Silicon Nitride Ceramic Bearings for High-Speed, Insulated & Corrosion-Resistant Applications

ADCERAX has over 20 years of experience in manufacturing silicon nitride ceramic bearings for industrial applications. Made from Si₃N₄ ceramic, these bearings perform reliably under high speed, high temperature, and corrosive conditions, offering excellent electrical insulation, low heat generation, and long service life. They are widely used in machine tool spindles, motors, chemical pumps, and vacuum systems, and have been exported to the United States, Germany, Japan, and many other industrial regions worldwide.

👉Partner with ADCERAX to enhance your equipment performance and secure a dependable ceramic bearing solution from a trusted factory source.

≥1200°C

Thermal Shock Resistant

(Stable under rapid temperature change)

(Safe for high-voltage motors)

High-Speed & Low-Friction

(Reduces heat and load)

(Compared with steel bearings)

What is Silicon Nitride Ceramic Bearing?

Silicon nitride ceramic bearing is a precision component made from Si₃N₄ advanced ceramic, known for its high strength, low density, and superior wear resistance. It delivers stable performance under extreme speed, temperature, and mechanical stress, making it ideal for engineering systems that demand durability, insulation, and low-friction operation.

Why Silicon Nitride Bearings Outlast Steel and Zirconia Bearings?

Silicon nitride (Si₃N₄) ceramic bearings outperform traditional steel and zirconia bearings in demanding industrial environments that require high speed, insulation, and corrosion resistance.They combine the strength of steel with the thermal and chemical stability of advanced ceramics, offering an ideal balance of durability and precision.

Silicon Nitride Ceramic Bearings vs. Steel & Zirconia Bearings

| Property | Silicon Nitride (Si₃N₄) | Steel Bearings | Zirconia (ZrO₂) |

| Density | ~3.2 g/cm³ (lightweight) | ~7.8 g/cm³ (heavy) | ~6.0 g/cm³ |

| Hardness (HV) | 1,400–1,700 | 700–800 | 1,100–1,200 |

| Bending Strength (MPa) | 600–800 | 2,000+ (but brittle under heat) | 500–700 |

| Thermal Conductivity (W/m·K) | 20–30 | 50+ | 2–3 |

| Thermal Expansion (×10⁻⁶/K) | 3.2 | 12 | 10 |

| Electrical Conductivity | Insulating | Conductive | Insulating |

| Corrosion Resistance | Excellent | Poor | Good |

| Temperature Limit | Up to 1,000 °C | Below 300 °C | ~600 °C |

| Weight Efficiency | 60% lighter than steel | — | 30% lighter than steel |

| Cost | Medium | Low | High |

Si₃N₄ vs. Steel Bearings:

Silicon nitride bearings run cooler, resist electrical erosion, and last 3–5× longer in motors and spindles. Steel bearings wear faster and corrode easily in humid or high-temperature environments.Si₃N₄ vs. Zirconia Bearings:

Zirconia bearings offer good corrosion resistance but are heavier and less thermally stable. Si₃N₄ bearings maintain higher strength at temperature and provide better high-speed balance.Best Choice for Industrial Users:

For high-speed, inverter-driven, or corrosive conditions — silicon nitride ceramic bearings deliver the most balanced performance-to-cost ratio, making them the preferred choice for advanced equipment manufacturers.

Silicon Nitride (Si3N4) Ceramic Bearing Properties

Si₃N₄ ceramic bearings offer exceptional mechanical strength, thermal stability, and insulation, making them ideal for high-speed motors, precision spindles, and chemical systems operating under heat, load, and corrosive environments.

Silicon Nitride Ceramic Bearing Technical Sheet

| Si3N4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

| Density (g/cm3) | 3.2 | 3.3 | 3.25 |

| Flexture strength (MPa) | 700 | 900 | 600~800 |

| Young Modulus (GPa) | 300 | 300 | 300~320 |

| Poisson’s ratio | 0.25 | 0.28 | 0.25 |

| Compressive strength (MPa) | 2500 | 3000 | 2500 |

| Hardness (GPa) | 15 | 16 | 15 |

| Fracture toughness (MPa*m1/2) | 5~7 | 6~8 | 6~7 |

| Maximum working temperature (℃) | 1100 | 1300 | 1100 |

| Thermal conductivity (W/m*K) | 20 | 25 | 80~100 |

| Thermal expansion coefficient (/℃) | 3*10-6 | 3.1*10-6 | 3*10-6 |

| Thermal shock resistance (ΔT ℃) | 550 | 800 | / |

Silicon Nitride Ceramic Bearing Characteristics

Mechanical Properties

Si₃N₄ ceramic bearings deliver high strength and excellent dimensional stability under high load and speed.

- Flexural strength: 750–850 MPa, maintaining precision under vibration and impact.

- Hardness: ~15 GPa, offering exceptional wear and abrasion resistance.

- Lightweight design reduces centrifugal force, extending grease life and minimizing deformation.

Chemical Properties

Engineered for corrosive and moisture-prone environments, silicon nitride bearings maintain stable performance where steel bearings fail.

- Chemically inert against acids, alkalis, and most solvents.

- Non-reactive and non-corrosive in coolants, deionized water, or vacuum.

- Ideal for chemical pumps, food processing, and cleanroom applications.

Physical Properties

Si₃N₄ bearings perform reliably under extreme temperatures and mechanical cycling.

- Continuous operating range: –50 °C to 800 °C, short-term up to 1000 °C in inert conditions.

- Low density (3.2 g/cm³) allows high-speed rotation with lower inertia.

- Excellent thermal shock resistance prevents cracking during rapid acceleration or load change.

Electrical Properties

Ceramic bearings silicon nitride act as natural electrical insulators, eliminating current leakage and shaft voltage damage.

- Volume resistivity: 10¹²–10¹⁴ Ω·cm, providing full insulation between rotor and stator.

- Prevents electrical pitting and fluting in inverter-driven motors.

- Ideal for EV drives, servo systems, and high-frequency spindle applications.

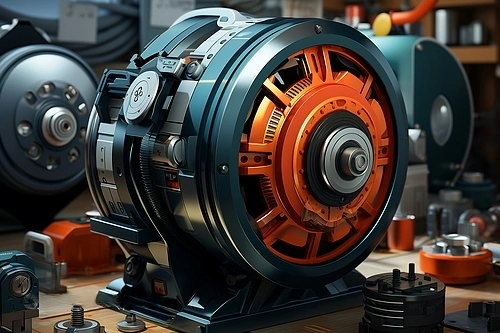

Si3N4 Silicon Nitride Ceramic Bearing Products

ADCERAX supplies silicon nitride ceramic bearings in various configurations, including ball bearings, roller bearings, and bearing rollers.

Each type is designed for high-speed, high-temperature, and corrosive environments, providing low friction, electrical insulation, and long-term durability for industrial equipment.

Silicon nitride ceramic ball bearing combines strength, low friction, and insulation for stable high-speed performance. They resist wear, corrosion, and electrical damage in demanding motor and spindle applications.

- Strong load capacity and wear resistance

- Stable at high speed and temperature

- Electrically insulated, corrosion proof

Silicon nitride roller bearings offer high load capacity, low friction, and excellent thermal stability. They perform reliably under heavy load and temperature variation, ensuring long service life.

- Strong load and heat resistance

- Stable at high speed

- Reduced friction and wear

Silicon nitride rollers are lightweight, strong, and chemically stable, suitable for hybrid or full-ceramic bearing use. They deliver smooth motion and low wear in motors, pumps, and precision machinery.

- Low density and high strength

- Corrosion and temperature resistant

- Durable under continuous rotation

🚀Silicon Nitride Bearings – No Rust, No Electrical Damage, No Downtime.

Si₃N₄ bearings eliminate failures caused by electric pitting, corrosion, and excessive heat in high-speed or inverter-driven systems.

ADCERAX provides custom-engineered ceramic bearing solutions with fast delivery and reliable technical support to keep your machines running longer and smoother.

Si3N4 Silicon Nitride Ceramic Bearing Applications

Silicon nitride (Si₃N₄) bearings are used in demanding environments where traditional steel bearings fail due to wear, corrosion, or electrical erosion. They are commonly applied in motors, machine tools, chemical pumps, and vacuum or energy systems, supporting industries such as automotive, aerospace, and manufacturing.

Electric Motors & Generators

- Prevents electrical pitting in inverter-driven systems and EV traction motors.

- Reduces heat and noise while extending motor lifespan.

- Common in EV drives, servo systems, and wind turbine generators.

🧩 Key Advantages:

- Electrical Insulation Efficiency

Si₃N₄ bearings provide dielectric strength above 15 kV/mm, completely isolating current between rotor and stator to eliminate electrical pitting and fluting. - Reduced Heat & Friction

The low density of 3.2 g/cm³ minimizes centrifugal force at high RPM, cutting frictional heat generation by over 40% compared to steel bearings. - Extended Operating Life

In inverter-driven motors, service life typically increases by 3–5 times, even under variable-frequency and high-speed conditions.

🔹Problem Solved:

A European EV-drive manufacturer faced frequent bearing failures due to stray currents in their high-frequency inverter motors, with replacement intervals every 6 months. After adopting ADCERAX Si₃N₄ ceramic bearings, current leakage was fully eliminated, reducing motor vibration by 35% and extending maintenance cycles to over 24 months.

This upgrade lowered downtime costs by 40% while stabilizing performance in both traction and regenerative modes.

Machine Tool Spindles & Precision Equipment

- Withstands high rotational speeds with low vibration.

- Ensures superior dimensional stability and accuracy during continuous machining.

- Used in CNC spindles, robotics joints, and aerospace instruments.

🧩 Key Advantages:

- High-Speed Stability

Si₃N₄ bearings withstand DN values exceeding 1.8 million, maintaining rotational accuracy under continuous high-speed CNC spindle operation. - Thermal Deformation Control

The low thermal expansion coefficient (3.2 × 10⁻⁶/K) minimizes spindle growth, keeping micron-level positioning accuracy even after hours of machining. - Extended Lubrication Life

Friction loss is reduced by 30–40%, extending grease service intervals and lowering maintenance frequency in high-duty production lines.

🔹Problem Solved:

- A Japanese CNC machining center experienced thermal drift and vibration at speeds above 20,000 rpm, affecting part tolerance stability. After switching to ADCERAX Si₃N₄ ceramic spindle bearings, temperature rise decreased by 22%, enabling continuous operation with precision repeatability within ±1 μm.

This improvement reduced tool change downtime by 18% and increased spindle bearing life by over 3×, optimizing both machining accuracy and production efficiency.

Chemical & Process Pumps

- Excellent resistance to acids, alkalis, and deionized water.

- Operates without lubrication, preventing contamination in chemical processes.

- Applied in chemical dosing pumps, semiconductor wet benches, and food-grade machinery.

🧩 Key Advantages:

- Corrosion Resistance Under Harsh Media

Si₃N₄ bearings maintain full mechanical strength after 1,000+ hours of exposure to acids, alkalis, and salt solutions, far outperforming stainless steel bearings. - Self-Lubricating Operation

Their ultra-smooth surface (Ra ≤ 0.02 µm) allows stable, oil-free rotation in corrosive or deionized liquid systems, preventing contamination and leakage. - Dimensional Stability at High Temperature

Withstand continuous service up to 800 °C, maintaining tight clearances under fluctuating thermal and chemical loads.

🔹Problem Solved:

- A U.S. chemical plant using stainless steel bearings in acid metering pumps suffered frequent corrosion and seizing every 3–4 months. After adopting ADCERAX Si₃N₄ ceramic bearings, operation cycles extended beyond 18 months without performance degradation.

The switch reduced unplanned shutdowns by 70% and eliminated product contamination, ensuring stable, maintenance-free operation in continuous chemical dosing lines.

Vacuum & High-Temperature Systems

- Non-outgassing, non-magnetic, and thermally stable up to 1000 °C.

- Ideal for vacuum furnaces, coating chambers, and heat-treatment tools.

🧩 Key Advantages:

- Stable Performance in Extreme Temperatures

Si₃N₄ bearings retain structural integrity up to 1000 °C in vacuum or inert atmospheres, preventing deformation during thermal cycling. - Zero Outgassing & Contamination

Manufactured with ultra-pure Si₃N₄ (≥ 99.8%) and no metallic binders, ensuring zero gas emission in UHV or clean processing chambers. - Long-Term Dimensional Precision

The thermal expansion coefficient of 3.2 × 10⁻⁶/K maintains accurate alignment in high-speed furnace drives and deposition systems.

🔹Problem Solved:

A European vacuum coating equipment manufacturer faced repeated bearing seizure in rotary stages at 850 °C due to metal oxidation and lubricant failure. After switching to ADCERAX Si₃N₄ ceramic bearings, the chamber remained particle-free and stable for over 1,500 hours of continuous operation.

Temperature drift decreased by 28%, and maintenance intervals extended from monthly to annual, significantly improving uptime and process reliability.

Custom Silicon Nitride Ceramic Bearings Manufacturer

ADCERAX specializes in custom silicon nitride ceramic bearings built to your drawings and engineering requirements.

We support non-standard dimensions, special clearances or preload, PEEK/PI cages, custom raceway geometry, and precision grinding for hybrid and full-ceramic bearing designs. Prototype samples and volume production are available with stable quality, verified tolerances, and on-time delivery.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

ADCERAX – Professional Si3N4 Ceramic Bearing Supplier

ADCERAX is a manufacturer and exporter of silicon nitride (Si₃N₄) ceramic bearings, providing both custom and mass-production solutions for high-speed, high-temperature, and corrosive industrial environments. With in-house sintering, precision grinding, and inspection, we ensure consistent tolerance, smooth rotation, and reliable performance for OEMs and engineering clients worldwide.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

ADCERAX integrates Si₃N₄ ceramic forming, precision grinding, assembly inspection, and quality testing into a unified production process. We provide custom bearing designs, non-standard sizes, and surface finishing — from prototype samples to bulk production.

-

Precision Machining & Dimensional Accuracy:

Each Si₃N₄ bearing is finished through CNC grinding and lapping to ensure precise roundness, smooth raceways, and low vibration. Tight tolerance and controlled surface finish guarantee stable rotation and extended service life. -

Batch Consistency & Quality Control:

Every production batch is inspected for density, sphericity, and wear resistance. Strict control of grain size and lubrication compatibility ensures high reliability in continuous and high-speed operation. -

Customization & Engineering Support:

We offer drawing-based customization, including cage material selection (PEEK, PI, stainless steel), hybrid/full-ceramic options, and special lubrication or coating needs. Engineering support is available for matching loads, speed limits, and thermal environments in demanding industrial applications.

ADCERAX specializes in producing silicon nitride (Si₃N₄) ceramic bearings through advanced forming, high-temperature sintering, precision grinding, and quality inspection. Our bearings ensure high roundness, low friction, and strong mechanical integrity, performing reliably under high speed, high temperature, and corrosive environments.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Capability Item | Typical Value / Description | ||

| Material Grades | Hot-pressed or gas-pressure sintered Si₃N₄ ceramic with fine-grain microstructure, high hardness (>1400 HV), and fracture toughness for high-speed and corrosive bearing applications. | ||

| Precision Machining | CNC grinding and lapping achieve tight tolerances (±0.002 mm) and perfect sphericity for smooth rotation and minimal vibration. Surfaces polished to Ra ≤ 0.02 µm for reduced friction. | ||

| Forming & Shaping | Custom bearing dimensions, cage integration, and raceway geometry optimized for load, temperature, and lubrication conditions. Hybrid and full-ceramic options available. | ||

| Flatness & Dimensional Control | Controlled sintering and precise grinding ensure uniform density, low porosity, and consistent roundness — maintaining stability under high-speed rotation. | ||

| Assembly & Quality Inspection | 100% visual and dimensional inspection with roundness, roughness, and dynamic balance testing to guarantee reliability for motors, pumps, and precision machinery. | ||

FAQ

A silicon nitride ceramic bearing is made from Si₃N₄ material that offers higher hardness, lighter weight, and complete corrosion resistance. Compared with steel bearings, it operates reliably under high-speed, high-temperature, and electrical environments.

Yes. Si₃N₄ ceramic bearings can be either full-ceramic (both balls and races made of Si₃N₄) or hybrid designs that use silicon nitride ceramic balls with steel races for lower cost and improved performance.

They are widely applied in machine tool spindles, chemical pumps, vacuum systems, and electric motors, where reliability, insulation, and clean operation are essential.

Yes. ADCERAX offers custom silicon nitride ceramic bearings according to your drawings or samples, including non-standard dimensions, cage materials, and hybrid configurations.

They can run dry in clean environments. However, adding light lubrication or grease significantly extends lifespan and reduces wear in high-speed silicon nitride ceramic bearings.

Yes. Si₃N₄ ceramic bearings are designed according to ISO and ABEC dimensional standards, meaning they can directly replace standard steel bearings without modification to the housing or shaft.

The outer diameter, inner bore, and width of our silicon nitride ceramic bearings fully match common steel series such as 6000, 6200, 6300, 6800, and 6900.

However, the lighter density and lower thermal expansion coefficient of Si₃N₄ provide extra advantages — maintaining tighter clearance under thermal load and preventing seizure at high speeds.

You can contact ADCERAX, a silicon nitride ceramic bearings manufacturer, for fast quotation by providing bearing size, load requirement, and quantity. Both prototypes and bulk orders are supported.

ADCERAX achieves extremely tight dimensional tolerances and surface finishes in Si₃N₄ ceramic bearings through advanced CNC grinding and precision lapping.

We can control dimensional accuracy up to ±0.002 mm and surface roughness to Ra ≤ 0.02 µm, ensuring exceptional roundness, uniform load distribution, and low vibration at high rotational speeds.

Si₃N₄ ceramic bearings are electrically insulating, blocking current flow between the rotor and stator.

This prevents arcing, surface pitting, and grease damage, ensuring stable operation and a much longer service life in inverter-driven motors.

ADCERAX applies strict quality control from raw material to finished bearing. Each Si₃N₄ bearing is inspected for density, roundness, and surface precision, with tolerances up to ±0.002 mm and Ra ≤ 0.02 µm.

All products undergo vibration and durability testing to ensure reliable performance under high speed and load conditions.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours