ADCERAX® Silicon Carbide Kiln Roller is engineered for continuous thermal cycling in roller hearth kilns where material flow, straightness retention, and temperature uniformity determine production stability. Its reaction-bonded SiC microstructure provides high modulus and low creep behavior, allowing the roller to maintain alignment under heavy ceramic loads and persistent exposure to alkali-rich kiln atmospheres. This combination of mechanical rigidity and thermal efficiency supports consistent firing results across lithium battery materials, technical ceramics, and large-format porcelain applications.

Core Advantages of the ADCERAX® Silicon Carbide Kiln Roller

-

High-Strength RBSiC Microstructure

-

High Flexural Strength

The roller maintains structural load capacity with a typical flexural strength of >200–250 MPa, supporting long spans without deformation.

This strength level enables reliable performance in roller kilns where ware loads can exceed several hundred kilograms per zone.

-

High Surface Hardness

The closed-pore SiC microstructure provides hardness comparable to HRA 88–90, reducing abrasion from kiln furniture and conveyed products.

This hardness level helps extend service life by limiting surface wear even after thousands of heating cycles.

-

High Elastic Modulus

The material’s elastic modulus supports long-span operation by mitigating bending and vibration at temperatures above 1,200 °C.

This ensures the roller retains straightness across kilns exceeding 40–60 m in total length.

-

Thermal Stability in Continuous Kiln Operation

-

High-Temperature Working Range

Stable operation is maintained at 1,350–1,380 °C in continuous firing conditions.

This minimizes distortion and prevents structural drift across long firing schedules.

-

Thermal Shock Resistance

The SiC matrix withstands abrupt changes in temperature, exceeding the performance of oxide-based rollers across repeated rapid-firing cycles.

This resilience reduces the risk of cracking during kiln startups, shutdowns, or emergency cooling events.

-

High Thermal Conductivity

The roller supports fast heat transfer, contributing to cycle-time reductions and more uniform temperature fields along the kiln.

This thermal advantage helps lower firing energy usage by 5–15% in many continuous production environments.

-

Chemical Resistance and Dimensional Stability

-

Alkali Vapor Resistance

The RBSiC structure withstands alkali vapors generated during calcination of LFP and high-nickel cathode materials, reducing surface corrosion rates by up to 40% compared with oxide rollers.

This resistance stabilizes surface roughness over extended runs, preventing contamination during high-value material processing.

-

Low Creep Deformation

The roller maintains dimensional stability with creep rates significantly below oxide ceramics in 1,200–1,350 °C furnace zones.

This allows sustained operation over multi-month kiln cycles without appreciable bending or sagging.

-

Straightness Retention

Precision-machined geometry supports straightness consistency even under heavy ware loading and elevated temperatures across long kiln spans.

This stability reduces ware misalignment and minimizes downstream defects in continuous production lines.

Technical Specifications of Silicon Carbide Kiln Roller

ADCERAX® Silicon Carbide Kiln Roller demonstrates stable mechanical, thermal, and chemical performance under continuous high-temperature cycling, reflecting the inherent characteristics of reaction-bonded silicon carbide used in demanding kiln environments.

| Property |

Specification |

| Material Composition |

Reaction-Bonded SiC (RBSiC / SiSiC) |

| Flexural Strength |

>200–250 MPa |

| Compressive Strength |

>1,500 MPa |

| Surface Hardness |

HRA 88–90 |

| Elastic Modulus |

>300 GPa |

| Thermal Conductivity |

35–45 W/m·K |

| Maximum Operating Temperature |

1,350–1,380 °C (continuous use) |

| Thermal Expansion Coefficient |

4.0–4.5 × 10⁻⁶ /K |

| Thermal Shock Resistance |

Stable after rapid ΔT cycles >250 °C |

| Bulk Density |

2.95–3.05 g/cm³ |

| Open Porosity |

<0.1% |

| Chemical Resistance |

Stable in alkali-rich, oxidizing, CO/CO₂ kilns |

| Creep Resistance |

Low creep at 1,200–1,350 °C |

| Oxidation Stability |

Stable up to 1,400 °C in air |

Dimensions of Silicon Carbide Kiln Roller

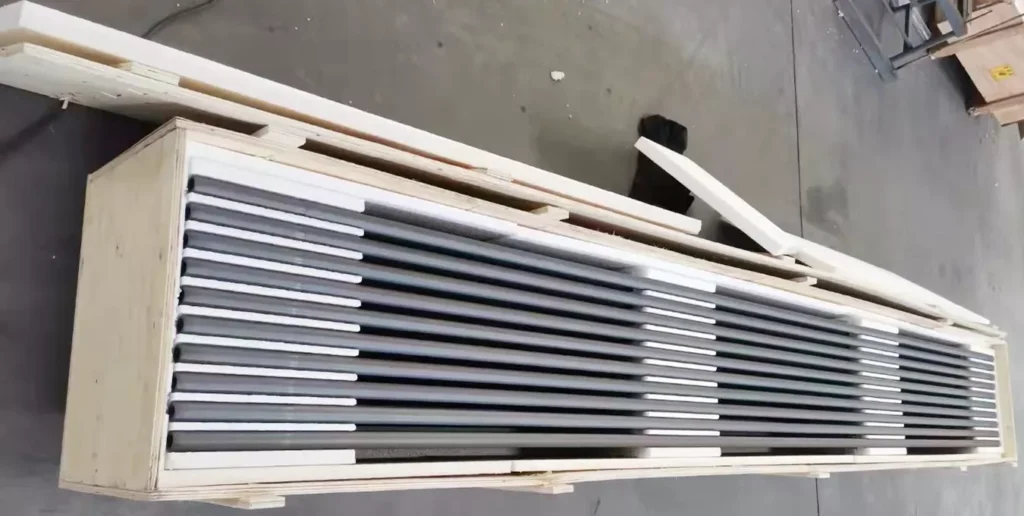

Packaging Overview for Silicon Carbide Kiln Roller

Silicon Carbide Kiln Roller is packed in reinforced wooden crates with foam-lined compartments to prevent contact and vibration during transport. Each roller is individually separated to avoid surface abrasion and structural impact in long-distance shipments. The overall packaging structure is designed to maintain stability under stacking, ensuring safe arrival for industrial kiln installation.

ADCERAX® Silicon Carbide Kiln Roller Resolves Critical Kiln-Line Challenges Across High-Demand Industrial Processes

The Silicon Carbide Kiln Roller from ADCERAX® is engineered to address process-level bottlenecks in continuous roller-hearth kilns where temperature uniformity, mechanical rigidity, and chemical durability directly influence production stability, yield consistency, and operating cost.

-

Silicon Carbide Kiln Roller in Lithium Cathode Calcination Lines

✅Key Advantages

1. Alkali-Vapor Stable RBSiC Matrix

The ADCERAX® Silicon Carbide Kiln Roller uses a reaction-bonded SiC matrix that maintains surface integrity in strong alkali vapor environments typical of LFP and high-nickel cathode kilns at 1,350–1,380 °C. Field experience shows that surface roughness growth rate can be reduced by 30–40% compared with conventional oxide rollers across 300–500 h firing campaigns.

2. Long-Cycle Straightness Retention

High flexural strength in the >200–250 MPa class and low creep at 1,200–1,350 °C allow the roller to keep transport alignment over extended production runs. In multi-zone cathode kilns, this performance helps maintain stable tracking across lines exceeding 40 m in length without reaching the sag levels that trigger emergency roller changes.

3. Reduced Contamination Risk for Active Materials

The dense SiC surface limits glaze formation and particle adhesion under continuous powder feed conditions. Plants upgrading to ADCERAX® Silicon Carbide Kiln Rollers have reported measurable reductions in contamination-related scrap, in some cases lowering powder batch rejection by 5–10% in high-throughput cathode production.

✅ ️Problem Solved

A cathode material producer operating two roller-hearth lines at 1,350–1,380 °C experienced frequent roller bowing and surface corrosion after 300–400 h of operation, leading to misalignment, uneven powder layers, and emergency kiln stoppages. Average unplanned downtime reached 3–4 shifts per quarter, with each stoppage associated with significant lost output and material rework. After replacing the most critical positions with ADCERAX® Silicon Carbide Kiln Rollers, the plant recorded a reduction in unplanned roller-related stoppages by over 50% within the next operating cycle. Variability in cathode performance linked to transport instability decreased, and the production team was able to extend planned maintenance intervals without sacrificing process stability.

-

Silicon Carbide Kiln Roller in Technical Ceramic Substrate Firing

✅Key Advantages

1. High Modulus Support for Long Kiln Lengths

The ADCERAX® Silicon Carbide Kiln Roller offers an elastic modulus above 300 GPa, which limits deflection under substrate loads at temperatures exceeding 1,200 °C. This stiffness is particularly important in kilns longer than 40–60 m, where small angular deviations can accumulate into visible warpage on large, thin substrates.

2. Thermal Conductivity for Uniform Heat Flow

Thermal conductivity in the range of 35–45 W/m·K helps smooth temperature gradients along the roller surface, reducing hot and cold bands during firing. In substrate lines retrofitted with SiC rollers, process engineers have documented decreases in temperature non-uniformity of 10–20 °C across the width of the kiln, supporting tighter control of shrinkage and flatness.

3. Dimensional Stability over Multiple Thermal Cycles

Low creep deformation at 1,200–1,350 °C supports geometric stability across many firing cycles, even when substrate batches are processed continuously. This behavior helps limit rejection rates in high-volume operations, where distortion-related scrap had previously risen to 8–15% when roller distortion accumulated over time.

✅ ️Problem Solved

A technical ceramics facility producing alumina and zirconia substrates reported increasing warp and thickness variation after repeated high-temperature cycles, with overall rejection climbing into the 10–12% range in peak months. Analysis showed that oxide rollers in a 50 m roller-hearth kiln had developed measurable deflection and uneven heat transfer behavior above 1,200 °C. After implementing ADCERAX® Silicon Carbide Kiln Rollers on the most sensitive zones, the plant recorded a drop in warp-related failures and brought total rejection back down toward 5–7%, while maintaining the same firing schedule. Improved straightness retention and more uniform heat flow also reduced re-lapping and re-polishing workloads downstream, stabilizing yield for high-precision substrate products.

-

Silicon Carbide Kiln Roller in High-Load Powder Metallurgy and Magnetic Material Sintering

✅Key Advantages

1. High Flexural Strength under Dense Loads

With flexural strength in the >200–250 MPa range, the ADCERAX® Silicon Carbide Kiln Roller supports heavy powder metallurgy and ferrite loads without reaching critical sag under 1,200–1,350 °C operating conditions. This capability is especially relevant where total ware weight per span can reach several hundred kilograms and campaigns extend over hundreds of hours.

2. Low Creep in Extended Soak Zones

The RBSiC composition exhibits low creep rates at typical sintering temperatures, which helps maintain roller geometry during long soak periods characteristic of high-density material cycles. Plants switching to SiC rollers have reported significantly lower mid-span deflection growth over time, allowing them to keep alignment within acceptable limits for tight-tolerance sintered components.

3. Wear-Resistant Transport Surface

The hard, closed-pore SiC surface (equivalent to HRA 88–90) maintains smooth contact with setters and trays across repeated loading and unloading operations. This reduces the rate of surface degradation and can extend operational life by factors of 2–4× compared with conventional oxide rollers in heavy-load lines, lowering the frequency of roller replacement campaigns.

✅ ️Problem Solved

A powder metallurgy plant operating long sintering cycles at 1,250–1,300 °C experienced progressive sag and surface wear on conventional rollers, which led to part tipping, dimensional drift, and periodic line slow-downs. Over a typical year, heavy-load lines required one or more unscheduled roller replacement events, with associated output losses and increased maintenance hours. After installing ADCERAX® Silicon Carbide Kiln Rollers in the most heavily loaded zones, measured mid-span deflection after comparable operating hours decreased, and emergency roller changes were eliminated over the next 12-month period. The plant noted improved dimensional consistency on critical parts and a tangible reduction in maintenance interventions tied directly to roller degradation.

ADCERAX® Silicon Carbide Kiln Roller User Guide for Stable, Safe, and Long-Cycle Kiln Operation

The Silicon Carbide Kiln Roller requires proper handling, installation, and operating discipline to achieve its full mechanical and thermal stability across continuous firing environments, ensuring consistent kiln alignment and long service life.

-

Handling and Pre-Installation Preparation

1. Proper Support During Unpacking

Rollers must be lifted with stable multi-point support to avoid bending stress concentrated at a single location. The use of sling belts or padded grips helps prevent accidental surface abrasion during crate removal. Careful handling minimizes micro-damage that may propagate under high-temperature cycling.

2. Inspection Before Assembly

Each roller should be visually examined for chips, cracks, or unexpected surface marks before installation. Dimensional straightness can be verified with a calibrated reference fixture to ensure compatibility with the kiln’s transport rails. Any deviation detected at this stage prevents alignment drift inside the furnace.

3. Controlled Pre-Heating Routine

A gradual warm-up protocol should be applied when running rollers for the first time after installation. Controlled ramping allows the material to stabilize thermally and eliminates sudden differential expansion that may induce stress. Uniform thermal adaptation enhances long-cycle stability.

-

Installation and Alignment in Roller-Hearth Kilns

1. Correct Seating on Bearing Blocks

Rollers must be placed so the seating interfaces are clean, flat, and free of foreign particles to avoid point-loading during rotation. Proper shimming ensures stable contact pressure across the entire length. Accurate seating reduces misalignment during high-temperature operation.

2. Consistent Axial Positioning

Axial shift limiters should be adjusted to maintain stable left-right positioning during operation. Excessive axial freedom may cause lateral movement that alters product transport patterns. Axial stability is crucial for consistent kiln throughput.

3. Rotation Check Before Heat-Up

Each roller should be rotated manually after installation to confirm friction-free movement. Detectable resistance or noise indicates bearing contamination or misalignment requiring immediate correction. Smooth rotation minimizes torque peaks during firing cycles.

-

Operating Guidelines Under High-Temperature Cycling

1. Maintain Stable Kiln Temperature Profiles

Rapid temperature fluctuations exceeding recommended thresholds can trigger thermal stress concentrations. Operating with controlled heating and cooling curves improves resilience during repeated 1,200–1,380 °C cycles. Predictable thermal gradients extend roller lifespan.

2. Avoid Overloading Transport Zones

Distributed product loading should remain within the kiln’s rated mass limits to prevent excessive bending stress. High-density ceramics or powder loads must be positioned evenly across spans. Balanced loads minimize mid-span deflection growth.

3. Regular Monitoring During Continuous Runs

Vibration, noise changes, or visible tracking deviations may signal early deformation. Establishing periodic inspection intervals during long campaigns enables early corrective action. Proactive monitoring avoids unplanned shutdowns.

-

Maintenance, Cleaning, and Replacement Scheduling

1. Surface Cleaning Between Campaigns

Deposits from powders, alkali vapors, or furnace gases should be removed with non-abrasive tools during maintenance downtime. Controlled cleaning prevents surface scratches that could evolve into stress points. Clean surfaces maintain uniform heat transfer.

2. Bearing and Support System Maintenance

Lubrication condition, bearing wear, and support block integrity must be checked routinely. A degraded bearing system transfers uneven torque, accelerating roller wear. Well-maintained supports preserve rotation accuracy.

3. Replacement Planning Based on Runtime Data

Cycles exceeding 300–500 hours in alkali-rich environments should be documented to predict material fatigue. Plants benefit from tracking straightness, vibration, and surface changes to determine optimal replacement timing. Data-driven scheduling stabilizes kiln availability.

![]()