Aluminum silicate fiber gasket is a high-temperature sealing and insulation component made from alumino-silicate (ceramic) fiber paper or board that has been cut or die-cut into specific shapes such as rings, frames, strips or custom profiles. This alumino-silicate ceramic fiber is a lightweight refractory material, typically with a classification temperature around 1100–1260 °C (≈2010–2300 °F), low thermal conductivity and good resistance to thermal shock, so the gasket can maintain a seal at elevated temperatures without collapsing or melting.

Aluminum Silicate Fiber Gasket Benefits

-

Stable high-temperature sealing

Designed for continuous operation in the 800–1100 °C range with classification up to 1260 °C, suitable for furnace doors and burner surrounds. -

Low thermal conductivity for energy saving

The insulating aluminum silicate fiber structure reduces heat loss through doors and joints, supporting lower fuel consumption and more stable process temperature. -

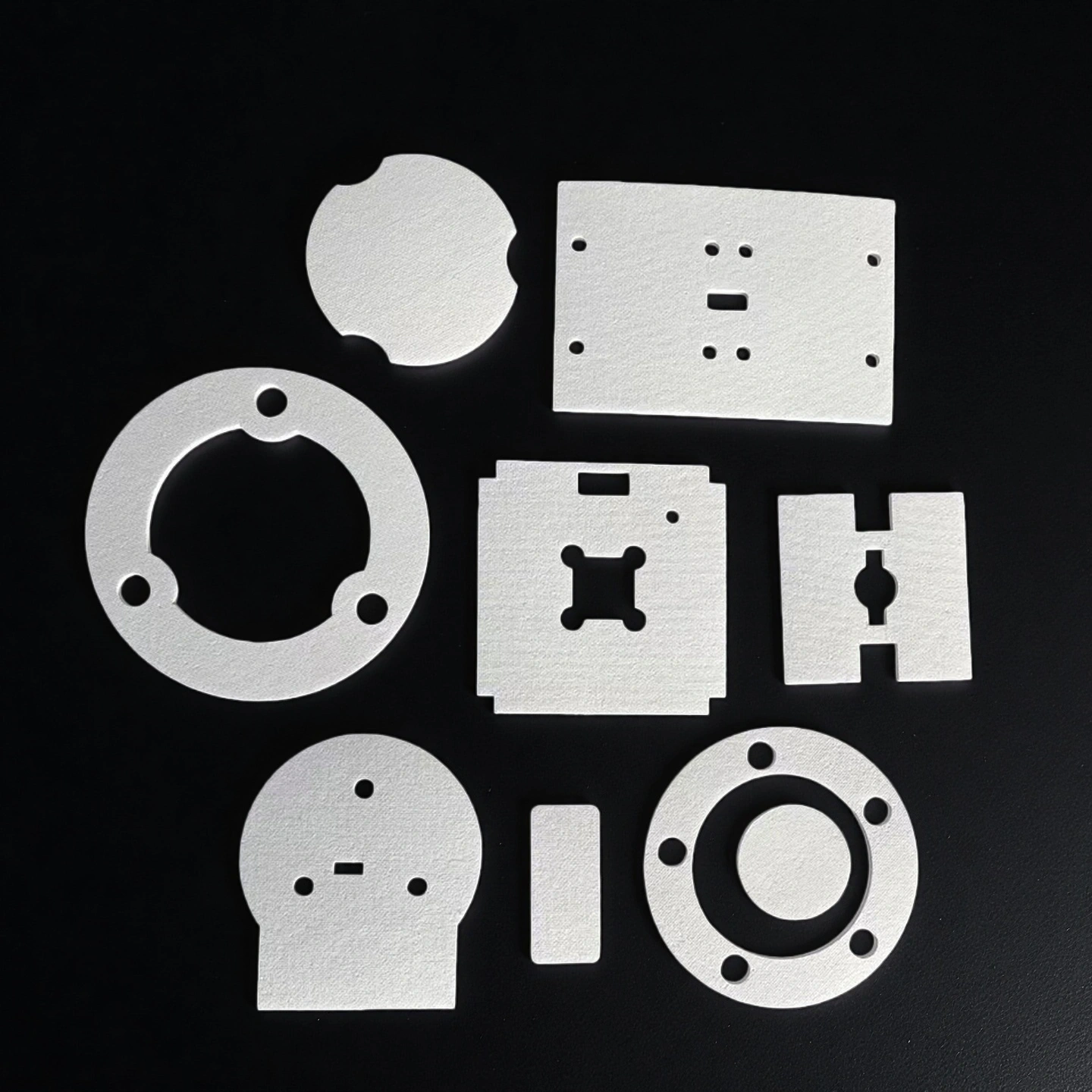

Flexible die-cut geometry

Parts can be produced as rings, frames, multi-hole plates and complex profiles from board or paper stock, matching existing metalwork without design changes. -

Clean, asbestos-free composition

The ceramic fiber base contains no asbestos and is engineered for industrial high-temperature insulation and sealing applications. -

Good compression and recovery

The material compresses under bolt load to fill surface irregularities and maintains contact over multiple heat-up and cool-down cycles where metal parts move with thermal expansion.

Aluminum Silicate Fiber Gaskets Properties

| Item | General Grade | Standard Grade | High Purity Grade | High Alumina Grade | Zirconia-Containing Grade |

| Classification Temperature (°C) | 1100 | 1260 | 1260 | 1360 | 1430 |

| Service Temperature (°C) | <1000 | 1050 | 1100 | 1200 | 1350 |

| Color | White | Off-white | Off-white | Off-white | Off-white |

| Bulk Density (kg/m³) | 260–320 | 260–320 | 260–320 | 260–320 | 260–320 |

| Permanent Linear Shrinkage (%) (24 h holding; based on 128 kg/m³) | <2.5 (1000°C) | <2.5 (1050°C) | <2.5 (1100°C) | <2.5 (1100°C) | <2.5 (1350°C) |

| Thermal Conductivity (W/m·K) (bulk density 128 kg/m³) | 0.085 (400°C) | 0.085 (400°C) | 0.085 (400°C) | 0.085 (400°C) | 0.085 (400°C) |

| 0.132 ( 800°C) | 0.132 ( 800°C) | 0.132 ( 800°C) | 0.132 ( 800°C) | 0.132 ( 800°C) | |

| 0.180 (1000°C) | 0.180 (1000°C) | 0.180 (1000°C) | 0.180 (1000°C) | ||

| Tensile Strength (MPa) (bulk density 128 kg/m³) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Chemical Composition (wt%) | |||||

| Al₂O₃ | 44 | 46 | 47–49 | 52–55 | 39–40 |

| Al₂O₃ + SiO₂ | 96 | 97 | 99 | 99 | – |

| Al₂O₃ + SiO₂ + ZrO₂ | – | – | – | – | 99 |

| ZrO₂ | – | – | – | – | 15–17 |

| Fe₂O₃ | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 |

| Na₂O + K₂O | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 |

Aluminum Silicate Ceramic Fiber Gaskets Specifications

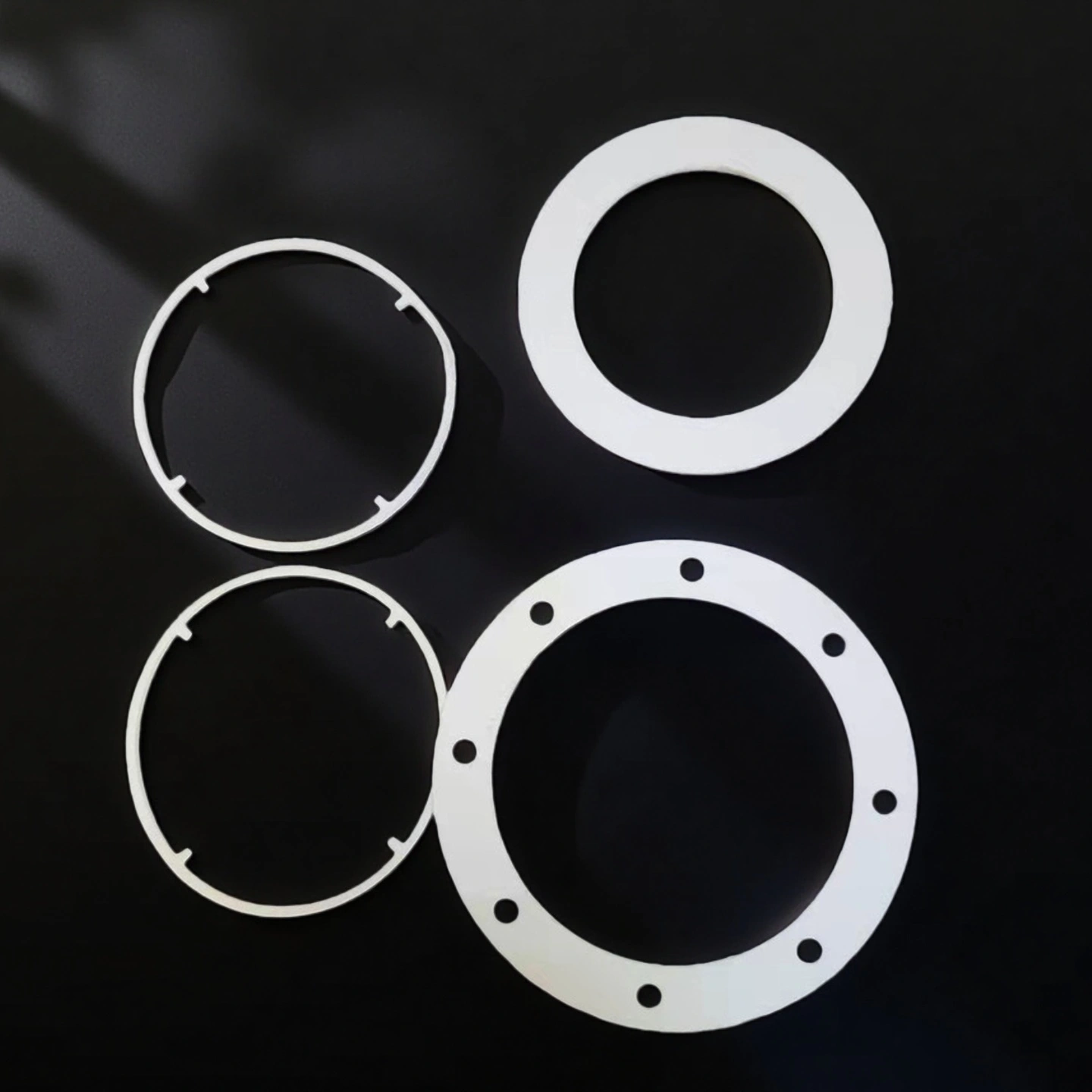

Type 1: Round Aluminum Silicate Fiber Gasket

| Item | Outer Dia *Inner Dia(mm) | Thickness (mm) | Operating Temperature(°c) |

| AT-GSL-DP1001 | 107*61 | 1-10 | 1260 |

| AT-GSL-DP1002 | 115*65 | 3 | 1260 |

| AT-GSL-DP1003 | 115*95 | 3 | 1260 |

| AT-GSL-DP1004 | 115*99 | 3 | 1260 |

| AT-GSL-DP1005 | 155*95 | 3 | 1260 |

| AT-GSL-DP1006 | 178*100 | 1-10 | 1260 |

| AT-GSL-DP1007 | 208*188 | 1-10 | 1260 |

| AT-GSL-DP1008 | 230*70 | 1-10 | 1260 |

| AT-GSL-DP1009 | 210*150 | 1-10 | 1260 |

| AT-GSL-DP1010 | 360*420 | 1-10 | 1260 |

| AT-GSL-DP1011 | 460*230 | 1-10 | 1260 |

| AT-GSL-DP1012 | 1220*610 | 1-10 | 1260 |

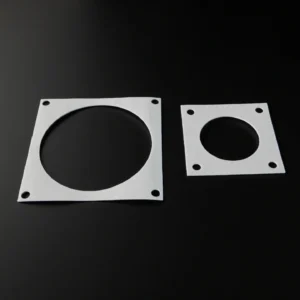

Type 2: Square Aluminum Silicate Fiber Gasket

| Item | Length *Width (mm) | Thickness (mm) | Operating Temperature(°C) |

| AT-GSL-DP2001 | 61*61 | 1-10 | 1260 |

| AT-GSL-DP2002 | 1220*610 | 1-10 | 1260 |

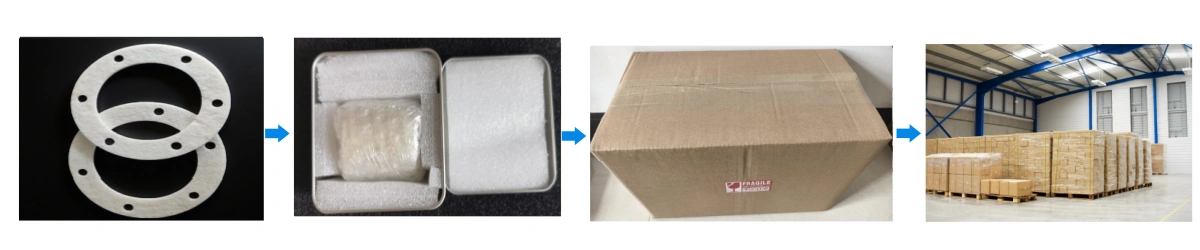

Aluminum Silicate Fiber Gaskets Packaging

- Gaskets are wrapped in moisture-resistant inner bags or paper to minimize dust and protect edges during transport.