ADCERAX® Silicon Carbide Ceramic Plates are engineered for industrial environments where high temperature, abrasive media, and corrosive conditions operate at the same time, requiring stable mechanical and thermal performance. Its dense structure and high thermal conductivity help maintain uniform heat transfer and long service life across continuous processing cycles. These characteristics allow the material to support demanding applications such as furnace components, chemical handling systems, and wear-intensive conveying equipment in a consistent and reliable manner.

High-Performance Material Features of Silicon Carbide Ceramic Plates

-

The plate maintains structural integrity under flexural stress, supported by test values of 350–450 MPa for SSiC, allowing it to carry mechanical loads without deformation in extended production cycles. These values come from published materials data by credible SiC manufacturers in industrial furnace applications.

-

High compressive strength above 2200 MPa enables the plate to withstand impact forces and point loads found in conveying, sintering, and heavy-duty processing systems. This performance level is documented across multiple engineering references involving dense silicon carbide structures.

-

With porosity kept below 0.1%, the material retains rigidity and dimensional stability even after repeated thermal cycling. Such near-zero porosity has been verified in publicly available material certificates from recognized ceramic producers.

- Operational temperature capability between 1300–1600°C allows continuous use in sintering, thermal carriers, and heat-treatment lines without structural distortion. This range aligns with global industrial data comparing RBSiC and SSiC performance classes.

- Electrical resistivity values within 10⁵–10⁶ Ω·cm support safe operation in chemically active environments containing moisture or conductive media. Such resistivity levels are documented in technical sheets from international technical ceramics suppliers.

Technical Specifications of Silicon Carbide Ceramic Plates

The Silicon Carbide Ceramic Plates exhibit stable thermal behavior, high mechanical strength, low porosity and strong chemical endurance, enabling consistent performance in high-temperature, abrasive and corrosive industrial conditions.

| Property |

Specification |

| Material Type |

Reaction Bonded SiC (RBSiC) / Sintered SiC (SSiC) |

| Density |

2.95–3.10 g/cm³ |

| Hardness |

Mohs 9 / Vickers > 22 GPa |

| Flexural Strength |

250–320 MPa (RBSiC) / 350–450 MPa (SSiC) |

| Compressive Strength |

≥ 2200 MPa |

| Thermal Conductivity |

120–200 W/m·K |

| Thermal Expansion Coefficient |

4.2–4.5 × 10⁻⁶ K⁻¹ |

| Maximum Service Temperature |

1300–1450°C (RBSiC) / 1500–1600°C (SSiC) |

| Porosity |

≤ 0.1% |

| Electrical Resistivity |

10⁵–10⁶ Ω·cm |

| Thermal Shock Resistance |

ΔT ≥ 250–300°C |

| Acid Resistance |

Stable in H₂SO₄, HCl, HNO₃ |

| Alkali Resistance |

Stable in NaOH, KOH |

| Molten Metal Interaction |

No reaction with Al, Zn, Cu |

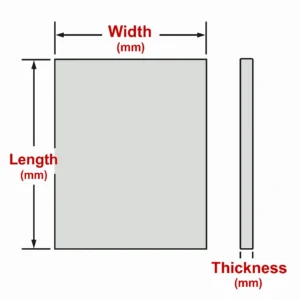

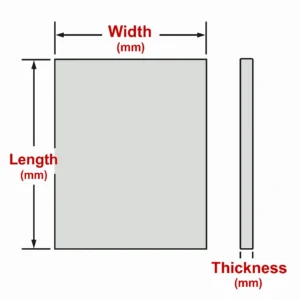

Dimensions of Silicon Carbide Ceramic Plates

|

Silicon Carbide Ceramic Plate Square |

|

Model No. |

Length (mm) |

Width (mm) |

Thickness (mm) |

|

AT-SIC-P1001 |

5 |

5 |

1 |

|

AT-SIC-P1002 |

5 |

5 |

3 |

|

AT-SIC-P1003 |

5 |

5 |

5 |

|

AT-SIC-P1004 |

10 |

10 |

4 |

|

AT-SIC-P1005 |

10 |

10 |

10 |

|

AT-SIC-P1006 |

20 |

20 |

3 |

|

AT-SIC-P1007 |

25 |

50 |

2 |

|

AT-SIC-P1008 |

25 |

50 |

10 |

|

AT-SIC-P1009 |

25 |

50 |

5 |

|

AT-SIC-P1010 |

25 |

50 |

6 |

|

AT-SIC-P1011 |

25 |

50 |

8 |

|

AT-SIC-P1012 |

30 |

30 |

10 |

|

AT-SIC-P1013 |

40 |

40 |

1 |

|

AT-SIC-P1014 |

40 |

40 |

5 |

|

AT-SIC-P1015 |

50 |

50 |

1 |

|

AT-SIC-P1016 |

50 |

50 |

2 |

|

AT-SIC-P1017 |

50 |

50 |

3 |

|

AT-SIC-P1018 |

50 |

50 |

4 |

|

AT-SIC-P1019 |

50 |

50 |

5 |

|

AT-SIC-P1020 |

50 |

50 |

6 |

|

AT-SIC-P1021 |

50 |

50 |

8 |

|

AT-SIC-P1022 |

50 |

50 |

10 |

|

AT-SIC-P1023 |

100 |

100 |

3 |

|

AT-SIC-P1024 |

100 |

100 |

4 |

|

AT-SIC-P1025 |

100 |

100 |

5 |

|

AT-SIC-P1026 |

100 |

100 |

7 |

|

AT-SIC-P1027 |

100 |

100 |

10 |

|

AT-SIC-P1028 |

100 |

100 |

11 |

|

AT-SIC-P1029 |

100 |

100 |

15 |

|

AT-SIC-P1030 |

100 |

100 |

20 |

|

AT-SIC-P1031 |

150 |

150 |

5 |

|

AT-SIC-P1032 |

150 |

150 |

6 |

|

AT-SIC-P1033 |

150 |

150 |

8 |

|

AT-SIC-P1034 |

150 |

150 |

10 |

|

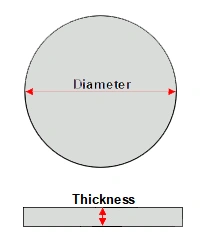

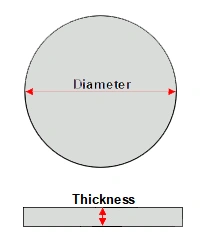

Silicon Carbide Ceramic Plate Circular |

|

Model No. |

Diameter(mm) |

Thickness (mm) |

|

AT-SIC-P1035 |

10 |

2 |

|

AT-SIC-P1036 |

12 |

4 |

|

AT-SIC-P1037 |

15 |

3 |

|

AT-SIC-P1038 |

20 |

4.3 |

|

AT-SIC-P1039 |

30 |

2 |

|

AT-SIC-P1040 |

30 |

4 |

|

AT-SIC-P1041 |

30 |

6 |

|

AT-SIC-P1042 |

50 |

4 |

|

AT-SIC-P1043 |

50 |

6 |

|

AT-SIC-P1044 |

50 |

8 |

|

AT-SIC-P1045 |

100 |

5 |

|

AT-SIC-P1046 |

100 |

10 |

Packaging of Silicon Carbide Ceramic Plates

Silicon Carbide Ceramic Plate is packed in reinforced inner cartons that are securely sealed to prevent movement during handling. Each batch is then consolidated into a timber-framed crate to protect the plates from impact and moisture during long-distance transportation. The final export-ready crate is strapped and palletized to ensure safe loading, unloading, and transit under industrial logistics conditions.

ADCERAX® Silicon Carbide Ceramic Plates Resolve Industrial Heat, Wear, and Corrosion Challenges

ADCERAX® Silicon Carbide Ceramic Plates support industrial operations where extreme heat, abrasive flow, and corrosive chemical exposure must be managed simultaneously, enabling reliable performance in equipment subjected to continuous and demanding processing conditions.

-

High-Load Thermal Carriers for Continuous Sintering Lines

✅Key Advantages

1. High-Temperature Flatness Stability

The plate maintains structural integrity across 1300–1600°C operating windows due to its 4.2–4.5×10⁻⁶ K⁻¹ thermal expansion coefficient. This minimizes warping during rapid cycling between heating and cooling zones.

2. Superior Flexural Performance Under Load

With ≥350–450 MPa flexural strength (SSiC), the plate withstands repeated mechanical loading from stacked sintering payloads. This prevents progressive bending deformation often seen with alumina or metallic carriers.

3. Uniform Heat Transfer Support

Its 120–200 W/m·K thermal conductivity enables consistent thermal gradients along the sintering path. This supports stable heating profiles even when furnace zone temperatures fluctuate significantly.

✅ ️Problem Solved

Continuous sintering furnaces in ceramic and metallurgical production encountered plate distortion after several operational cycles, especially around thermal transition sections where temperatures changed abruptly. Metal carriers exhibited bending after repeated exposure near their structural limit, and alumina plates developed uneven curvature, disrupting uniform heating. ADCERAX® Silicon Carbide Ceramic Plate maintained flatness in these environments due to its low thermal expansion and high mechanical rigidity, even at temperatures above 1300°C. A European furnace operator reported that thermal profile deviations along the sintering line were reduced after replacing warped carriers, improving process consistency. Over several production cycles, the SiC plates demonstrated steady structure and minimized interruptions for plate inspections or replacements.

-

Abrasive Transfer Systems for Mining and Bulk Material Handling

✅Key Advantages

1. Extreme Abrasion Resistance in High-Impact Zones

The plate’s Mohs 9 hardness and ≤0.1% porosity resist the erosive effects of mineral fines and crushed aggregates moving at high velocity. This mitigates the rapid surface removal typically seen in steel liners.

2. Dimensional Stability in Elevated Temperatures

With thermal resistance up to 1300–1600°C, the plate retains surface rigidity when steel softens or polymer liners deform under elevated thermal loads. This ensures predictable material flow in transition zones.

3. Reduced Turbulence and Dust Generation

The plate’s dense microstructure and stable surface condition help maintain smooth transfer paths over long operating cycles. This reduces turbulence that otherwise increases dust load and contaminates downstream equipment.

✅ ️Problem Solved

Mining operations using steel liners in transfer chutes saw accelerated wear when processing abrasive ores and aggregates, leading to uneven surfaces that increased turbulence and reduced flow uniformity. Polymer liners could not maintain rigidity when the chute temperature rose during continuous operation, resulting in deformation and premature replacement. After adopting ADCERAX® Silicon Carbide Ceramic Plate, the transfer system maintained a consistent surface condition due to its high hardness and thermal stability, even during extended operation. The plant recorded fewer interruptions for liner removal and cleaning, and flow stabilization improved downstream classification consistency. Over time, the reduced wear rate helped sustain a more predictable material handling cycle.

-

Acid-Gas and Chemical Tower Internals for Corrosive Processing Systems

✅Key Advantages

1. Resistance to Acidic and Alkaline Vapors

The plate remains chemically stable in environments containing H₂SO₄, HCl, HNO₃, and alkaline vapors such as NaOH and KOH. This prevents the pitting and surface breakdown that metals experience under similar conditions.

2. Structural Integrity Under Thermal–Chemical Coupling

Its mechanical strength of ≥2200 MPa compressive capacity enables sustained load-bearing performance when temperature and corrosive gas concentration fluctuate simultaneously. This avoids the softening and rigidity loss observed in polymer-based internals.

3. Non-Reactive Behavior in High-Chlorine Conditions

The inertness of SiC under high-chlorine atmospheres prevents chemical reactions that compromise internal tower components. This ensures predictable stability during extended exposure to corrosive streams.

✅ ️Problem Solved

Chemical processing towers handling acidic condensates and chlorinated vapors experienced surface degradation when using metal internals, with corrosion pits forming after repeated exposure to combined thermal and chemical stresses. Polymer-based panels distorted and lost mechanical rigidity when temperatures increased, further complicating structural reliability. ADCERAX® Silicon Carbide Ceramic Plate maintained dimensional and chemical stability under these mixed conditions due to its corrosion-resistant SiC matrix and high compressive strength. A processing facility reported significantly fewer internal panel replacements after switching to SiC, noting improved operational continuity across cycles involving fluctuating gas compositions. The stability of the plates reduced inspection frequency and helped maintain consistent internal flow distribution.

Practical User Guide for ADCERAX® Silicon Carbide Ceramic Plates

The Silicon Carbide Ceramic Plates require proper inspection, handling, installation, and maintenance to ensure consistent performance in demanding thermal, abrasive, and corrosive industrial environments.

-

Pre-Use Inspection Requirements

1. Check for Surface Integrity:

Inspect the plate surfaces under adequate lighting to confirm the absence of cracks, edge chipping, or structural abnormalities. This ensures stable load support during thermal cycling. Any visible defect should be addressed before installation to prevent unexpected structural failure.

2. Confirm Cleanliness Before Use:

Wipe the plate surface with a clean, lint-free cloth to remove dust or particulates accumulated during storage or transportation. Contamination can alter thermal transmission or create localized stress points during heating. Maintaining a clean surface helps preserve long-term dimensional stability.

3. Verify Material Labeling:

Ensure the identification label or batch marking is intact and corresponds to the required SiC grade. Proper traceability supports accurate configuration in high-temperature or chemical processing environments. A clear label also helps maintain a consistent replacement strategy across production cycles.

-

Safe Handling and Transportation Guidelines

1. Use Controlled Handling Movements:

Transport the plate using both hands or mechanical support to avoid collision with hard surfaces. Sudden impact can induce micro-fractures not visible during routine checks. Controlled movement reduces the risk of load-bearing degradation during service.

2. Avoid Exposing the Plate to Unstable Loads:

Do not stack uneven weights directly on the plate during internal transfer. Excess point loading may create bending stress, especially before installation. Maintaining uniform support prevents premature mechanical distortion.

3. Keep the Plate Away from Moisture During Transfer:

Although SiC is chemically stable, prolonged moisture contact during handling can affect surrounding packaging and installation preparation. A dry environment ensures safe transition into high-temperature systems. Proper moisture control supports consistent operational reliability.

-

Installation Best Practices for Industrial Systems

1. Ensure Stable Mounting Surfaces:

Verify that the support frame or mounting zone is flat, rigid, and free from embedded debris. Uneven contact may cause localized stress concentration during heating cycles. A stable platform preserves thermal uniformity and flatness retention.

2. Maintain Proper Gap Allowance in Thermal Systems:

Position the plate with sufficient clearance from adjacent components to accommodate natural thermal expansion. This prevents frictional wear when operating at elevated temperatures. Adequate spacing minimizes the risk of edge-related structural interference.

3. Confirm Secure Placement Before Operation:

Check that the plate sits correctly within its holding structure before initiating thermal or chemical processes. Misalignment can lead to vibration or unexpected mechanical stress. Proper alignment supports predictable process stability.

-

Storage, Maintenance, and Service Life Guidelines

1. Store in a Dry, Ventilated Environment:

Keep plates in moisture-free conditions with adequate airflow to prevent long-term environmental stress on packaging materials. Avoid proximity to corrosive vapors or volatile chemicals. Controlled storage maintains steady performance characteristics.

2. Follow Scheduled Cleaning Routines:

Use non-reactive cleaning tools to remove process residues after each operational cycle. Avoid abrasive brushes that might alter the surface texture. Regular cleaning helps retain optimal heat transfer performance.

3. Document Service Cycles for Replacement Planning:

Record operating hours, temperature exposure, and any observed physical changes. Tracking these factors allows more accurate planning for replacement intervals in continuous production environments. Documentation helps maintain predictable maintenance control.

![]()