Custom & Machined Alumina Parts for Industrial, Electrical & Semiconductor Systems

ADCERAX is a China-based manufacturer of custom alumina parts, specializing in precision-made irregular and insulating components for industrial, semiconductor, and electrical engineering applications. Our alumina oxide parts deliver proven performance. From alumina heaters and nozzles for thermal systems, to fibers, screws, bearings and gauges for mechanical and electronic assemblies, every component is crafted for durability, precision, and clean operation.

✅Small Batch Customization & Rapid Samples

✅Precision Machining Capability

✅Expert Engineering Support

✅On-Time Production Delivery

What Are Alumina Ceramic Parts?

Alumina parts are precision-engineered mechanical and structural support components made from alumina ceramic (Al₂O₃). These alumina ceramic components are used across a wide range of demanding applications — including industrial machinery, semiconductor processing, electrical insulation systems, vacuum and analytical instruments, chemical processing equipment, and thermal control assemblies.

Typical products include spacers, housings, fixtures, wear pads, insulating sleeves, and precision holders, all designed to maintain performance under extreme temperature, voltage, or chemical exposure.

Alumina Ceramic Parts Properties

Manufactured through high-temperature sintering and precision machining, alumina ceramic components offer exceptional dimensional stability, thermal resistance, and chemical inertness.

Mechanical Strength of Alumina Parts

ADCERAX ceramic alumina parts provide excellent wear resistance and dimensional precision for demanding assemblies.

- Flexural strength >350 MPa, compressive strength to 2000 MPa

- Vickers hardness 1800 HV for excellent wear resistance

- Stable dimensions after repeated thermal & mechanical cycles

Chemical Properties of Alumina Parts

High-purity alumina oxide parts ensure excellent chemical inertness across harsh industrial environments.

- Resistant to acids, alkalis, and solvents (pH 1–14)

- No metal ion contamination during contact with process fluids

- Corrosion resistance efficiency over 98% in long-term operation

Thermal Performance of Alumina Parts

Alumina ceramic components are engineered for continuous operation in high-temperature and thermal-cycling systems.

- Continuous service temperature up to 1730 °C(99.7%)

- Low thermal expansion (6–8 × 10⁻⁶ /K) ensures assembly integrity

- Reliable under rapid temperature fluctuations or heating processes

Electrical Properties of Alumina Parts

Alumina precision parts deliver stable insulation and low dielectric loss for high-voltage or electronic devices.

- Dielectric strength greater than 12 kV/mm

- Stable insulation up to 1200 °C continuous exposure

- Low electrical loss and no conductive ion migration

Alumina & Al2O3 Parts Products

ADCERAX alumina parts cover a broad range of precision-engineered components, including screws, bearings, heaters, igniters, nozzles, and gauges, etc.

Each part is produced from high-purity alumina ceramic (96–99.7%) to ensure precise fit, stable performance, and long lifespan.

Alumina ceramic bearings deliver smooth rotation and excellent wear resistance under heat or chemical exposure.

- Low friction and high hardness improve service lifespan

- Stable operation up to 1000 °C and high-speed use

- Corrosion-proof for chemical, vacuum, and cleanroom systems

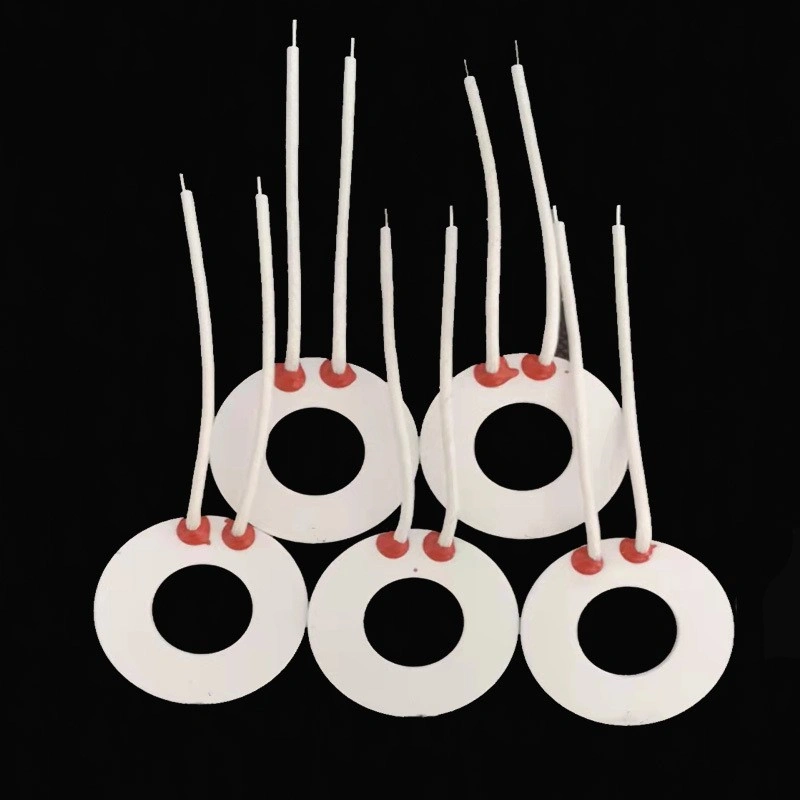

Alumina ceramic heaters provide uniform heat distribution and excellent insulation for precision thermal control.

- High thermal conductivity with stable electrical insulation

- Fast heating response and precise temperature control

- Ideal for semiconductor, lab, and analytical devices

Alumina ceramic igniters ensure stable ignition and long working life for furnaces and gas systems.

- Resistant to oxidation and thermal shock cycles

- Operates reliably up to 1300 °C continuous use

- Fast heating with low power consumption

Alumina ceramic nozzles deliver accurate flow and exceptional wear resistance for abrasive or chemical media.

- High hardness resists erosion from particles or gases

- Thermal stability ensures consistent spray performance

- Corrosion-resistant for chemical, TIG, and welding systems

Alumina gauges ensure precise dimensional stability and insulation for accurate calibration work.

- Machined accuracy within ±0.005 mm

- Consistent size under heat and humidity variation

- Ideal for semiconductor and lab calibration tools

Alumina oxide ceramic fiber provides excellent insulation and strength for high-temperature sealing and lining.

- Resists continuous heat up to 1200 °C

- Low thermal conductivity ensures energy efficiency

- Excellent stability under chemical or thermal cycling

Alumina laser reflectors feature high reflectivity and dielectric strength for optical and laser applications.

- Precision-ground surfaces ensure light stability

- High-purity alumina prevents signal distortion

- Thermal stability supports continuous laser operation

Alumina ceramic screws provide high strength, insulation, and corrosion resistance for industrial use.

- High-purity alumina ensures excellent dielectric insulation

- Resists acids, alkalis, and corrosion in harsh conditions

- Stable torque strength maintains reliable long-term fastening

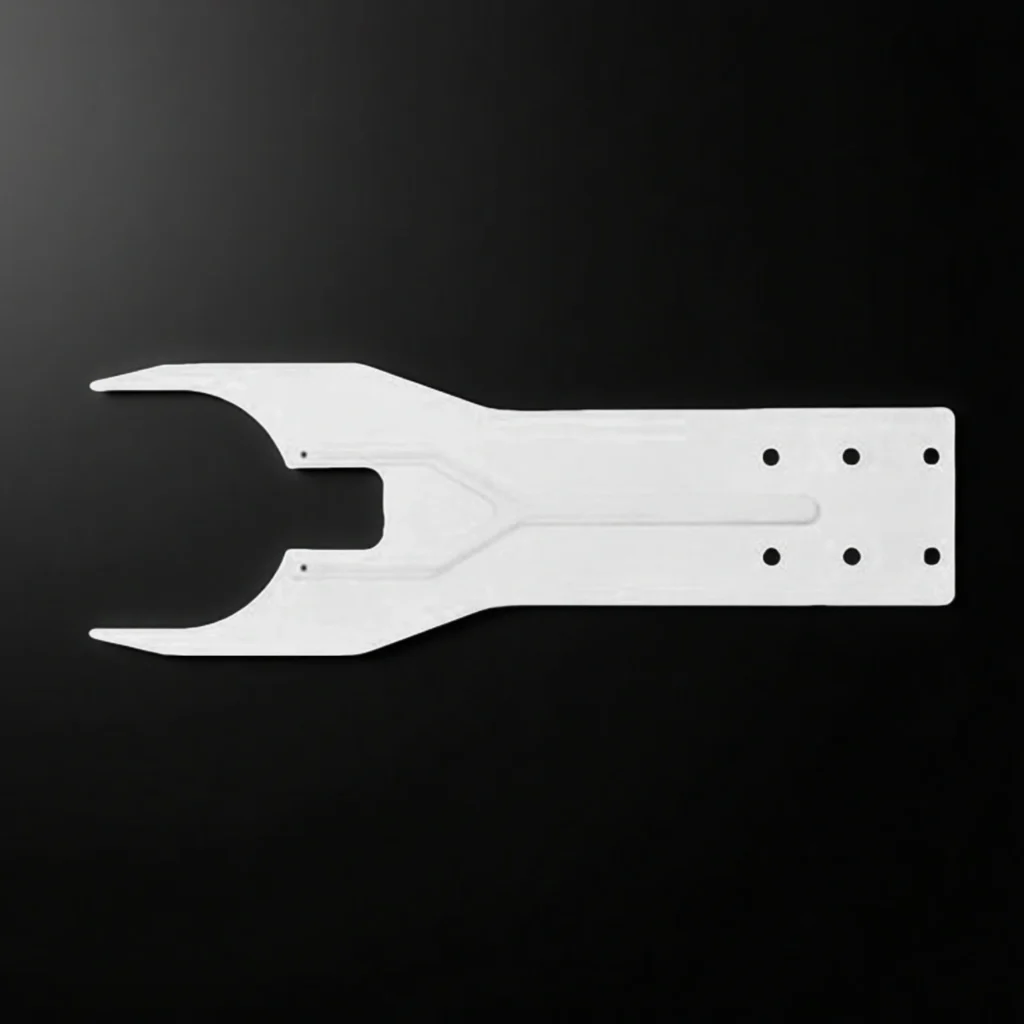

Alumina ceramic robot arms combine rigidity, cleanliness, and electrical insulation for automation systems.

- Lightweight and strong for precision handling

- No particle generation, ideal for cleanrooms

- Resists heat and corrosion for extended service life

💎 Precision You Can Specify — Customized Alumina Parts by ADCERAX

From design and sample development to mass production, our alumina precision parts deliver accuracy, purity, and reliability across a wide range of global industries. Get tailored engineering support, factory pricing, and your project quote in 24 hours.

Alumina Oxide Parts Applications

Alumina parts are used in industrial, semiconductor, and electrical systems requiring high strength and insulation. They function as insulators, spacers, bearings, and protective sleeves in chemical equipment, vacuum assemblies, and precision instruments, ensuring high performance under heat, wear, and corrosion.

🔧 Industrial Equipment

Application:Wear-resistant spacers, rings, and sleeves for pumps, valves, and precision machinery under load and abrasion.

Challenges: Standard metal parts often corrode, seize, or deform when exposed to chemicals or thermal cycling.

🧩 ADCERAX Solution:

High-purity alumina ensures wear and corrosion resistance in continuous operation.

Machined precision within ±0.05 mm guarantees stable fit and smooth motion.

Long service life reduces downtime and maintenance costs.

- 🎯 ADCERAX alumina parts help manufacturers minimize maintenance downtime, extend equipment lifespan, and maintain process stability across demanding industrial environments.

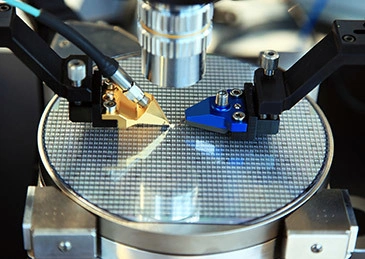

💡 Semiconductor & Electronics

📍Application: Wafer handling fixtures, isolation parts, vacuum chucks, and substrates for clean, particle-controlled processes.

- ⚡Challenges: Metallic parts release contaminants and lose stability under high temperature or plasma conditions.

🧩 ADCERAX Solution:

Ultra-clean alumina (99.7% Al₂O₃) ensures minimal particle generation and electrical insulation.

High dimensional stability supports precise motion in automated systems.

Non-contaminating and corrosion-free for vacuum or plasma chambers.

- 🎯 ADCERAX alumina parts enable semiconductor equipment to maintain ultra-clean operation, dimensional accuracy, and reliability in wafer-level environments.

⚗️ Chemical & Laboratory Systems

📍Application: Corrosion-proof housings, gauges, guides, and furnace components for analytical instruments and thermal processing.

- ⚡Challenges: Standard glass or metal components degrade under acid, alkali, or solvent exposure.

🧩 ADCERAX Solution:

Chemically inert alumina resists nearly all reagents (pH 1–14).

Maintains structural integrity up to 1730 °C during long-term use.

Precision-polished surfaces prevent contamination and ensure analytical purity.

- 🎯 ADCERAX alumina parts provide long-lasting chemical resistance, high-purity testing environments, and consistent results in analytical and research applications.

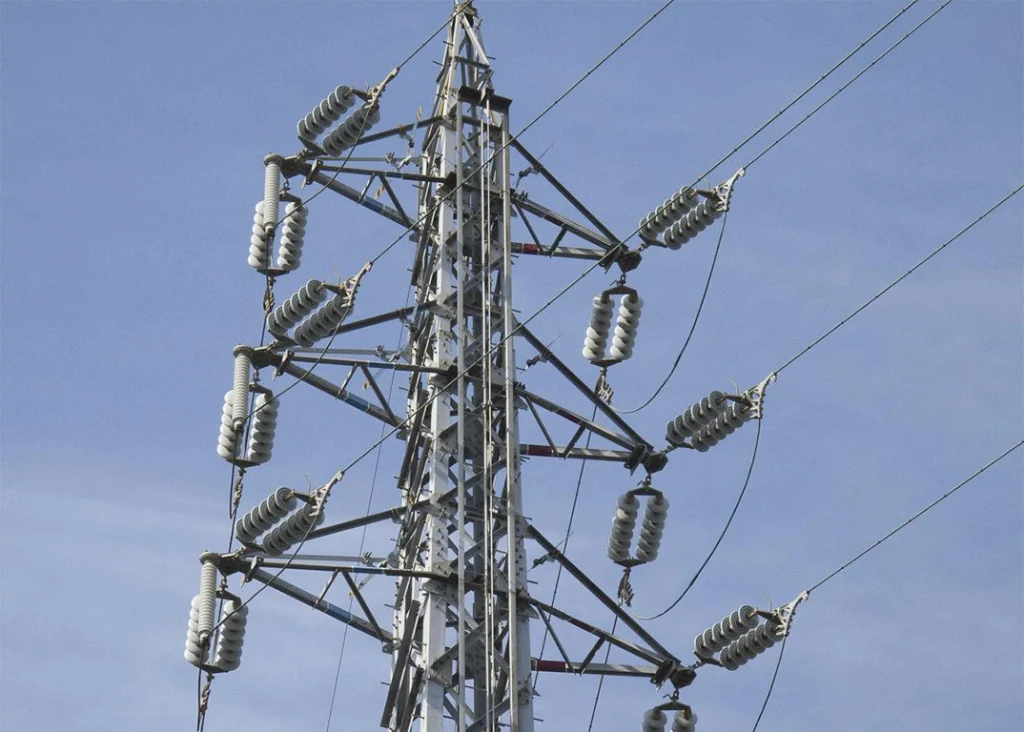

⚙️ Electrical & Power Systems

📍Application: High-voltage insulators, standoffs, and protective sleeves for sensors, converters, and power distribution.

- ⚡Challenges: Polymer and metal parts lose insulation strength or deform under heat and voltage cycling.

🧩 ADCERAX Solution:

Machined alumina provides stable dielectric insulation up to 12 kV/mm.

High-purity Al₂O₃ prevents conductive ion migration or arcing.

Tight-tolerance parts ensure secure, reliable assembly performance.

- 🎯 ADCERAX alumina parts enhance equipment safety, maintain voltage stability, and ensure long-term reliability in power and control systems.

Customize Alumina Ceramic Components Factory

ADCERAX is a professional alumina ceramic parts manufacturer, specializing in customized components with complex geometries, tight tolerances, and Al₂O₃ purity grades from 96%,99%- 99.7%. Each part can be precisely made according to your drawings or samples. Custom alumina ceramic parts are typically produced and delivered within 3–7 weeks.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

ADCERAX – Your Trusted Alumina Parts supplier

ADCERAX is a trusted China alumina ceramic parts wholesaler, providing factory-direct supply, consistent quality, and full technical support for global OEM customers. From standard alumina components to custom-machined ceramic assemblies, we deliver precision manufacturing, short lead times, and dependable engineering service worldwide.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

ADCERAX integrates design, machining, quality control, and logistics into one seamless process. Our one-stop manufacturing approach for alumina ceramic parts reduces coordination costs, shortens lead time, and ensures consistent quality from prototype to bulk production.

-

Precision Machining Assurance:

Each alumina part is validated from drawing to production, with dimensional accuracy within ±0.05 mm to ensure a precise fit and stable assembly performance. -

Batch Quality Consistency:

Every production batch of custom alumina components undergoes strict QC on density, surface finish, and mechanical strength to maintain reliable performance across applications. -

Technical Engineering Support:

Our engineers assist OEM clients with material selection, tolerance optimization, and structural design, helping improve part lifespan and reduce maintenance costs in operation.

ADCERAX focuses on the manufacturing of alumina parts, combining precision CNC machining with strict quality control to ensure consistency in every batch. The result is high-density ceramic components with excellent dimensional accuracy and long service life.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Capability Item | Typical Value / Description | ||

| Material Grades | 96%–99.7% Al₂O₃ high-purity alumina for machined alumina parts offering superior hardness, insulation, and corrosion resistance. | ||

| Dimension Range | Custom components available from micro-size insulators to large structural parts, with tolerances of ±0.05–0.2 mm depending on geometry. | ||

| Forming Methods | Isostatic pressing, precision CNC machining, and fine grinding ensure high density, dimensional stability, and repeatable accuracy. | ||

| Processing | Controlled sintering up to 1,730 °C guarantees full densification; secondary polishing and lapping improve precision fits. | ||

| Surface Finish | Ground or polished finishes achieve Ra < 0.4 µm for smooth contact surfaces and consistent assembly performance. | ||

Frequently Asked Questions about Alumina Parts

The manufacturing of alumina parts combines isostatic pressing, high-temperature sintering up to 1,730 °C, and precision CNC machining to achieve dense and stable ceramics.

Final grinding, polishing, or lapping ensures tight tolerances and smooth surfaces ready for assembly.

To prepare an accurate quote, please provide your drawing or sample, including key dimensions (ID, OD, length, thickness) and tolerance requirements.

Also specify the alumina grade (95%–99.8% Al₂O₃), quantity, and any surface finish or machining details.

Our team will confirm technical feasibility and offer a detailed quotation within 24 hours.

Yes, ADCERAX provides various alumina ceramic components for sale that are ideal for laboratory and analytical equipment, including furnace supports, igniters, and insulation parts.

All components are precision-machined for stability, durability, and electrical insulation, ensuring reliable performance under repeated thermal cycles.

Custom designs are available — send us your drawing or sample, and our engineers will prepare a tailored quotation.

Since most industrial alumina ceramic parts are custom-made, prices depend on the drawing, dimensions, tolerance, and alumina purity grade (96%–99.7%). ADCERAX offers factory-direct quotations based on your specific requirements, ensuring fair pricing and consistent quality.

You can send your part specifications or 3D files to receive a detailed price list within 24 hours.

Yes, ADCERAX offers fair price alumina ceramic parts with flexible discounts for bulk and custom orders.

As a professional alumina ceramic parts supply factory, we provide stable quality, short lead times, and periodic promotions for long-term OEM partners.

Contact us today to get your best offer.

Yes. ADCERAX specializes in manufacturing alumina custom parts and alumina irregular parts through precision CNC machining and custom tooling.

We can achieve complex geometries such as cavities, threads, and step structures while maintaining tight tolerances and excellent surface finish.

ADCERAX is a trusted China alumina ceramic parts manufacturer providing factory-direct pricing, precision machining, and strict quality control.

We support custom alumina components with fast lead times, stable consistency, and responsive technical service for global OEM projects.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Get a Fast Quote for Your Custom Precision Alumina Parts

Share your drawings or part specifications with the ADCERAX engineering team to receive a fast and competitive quotation. Whether you need standard alumina components or custom-machined ceramic parts, we ensure precision manufacturing, stable quality, and on-time global delivery.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours