High-temperature industrial environments often expose materials to thermal gradients, corrosive gases, and mechanical stress, which can lead to premature failure. Many traditional materials fail under such harsh conditions, resulting in increased downtime and operational costs. Industrial alumina tubes offer a reliable solution to these challenges by maintaining structural integrity, thermal stability, and chemical resistance, ensuring optimal performance in demanding applications.

This article examines high-temperature behaviors, structural requirements, application scenarios, and supplier evaluation criteria while presenting a comprehensive approach for selecting industrial alumina tube components across multiple industries.

Consequently, the following sections establish a structured technical foundation, enabling precise material selection and ensuring consistent performance under elevated thermal and chemical loads.

Material Properties of Industrial Alumina Tube for High-Temperature and Corrosive Environments

A high-temperature environment often requires materials capable of maintaining structural integrity and chemical stability; therefore, industrial alumina tube properties must be evaluated carefully before integration into critical systems.

Why High-Temperature and Reactive Systems Require Materials with Enhanced Stability

High-temperature processes often expose structural components to thermal gradients, corrosive gases, and mechanical fatigue, and industrial alumina tube assemblies must therefore provide consistent resilience. Moreover, many traditional materials fail prematurely when subjected to repeated thermal cycling, which increases replacement frequency and operational risk. Consequently, a more durable ceramic structure becomes necessary to maintain system reliability.

Additionally, thermal fluctuations exceeding 1200 °C frequently accelerate oxidation, distortion, and micro-fracture propagation in conventional tubing, and these issues directly compromise equipment accuracy and stability. Furthermore, reactive atmospheres introduce chemical pathways that degrade metal substrates more rapidly, particularly when exposed to acidic or alkaline compounds for extended durations. As a result, selecting a tube material that withstands both temperature and chemical stress is essential for maintaining predictable performance.

Thus, application environments characterized by corrosive species, temperature spikes, or sustained high heat demand materials engineered for long-term resistance, and industrial alumina tube solutions provide a dependable foundation for such conditions.

Thermal Stability and Structural Integrity of 99–99.5% Alumina

High-purity alumina formulations between 99% and 99.5% maintain crystalline stability at 1400–1700 °C, and this thermal endurance allows industrial alumina tube components to support continuous high-temperature operations. Furthermore, these purity levels reduce structural creep and suppress grain-boundary softening, which enhances longevity. Consequently, thermal durability becomes a central advantage in harsh furnace applications.

In addition, the predictable thermal expansion behavior of dense alumina reduces stress accumulation during rapid heating cycles, and steady expansion rates support dimensional integrity. Moreover, thermal-shock resistance improves markedly when porosity remains below 5%, as low porosity minimizes crack initiation1 sites. Therefore, high-purity alumina stands out in processes involving repeated heat cycling.

Hence, maintaining structural uniformity under sustained heat ensures component stability, and industrial alumina tube materials are frequently selected for systems requiring consistent high-temperature reliability.

Resistance to Corrosive Media and Reactive Atmospheres

Alumina exhibits strong resistance to chlorine-bearing gases, sulfur-rich atmospheres, and high-alkalinity environments, and this characteristic improves the longevity of industrial alumina tube installations. Additionally, the absence of metallic phases eliminates galvanic interactions, particularly in mixed-media chemical reactors. Consequently, corrosion-driven dimensional loss is minimized during extended operation.

Furthermore, industrial alumina tube components remain dimensionally stable when acid exposure exceeds 100 hours at elevated temperatures, and this performance surpasses many alloy-based tubes. Moreover, alumina maintains inertness in oxidizing atmospheres up to 1600 °C, preserving surface morphology and structural strength. Therefore, chemically aggressive environments often benefit from the inherent inertness of alumina ceramics.

Thus, in processing systems handling corrosive liquids or gases, alumina provides a strong material advantage by ensuring long-term durability and consistent functional output.

Electrical Insulation and Dielectric Stability

Industrial alumina tube materials provide dielectric strengths commonly exceeding 10 kV/mm at ambient temperature, and this high insulation level remains relatively stable as temperatures rise. Moreover, alumina maintains dielectric integrity even under fluctuating humidity levels, which enhances measurement accuracy in electrically sensitive assemblies. Consequently, alumina serves effectively in thermal-electrical isolation structures.

Additionally, dielectric losses remain low across a broad frequency range, and this stability supports precise sensor functionality in high-temperature sensing systems. Furthermore, alumina’s resistivity typically remains above 10¹² Ω·cm at elevated temperatures, significantly reducing leakage pathways. Therefore, alumina accommodates applications where both thermal and electrical loads converge.

Hence, industrial alumina tube components are well suited for systems requiring simultaneous thermal resistance and electrical isolation, particularly in instrumentation and controlled electrical environments.

Summary Table: Key Material Properties of Industrial Alumina Tube

| Property | Typical Value | Notes |

|---|---|---|

| Purity (%) | 99–99.5 | High-temperature grade |

| Max Operating Temperature (°C) | 1400–1700 | Depends on atmosphere |

| Dielectric Strength (kV/mm) | 8–12 | Stable across temperature |

| Porosity (%) | <5 | Enhances shock resistance |

| Chemical Stability | High | Resistant to acids and alkalis |

Application Scenarios of Industrial Alumina Tube Across Metallurgy, Chemical Processing, Energy, and Instrumentation Industries

Industrial processes relying on an industrial alumina tube require stable material performance across diverse operating environments, and these application scenarios reveal how different sectors depend on thermal and chemical durability.

Why Diverse Industrial Processes Require High-Purity and High-Stability Tubular Components

Multiple industrial sectors operate under elevated temperatures, corrosive atmospheres, or stringent measurement conditions, and an industrial alumina tube must therefore exhibit consistent performance to sustain process reliability. Furthermore, traditional tubing materials often fail when exposed to thermal intensities exceeding 1200 °C or chemically active media, which disrupts operating cycles and increases equipment wear. Consequently, the need for material solutions supporting thermal strength, chemical inertness, and dimensional stability becomes evident in these environments.

Moreover, continuous process plants often require components that maintain purity levels above 99% to avoid contamination, particularly when sensitive chemical reactions are involved. Likewise, equipment in advanced energy systems relies on ceramic stability to preserve operational uniformity across long production intervals. Hence, these considerations demonstrate the diverse reliance on engineered ceramic tubing.

Thus, identifying sector-specific requirements clarifies why industrial alumina tube components are distributed across numerous applications that demand predictable material behavior.

High-Temperature Furnace Tubes in Metallurgy and Heat Treatment

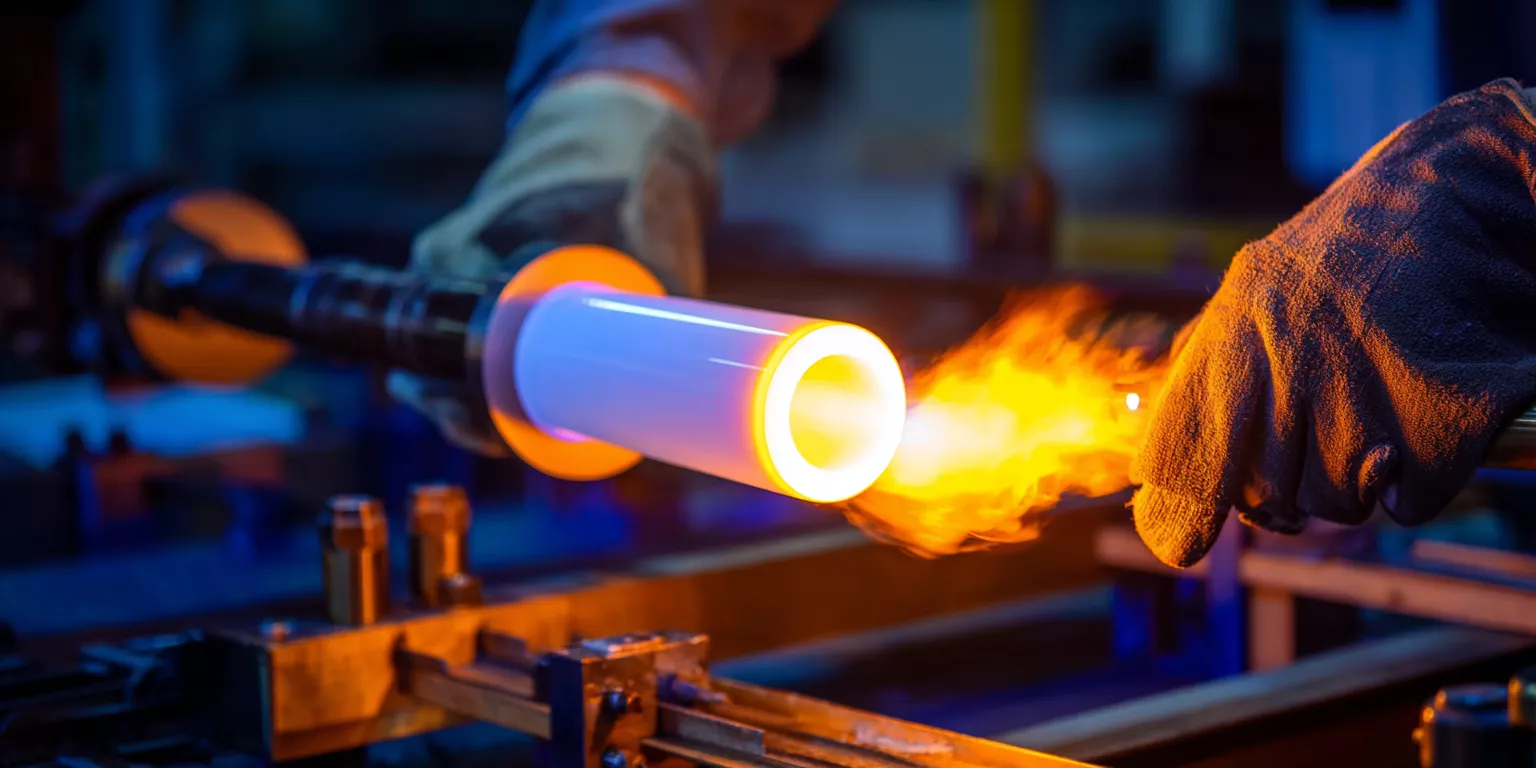

Metallurgical furnaces often operate in temperature ranges between 1300 °C and 1600 °C, and such environments favor the use of an industrial alumina tube because of its thermal endurance. Additionally, furnace chambers require components that retain straightness and resist shrinkage during prolonged exposure, particularly when processing cycles exceed 50 hours. Consequently, alumina-based furnace tubes contribute significantly to maintaining chamber uniformity and thermal distribution.

Furthermore, alumina compositions with porosity values below 5% resist crack initiation, which is critical during rapid heating schedules. Similarly, dimensional retention under extreme heat reduces alignment deviations when supporting mechanical structures. Therefore, furnace systems incorporating high-purity alumina ensure stable outcomes across repeated process cycles.

Thus, industrial alumina tube elements remain central to metallurgical and heat-treatment operations requiring high thermal stability and prolonged service life.

Protective Tubes for Temperature Measurement Systems

Temperature measurement assemblies often demand stable housings for sensors operating above 1100 °C, and an industrial alumina tube provides insulation and structural protection for such devices. Moreover, protective tubes help maintain measurement accuracy by preventing chemical interference, especially in atmospheres containing sulfur or chlorine2. Consequently, measurement components retain calibration consistency across extended use.

Additionally, thin-wall alumina tubes between 1.5 mm and 3 mm improve thermal response time, which enhances monitoring accuracy in dynamic thermal fields. Furthermore, structural rigidity above 200 MPa supports probe stability during insertion into high-temperature zones. Hence, measurement systems benefit from the convergence of thermal and mechanical reliability.

Thus, industrial alumina tube housings serve as dependable enclosures in precision temperature-control architectures.

Corrosion-Resistant Conduits in Chemical Transport and Reactive Environments

Chemical reactors frequently contain acid concentrations above 20% or alkaline streams exceeding pH 12, and such conditions demand corrosion-resistant pathways; an industrial alumina tube effectively addresses these challenges by maintaining chemical neutrality. Furthermore, metallic tubing often undergoes pitting or oxidation under these constraints, which disrupts flow uniformity and increases maintenance intervals. Consequently, ceramic tubing offers a more stable conduit for reactive media.

Moreover, industrial alumina tube structures maintain dimensional accuracy when exposed to corrosive environments for more than 100 operational hours, which supports predictable flow patterns. Likewise, alumina’s inert surface chemistry minimizes material exchange with process fluids, thereby reducing contamination risks in sensitive formulations. Therefore, chemical transport systems achieve enhanced reliability through alumina’s inherent stability.

Thus, alumina conduits are widely adopted in reactors, transfer lines, and containment zones requiring long-term chemical durability.

High-Purity Components for Laboratory and Analytical Equipment

Laboratory furnaces and analytical instruments frequently require contamination-free materials, and an industrial alumina tube provides purity levels exceeding 99% to maintain measurement integrity. Additionally, controlled porosity improves gas flow uniformity within reaction chambers, which is essential for experiments operating above 1000 °C. Consequently, alumina components support repeatable results across multiple testing cycles.

Furthermore, analytical systems depend on insulating structures capable of resisting dielectric losses under thermal exposure, and alumina’s stability enhances signal fidelity. Likewise, maintaining dimensions within ±0.15 mm is crucial in partitioned instrument housings. Therefore, laboratory apparatus benefits from the precision and purity offered by engineered alumina tubing.

Thus, industrial alumina tube parts contribute significantly to the performance of instrumentation focused on high-temperature, high-accuracy operations.

Application Summary for Industrial Alumina Tube

| Application Sector | Operating Range | Key Requirement |

|---|---|---|

| Metallurgy | 1300–1600 °C | Thermal endurance |

| Measurement Systems | >1100 °C | Signal stability |

| Chemical Processing | pH 1–14 | Corrosion resistance |

| Laboratory Equipment | >1000 °C | High purity |

| Energy Systems | Cyclic heating | Structural consistency |

Failure Modes, Common Problems, and How Industrial Alumina Tubes Solve These Issues

Repeated exposure to thermal gradients and corrosive atmospheres often challenges component durability, and an industrial alumina tube can mitigate several recurring failure mechanisms in demanding environments.

Why Conventional Tubing Materials Frequently Fail in Demanding Industrial Environments

Many industrial systems operate above 1200 °C or involve chemically reactive media, and under such conditions conventional tubes frequently exhibit structural instability. Furthermore, metallic or low-purity ceramic tubes may deform or oxidize when subjected to sustained heat loads or aggressive atmospheres, ultimately disrupting operational continuity. Consequently, identifying how failure originates provides essential context for selecting more resilient materials.

Moreover, accelerated fatigue often arises when components encounter repeated thermal cycles that exceed 200 rapid-heating iterations, because temperature differentials produce internal stress concentrations. Likewise, corrosion pathways intensify when chlorine-bearing or sulfur-bearing environments exceed specific exposure thresholds, causing uniform material loss. Hence, examining the conditions that precipitate these failures highlights the need for improved material solutions.

Thus, understanding the mechanisms behind premature degradation clarifies why industrial alumina tube components offer a structurally superior alternative in thermally and chemically demanding facilities.

Thermal Cracking Driven by Rapid Heat Cycling

Thermal cracking often develops when tubes experience abrupt temperature changes exceeding 300 °C per minute, and this rapid fluctuation amplifies internal stresses. Additionally, inconsistent material density or residual porosity accelerates crack initiation during heating phases, particularly when tubes operate near 1500 °C. Consequently, fracture propagation becomes inevitable in tubes lacking sufficient thermal resilience.

Furthermore, repeated cycling can induce micro-crack networks originating at grain boundaries, and these defects eventually compromise dimensional stability. Similarly, non-uniform wall thickness magnifies localized heating, increasing stress gradients during sustained operation. Therefore, thermal-shock mitigation requires materials capable of maintaining crystalline integrity under intense fluctuations.

Thus, the reliable performance of an industrial alumina tube during abrupt thermal transitions stems from its stable microstructure and low porosity, which collectively restrict crack formation.

Deformation and Creep Under Sustained High Loads

Continuous furnace operation above 1400 °C often introduces creep deformation, and weakened structural rigidity leads to misalignment throughout the assembly. Moreover, prolonged exposure beyond 200 operational hours tends to accelerate grain-boundary sliding in low-density materials, resulting in measurable sag across tube spans. Consequently, equipment calibration may drift when structural components lose form stability.

Additionally, creep rates increase significantly when the applied mechanical load exceeds 5 MPa, and such deformation disrupts heat-flow uniformity within thermal systems. Likewise, dimensional drift interferes with component interfaces, influencing sealing conditions. Hence, advanced ceramics with higher modulus values provide clear advantages under sustained thermal loads.

Thus, industrial alumina tube components maintain dimensional accuracy across extended cycles due to their elevated creep resistance and consistent structural framework.

Chemical Erosion and Surface Degradation in Reactive Media

Exposure to acidic or alkaline solutions with pH values between 1 and 143 can erode many tube materials, yet alumina withstands such interactions with minimal degradation. Furthermore, corrosion accelerates when reaction temperatures surpass 1000 °C, which causes noticeable pitting in metallic alternatives. Consequently, the maintenance cycle shortens significantly when incompatible tube materials are selected.

Moreover, chlorine-rich processing streams often trigger oxidation-reduction sequences that weaken conventional substrates. Likewise, sulfur-based compounds increase surface roughness when contact durations exceed 48 hours. Therefore, longevity in reactive environments depends on chemical inertness, particularly when surface stability influences downstream processes.

Thus, the inherent corrosion resistance of an industrial alumina tube ensures predictable performance in aggressive chemical systems while reducing the frequency of component replacement.

Surface Spalling and Coating Instability

Surface spalling occurs when thermal expansion incompatibilities arise between coatings and substrate materials, and temperature spikes above 1200 °C exacerbate this separation. Additionally, heterogeneous grain structures in poorly processed tubes increase the likelihood of surface fragmentation that can contaminate process streams. Consequently, surface instability introduces reliability risks in high-precision operations.

Furthermore, coating defects propagate more rapidly when thermal gradients exceed 20 °C per centimeter, because differential expansion accelerates mechanical separation. Likewise, repeated exposure to oxidizing environments intensifies spall formation through micro-structural distortion. Therefore, coating compatibility and substrate uniformity remain critical considerations for minimizing failure.

Thus, industrial alumina tube components with uniform density and controlled grain size reduce the likelihood of spalling, supporting long-term system cleanliness and reliability.

Failure-Mode Summary for Industrial Alumina Tube

| Failure Mode | Typical Trigger Condition | Alumina Advantage |

|---|---|---|

| Thermal Cracking | >300 °C/min cycling | Low porosity reduces stress |

| Creep Deformation | >1400 °C sustained | High modulus maintains shape |

| Chemical Erosion | pH 1–14 at >1000 °C | Chemical inertness |

| Surface Spalling | Thermal gradients >20 °C/cm | Uniform microstructure |

| Oxidation Damage | Sulfur/Chlorine exposure | Stable oxide surface |

Supplier Evaluation Guide: How to Select a Reliable Industrial Alumina Tube Manufacturer

Reliable long-term performance in thermal and chemical systems depends on the supplier’s technical capability, and selecting an industrial alumina tube manufacturer requires disciplined evaluation across multiple criteria.

Why Reliable Supply and Manufacturing Capability Determine Long-Term System Stability

Critical components exposed to high-temperature or corrosive conditions require consistent dimensional accuracy, and an industrial alumina tube must therefore originate from a supplier with controlled production processes. Moreover, inconsistent sintering cycles, density variations above 3%, or unstable raw material quality may introduce structural weaknesses that compromise downstream operations. Consequently, a manufacturer’s internal controls significantly influence module reliability.

Furthermore, high-purity applications demand repeatable batch chemistry, especially when alumina content must remain between 99% and 99.5% to ensure thermal and chemical stability. Likewise, high-temperature systems often require tolerances below ±0.2 mm, which only specialized equipment can achieve. Hence, supplier capability governs predictability across extended operating cycles.

Thus, evaluating production competency becomes essential for selecting industrial alumina tube suppliers capable of meeting advanced engineering requirements.

Direct Manufacturing Capabilities and Process Control

A qualified supplier must demonstrate rigorous control of forming, sintering, and machining stages, and such control ensures that industrial alumina tube components maintain uniform microstructure. Additionally, isostatic pressing can achieve density levels above 3.85 g/cm³, which enhances thermal-shock performance in systems experiencing rapid cycling. Consequently, process control directly affects product longevity.

Moreover, precision grinding equipment must maintain dimensional tolerances below ±0.15 mm, which is crucial when dealing with long tubes exceeding 800 mm. Similarly, automated kilns with adjustable heating profiles reduce thermal gradients to under 5 °C per zone, preserving structural uniformity. Therefore, advanced machinery remains a defining indicator of reliable output.

Thus, direct manufacturing capability establishes the foundation for consistent high-quality alumina tubing across numerous industrial applications.

Technical Competence and Engineering Collaboration

Sophisticated applications often require full parameter validation, and manufacturers offering engineering support can tailor industrial alumina tube configurations to system-specific constraints. Additionally, compatibility studies addressing thermal expansion, chemical exposure, and interface geometry ensure that tube performance aligns with operational conditions. Consequently, engineering collaboration reduces integration risks significantly.

Furthermore, suppliers with access to metrology tools such as CMM systems offer dimensional verification within ±0.01 mm, enabling precise alignment with OEM specifications. Likewise, materials laboratories capable of conducting porosity, phase composition, and mechanical strength analyses provide valuable data for demanding environments. Hence, technical competence influences application suitability.

Thus, collaboration between supplier engineering teams and industrial users ensures proper selection, customization, and validation of alumina components under real-world constraints.

Quality Assurance, Batch Consistency, and Inspection Protocols

High-performance installations require dependable batch-to-batch consistency, and robust quality systems ensure that industrial alumina tube components meet defined characteristics. Moreover, QA frameworks verifying parameters such as density, porosity, and modulus maintain uniformity across manufacturing cycles. Consequently, strong quality systems reduce the likelihood of premature failure.

Furthermore, inspection processes involving ultrasonic scanning or microscopy can detect internal flaws as small as 50 μm, and these early detections prevent defective tubes from entering critical assemblies. Likewise, destructive test sampling at frequencies above 1% per batch helps maintain statistical stability. Therefore, companies prioritizing advanced QA measures offer more predictable products.

Thus, adopting rigorous inspection protocols ensures that industrial alumina tube shipments deliver dependable performance across extended operating periods.

Supplier Evaluation Summary for Industrial Alumina Tube

| Evaluation Area | Critical Metric | Required Level |

|---|---|---|

| Purity Control | Al₂O₃ % | 99–99.5 |

| Tolerance Capability | Diameter (mm) | ±0.15–0.20 |

| Density Uniformity | g/cm³ | >3.85 |

| Structural Inspection | Defect size (μm) | <50 |

| Thermal Cycle Stability | ΔT per cycle | <300 °C |

Why Industrial Buyers Prefer Factory-Direct Manufacturers for Alumina Tube Procurement

Factory-direct sourcing often provides higher operational assurance in critical environments, and selecting an industrial alumina tube from direct manufacturers strengthens supply reliability and engineering alignment.

Why Direct Manufacturing Sources Offer Higher Operational Assurance

High-temperature and chemically reactive applications require consistent quality, and an industrial alumina tube delivered directly from the factory avoids variability introduced by intermediaries. Moreover, production timelines become more predictable when communication occurs with the manufacturing source, because process adjustments can be implemented without delay. Consequently, operational reliability improves when product specifications, tolerances, and material properties are verified at the origin.

Furthermore, batch uniformity is easier to maintain when manufacturing routes remain transparent, especially when purity levels must remain between 99% and 99.5% for thermal stability. Likewise, direct suppliers can provide documentation for shrinkage rates, modulus values, and porosity levels with measurement precision better than ±2%. Hence, accessing original production data supports long-term system predictability.

Thus, factory-direct relationships provide improved visibility, tightening the link between application requirements and the performance of an industrial alumina tube placed into service.

Reduced Downtime Risk Through Stable Supply and Controlled Lead Times

Factories with established kiln capacity and inventory programs maintain stable lead times, and these capabilities reduce unexpected delays for industrial alumina tube replenishment. Additionally, direct access to production scheduling allows users to coordinate deliveries around maintenance cycles, which minimizes operational interruptions. Consequently, downtime exposure decreases significantly in systems requiring frequent component turnover.

Moreover, facilities producing more than 500 units per batch can maintain safety stock, ensuring uninterrupted supply during peak demand. Likewise, production timelines between 15–25 days support predictable planning in environments where equipment access windows are tightly constrained. Therefore, factory-based fulfillment enhances scheduling stability for critical-path installations.

Thus, dependable supply cycles from direct manufacturers lessen the risk of production stoppages, establishing a more reliable sourcing foundation for industrial alumina tube components.

Enhanced Technical Communication and Customization Responsiveness

Direct manufacturers provide rapid access to engineering teams capable of adjusting designs for complex assemblies, and such responsiveness helps optimize industrial alumina tube geometry. Moreover, immediate feedback on drawings, tolerances, and interface requirements enables faster refinement of mating parts, particularly when thermal expansion must align within the 6–8 × 10⁻⁶/°C range. Consequently, customization becomes more precise and better aligned with system constraints.

Furthermore, communication with production engineers accelerates troubleshooting in applications where wall-thickness variations must remain inside ±0.1 mm to prevent thermal imbalance. Similarly, surface-finish parameters—such as Ra values below 0.8 μm—can be validated more quickly when requests are made directly to machining personnel. Hence, direct communication supports accurate adaptation to equipment-specific conditions.

Thus, factory-direct engagement fosters efficient customization cycles, strengthening the technical suitability of industrial alumina tube components across specialized environments.

Predictability and Risk Reduction in Long-Term Procurement Programs

Long-term procurement programs require stability in pricing, material composition, and dimensional repeatability, and factory-direct sourcing improves traceability across batches. Additionally, consistent raw-material selection reduces variability in shrinkage and density, which is critical when insertion tolerances rely on deviations under 0.2 mm. Consequently, project-level risk decreases as variability narrows.

Moreover, direct producers maintain statistical-process-control records that capture firing curves, defect rates, and dimensional trends over time, supporting audit-ready traceability. Likewise, order histories exceeding 12 months often reveal lower variability when tube production remains in-house. Therefore, long-term planning becomes more dependable when relying on factory-originated components.

Thus, engaging directly with manufacturers enhances procurement stability, ensuring that industrial alumina tube performance remains consistent across extended operational cycles.

Factory-Direct Procurement Summary for Industrial Alumina Tube

| Key Advantage | Measurable Metric | Impact |

|---|---|---|

| Lead-Time Stability | 15–25 days | Reduced downtime |

| Dimensional Repeatability | <±0.2 mm | Consistent integration |

| Purity Consistency | 99–99.5% | Reliable high-temperature performance |

| Engineering Response Time | <48 hours | Faster customization |

| Batch Traceability | Full SPC data | Lower procurement risk |

Conclusion

Industrial alumina tube solutions offer stable performance in high-temperature and corrosive environments, ensuring consistent reliability across metallurgical, chemical, energy, and analytical applications.

FAQ

What purity range is typically required for high-temperature applications?

High-temperature operations generally require alumina purity between 99% and 99.5%, because this range maintains phase stability, structural integrity, and chemical resistance in environments exceeding 1400 °C.

How does wall-thickness variation affect thermal system performance?

Even a deviation above ±0.1 mm may alter heat flow distribution by creating localized hotspots, and such imbalance reduces the long-term reliability of an industrial alumina tube under cyclic heating.

Why are straightness and end-face processing important in furnace assemblies?

Straightness below 0.3% and end-face flatness under 0.05 mm enhance structural alignment, thereby improving sealing performance and reducing stress concentrations during extended thermal operation.

Can industrial alumina tube components be customized for specialized reactors?

Yes. Custom lengths between 100 mm and 1500 mm, controlled tolerances, and specific interface geometries enable reliable integration into reactors requiring precise thermal, chemical, or structural compatibility.

References:

-

Learn how crack initiation impacts material durability and why controlling it is crucial for improving thermal-shock resistance. ↩

-

Discover how protective tubes safeguard sensors from chemical interference, ensuring precise measurements in harsh environments like those with sulfur or chlorine. ↩

-

Learn how acidic and alkaline solutions across the pH scale interact with different materials and why some, like alumina, resist degradation. ↩