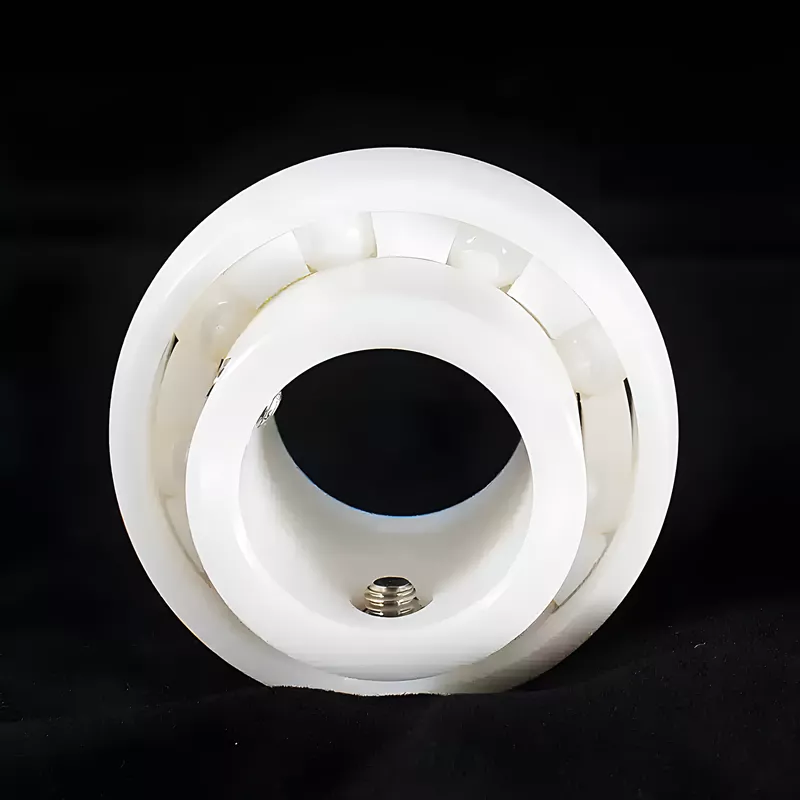

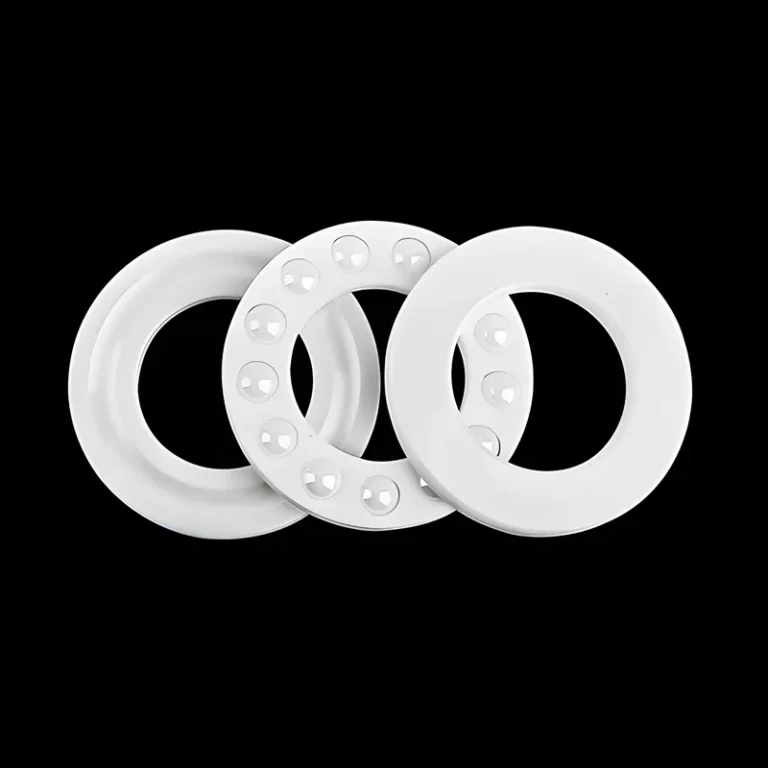

ADCERAX® Zirconia Ceramic Outer Spherical Ball Bearing is designed with a spherical outer race that allows controlled alignment adjustment between shaft and housing under dynamic or uneven mounting conditions. This geometry enables stable rotation in equipment exposed to thermal gradients, corrosive media, or vibration where conventional ceramic or steel bearings lose stability. It is therefore used in chemical processing, heat‑treatment machinery, marine pump assemblies, and other continuous‑duty systems where maintaining alignment directly affects service life and operational uptime.

Features of Zirconia Ceramic Outer Spherical Ball Bearing

- Misalignment Compensation with Spherical Outer Race

±3° spherical tolerance allows operation under housing misalignment without excessive edge loading.

This feature enables consistent shaft rotation under structural deflection, thermal expansion, or vibration-induced skew.

Over 60% of bearing failures in corrosive environments are attributed to improper alignment — this geometry addresses that root cause. - High-Temperature Operation in Ceramic Integrity

600 °C continuous use is supported when paired with stainless steel or ceramic cages.

Compared to standard steel bearings failing at ~300 °C, zirconia structure maintains dimensional stability and hardness.

Thermal expansion coefficient of 10.5×10⁻⁶ /K ensures compatibility with most industrial housing materials under gradient stress. - Corrosion Resistance in Harsh Process Environments

99.8% ZrO₂ ceramic phase resists degradation from acids, alkalis, and saline solutions.

Tests confirm that bearings submerged in 5% HCl for 72 hours exhibit <0.03% mass loss, compared to >1.5% in 440C steel.

This makes it viable for continuous-duty in chemical reactors, marine pumps, and gas scrubber systems without auxiliary coatings.

Technical Properties of Zirconia Ceramic Outer Spherical Ball Bearing

The Zirconia Ceramic Outer Spherical Ball Bearing is built for environments requiring precise rotational alignment under structural deflection, elevated temperatures, and continuous chemical exposure. Its material integrity and structural geometry enable stable performance in systems subjected to high thermal gradients, corrosive process media, and persistent mechanical misalignment.

| Property | Specification |

|---|---|

| Material Composition | ≥ 99.8% Yttria-Stabilized Zirconia (ZrO₂) |

| Density | 5.95 g/cm³ |

| Thermal Conductivity | 2.5 W/m·K at 25 °C |

| Fracture Toughness | 8.0 MPa·m¹ᐟ² |

| Flexural Strength | 900 MPa (3-point bending) |

| Hardness (Vickers) | 1250 HV |

| Thermal Expansion Coefficient | 10.5 × 10⁻⁶ /K |

| Maximum Working Temperature | 600 °C (with metallic or ceramic cage) |

| Electrical Resistivity | >10¹² Ω·cm (room temperature) |

| Corrosion Resistance | <0.03% mass loss in 5% HCl (72h) |

| Magnetic Properties | Non-magnetic |

| Outer Race Geometry | Spherical, compensates up to ±3° misalignment |

| Lubrication Requirement | Low, optional dry or solid lubricant compatible |

| Surface Finish (Rolling Elements) | Ra < 0.02 μm, mirror-polished |

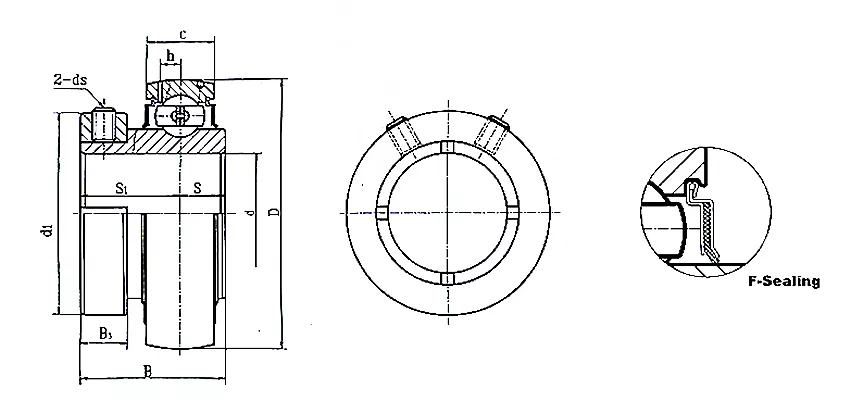

Specifications of Zirconia Ceramic Outer Spherical Ball Bearing

| Model No. | Bearing Type | Bore Diameter (d) | Outer Diameter (D) | Total Width (B) | Inner Ring Width (S) | Shoulder Height (S1) | Min. Fillet Radius (r min) | Grease Hole Dia. (G) | Thread Size (ds) |

| AT-YHG-ZCUC210 | UC210 | 50mm | 90 | 51.6 | 23 | 62.2 | 1.1 | 9 | 5/16-24 M8*1 |

| AT-YHG-ZCUC210-29 | UC210-29 | 1 13/16 | 90 | 51.6 | 23 | 62.2 | 1.1 | 9 | 5/16-24 M8*1 |

| AT-YHG-ZCUC210-30 | UC210-30 | 1 7/8 | 90 | 51.6 | 23 | 62.2 | 1.1 | 9 | 5/16-24 M8*1 |

| AT-YHG-ZCUC210-31 | UC210-31 | 1 15/16 | 90 | 51.6 | 23 | 62.2 | 1.1 | 9 | 5/16-24 M8*1 |

| AT-YHG-ZCUC210-32 | UC210-32 | 2(s) | 90 | 51.6 | 23 | 62.2 | 1.1 | 9 | 5/16-24 M8*1 |

| AT-YHG-ZCUC211 | UC211 | 55mm | 100 | 55.6 | 25 | 68.9 | 1.5 | 10 | 3/8-24 M10*1.25 |

| AT-YHG-ZCUC211-32 | UC211-32 | 2 | 100 | 55.6 | 25 | 68.9 | 1.5 | 10 | 3/8-24 M10*1.25 |

| AT-YHG-ZCUC211-33 | UC211-33 | 2 1/16 | 100 | 55.6 | 25 | 68.9 | 1.5 | 10 | 3/8-24 M10*1.25 |

| AT-YHG-ZCUC211-34 | UC211-34 | 2 1/8 | 100 | 55.6 | 25 | 68.9 | 1.5 | 10 | 3/8-24 M10*1.25 |

| AT-YHG-ZCUC211-35 | UC211-35 | 2 3/16 | 100 | 55.6 | 25 | 68.9 | 1.5 | 10 | 3/8-24 M10*1.25 |

| AT-YHG-ZCUC212 | UC212 | 60mm | 110 | 65.1 | 27 | 76 | 1.5 | 10 | 3/8-24 M10*1.25 |

| AT-YHG-ZCUC212-36 | UC212-36 | 2 1/4 | 110 | 65.1 | 27 | 76 | 1.5 | 10 | 3/8-24 M10*1.25 |

| AT-YHG-ZCUC212-37 | UC212-37 | 2 5/16 | 110 | 65.1 | 27 | 76 | 1.5 | 10 | 3/8-24 M10*1.25 |

| AT-YHG-ZCUC212-38 | UC212-38 | 2 3/8 | 110 | 65.1 | 27 | 76 | 1.5 | 10 | 3/8-24 M10*1.25 |

| AT-YHG-ZCUC212-39 | UC212-39 | 2 7/16 | 110 | 65.1 | 27 | 76 | 1.5 | 10 | 3/8-24 M10*1.25 |

| AT-YHG-ZCUC213 | UC213 | 65mm | 120 | 65.1 | 28 | 82.5 | 1.5 | 12 | 3/8-24 M10*1.25 |

| AT-YHG-ZCUC213-40 | UC213-40 | 2 1/2 | 120 | 65.1 | 28 | 82.5 | 1.5 | 12 | 3/8-24 M10*1.25 |

| AT-YHG-ZCUC213-41 | UC213-41 | 2 9/16 | 120 | 65.1 | 28 | 82.5 | 1.5 | 12 | 3/8-24 M10*1.25 |

| AT-YHG-ZCUC214 | UC214 | 70mm | 125 | 74.6 | 29 | 89 | 1.5 | 12 | 7/16-20 M12-1.5 |

| AT-YHG-ZCUC214-42 | UC214-42 | 2 5/8 | 125 | 74.6 | 29 | 89 | 1.5 | 12 | 7/16-20 M12-1.5 |

| AT-YHG-ZCUC214-43 | UC214-43 | 2 11/16 | 125 | 74.6 | 29 | 89 | 1.5 | 12 | 7/16-20 M12-1.5 |

| AT-YHG-ZCUC214-44 | UC214-44 | 2 3/4 | 125 | 74.6 | 29 | 89 | 1.5 | 12 | 7/16-20 M12-1.5 |

| AT-YHG-ZCUC215 | UC215 | 75mm | 130 | 77.8 | 30 | 94 | 1.5 | 12 | 7/16-20 M12-1.5 |

| AT-YHG-ZCUC215-45 | UC215-45 | 2 13/16 | 130 | 77.8 | 30 | 94 | 1.5 | 12 | 7/16-20 M12-1.5 |

| AT-YHG-ZCUC215-46 | UC215-46 | 2 7/8 | 130 | 77.8 | 30 | 94 | 1.5 | 12 | 7/16-20 M12-1.5 |

| AT-YHG-ZCUC215-47 | UC215-47 | 2 15/19 | 130 | 77.8 | 30 | 94 | 1.5 | 12 | 7/16-20 M12-1.5 |

| AT-YHG-ZCUC215-48 | UC215-48 | 3 | 130 | 77.8 | 30 | 94 | 1.5 | 12 | 7/16-20 M12-1.5 |

| AT-YHG-ZCUC216 | UC216 | 80mm | 140 | 82.6 | 32 | 100 | 2 | 14 | 7/16-20 M12-1.5 |

| AT-YHG-ZCUC216-50 | UC216-50 | 3 1/8 | 140 | 82.6 | 32 | 100 | 2 | 14 | 7/16-20 M12-1.5 |

| AT-YHG-ZCUC217 | UC217 | 85mm | 150 | 85.7 | 34 | 107.1 | 2 | 14 | 7/16-20 M12-1.5 |

| AT-YHG-ZCUC217-52 | UC217-52 | 3 1/4 | 150 | 85.7 | 34 | 107.1 | 2 | 14 | 7/16-20 M12-1.5 |

| AT-YHG-ZCUC217-55 | UC217-55 | 3 7/16 | 150 | 85.7 | 34 | 107.1 | 2 | 14 | 7/16-20 M12-1.5 |

| AT-YHG-ZCUC218 | UC218 | 90mm | 160 | 96 | 36 | 111.7 | 2 | 15 | 1/2-20 M12-1.5 |

| AT-YHG-ZCUC218-56 | UC218-56 | 3 1/2 | 160 | 96 | 36 | 111.7 | 2 | 15 | 1/2-20 M12-1.5 |

| AT-YHG-ZCUC204 | UC204 | 20mm | 47 | 31 | 16 | 29.3 | 1 | 4.5 | 1/4-28 M6*1 |

| AT-YHG-ZCUC204-12 | UC204-12 | 3/4 | 47 | 31 | 16 | 29.3 | 1 | 4.5 | 1/4-28 M6*1 |

| AT-YHG-ZCUC205 | UC205 | 25mm | 52 | 34 | 17 | 33.8 | 1 | 5 | 1/4-28 M6*1 |

| AT-YHG-ZCUC205-14 | UC205-14 | 7/8 | 52 | 34 | 17 | 33.8 | 1 | 5 | 1/4-28 M6*1 |

| AT-YHG-ZCUC205-15 | UC205-15 | 1 5/16 | 52 | 34 | 17 | 33.8 | 1 | 5 | 1/4-28 M6*1 |

| AT-YHG-ZCUC205-16 | UC205-16 | 1 | 52 | 34 | 17 | 33.8 | 1 | 5 | 1/4-28 M6*1 |

| AT-YHG-ZCUC206 | UC206 | 30mm | 62 | 38.1 | 19 | 40.8 | 1 | 5 | 1/4-28 M6*1 |

| AT-YHG-ZCUC206-17 | UC206-17 | 1 1/16 | 62 | 38.1 | 19 | 40.8 | 1 | 5 | 1/4-28 M6*1 |

| AT-YHG-ZCUC206-18 | UC206-18 | 1 1/8 | 62 | 38.1 | 19 | 40.8 | 1 | 5 | 1/4-28 M6*1 |

| AT-YHG-ZCUC206-19 | UC206-19 | 1 3/16 | 62 | 38.1 | 19 | 40.8 | 1 | 5 | 1/4-28 M6*1 |

| AT-YHG-ZCUC206-20 | UC206-20 | 11/4(s) | 62 | 38.1 | 19 | 40.8 | 1 | 5 | 1/4-28 M6*1 |

| AT-YHG-ZCUC207 | UC207 | 35mm | 72 | 42.9 | 20 | 46.8 | 1.1 | 6 | 1/4-28 M6*1 |

| AT-YHG-ZCUC207-20 | UC207-20 | 1 1/4 | 72 | 42.9 | 20 | 46.8 | 1.1 | 6 | 1/4-28 M6*1 |

| AT-YHG-ZCUC207-21 | UC207-21 | 1 5/16 | 72 | 42.9 | 20 | 46.8 | 1.1 | 6 | 1/4-28 M6*1 |

| AT-YHG-ZCUC207-22 | UC207-22 | 1 3/8 | 72 | 42.9 | 20 | 46.8 | 1.1 | 6 | 1/4-28 M6*1 |

| AT-YHG-ZCUC207-23 | UC207-23 | 1 7/16 | 72 | 42.9 | 20 | 46.8 | 1.1 | 6 | 1/4-28 M6*1 |

| AT-YHG-ZCUC208 | UC208 | 40mm | 80 | 42.9 | 21 | 52.8 | 1.1 | 8 | 5/16-24 M8*1 |

| AT-YHG-ZCUC208-24 | UC208-24 | 1 1/2 | 80 | 42.9 | 21 | 52.8 | 1.1 | 8 | 5/16-24 M8*1 |

| AT-YHG-ZCUC208-25 | UC208-25 | 1 9/16 | 80 | 42.9 | 21 | 52.8 | 1.1 | 8 | 5/16-24 M8*1 |

| AT-YHG-ZCUC209 | UC209 | 45mm | 85 | 49.2 | 22 | 58.6 | 1.1 | 8 | 5/16-24 M8*1 |

| AT-YHG-ZCUC209-26 | UC209-26 | 1 5/8 | 85 | 49.2 | 22 | 58.6 | 1.1 | 8 | 5/16-24 M8*1 |

| AT-YHG-ZCUC209-27 | UC209-27 | 1 11/16 | 85 | 49.2 | 22 | 58.6 | 1.1 | 8 | 5/16-24 M8*1 |

| AT-YHG-ZCUC209-28 | UC209-28 | 1 3/4 | 85 | 49.2 | 22 | 58.6 | 1.1 | 8 | 5/16-24 M8*1 |

Packaging of Zirconia Ceramic Outer Spherical Ball Bearing

Zirconia Ceramic Outer Spherical Ball Bearing is individually cushioned and packed in reinforced cartons to prevent chipping or misalignment during transit. All cartons are systematically shelved in climate-controlled storage before shipment. Bulk orders are palletized and loaded onto trucks with protective strapping to ensure stability in international logistics.