Advanced Boron Nitride (BN) Crucible | Precision for High-Temperature Metal Processing

Boron nitride (BN) crucibles are used for clean melting and high-temperature processing of metals and alloys. Their non-wetting and chemically inert properties prevent contamination and make them ideal for aluminum, magnesium, copper, precious metals, titanium alloys and silicon under vacuum or inert atmospheres.

With over 20 years of experience, ADCERAX focuses on producing standard and custom BN crucibles for metal melting, evaporation, casting, and laboratory thermal applications. Each crucible is built for stable heating cycles, smooth inner surfaces and reliable performance in demanding furnace environments.

What is a Boron Nitride Ceramic Crucible?

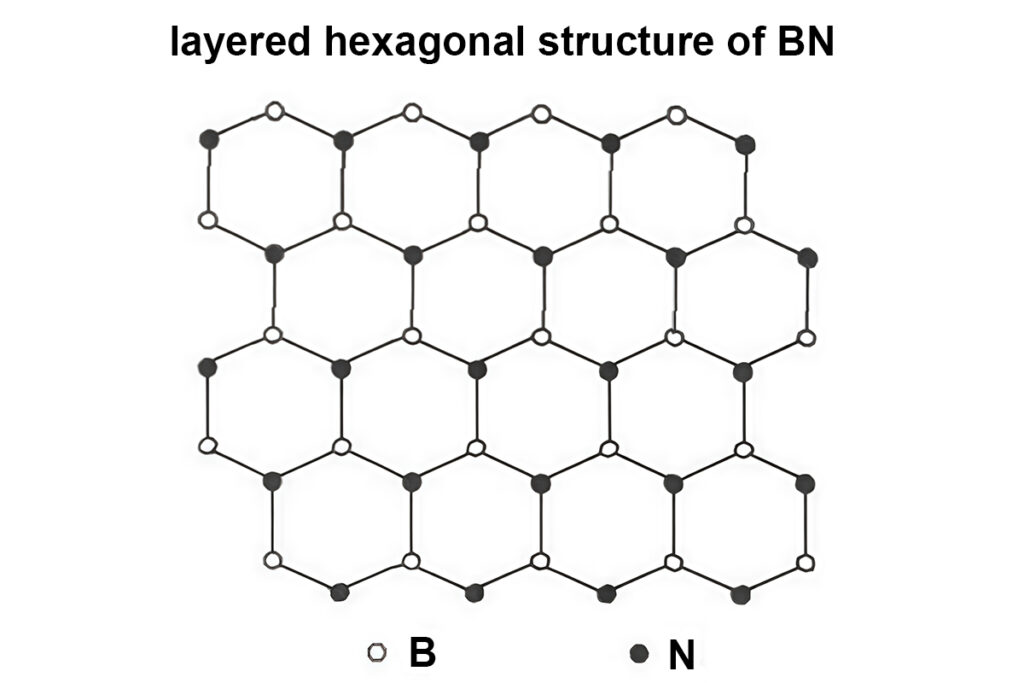

A boron nitride crucible is a high-performance ceramic vessel manufactured from hot-pressed hexagonal boron nitride (h-BN), designed for processes that require clean handling of molten metals, reactive alloys and high-temperature materials. Its layered crystal structure and covalent bonding provide a unique combination of non-wetting behavior, low chemical reactivity, high thermal conductivity, electrical insulation and resistance to thermal shock.

Why Choose BN Crucibles Over Graphite or Alumina

Unlike graphite, alumina or zirconia crucibles, BN crucibles remain chemically inert and non-reactive to molten aluminum, magnesium, copper, silicon, titanium alloys and precious metals. This prevents contamination, facilitates easy demolding and ensures consistent melt purity in vacuum, inert gas or reducing atmospheres up to 1800–2000 °C.

| Property / Feature | BN Crucible (Boron Nitride) | Graphite Crucible | Alumina Crucible | Zirconia Crucible |

| Reaction with Molten Metals | Non-wetting, non-reactive to Al, Mg, Cu, Ti alloys, Si, precious metals | Reacts with oxygen, may contaminate melt | Can react with active metals (Al, Mg) | More stable but may react with Ti & Si at high temp |

| Contamination Risk | Very low – clean melt surface | Medium – carbon contamination possible | Medium – oxide residues may enter melt | Low to medium, depending on alloy |

| Max Working Temperature | 1800–2000 °C (vacuum/inert gas) | Up to ~3000 °C in inert, but oxidizes above 500 °C in air | 1600–1700 °C | 2000+ °C but heavy and slow to heat |

| Thermal Shock Resistance | Excellent – rapid heating/cooling tolerable | Moderate – cracks if heated unevenly | Poor to moderate | Low – high risk of cracking |

| Electrical Properties | Excellent electrical insulator | Conductive | Insulator | Insulator |

| Ease of Demolding / Release | Easy – metals do not stick to surface | Sticking depends on surface oxidation | Molten metals wet surface – hard to release | Better than alumina, but sticking still possible |

Boron Nitride Crucible Properties

For users concerned about metal purity, oxidation and demolding, BN crucibles offer unmatched performance. They offer high thermal stability, non-wetting behavior and chemical inertness, preventing molten aluminum, magnesium, copper, silicon and precious metals from sticking or getting contaminated. This ensures high-purity melts and easy release even under repeated thermal cycles.

🔥Thermal Performance

- Safe Working Temperature: Up to 1800 °C in vacuum or argon; short-term resistance to 2000 °C depending on crucible shape and wall thickness.

- No Thermal Cracking:Low thermal expansion prevents cracking during rapid heating or cooling in melting furnaces.

- Uniform Heat Transfer:BN wall provides stable and even heating, reducing hot spots and melt defects.

🧪 Metal Compatibility and Purity

- Non-Wetting Surface:Molten Al, Mg, Cu, Au, Ag, Si or Ti alloys do not stick to BN, easy pouring and demolding.

- Ultra-Low Contamination:No carbon, oxygen, or refractory impurities—suitable for high-purity alloys and crystal growth.

- No Reaction Layer Formation:BN does not form intermetallic compounds or oxide layers with molten metals.

🏗 Structural & Mechanical Reliability

- Stable Wall Geometry:Cylindrical, conical or overflow-style crucibles remain dimensionally stable under repeated thermal cycles.

- Customizable Thickness:Walls from 1 mm (lab use) to 10 mm (industrial melting); bottom thickening available for longer lifespan.

- Machinable Accuracy:Internal diameter, nozzle outlet or cover connection can be precisely machined to ±0.05–0.20 mm.

⚙ Furnace & Process Compatibility

- Compatible Furnace Types:Induction melting furnaces, resistance heaters, vacuum evaporation chambers, crystal growth setups, vertical casting systems.

- Atmosphere Adaptability:Performs reliably in vacuum, argon, nitrogen, hydrogen and reducing atmospheres.

- Operational Convenience:Smooth inner surface, easy to clean, reusable if not exposed to thermal shock or mechanical impact.

Boron Nitride (BN) Crucible Types Made in China

ADCERAX specializes in boron nitride crucibles, including hot-pressed BN crucibles, pyrolytic BN (PBN) crucibles and BN crucible liners. Designed for high-purity metal processing, vacuum evaporation and thermal research, these crucibles provide excellent resistance to sticking, thermal shock and chemical attack. Both standard and custom shapes are available to match different furnace chambers, melting systems and process requirements.

Custom BN crucibles can be machined into cylindrical, conical, stepped, lidded or spouted shapes. ADCERAX supports customized inner cavities, overflow ports, tapered walls and crucible liners according to drawings or 3D models, meeting specific furnace sizes and melting processes.

PBN crucibles are CVD-formed with >99% purity and a dense, gas-tight structure. They ensure high cleanliness in semiconductor evaporation, metal melting and crystal growth. ADCERAX provides custom wall thickness, flanges and cavity shapes to fit MBE, PVD or vacuum furnace systems.

BN crucible liners protect graphite, quartz or metal crucibles from corrosion and contamination during high-temperature melting. Their smooth, non-wetting surface prevents alloy adhesion and ensures clean demolding. Custom sizes, stepped bases and tapered liners are available to fit existing furnace chambers.

💡 Pure Melts. Precise Machining. Proven Reliability — ADCERAX BN Crucible

ADCERAX BN crucibles give you clean melts, stable performance up to 1800 °C and custom designs that fit your furnace perfectly. Tell us your size, temperature and metal type — we’ll take care of the rest.

Boron Nitride (BN) Crucible Applications

Boron Nitride (BN) ceramics are widely used in semiconductor processing, precision machinery, metallurgy, and laboratory equipment. They serve essential roles in components such as insulating rings, tubes, plates, and spacers supporting high-temperature operations, vacuum systems, and precision instruments across multiple industrial fields.

Metallurgy & Metal Melting

Application: BN crucibles are used for melting aluminum, magnesium, copper, titanium, precious metals and silicon.

Challenges: Molten metals tend to stick to alumina or graphite crucibles, causing contamination, carbon pollution, or cracking after repeated heating. Traditional ceramic crucibles also have long lead times for custom sizes, delaying production.

🧩 ADCERAX Solution:

- Hot-pressed BN and PBN crucibles with non-wetting surface, chemical inertness & minimal contamination

- Custom sizes from 3 ml to 4000 ml, ±0.05–0.1 mm machining tolerance

- BN liners extend graphite crucible lifespan by 2–4×

- Ready-to-ship standard sizes + custom OEM available

- 🔹Case Example:

A German copper casting plant replaced alumina crucibles with ADCERAX BN crucibles. Metal purity increased from 99.7 % to 99.92 %, and crucible replacement cycle extended from 1 month to 3 months—saving USD 26,000 per year in downtime and material loss.

Vacuum & Thermal Processing

Application: BN crucibles are used in vacuum furnaces, brazing, induction heating and high-temperature treatment of reactive metals like titanium, zirconium and niobium. Their non-wetting and inert surface ensures clean metal melting under vacuum or inert gas.

Challenges: In vacuum or inert atmospheres above 1500 °C, alumina and graphite crucibles often crack, react with molten metals, or release oxygen/carbon impurities—causing poor melt purity and unstable thermal cycles.

🧩 ADCERAX Solution:

- Hot-pressed BN and PBN crucibles with low vapor pressure, non-reactive to Ti, Zr, Nb and reactive alloys.

- Precision machining to ±0.05 mm; lidded, stepped or overflow-port crucibles available from 5 ml to 3000 ml.

- Suitable for vacuum furnaces, induction coils and thermal evaporation systems without carbon or oxygen pollution.

- 🔹Case Example:

A Japanese vacuum furnace company used BN crucibles for titanium brazing instead of graphite crucibles. Oxygen content in melt dropped from 0.035% to 0.008%, and crucible lifespan increased from 15 to 60 cycles—saving over USD 22,000 annually in replacement and maintenance costs.

Crystal Growth & Semiconductor Material

Application: BN crucibles serve as evaporation containers in PVD, MOCVD, silicon crystal pulling and GaAs/InP semiconductor processing, ensuring stable molten conditions and no contamination.

Challenges: Quartz or graphite crucibles release oxygen or carbon at high temperatures, affecting crystal color, resistivity or purity. Crystal cracking and oxide interface defects also occur during cooling.

🧩 ADCERAX Solution:

- PBN crucibles (CVD-grown, >99.9% purity) offer gas-tight walls for ultra-pure gallium, germanium and silicon evaporation.

- Custom flanges, tapered cavities and MBE-compatible bottoms available.

- Dimensional precision ±0.05 mm, suitable for 1–8 inch crystal systems.

- 🔹Case Example:

A German MOCVD lab replaced graphite crucibles with ADCERAX PBN crucibles for GaN growth. Carbon contamination dropped from 3.6 ppm to <0.5 ppm, wafer yield increased by 9%, and cleaning intervals extended from 1 week to 1 month.

Laboratory & Research Institutes

Application: BN crucible is used for small-batch metal melting, thermal analysis, high-temperature experiments, glass research and sample purification in universities and R&D laboratories.

Challenges: Research environments require small quantities but high precision—conventional crucibles crack after repeated heating or introduce impurities that affect test accuracy.

🧩 ADCERAX Solution:

- BN crucibles available from 3 ml to 500 ml, suitable for DTA/DSC, TGA and induction furnace experiments.

- No minimum order quantity (MOQ), fast prototyping, drawings or sample-based customization.

- Clean, non-wetting surfaces for easy sample removal and accurate analysis.

- 🔹Case Example:

A U.S. university materials lab adopted BN crucibles for titanium alloy phase transition research. Sample oxidation decreased by 80%, and measurement repeatability improved from ±2.3 °C to ±0.6 °C.

Custom Boron Nitride Crucible Manufacturer

ADCERAX builds custom BN crucibles with precision cavities, stable wall thickness and non-wetting surfaces—made to your drawings with tolerances to ±0.05 mm. From prototypes to batch supply, we deliver reliable results within 3–9 weeks.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

Trusted Boron Nitride Crucible Supplier with Precision Manufacturing

BN Crucible Processing Capacity

ADCERAX produces boron nitride ceramic crucible entirely in-house—from hot-pressing raw BN powder to precision CNC finishing. This ensures full control of density, purity, and dimensional accuracy.

🔷 In-House Forming & Sintering: BN powder is hot-pressed into blocks or crucible blanks under controlled pressure and temperature to ensure consistent density and microstructure.

🔷 CNC Precision Machining: 5-axis machines shape deep cavities, tapered walls, spouts and sealing rims with dimensional accuracy up to ±0.05 mm.

🔷 Flexible Production Scale: Supports prototypes, small batches and volume orders. Standard sizes to 4000 ml, no strict MOQ for custom crucibles.

BN Crucible Benefits of ADCERAX

Boron nitride (BN) ceramic crucibles are designed for clean melting, alloy processing and crystal growth where traditional ceramics fail.

Clean Melting – Chemically inert and non-wetting to aluminum, magnesium, copper, silicon and precious metals, ensuring high-purity melts.

Longer Service Life – Withstands thermal shock and corrosion, reducing furnace downtime and replacement cost.

Smooth Release – Molten metals do not stick to the surface, allowing easy pouring and demolding.

Process Stability – Ideal for high-temperature work in vacuum, inert or reducing atmospheres.

Why Choose ADCERAX for Your Boron Nitride Crucible Factory?

Selecting the right boron nitride crucible manufacturer directly impacts melt quality, furnace stability and production yield. ADCERAX delivers high-purity BN crucibles with reliable lead times, precise machining and consistent performance, making us a trusted partner for demanding thermal and metal processing applications.

Factory Direct & Competitive Pricing

Direct manufacturer eliminating intermediaries for cost-effective solutions without compromising quality.

Expert Engineering Support

20+ years of B2B experience providing unparalleled technical support and collaborative design.

Flexible Customization

Agile manufacturing for small-batch customization and rapid prototyping capabilities.

Quality Control

Stringent quality measures from raw material inspection to final product testing.

24/7 Technical Support

24-hour response guarantee with dedicated support for global clientele.

500+ Satisfied Customers

Trusted by global customers for advanced ceramic materials and precision components.

Boron Nitride (BN) Crucible Products Quality & Certifications

FAQ

Boron nitride crucibles outperform alumina and graphite when purity, non-wetting behavior and clean melt processing are required. Unlike alumina, BN does not crack under thermal shock or react with molten metals. Unlike graphite, it does not carbon-contaminate alloys or require inert coatings.

| Property / Performance | Boron Nitride (BN) | Alumina (Al₂O₃) | Graphite |

|---|---|---|---|

| Max Working Temp (Vacuum/Inert) | 1800 °C | 1700 °C | 3000 °C (but oxidizes >500 °C in air) |

| Reaction with Molten Al, Mg, Cu | No wetting / No reaction | Reacts slightly, causes sticking & erosion | Reacts, causes carbide formation & contamination |

| Metal Sticking / Demolding | No sticking, clean release | High sticking risk | Adhesion and residue buildup |

| Contamination Risk | Very low – no carbon or oxygen release | Possible oxide contamination | Carbon contamination, discoloration |

| Thermal Shock Resistance | Excellent | Moderate (cracks on rapid heating/cooling) | Good but brittle during machining |

| Machinability (± tolerance) | Easy, up to ±0.05 mm | Difficult, diamond tools required | Easy, but particles contaminate melt |

| Cost vs. Lifetime | Higher cost but longer life & cleaner output | Lower cost, shorter life in metal melting | Lower cost but requires coatings & inert gas |

Hot-pressed BN crucibles (BN) are sintered under pressure and machined to shape. They have good mechanical strength and are cost-effective for most metal processing applications.

Pyrolytic boron nitride crucibles (PBN) are made via CVD in high vacuum, giving >99.9% purity and fully dense, gas-tight microstructure. They are ideal for semiconductor thin-film evaporation, MBE, crystal growth, and high-purity environments.

Yes. ADCERAX produces custom boron nitride crucibles in cylindrical, conical, tapered, stepped wall, flanged, spouted and lidded designs. We also manufacture BN crucible liners to fit graphite, quartz or metal crucibles. Drawings, 3D models or sample parts can be used to match any furnace geometry or charge volume.

BN crucibles are suitable for aluminum, magnesium, copper, zinc, gold, silver, silicon, titanium and other reactive or precious metals. Thanks to their non-wetting surface, molten metals do not stick or absorb contaminants, making BN ideal for high-purity alloy melting, crystal growth, evaporation coating and vacuum heat treatment.

Up to 1800 °C in vacuum or inert atmospheres such as nitrogen or argon.

Below 1000 °C in oxidizing atmosphere (air), unless coated or protected.

For PBN crucibles, usage can reach 2000 °C in ultra-high vacuum due to their high purity and gas-tight structure.

Service life depends on metal type, thermal cycling, cleanliness of furnace atmosphere and mechanical handling. Under normal aluminum or copper melting, a BN crucible may run 50–200 cycles. For silicon, titanium or precious metals, lifetime may be shorter but melt purity remains higher than other materials.

Yes. BN is non-porous, non-reactive and electrically insulating. It produces no outgassing, making it compatible with vacuum furnaces, induction melting systems, PVD coating equipment and crystal growth chambers.

After use, allow the crucible to cool naturally, remove solidified residue mechanically or with a soft ceramic scraper—no chemical or water cleaning is recommended. Store in a dry, clean container to avoid moisture absorption or accidental impact. Avoid rapid thermal shock.

ADCERAX offers bn ceramic crucible for silicon for sale with high purity, non-wetting behavior and excellent thermal stability for silicon melting, evaporation and crystal growth. We supply both standard and custom BN crucibles and liners to fit PVD, MBE and vacuum furnace systems. Factory-direct production ensures consistent quality, precise machining and reliable delivery.

To get an accurate BN crucible price, simply send us the capacity (ml), drawing or diameter × height, with or without lid, and required purity. ADCERAX will reply within 12–24h with quotation, lead time and shipping options. No MOQ for prototypes.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours