Alumina gauges are precision gauging tools and reference artefacts made from alumina (Al₂O₃) advanced ceramic. They are used to verify dimensions, set up fixtures, and perform go/no-go checks in machining cells, metrology labs, and cleanroom or wash-down environments. Because alumina is non-magnetic, chemically inert, wear-resistant, and thermally stable, these gauges maintain size and surface condition under frequent cleaning and in areas where steel gauges may corrode or attract debris.

Alumina Gauges Benefits

- Stable pass/fail window — tight tolerance bands with matched Go/No-Go deltas.

- Non-magnetic & inert surfaces — better near magnets, coolants, and cleaners.

- Cleanroom-friendly finish — polished faces reduce particle hold and residue.

- Corrosion resistance — consistent readings after repeated wet cleaning.

- Traceable identification — optional laser-etched IDs for set management.

Alumina Gauges Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina Ceramic Gauges Size

Type 1: Alumina Ceramic Pin

| Alumina Ceramic Pin Gauge | ||||

| Item No. | Size(mm) | Set interval | Accuracy(H) | Weight(g) |

| AT-CMT-1001 | 0.30-0.699 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 50 |

| AT-CMT-1002 | 0.70-0.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 60 |

| AT-CMT-1003 | 1.0-2.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 70 |

| AT-CMT-1004 | 3.0-3.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 80 |

| AT-CMT-1005 | 4.0-4.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 90 |

| AT-CMT-1006 | 5.0-5.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 100 |

| AT-CMT-1007 | 6.0-6.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 110 |

| AT-CMT-1008 | 7.0-7.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 120 |

| AT-CMT-1009 | 8.0-8.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 130 |

| AT-CMT-1010 | 9.0-9.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 140 |

| AT-CMT-1011 | 10.0-10.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 145 |

| AT-CMT-1012 | 11.0-11.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 150 |

| AT-CMT-1013 | 12.0-12.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 155 |

| AT-CMT-1014 | 13.0-13.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 160 |

| AT-CMT-1015 | 14.0-14.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 165 |

| AT-CMT-1016 | 15.0-15.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 170 |

| AT-CMT-1017 | 16.0-16.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 175 |

| AT-CMT-1018 | 17.0-17.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 180 |

| AT-CMT-1019 | 18.0-18.999 | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 185 |

| AT-CMT-1020 | 20.2-40mm | 0.001/0.005/0.01/0.02/0.05/0.1/0.5/1.0mm | ±0.001/0.0005mm | 190 |

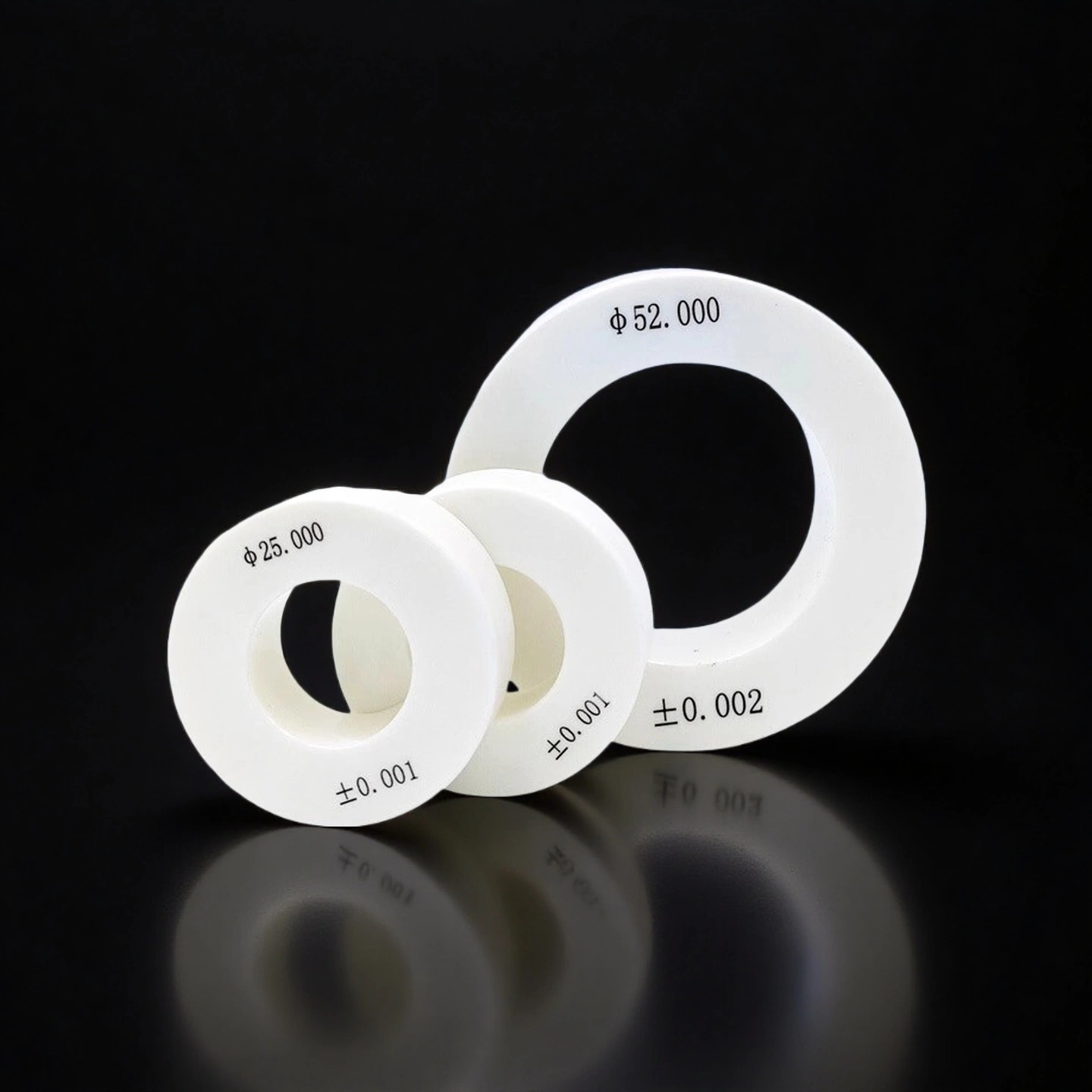

Type 2: Alumina Ring Gauges

| Alumina Ring Gauges | ||

| Item No. | Diameter (mm) | Thickness (mm) |

| AT-CMT-RG01 | Customize | |

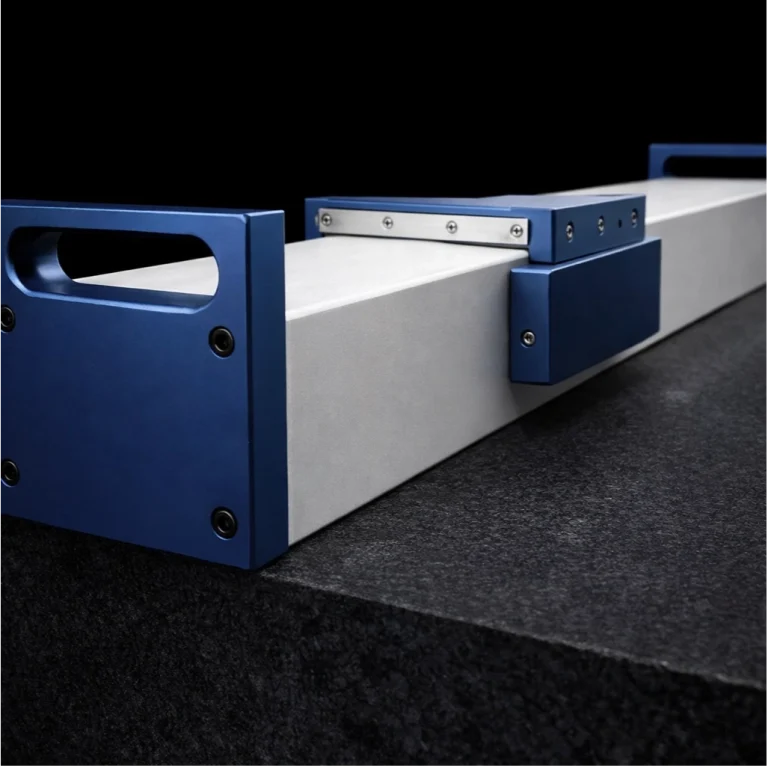

Type 3: Alumina Gauges Blocks

| Item | Gauge Size(mm) | Grades of Gauge Blocks(H) | Options for Grades(h) | Weight (g) |

| AT-CMT-015 | 0.5mm | 1 | 1/0/K | 10 |

| AT-CMT-016 | 0.5mm | 0 | 1/0/K | 11 |

| AT-CMT-017 | 25mm | 1 | 1/0/K | 26 |

| AT-CMT-018 | 25mm | 0 | 1/0/K | 27 |

| AT-CMT-019 | 30mm | 1 | 1/0/K | 28 |

| AT-CMT-020 | 30mm | 0 | 1/0/K | 29 |

| AT-CMT-021 | 40mm | 1 | 1/0/K | 30 |

| AT-CMT-022 | 40mm | 0 | 1/0/K | 31 |

| AT-CMT-023 | 41.2mm | 1 | 1/0/K | 32 |

| AT-CMT-024 | 41.2mm | 0 | 1/0/K | 33 |

| AT-CMT-025 | 41.3mm | 1 | 1/0/K | 34 |

| AT-CMT-026 | 41.3mm | 0 | 1/0/K | 35 |

| AT-CMT-027 | 50mm | 1 | 1/0/K | 36 |

| AT-CMT-028 | 50mm | 0 | 1/0/K | 37 |

| AT-CMT-029 | 60mm | 1 | 1/0/K | 38 |

| AT-CMT-030 | 60mm | 0 | 1/0/K | 39 |

| AT-CMT-031 | 70mm | 1 | 1/0/K | 40 |

| AT-CMT-032 | 70mm | 0 | 1/0/K | 41 |

| AT-CMT-033 | 75mm | 1 | 1/0/K | 42 |

| AT-CMT-034 | 75mm | 0 | 1/0/K | 43 |

| AT-CMT-035 | 80mm | 1 | 1/0/K | 44 |

| AT-CMT-036 | 80mm | 0 | 1/0/K | 45 |

| AT-CMT-037 | 81.5mm | 1 | 1/0/K | 46 |

| AT-CMT-038 | 81.5mm | 0 | 1/0/K | 47 |

| AT-CMT-039 | 90mm | 1 | 1/0/K | 48 |

| AT-CMT-040 | 90mm | 0 | 1/0/K | 49 |

| AT-CMT-041 | 100mm | 1 | 1/0/K | 50 |

| AT-CMT-042 | 100mm | 0 | 1/0/K | 51 |

| AT-CMT-043 | 125mm | 1 | 1/0/K | 52 |

| AT-CMT-044 | 125mm | 0 | 1/0/K | 53 |

| AT-CMT-045 | 150mm | 1 | 1/0/K | 54 |

| AT-CMT-046 | 150mm | 0 | 1/0/K | 55 |

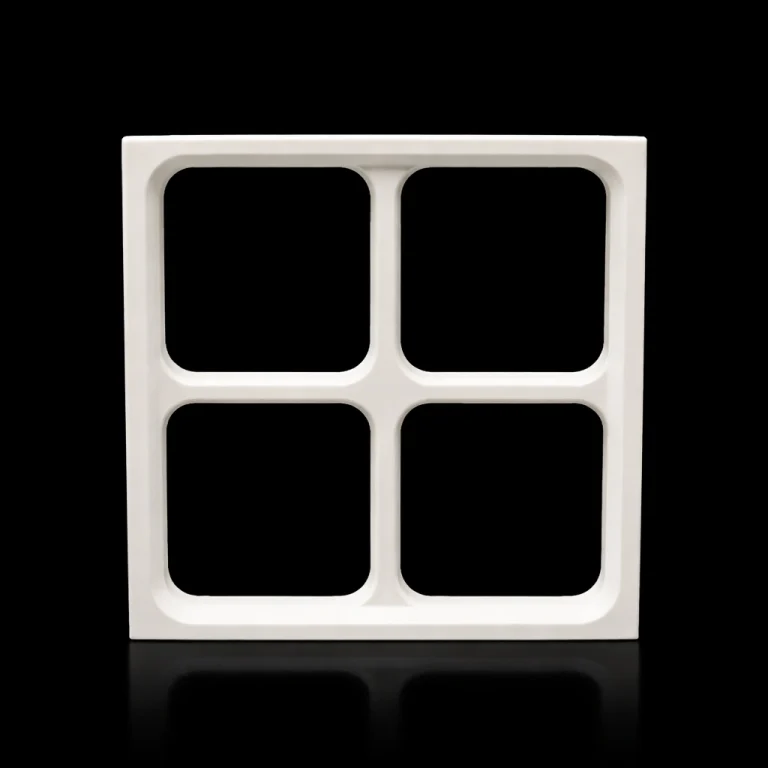

Type 4: Alumina Gauges Block Sets

| Item | Gauge Size(mm) | Increments(mm) | Total Blocks | Grades of Gauge Blocks(h) | Weight (g) |

| AT-CMT-001 | 1-1.5mm | 0.01 | 51 | 1 | 12 |

| AT-CMT-002 | 1-1.5mm | 0.01 | 51 | 0 | 13 |

| AT-CMT-003 | 1.6-1.9mm | 0.1 | 4 | 1 | 14 |

| AT-CMT-004 | 1.6-1.9mm | 0.01 | 31 | 0 | 15 |

| AT-CMT-005 | 2-6.5mm | 0.5 | 10 | 1 | 16 |

| AT-CMT-006 | 2-6.5mm | 0.5 | 10 | 0 | 17 |

| AT-CMT-007 | 7-9.5mm | 0.5 | 6 | 1 | 18 |

| AT-CMT-008 | 7-9.5mm | 0.5 | 6 | 0 | 19 |

| AT-CMT-009 | 10-13.5mm | 0.5 | 8 | 1 | 20 |

| AT-CMT-010 | 10-13.5mm | 0.5 | 8 | 0 | 21 |

| AT-CMT-011 | 14-19.5mm | 0.5 | 12 | 1 | 22 |

| AT-CMT-012 | 14-19.5mm | 0.5 | 12 | 0 | 23 |

| AT-CMT-013 | 20-24.5mm | 0.5 | 10 | 1 | 24 |

| AT-CMT-014 | 20-24.5mm | 0.5 | 10 | 0 | 25 |

Detailed Size of Gauge Blocks

| Gauge Size(mm) | 1-1.5mm | 1.6-1.9mm | 1.6-1.9mm | 2-6.5mm | 7-9.5mm | 10-13.5 mm | 14-19.5 mm | 20-24.5 mm |

| Increments(mm) | 0.01 | 0.1 | 0.01 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| 1 | 1 | 1.6 | 1.6 | 2 | 7 | 10 | 14 | 20 |

| 2 | 1.01 | 1.7 | 1.61 | 2.5 | 7.5 | 10.5 | 14.5 | 20.5 |

| 3 | 1.02 | 1.8 | 1.62 | 3 | 8 | 11 | 15 | 21 |

| 4 | 1.03 | 1.9 | 1.63 | 3.5 | 8.5 | 11.5 | 15.5 | 21.5 |

| 5 | 1.04 | 1.64 | 4 | 9 | 12 | 16 | 22 | |

| 6 | 1.05 | 1.65 | 4.5 | 9.5 | 12.5 | 16.5 | 22.5 | |

| 7 | 1.06 | 1.66 | 5 | 13 | 17 | 23 | ||

| 8 | 1.07 | 1.67 | 5.5 | 13.5 | 17.5 | 23.5 | ||

| 9 | 1.08 | 1.68 | 6 | 18 | 24 | |||

| 10 | 1.09 | 1.69 | 6.5 | 18.5 | 24.5 | |||

| 11 | 1.1 | 1.7 | 19 | |||||

| 12 | 1.11 | 1.71 | 19.5 | |||||

| 13 | 1.12 | 1.72 | ||||||

| 14 | 1.13 | 1.73 | ||||||

| 15 | 1.14 | 1.74 | ||||||

| 16 | 1.15 | 1.75 | ||||||

| 17 | 1.16 | 1.76 | ||||||

| 18 | 1.17 | 1.77 | ||||||

| 19 | 1.18 | 1.78 | ||||||

| 20 | 1.19 | 1.79 | ||||||

| 21 | 1.2 | 1.8 | ||||||

| 22 | 1.21 | 1.81 | ||||||

| 23 | 1.22 | 1.82 | ||||||

| 24 | 1.23 | 1.83 | ||||||

| 25 | 1.24 | 1.84 | ||||||

| 26 | 1.25 | 1.85 | ||||||

| 27 | 1.26 | 1.86 | ||||||

| 28 | 1.27 | 1.87 | ||||||

| 29 | 1.28 | 1.88 | ||||||

| 30 | 1.29 | 1.89 | ||||||

| 31 | 1.3 | 1.9 | ||||||

| 32 | 1.31 | |||||||

| 33 | 1.32 | |||||||

| 34 | 1.33 | |||||||

| 35 | 1.34 | |||||||

| 36 | 1.35 | |||||||

| 37 | 1.36 | |||||||

| 38 | 1.37 | |||||||

| 39 | 1.38 | |||||||

| 40 | 1.39 | |||||||

| 41 | 1.4 | |||||||

| 42 | 1.41 | |||||||

| 43 | 1.42 | |||||||

| 44 | 1.43 | |||||||

| 45 | 1.44 | |||||||

| 46 | 1.45 | |||||||

| 47 | 1.46 | |||||||

| 48 | 1.47 | |||||||

| 49 | 1.48 | |||||||

| 50 | 1.49 | |||||||

| 51 | 1.5 |

Alumina Gauges Packaging

- Individual anti-scuff sleeves or foam-in-box; set boxes with size map