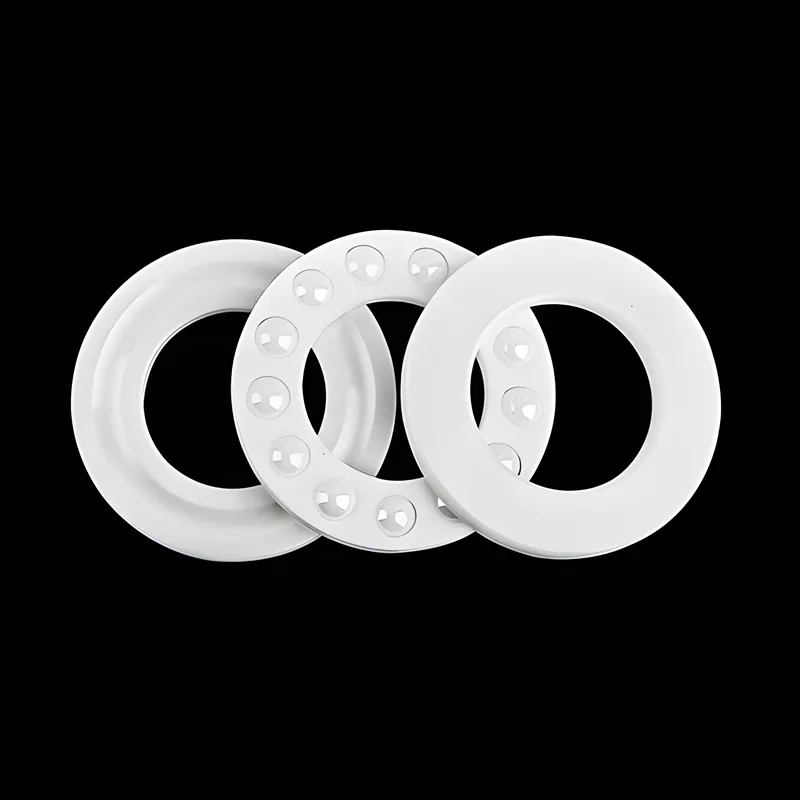

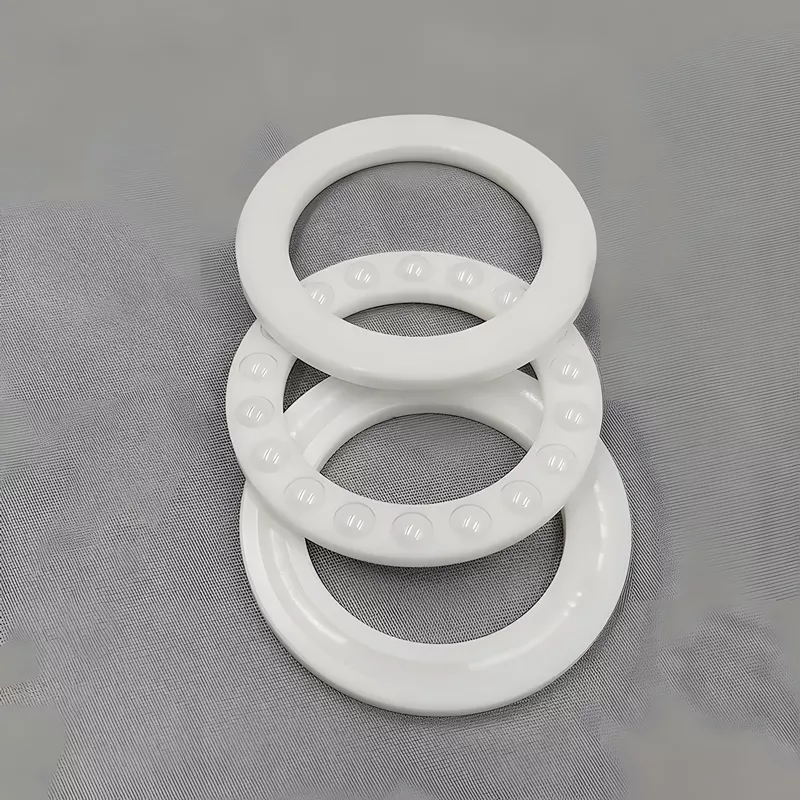

ADCERAX® Zirconia Ceramic Thrust Ball Bearing is engineered specifically for axial load transfer in environments involving sustained heat, corrosive media, or electrical insulation requirements. Its full-ceramic structure maintains mechanical stability when operating in chemical pumps, fuel cell modules, and high-temperature compressor assemblies where conventional radial‑focused or alignment‑dependent bearing types are unsuitable. The material’s non‑magnetic and non‑conductive characteristics support clean, vacuum, and instrumentation environments, ensuring reliable performance where axial force control and contamination avoidance are critical.

Features of Zirconia Ceramic Thrust Ball Bearing

- Maintains structural integrity up to +400 °C continuous, with peak exposure tolerance reaching +700 °C in dry or vacuum environments. This eliminates failure caused by thermal distortion found in radial bearing geometries.

- In steam turbines and hot gas compressors, dimension shift under load remains below ±0.015 mm, preventing axial misalignment across prolonged duty cycles.

Thermal expansion coefficient of 10.5×10⁻⁶ /K ensures compatibility with most industrial housing materials under gradient stress. - Surface roughness < 0.02 μm and closed-pore zirconia matrix allow operation under thermal shock without fracture or bearing seizure.

- Unlike spherical or angular contact bearings, this axial-only design withstands pH 1–14 exposure while retaining over 95% load capacity after 96h H₂SO₄ immersion (lab tested).

- In marine pump applications, zirconia thrust assemblies last 3.2× longer than stainless steel types under identical chloride concentration and pressure cycling.

- In chemical separators, no surface pitting or chemical leaching observed after 72h NaOH at 85 °C, maintaining full electrical resistance >10¹² Ω·cm.

- Standard configuration rated for dynamic axial loads of 0.5–20 kN, with static thresholds reaching up to 30 kN, depending on bore and contact angle.

- ZrO₂ balls in G10–G20 precision grade provide consistent load balance and misalignment control, critical in non-lubricated axial setups.

- Compared with deep groove bearings, wear rate is reduced by 68% in 1000 h continuous thrust simulation under 350 °C / 10 kN loading.

Technical Properties of Zirconia Ceramic Thrust Ball Bearing

Designed for high-demand axial load systems, the Zirconia Ceramic Thrust Ball Bearing delivers stable mechanical performance in corrosive, non-magnetic, and thermally intensive environments. Its full-ceramic configuration ensures structural integrity across wide temperature gradients and enables frictionless operation without lubrication, especially in applications where electrical insulation and chemical inertness are mandatory.

| Property | Specification |

|---|---|

| Material Composition | Yttria-stabilized ZrO₂ (≥ 99.8%) |

| Density | 6.05 g/cm³ ± 0.02 |

| Flexural Strength | ≥ 1000 MPa |

| Vickers Hardness | ≥ 1200 HV (0.5 kg load) |

| Fracture Toughness | ≥ 8 MPa·m¹ᐟ² |

| Thermal Conductivity | 2.2 W/m·K (25 °C) |

| Max Continuous Temperature | +400 °C, short-term peak +700 °C |

| Thermal Expansion Coefficient | 10.5 × 10⁻⁶ /K (20–400 °C) |

| Electrical Resistivity | > 10¹² Ω·cm |

| Acid Resistance Stability | No degradation after 96h in H₂SO₄ (pH 1) |

| Alkali Resistance Stability | Surface intact after 72h NaOH exposure (85 °C) |

| Surface Finish (Raceway) | Ra < 0.02 μm, mirror-ground |

| Ball Grade Compatibility | G10–G20 ceramic ZrO₂ spheres |

| Magnetic Permeability | Zero (non-magnetic) |

| Lubrication Mode | Dry-run capable / vacuum grease optional |

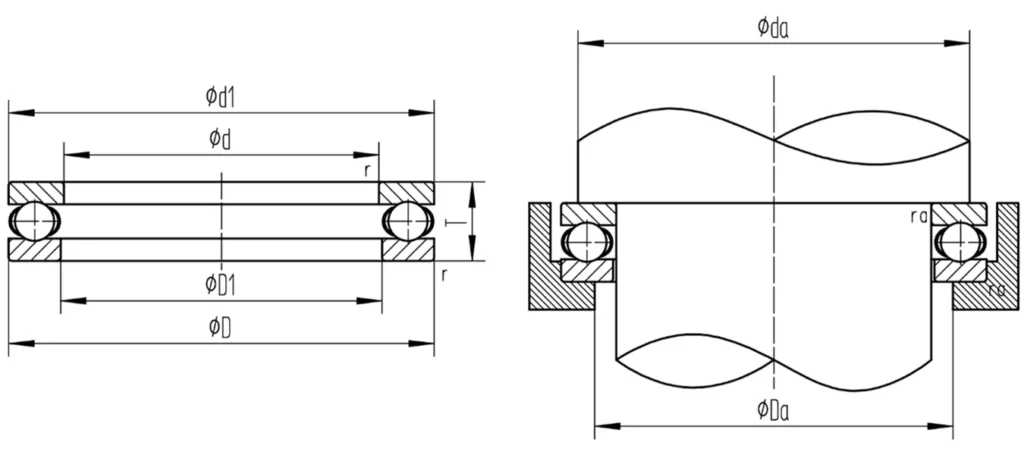

Specifications of Zirconia Ceramic Thrust Ball Bearing

| Model No. | Bearing No. | Bore Diameter (d, mm) | Outer Diameter (D, mm) | Width (T, mm) | Min. Chamfer (r, mm) | Shaft Shoulder Dia. (d1, mm) | Housing Shoulder Dia. (D1, mm) | Weight (kg) |

| AT-YHG-ZC51108 | 51108 | 40 | 60 | 13 | 0.3 | 60 | 42 | 0.0920 |

| AT-YHG-ZC51208 | 51208 | 40 | 68 | 19 | 0.6 | 68 | 42 | 0.2100 |

| AT-YHG-ZC51109 | 51109 | 45 | 65 | 14 | 0.3 | 65 | 47 | 0.1100 |

| AT-YHG-ZC51209 | 51209 | 45 | 73 | 20 | 0.6 | 73 | 47 | 0.2400 |

| AT-YHG-ZC51110 | 51110 | 50 | 70 | 14 | 0.3 | 70 | 52 | 0.1200 |

| AT-YHG-ZC51210 | 51210 | 50 | 78 | 22 | 0.6 | 78 | 52 | 0.2900 |

| AT-YHG-ZC51111 | 51111 | 55 | 78 | 16 | 0.3 | 78 | 57 | 0.1700 |

| AT-YHG-ZC51211 | 51211 | 55 | 90 | 25 | 0.6 | 90 | 57 | 0.4600 |

| AT-YHG-ZC51112 | 51112 | 60 | 85 | 17 | 1.0 | 85 | 62 | 0.2200 |

| AT-YHG-ZC51212 | 51212 | 60 | 95 | 26 | 1.0 | 95 | 62 | 0.5200 |

| AT-YHG-ZC51113 | 51113 | 65 | 90 | 18 | 1.0 | 90 | 67 | 0.2500 |

| AT-YHG-ZC51213 | 51213 | 65 | 100 | 27 | 1.0 | 100 | 67 | 0.5800 |

| AT-YHG-ZC51114 | 51114 | 70 | 95 | 18 | 1.0 | 95 | 72 | 0.2700 |

| AT-YHG-ZC51214 | 51214 | 70 | 105 | 27 | 1.0 | 105 | 72 | 0.6100 |

| AT-YHG-ZC51115 | 51115 | 75 | 100 | 19 | 1.0 | 100 | 77 | 0.3000 |

| AT-YHG-ZC51215 | 51215 | 75 | 110 | 27 | 1.0 | 110 | 77 | 0.6500 |

| AT-YHG-ZC51116 | 51116 | 80 | 105 | 19 | 1.0 | 105 | 82 | 0.3200 |

| AT-YHG-ZC51216 | 51216 | 80 | 115 | 28 | 1.0 | 115 | 82 | 0.7200 |

| AT-YHG-ZC51117 | 51117 | 85 | 110 | 19 | 1.0 | 110 | 87 | 0.3400 |

| AT-YHG-ZC51217 | 51217 | 85 | 125 | 31 | 1.0 | 125 | 88 | 0.9400 |

| AT-YHG-ZC51118 | 51118 | 90 | 120 | 22 | 1.0 | 120 | 92 | 0.5000 |

| AT-YHG-ZC51218 | 51218 | 90 | 135 | 35 | 1.1 | 135 | 93 | 1.3800 |

| AT-YHG-ZC51120 | 51120 | 100 | 135 | 25 | 1.0 | 135 | 102 | 0.7400 |

| AT-YHG-ZC51220 | 51220 | 100 | 150 | 38 | 1.1 | 150 | 103 | 1.7300 |

| AT-YHG-ZC51122 | 51122 | 110 | 145 | 25 | 1.0 | 145 | 112 | 0.8000 |

| AT-YHG-ZC51124 | 51124 | 110 | 155 | 25 | 1.0 | 155 | 122 | 0.8600 |

| AT-YHG-ZC51100 | 51100 | 10 | 24 | 9 | 0.3 | 24 | 17 | 0.0150 |

| AT-YHG-ZC51200 | 51200 | 10 | 26 | 11 | 0.6 | 26 | 12 | 0.0220 |

| AT-YHG-ZC51101 | 51101 | 12 | 26 | 9 | 0.3 | 26 | 13 | 0.0160 |

| AT-YHG-ZC51201 | 51201 | 12 | 28 | 11 | 0.6 | 28 | 14 | 0.0240 |

| AT-YHG-ZC51102 | 51102 | 15 | 28 | 9 | 0.6 | 28 | 16 | 0.0180 |

| AT-YHG-ZC51202 | 51202 | 15 | 32 | 12 | 0.6 | 32 | 17 | 0.0330 |

| AT-YHG-ZC51103 | 51103 | 17 | 30 | 9 | 0.3 | 30 | 18 | 0.0190 |

| AT-YHG-ZC51203 | 51203 | 17 | 35 | 12 | 0.6 | 35 | 19 | 0.0380 |

| AT-YHG-ZC51104 | 51104 | 20 | 35 | 10 | 0.4 | 35 | 21 | 0.0280 |

| AT-YHG-ZC51204 | 51204 | 20 | 40 | 14 | 0.4 | 40 | 22 | 0.0590 |

| AT-YHG-ZC51105 | 51105 | 25 | 42 | 11 | 0.6 | 42 | 26 | 0.0430 |

| AT-YHG-ZC51205 | 51205 | 25 | 47 | 15 | 0.6 | 47 | 27 | 0.0850 |

| AT-YHG-ZC51106 | 51106 | 30 | 47 | 11 | 0.6 | 47 | 32 | 0.0490 |

| AT-YHG-ZC51206 | 51206 | 30 | 52 | 16 | 0.6 | 52 | 32 | 0.1100 |

| AT-YHG-ZC51107 | 51107 | 35 | 52 | 12 | 0.6 | 52 | 37 | 0.0620 |

| AT-YHG-ZC51207 | 51207 | 35 | 62 | 18 | 1.0 | 62 | 37 | 0.1600 |

| AT-YHG-ZCUC206-18 | UC206-18 | 1 1/8 | 62 | 38.1 | 19 | 40.8 | 1 | 5 |

| AT-YHG-ZCUC206-19 | UC206-19 | 1 3/16 | 62 | 38.1 | 19 | 40.8 | 1 | 5 |

| AT-YHG-ZCUC206-20 | UC206-20 | 11/4(s) | 62 | 38.1 | 19 | 40.8 | 1 | 5 |

| AT-YHG-ZCUC207 | UC207 | 35mm | 72 | 42.9 | 20 | 46.8 | 1.1 | 6 |

| AT-YHG-ZCUC207-20 | UC207-20 | 1 1/4 | 72 | 42.9 | 20 | 46.8 | 1.1 | 6 |

| AT-YHG-ZCUC207-21 | UC207-21 | 1 5/16 | 72 | 42.9 | 20 | 46.8 | 1.1 | 6 |

| AT-YHG-ZCUC207-22 | UC207-22 | 1 3/8 | 72 | 42.9 | 20 | 46.8 | 1.1 | 6 |

| AT-YHG-ZCUC207-23 | UC207-23 | 1 7/16 | 72 | 42.9 | 20 | 46.8 | 1.1 | 6 |

| AT-YHG-ZCUC208 | UC208 | 40mm | 80 | 42.9 | 21 | 52.8 | 1.1 | 8 |

| AT-YHG-ZCUC208-24 | UC208-24 | 1 1/2 | 80 | 42.9 | 21 | 52.8 | 1.1 | 8 |

| AT-YHG-ZCUC208-25 | UC208-25 | 1 9/16 | 80 | 42.9 | 21 | 52.8 | 1.1 | 8 |

| AT-YHG-ZCUC209 | UC209 | 45mm | 85 | 49.2 | 22 | 58.6 | 1.1 | 8 |

| AT-YHG-ZCUC209-26 | UC209-26 | 1 5/8 | 85 | 49.2 | 22 | 58.6 | 1.1 | 8 |

| AT-YHG-ZCUC209-27 | UC209-27 | 1 11/16 | 85 | 49.2 | 22 | 58.6 | 1.1 | 8 |

| AT-YHG-ZCUC209-28 | UC209-28 | 1 3/4 | 85 | 49.2 | 22 | 58.6 | 1.1 | 8 |

Packaging of Zirconia Ceramic Thrust Ball Bearing

Zirconia Ceramic Thrust Ball Bearing is packaged in foam-lined tubes and double-layer cartons to prevent any mechanical shock. Each unit is stored in humidity-controlled shelving before shipment. Final packing is palletized and shrink-wrapped for stable global transport.