ADCERAX® Zirconia Ceramic Self-Aligning Ball Bearing is designed for rotating equipment operating in environments where both alignment variation and chemical exposure are present. Its full-ceramic structure maintains stability under temperature changes and corrosive media while allowing the bearing to compensate for shaft misalignment during operation. This combination supports longer service cycles, reduced vibration, and reliable performance across chemical processing, marine drive components, metallurgy systems, and industrial fans.

Adaptive Engineering Features of Zirconia Ceramic Self-Aligning Ball Bearing

- ±2° misalignment compensation ensures shaft runout or housing inaccuracy is automatically corrected, reducing vibration risk under dynamic conditions.

- Unlike thrust or angular bearings, the self-aligning structure prevents premature fatigue from axial skew by adjusting internally.

- 20–25× lifecycle extension in misaligned installations has been observed in marine propulsion systems.

- Constructed with 100% YSZ zirconia, it maintains mechanical strength over −70°C to 600°C, where metal-backed bearings structurally deform.

- Corrosion tests show ZrO₂ surface degradation <0.05 mm/year in pH 1–14 media, unlike other types that require protective coatings.

- Unlike deep groove or thrust types, this bearing’s internal ring profile tolerates deflection without compromising contact points.

- The self-aligning mechanism achieves 35–45% lower resonance amplitude in high-speed fans than fixed-contact designs.

- In metallurgy plants, up to 1200 MPa flexural strength of the ceramic rings dampens impact force and preserves inner geometry.

- Deep groove and angular bearings transmit misalignment stress directly; this type absorbs and redirects it across the twin-row layout.

Technical Properties of Zirconia Ceramic Self-Aligning Ball Bearing

The Zirconia Ceramic Self-Aligning Ball Bearing is engineered for rotational systems requiring automatic axis compensation, high load endurance under shaft offset, and inert operation in corrosive or temperature-variable environments.

| Property | Specification |

|---|---|

| Material Composition | Yttria-Stabilized Zirconia (ZrO₂) |

| Bearing Type | Double-row, self-aligning full ceramic |

| Misalignment Tolerance | ±2° (internal geometry compensation) |

| Flexural Strength | 900–1200 MPa |

| Hardness | ≥ HRA 85 (HV ~1200) |

| Thermal Expansion | 10.5 × 10⁻⁶ /K |

| Density | 6.05 g/cm³ |

| Operating Temperature | −70°C to 600°C (cage dependent) |

| Friction Coefficient | ~0.0012 in dry air, light load |

| Corrosion Resistance | Stable from pH 1 to 14 |

| Electrical Insulation | >10¹² Ω·cm (non-conductive) |

| Magnetic Properties | Non-magnetic / non-conductive |

| Load Distribution Mode | Dual-path rolling, self-adjusting contact arc |

| Structural Configuration | Twin-track raceway, onion-arc profile |

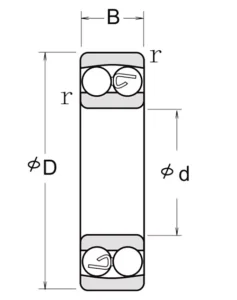

Specifications of Zirconia Ceramic Self-Aligning Ball Bearing

| Model Code | Bearing No. | d (Bore Ø, mm) | D (Outer Ø, mm) | BB (Width, mm) | r (Min. Chamfer, mm) | Mass (kg) |

| AT-YHG-ZC135 | 135 | 6 | 19 | 6 | 0.3 | 0.0070 |

| AT-YHG-ZC126 | 126 | 6 | 19 | 6 | 0.3 | 0.0070 |

| AT-YHG-ZC127 | 127 | 7 | 22 | 7 | 0.3 | 0.0110 |

| AT-YHG-ZC108 | 108 | 8 | 22 | 7 | 0.3 | 0.0110 |

| AT-YHG-ZC129 | 129 | 9 | 26 | 8 | 0.6 | 0.0170 |

| AT-YHG-ZC1200 | 1200 | 10 | 30 | 9 | 0.6 | 0.0260 |

| AT-YHG-ZC2200 | 2200 | 10 | 30 | 14 | 0.6 | 0.0360 |

| AT-YHG-ZC1300 | 1300 | 10 | 25 | 11 | 0.6 | 0.0450 |

| AT-YHG-ZC2300 | 2300 | 10 | 25 | 17 | 0.6 | 0.0650 |

| AT-YHG-ZC1201 | 1201 | 12 | 32 | 10 | 0.6 | 0.0310 |

| AT-YHG-ZC2201 | 2201 | 12 | 32 | 14 | 0.6 | 0.0410 |

| AT-YHG-ZC1301 | 1301 | 12 | 37 | 12 | 1.0 | 0.0520 |

| AT-YHG-ZC2301 | 2301 | 12 | 37 | 17 | 1.0 | 0.0730 |

| AT-YHG-ZC1202 | 1202 | 15 | 11 | 11 | 0.6 | 0.0380 |

| AT-YHG-ZC2202 | 2202 | 15 | 14 | 14 | 0.6 | 0.0460 |

| AT-YHG-ZC1302 | 1302 | 15 | 13 | 13 | 1.0 | 0.0720 |

| AT-YHG-ZC2302 | 2302 | 15 | 17 | 17 | 1.0 | 0.0880 |

| AT-YHG-ZC1203 | 1203 | 17 | 12 | 12 | 0.6 | 0.0560 |

| AT-YHG-ZC2203 | 2203 | 17 | 16 | 16 | 0.6 | 0.0680 |

| AT-YHG-ZC1303 | 1303 | 17 | 14 | 14 | 1.0 | 0.1000 |

| AT-YHG-ZC2303 | 2303 | 17 | 19 | 19 | 1.0 | 0.1200 |

| AT-YHG-ZC7908 | 7908 | 40 | 62 | 12 | 0.6 | 0.0900 |

| AT-YHG-ZC7008 | 7008 | 40 | 68 | 15 | 1.0 | 0.1500 |

| AT-YHG-ZC7208 | 7208 | 40 | 80 | 18 | 1.1 | 0.2800 |

| AT-YHG-ZC7308 | 7308 | 40 | 90 | 23 | 1.5 | 0.4900 |

| AT-YHG-ZC7909 | 7909 | 45 | 68 | 12 | 0.6 | 0.0970 |

| AT-YHG-ZC7009 | 7009 | 45 | 75 | 16 | 1.0 | 0.1900 |

| AT-YHG-ZC7209 | 7209 | 45 | 85 | 19 | 1.1 | 0.3200 |

| AT-YHG-ZC7309 | 7309 | 45 | 100 | 25 | 1.5 | 0.6400 |

| AT-YHG-ZC7910 | 7910 | 50 | 72 | 123 | 0.6 | 0.1000 |

| AT-YHG-ZC7010 | 7010 | 50 | 80 | 16 | 1.0 | 0.2000 |

| AT-YHG-ZC7210 | 7210 | 50 | 90 | 20 | 1.1 | 0.3500 |

| AT-YHG-ZC7310 | 7310 | 50 | 110 | 27 | 2.0 | 0.8200 |

| AT-YHG-ZC7911 | 7911 | 55 | 80 | 13 | 1.0 | 0.1500 |

| AT-YHG-ZC7011 | 7011 | 55 | 90 | 18 | 1.1 | 0.2900 |

| AT-YHG-ZC7211 | 7211 | 55 | 100 | 21 | 1.5 | 0.4800 |

| AT-YHG-ZC7311 | 7311 | 55 | 120 | 29 | 2.0 | 1.0500 |

| AT-YHG-ZC7912 | 7912 | 60 | 85 | 13 | 1.0 | 0.1500 |

| AT-YHG-ZC7012 | 7012 | 60 | 95 | 18 | 1.1 | 0.3200 |

| AT-YHG-ZC7212 | 7212 | 60 | 110 | 22 | 1.5 | 0.6000 |

| AT-YHG-ZC7312 | 7312 | 60 | 130 | 31 | 2.1 | 1.3200 |

| AT-YHG-ZC7913 | 7913 | 65 | 90 | 13 | 1.0 | 0.1700 |

| AT-YHG-ZC7013 | 7013 | 65 | 100 | 18 | 1.1 | 0.3400 |

| AT-YHG-ZC7213 | 7213 | 65 | 120 | 23 | 1.5 | 0.7700 |

| AT-YHG-ZC7313 | 7313 | 65 | 140 | 33 | 2.1 | 1.6200 |

| AT-YHG-ZC7914 | 7914 | 70 | 100 | 16 | 1.0 | 0.2700 |

| AT-YHG-ZC7014 | 7014 | 70 | 110 | 20 | 1.1 | 0.4700 |

| AT-YHG-ZC7214 | 7214 | 70 | 125 | 24 | 1.5 | 0.8400 |

| AT-YHG-ZC7314 | 7314 | 70 | 150 | 35 | 2.1 | 1.9800 |

| AT-YHG-ZC7915 | 7915 | 75 | 105 | 16 | 1.0 | 0.2800 |

| AT-YHG-ZC7015 | 7015 | 75 | 115 | 20 | 1.1 | 0.5000 |

| AT-YHG-ZC7215 | 7215 | 75 | 130 | 25 | 1.5 | 0.9200 |

| AT-YHG-ZC7916 | 7916 | 80 | 110 | 16 | 1.0 | 0.3000 |

| AT-YHG-ZC7016 | 7016 | 80 | 125 | 22 | 1.1 | 0.6700 |

| AT-YHG-ZC7216 | 7216 | 80 | 140 | 26 | 2.0 | 1.0900 |

| AT-YHG-ZC7017 | 7017 | 85 | 130 | 22 | 1.1 | 0.7100 |

| AT-YHG-ZC7217 | 7217 | 85 | 150 | 28 | 2.0 | 1.3500 |

| AT-YHG-ZC7918 | 7918 | 90 | 125 | 18 | 1.1 | 0.4500 |

| AT-YHG-ZC7018 | 7018 | 90 | 140 | 24 | 1.5 | 0.9200 |

| AT-YHG-ZC7919 | 7919 | 95 | 130 | 18 | 1.1 | 0.4600 |

| AT-YHG-ZC7019 | 7019 | 95 | 145 | 24 | 1.5 | 0.9500 |

| AT-YHG-ZC7920 | 7920 | 100 | 140 | 20 | 1.1 | 0.6400 |

| AT-YHG-ZC7020 | 7020 | 100 | 150 | 24 | 1.5 | 0.9900 |

| AT-YHG-ZC7921 | 7921 | / | 145 | 20 | 1.1 | 0.6600 |

| AT-YHG-ZC7922 | 7922 | / | 150 | 20 | 1.1 | 0.6900 |

| AT-YHG-ZC2312 | 2312 | 60 | 130 | 46 | 2.0 | 2.0000 |

| AT-YHG-ZC1213 | 1213 | 65 | 120 | 23 | 1.5 | 0.8800 |

| AT-YHG-ZC2213 | 2213 | 65 | 120 | 31 | 1.5 | 1.1200 |

| AT-YHG-ZC1313 | 1313 | 65 | 14 | 33 | 2.1 | 1.8800 |

| AT-YHG-ZC2313 | 2313 | 65 | 140 | 48 | 2.1 | 2.4800 |

| AT-YHG-ZC1214 | 1214 | 70 | 125 | 24 | 1.5 | 0.9700 |

| AT-YHG-ZC2214 | 2214 | 70 | 125 | 31 | 1.5 | 1.1700 |

| AT-YHG-ZC1314 | 1314 | 70 | 150 | 35 | 2.1 | 2.3000 |

| AT-YHG-ZC2314 | 2314 | 70 | 150 | 51 | 2.1 | 3.2500 |

| AT-YHG-ZC1215 | 1215 | 75 | 130 | 25 | 15.0 | 1.0500 |

| AT-YHG-ZC2215 | 2215 | 75 | 130 | 31 | 15.0 | 1.2500 |

| AT-YHG-ZC1315 | 1315 | 75 | 160 | 37 | 2.1 | 2.7000 |

| AT-YHG-ZC2315 | 2315 | 75 | 160 | 55 | 2.1 | 3.8500 |

| AT-YHG-ZC1216 | 1216 | 80 | 140 | 26 | 1.5 | 1.2800 |

| AT-YHG-ZC2216 | 2216 | 80 | 140 | 33 | 1.5 | 1.5500 |

| AT-YHG-ZC1316 | 1316 | 80 | 170 | 39 | 2.1 | 3.1700 |

| AT-YHG-ZC2316 | 2316 | 80 | 170 | 58 | 2.1 | 4.8500 |

| AT-YHG-ZC1217 | 1217 | 85 | 150 | 28 | 2.0 | 1.5900 |

| AT-YHG-ZC2217 | 2217 | 85 | 150 | 36 | 2.0 | 1.9400 |

| AT-YHG-ZC1317 | 1317 | 85 | 180 | 41 | 3.0 | 3.7800 |

| AT-YHG-ZC2317 | 2317 | 85 | 180 | 60 | 3.0 | 5.3000 |

| AT-YHG-ZC1218 | 1218 | 90 | 160 | 30 | 2.0 | 1.9100 |

| AT-YHG-ZC2218 | 2218 | 90 | 160 | 40 | 2.0 | 2.5600 |

| AT-YHG-ZC1318 | 1318 | 90 | 190 | 43 | 3.0 | 4.4000 |

| AT-YHG-ZC2318 | 2318 | 90 | 190 | 64 | 3.0 | 6.3500 |

| AT-YHG-ZC1219 | 1219 | 95 | 170 | 32 | 3.1 | 2.3500 |

| AT-YHG-ZC2219 | 2219 | 95 | 170 | 43 | 2.1 | 3.0800 |

| AT-YHG-ZC1319 | 1319 | 95 | 200 | 45 | 3.0 | 5.0700 |

| AT-YHG-ZC2319 | 2319 | 95 | 200 | 67 | 3.0 | 7.3600 |

| AT-YHG-ZC1220 | 1220 | 100 | 180 | 34 | 2.1 | 2.8000 |

| AT-YHG-ZC2220 | 2220 | 100 | 180 | 46 | 2.1 | 3.7500 |

| AT-YHG-ZC1221 | 1221 | 105 | 190 | 36 | 2.1 | 3.3600 |

| AT-YHG-ZC2221 | 2221 | 105 | 190 | 50 | 2.1 | 4.6700 |

| AT-YHG-ZC1222 | 1222 | 110 | 200 | 38 | 2.1 | 3.9600 |

| AT-YHG-ZC2222 | 2222 | 110 | 200 | 53 | 2.1 | 5.4600 |

| AT-YHG-ZC1204 | 1204 | 20 | 47 | 14 | 1.0 | 0.0900 |

| AT-YHG-ZC2204 | 2204 | 20 | 47 | 18 | 1.0 | 0.1100 |

| AT-YHG-ZC1304 | 1304 | 20 | 52 | 15 | 1.1 | 0.1300 |

| AT-YHG-ZC2304 | 2304 | 20 | 52 | 21 | 1.1 | 0.1600 |

| AT-YHG-ZC1205 | 1205 | 25 | 52 | 15 | 1.0 | 0.1100 |

| AT-YHG-ZC2205 | 2205 | 25 | 52 | 18 | 1.0 | 0.1300 |

| AT-YHG-ZC1305 | 1305 | 25 | 62 | 17 | 1.1 | 0.2000 |

| AT-YHG-ZC2305 | 2305 | 25 | 62 | 24 | 1.1 | 0.2300 |

| AT-YHG-ZC1206 | 1206 | 30 | 62 | 16 | 1.0 | 0.1700 |

| AT-YHG-ZC2206 | 2206 | 30 | 62 | 20 | 1.0 | 0.2000 |

| AT-YHG-ZC1306 | 1306 | 30 | 72 | 19 | 1.1 | 0.3000 |

| AT-YHG-ZC2306 | 2306 | 30 | 72 | 27 | 1.1 | 0.3800 |

| AT-YHG-ZC1207 | 1207 | 35 | 72 | 17 | 1.1 | 0.2500 |

| AT-YHG-ZC2207 | 2207 | 35 | 72 | 23 | 1.1 | 0.3100 |

| AT-YHG-ZC1307 | 1307 | 35 | 80 | 21 | 1.5 | 0.3900 |

| AT-YHG-ZC2307 | 2307 | 35 | 80 | 31 | 1.5 | 0.5200 |

| AT-YHG-ZC1208 | 1208 | 40 | 80 | 18 | 1.1 | 0.3200 |

| AT-YHG-ZC2208 | 2208 | 40 | 80 | 23 | 1.1 | 0.3900 |

| AT-YHG-ZC1308 | 1308 | 40 | 90 | 23 | 1.5 | 0.5500 |

| AT-YHG-ZC2308 | 2308 | 40 | 90 | 33 | 1.5 | 0.7100 |

| AT-YHG-ZC1209 | 1209 | 45 | 85 | 19 | 1.1 | 0.3600 |

| AT-YHG-ZC2209 | 2209 | 45 | 85 | 23 | 1.1 | 0.4200 |

| AT-YHG-ZC1309 | 1309 | 45 | 100 | 25 | 1.5 | 0.7400 |

| AT-YHG-ZC2309 | 2309 | 45 | 100 | 36 | 1.5 | 0.9500 |

| AT-YHG-ZC1210 | 1210 | 50 | 90 | 20 | 1.1 | 0.4000 |

| AT-YHG-ZC2210 | 2210 | 50 | 90 | 23 | 1.1 | 0.4500 |

| AT-YHG-ZC1310 | 1310 | 50 | 110 | 27 | 2.0 | 0.9300 |

| AT-YHG-ZC2310 | 2310 | 50 | 110 | 40 | 2.0 | 1.2600 |

| AT-YHG-ZC1211 | 1211 | 55 | 100 | 21 | 1.5 | 0.5400 |

| AT-YHG-ZC2211 | 2211 | 55 | 100 | 25 | 1.5 | 0.6200 |

| AT-YHG-ZC1311 | 1311 | 55 | 120 | 29 | 2.0 | 1.2200 |

| AT-YHG-ZC2311 | 2311 | 55 | 120 | 43 | 2.0 | 1.6200 |

| AT-YHG-ZC1212 | 1212 | 60 | 110 | 22 | 1.5 | 0.6900 |

| AT-YHG-ZC2212 | 2212 | 60 | 110 | 28 | 1.5 | 0.8400 |

| AT-YHG-ZC1312 | 1312 | 60 | 130 | 31 | 2.0 | 1.5100 |

Packaging of Zirconia Ceramic Self-Aligning Ball Bearing

Zirconia Ceramic Self-Aligning Ball Bearing units are individually wrapped in protective sleeves and arranged in reinforced cardboard partitions. All boxed products are stored in humidity-controlled racks before dispatch. Final shipments are palletized and loaded securely to prevent vibration or surface damage in transit.