automation assemblies, designed with tight tolerance control, fast lead times, and reliable global delivery.

👉 Explore our specifications and applications below, or request a quotation for bulk supply and customize solutions.

≥1650 °C

High Thermal Stability

(Suitable for Furnace Insulation & Heating Assemblies)

(Standard ID/OD + Custom Ring Sizes Available)

Precision Dimensional Control

(Consistent Fit for Mechanical & Electrical Applications)

(Reliable Electrical Insulation in High-Voltage & Vacuum Systems)

What are Alumina Rings?

Alumina Ceramic Ring Composition

An alumina ring (also called an alumina ceramic ring) is a circular advanced-ceramic component used as an insulator, spacer, guide, or seal in harsh environments. Built from dense Al₂O₃, it pairs high thermal stability with strong dielectric strength and abrasion resistance.

They are typically manufactured in different purities—such as 92%, 95%, 99%, or 99.7% alumina—to balance cost, mechanical strength, and high-temperature performance. The most stable form, alpha alumina, is often chosen for critical applications requiring hardness and chemical inertness.

| Available Purity Grades | ||

|---|---|---|

| 96% Alumina (Al₂O₃) | Cost-effective option for general high-temperature and wear applications | Standard Grade |

| 99% Alumina (Al₂O₃) | Enhanced mechanical strength and thermal properties for demanding environments.Balanced performance and price | General Grade |

| 99.5%-99.7% Alumina (Al₂O₃) | Highest temperature resistance (1730°C), superior electrical insulation, excellent chemical inertness.Ideal for vacuum, semiconductor, and high-temp use | High Purity |

Alumina Ring Benefits & Properties

Alumina ceramic rings combine thermal stability, electrical insulation, and wear resistance, making them ideal for furnaces, pumps, and automation systems. Reliable performance ensures long service life in demanding industrial environments.

Alumina Ceramic Ring Benefits

ID/OD control (±0.2 mm) ensures reliable fit in pumps, valves, and automation systems.

Excellent electrical insulation for high-voltage, vacuum, and electronic applications.

Durable in furnace insulation, coil supports, and heating element assemblies.

Withstands mechanical friction and chemical exposure, extending service life in fluid and sealing systems.

Alumina Ceramic Ring Properties

| Property | 96% Al₂O₃ | 99% Al₂O₃ | 99.5% Al₂O₃ | 99.7% Al₂O₃ |

| Density (g/cm³) | 3.65–3.8 | 3.8–3.9 | 3.9 | ≥3.93 |

| Hardness (Mohs) | 8.8 | 9 | 9 | 9.1 |

| Max Operating Temp (°C) | 1600 | 1680 | 1700 | 1730 |

| Flexural Strength (MPa) | 260 | 300 | 320 | 330 |

| Thermal Conductivity (W/m·K) | 22 | 24 | 27 | 29 |

| Volume Resistivity (Ω·cm) | 10¹³–10¹⁵ | 10¹⁴–10¹⁵ | >10¹⁴ | >10¹⁵ |

| Dielectric Strength(kV/mm) | 15 | 19 | 21 | 22 |

Alumina Ring Products & Function

Designed for demanding environments, alumina rings combine strength, wear resistance, and insulation properties. They provide secure wafer positioning in polishing tools, extend equipment life, and maintain accuracy in diverse precision applications.

Alumina seal ring provides reliable insulation, sealing, and wear protection in precision equipment and industrial systems.

- Ensures tight sealing performance under high pressure or vacuum.

- Prevents leakage and contamination in sensitive processing environments.

- Maintains stability at high temperatures with extended service life.

Alumina Raschig Rings provide strong chemical resistance and a large surface area for efficient mass transfer.

- High chemical resistance ensures long-term stability in corrosive media.

- Large surface area improves gas-liquid contact efficiency.

- Reliable performance in distillation, absorption, and scrubbing systems.

Alumina ceramic ring slices offer utstanding reliability and consistent performance under demanding conditions

- Longer lifespan reduces overall cost of ownership

- Stable wafer handling improves production yield rates.

- Customizable dimensions adapt to various polishing equipment.

Alumina ceramic washers offer high insulation, wear resistance, and stability for reliable use in demanding assemblies.

- Excellent electrical insulation ensures safe operation.

- High wear resistance extends service lifespan.

- Stable dimensions under heat maintain accuracy.

Supplying 50+ countries, trusted by semiconductor, PV, and chemical leaders worldwide

ISO9001 certified manufacturing • On-time delivery rate 98.6%

Alumina Ceramic Ring Applications

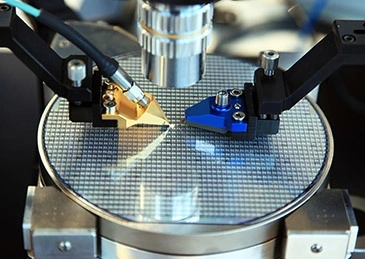

Alumina ceramic rings are widely used in wafer polishing, precision grinding, and sealing applications, ensuring stable performance in semiconductor and industrial systems.

Semiconductor & Electronics

📌 Application: Used in wafer polishing, CMP, and double-side lapping equipment to retain wafers during grinding and finishing.

⚙️ Performance Benefits: Enhances wafer yield, minimizes edge chipping, and ensures process repeatability.

🎯 Procurement Priorities: Tight tolerance (±0.02 mm), contamination-free finish, and extended service life.

👉 ADCERAX supplies precision retaining rings with both stock and custom geometries for semiconductor applications.

Precision Machinery & Automation

📌 Application: Functions as sealing, positioning, and load-bearing components in grinding, lapping, and automated polishing machines.

⚙️ Operational Advantages: Extends equipment uptime, reduces replacement cycles, and supports stable machine operation.

🎯 Engineering Requirements: Durability under continuous load, adaptable design, and optimized cost-performance ratio.

👉 ADCERAX offers standard rings and engineered solutions to fit diverse machinery systems.

Energy & Thermal Systems

📌 Application: Serves in furnace systems, thermal processing equipment, and sealing interfaces exposed to high temperatures.

⚙️ Performance Benefits: Resists thermal cycling, maintains dimensional integrity, and delivers consistent high-temperature performance.

🎯 Procurement Priorities: Proven heat resistance, repeatable quality assurance, and reliable global logistics.

👉 ADCERAX delivers alumina rings with factory-direct supply, engineering support, and fast global delivery.

Chemical & Environmental Engineering

📌 Application: Used in chemical reactors, distillation towers, fluid handling, and gas treatment systems.

⚙️ Operational Advantages: Delivers strong corrosion resistance, prevents leakage, and enhances system efficiency.

🎯 Engineering Requirements: Anti-corrosive material, long service intervals, and scalable bulk supply.

👉 ADCERAX delivers Raschig-style and customized alumina rings for industrial chemical processes.

China Alumina Ring Custom Supplier

ADCERAX supplies alumina ceramic rings directly from our China factory, combining bulk availability with full customization support. Beyond standard stock, we provide engineered solutions tailored to wafer polishing, sealing, and high-temperature applications.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

ADCERAX – Your Trusted Alumina Ring Supplier

Choosing the right supplier is critical for your supply chain. We are a trusted China alumina ceramic ring manufacturer and global supplier, dedicated to providing exceptional value, quality, and service. Whether you need wholesale supply or a custom-engineered part, we are your reliable source.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

Alumina Ceramic Ring Factory-ADCERAX

ADCERAX is a professional China alumina ring manufacturer and supplier, offering a full range of insulating rings, sealing rings, spacers, and precision ring slices. With over 20 years of ceramic production expertise, we support global customers in the USA, Germany, Japan, and other industrial markets, meeting strict QC requirements. Using advanced forming, sintering, and machining processes, we deliver products with tight dimensional accuracy, excellent dielectric strength, and long-term reliability.

- 92%–99.7% high-purity alumina for heat resistance and insulation stability

- Custom ID/OD/height rings made from drawings or samples

- Fast prototyping (7–15 days) & flexible MOQ

- Rigorous QC on tolerance, dielectric strength, and surface finish

- Engineering support for OEM designs and application-specific solutions

Alumina Ring Processing

This section shows our strengths in alumina ceramic ring production, from material purity to high-temperature firing and finishing. ADCERAX supplies customized rings for furnace insulation, pump sealing, electrical insulation, and automation systems.

| Technical Capabilities Overview | |

|---|---|

| Material Grades | 92%, 95%, 99%, 99.5–99.7% Al₂O₃– suitable for high-temperature, electrical, and wear-resistant applications |

| Diameter Range | ID: 5–150 mm, OD: up to 200 mm, Height: customizable; tolerance typically ±0.2 mm |

| Forming Methods | Dry pressing, isostatic pressing, and CNC machining for precise geometry |

| Processing | High-temperature sintering, surface grinding, polishing, and edge chamfering |

| Surface Finish | Smooth / Ground / Polished, depending on performance requirements |

| Customization | OEM solutions supported with drawings or samples for tailored designs |

Alumina Ceramic Ring Quality & Certifications

FAQ

For high-temperature insulation and standoffs, alumina in the high-purity(99.5%–99.7% Al₂O₃) range is commonly selected. If you require maximum hardness and phase stability, specify an alpha alumina ring.

When evaluating ceramic rings, buyers often compare alumina, zirconia, and silicon carbide to balance thermal performance, mechanical properties, and cost.

| Property / Material | Alumina (Al₂O₃) | Zirconia (ZrO₂) | Silicon Carbide (SiC) |

|---|---|---|---|

| Max. Service Temp. | 1650–1750 °C | 1000–1200 °C | ~1800 °C |

| Dielectric Strength | Excellent (≥10 kV/mm) | Good | Poor (semiconductive) |

| Toughness | Moderate | Very High | Moderate |

| Thermal Shock Resistance | Fair | Moderate | Excellent |

| Wear Resistance | High | High | Very High |

| Typical Applications | Furnace insulation, pump seals, electrical insulators | Bearings, cutting tools, high-load components | Kiln parts, wear parts, thermal shock environments |

| Relative Cost | ★ (Low) | ★★★★ (High) | ★★★ (Medium–High) |

Choose Alumina if you need cost-effective, electrically insulating rings with strong heat resistance.

Choose Zirconia for high-toughness, high-load applications, despite higher cost.

Choose Silicon Carbide where extreme thermal shock and wear resistance are critical, but insulation is not required.

Standard ID ranges from 5–150 mm and OD up to 200 mm, with typical tolerances of ±0.2 mm. Tighter tolerances can be provided for precision assemblies.

Yes. OEM customization is supported, including ID/OD/height adjustments, grooves, chamfers, slots, and drilled holes.

With dielectric strength typically ≥10 kV/mm, alumina rings provide stable insulation in high-voltage, vacuum, and electronic systems.

Standard-size alumina rings can usually ship within 7–10 days. For drawing-based or fully customized items, lead times depend on geometry and order volume, typically 3–9 weeks. Share your target schedule and we’ll align production capacity to meet your deadline.

Yes. ADCERAX supplies alumina ceramic rings directly from our factory in China, ensuring cost-effective pricing without middleman markups. Prices are determined by purity level, dimensions, tolerance, and order volume. Whether you need standard insulating rings or customized sealing and spacer rings, we provide competitive quotations with high quality and international delivery support.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Get a Quote for Your Custom Alumina Ring Project

Ready to enhance your application with high-quality alumina ceramic ring? Contact our team of experts to discuss your project or request a quote for your custom alumina ceramic ring . We provide timely and competitive quotes to help you make informed purchasing decisions.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours