Alumina oxide ceramic fiber (often called high-alumina polycrystalline fiber or PCW fiber) is a high-temperature insulating material made predominantly from Al₂O₃. It is produced by sol–gel or similar processes, then fired to create fine, interlocked crystalline fibers. The result is a lightweight, low-thermal-conductivity insulation that maintains dimensional stability at very high temperatures.

Alumina ceramic Fiber Advantages

- Module Pre-Compression: Controlled preload improves joint tightness, reducing heat loss at panel interfaces.

- Low-Shot Fiber Network: Reduces dusting and preserves thermal performance in fast ramp cycles.

- Edge-Stable Boards: Vacuum-formed with trimmed edges for consistent fit and reduced rework on site.

- Anchor-Ready Geometry: Module slots/back-cuts compatible with typical Y/V anchors and washers.

- Retrofit-Friendly Shaping: Burner ports, peep-sight rings, and step-laps manufactured to drawing to minimize field machining.

Alumina Oxide Ceramic Fiber Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina Oxide Ceramic Fiber Specifications

Type 1: Alumina Ceramic Fiber Board

| Alumina Ceramic Fiber Board | |||||

| Item No. | Length(mm) | Width (mm) | Thickness (mm) | Temperature℃ | SiO2+Al2O3(%) |

| AT-AO-XW1001 | 600 | 400 | 20-150 | 1000℃-1800℃ | 96%-99.8% |

| AT-AO-XW1002 | 900 | 600 | 20—150 | ||

| AT-AO-XW1003 | 1000 | 500 | 20-150 | ||

| AT-AO-XW1004 | 1000 | 600 | 20-150 | ||

| AT-AO-XW1005 | 1100 | 700 | 10-150 | ||

| AT-AO-XW1006 | 1200 | 1000 | 10—150 | ||

Type 2: Alumina Fiber Blanket

| Alumina Fiber Blanket | |||||

| Item no. | Working Temp.(℃) | Density(kg/m3) | Length(mm) | Width(mm) | Thickness(mm) |

| AT-GSL-T1001 | 1260 | 96 128 160 | 7200 | 610 | 6 |

| AT-GSL-T1002 | 96 128 160 | 15000 | 610 | 10 | |

| AT-GSL-T1003 | 96 128 160 | 7200 | 610 | 20 | |

| AT-GSL-T1004 | 96 128 160 | 7200 | 610 | 25 | |

| AT-GSL-T1005 | 96 128 160 | 5000 | 610 | 30 | |

| AT-GSL-T1006 | 96 128 160 | 3600 | 610 | 50 | |

| AT-GSL-T1007 | 1400 | 96 128 160 | 7200 | 610 | 6 |

| AT-GSL-T1008 | 96 128 160 | 15000 | 610 | 10 | |

| AT-GSL-T1009 | 96 128 160 | 7200 | 610 | 20 | |

| AT-GSL-T1010 | 96 128 160 | 7200 | 610 | 25 | |

| AT-GSL-T1011 | 96 128 160 | 5000 | 610 | 30 | |

| AT-GSL-T1012 | 96 128 160 | 3600 | 610 | 50 | |

Type 3: Alumina Fiber Plug

| Alumina Fiber Plug | ||

| Item No. | Bottom Diameter(mm) | Height (mm) |

| AT-AO-DT001 | 50 | 70 |

| AT-AO-DT002 | 57 | 100 |

| AT-AO-DT003 | 65 | 65 |

| AT-AO-DT004 | 65 | 110 |

| AT-AO-DT005 | 70 | 70 |

| AT-AO-DT006 | 70 | 110 |

| AT-AO-DT007 | 70 | 90 |

| AT-AO-DT008 | 75 | 120 |

| AT-AO-DT009 | 80 | 100 |

| AT-AO-DT010 | 80 | 125 |

| AT-AO-DT011 | 85 | 135 |

| AT-AO-DT012 | 90 | 140 |

| AT-AO-DT013 | 90 | 200 |

| AT-AO-DT014 | 90 | 270 |

| AT-AO-DT015 | 95 | 130 |

| AT-AO-DT016 | 100 | 150 |

| AT-AO-DT017 | 105 | 180 |

| AT-AO-DT018 | 110 | 140 |

| AT-AO-DT019 | 120 | 160 |

| AT-AO-DT020 | 170 | 110 |

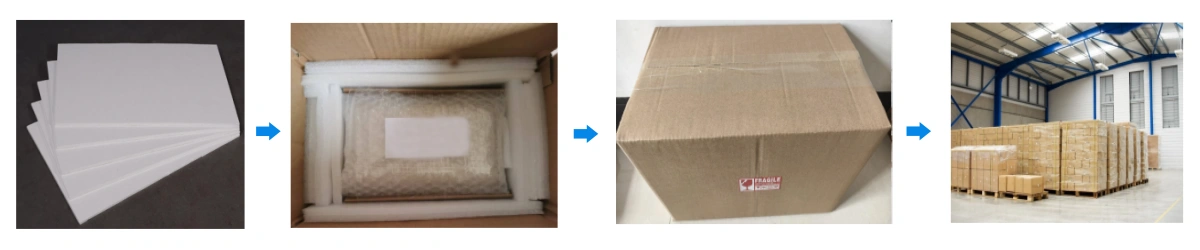

Alumina Oxide Ceramic Fiber Packaging

- Moisture-resistant wrap with corner protection for boards and shapes.