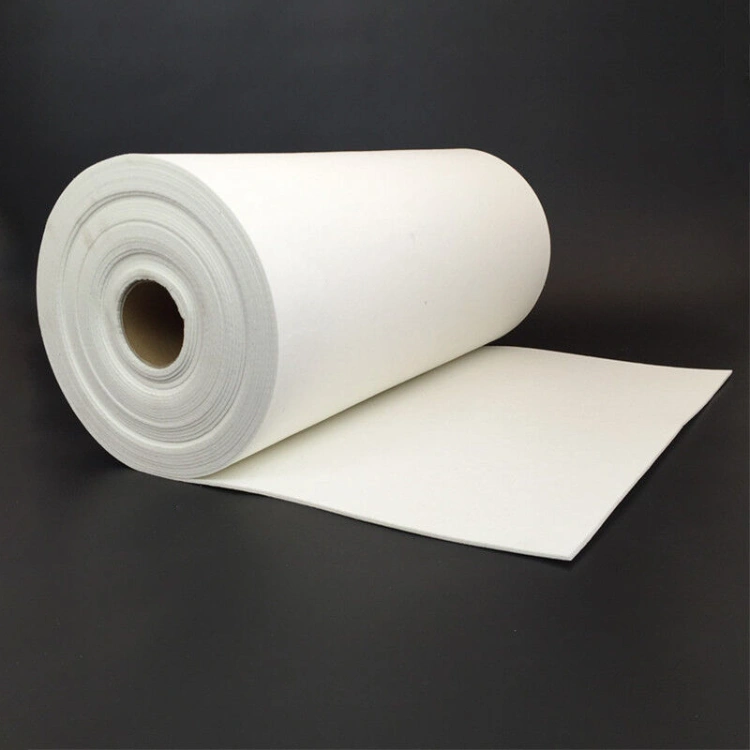

Aluminum silicate fiber paper is a thin, flexible high-temperature insulation sheet made from alumina–silica ceramic fibers with a small amount of organic binder, formed into uniform rolls or sheets. It is designed for continuous use at elevated temperatures (typically up to around 1260 °C, depending on grade) and is used as a lightweight thermal barrier and sealing material in industrial furnaces, kilns, heaters and non-ferrous metal systems.

Aluminum Silicate Ceramic Fiber Paper Benefits

-

Thin yet efficient insulation

Achieves significant heat loss reduction in thicknesses from 1–5 mm, ideal as a backup or interface layer in dense refractory linings. -

Clean-burning binder and low shot content

Fiber-washing and controlled binder levels help minimize unfiberized shot and smoke during first heat-up, reducing contamination risk in metal and glass processes. -

Dimensional uniformity for precise sealing

Tight control of thickness and density across the roll ensures consistent compression and sealing performance along furnace doors and access ports. -

Good chemical resistance in industrial atmospheres

Resists most common furnace atmospheres and many process chemicals, making it suitable for petrochemical heaters, non-ferrous casting and thermal oxidizers. -

Easy processing into gaskets and strips

Can be die-cut, water-jet cut, or slit into narrow strips without fraying, simplifying installation and replacement work.

Aluminum Silicate Ceramic Fiber Paper Properties

| Item | General Grade | Standard Grade | High Purity Grade | High Alumina Grade | Zirconia-Containing Grade |

| Classification Temperature (°C) | 1100 | 1260 | 1260 | 1360 | 1430 |

| Service Temperature (°C) | <1000 | 1050 | 1100 | 1200 | 1350 |

| Color | White | Off-white | Off-white | Off-white | Off-white |

| Bulk Density (kg/m³) | 260–320 | 260–320 | 260–320 | 260–320 | 260–320 |

| Permanent Linear Shrinkage (%) (24 h holding; based on 128 kg/m³) | <2.5 (1000°C) | <2.5 (1050°C) | <2.5 (1100°C) | <2.5 (1100°C) | <2.5 (1350°C) |

| Thermal Conductivity (W/m·K) (bulk density 128 kg/m³) | 0.085 (400°C) | 0.085 (400°C) | 0.085 (400°C) | 0.085 (400°C) | 0.085 (400°C) |

| 0.132 ( 800°C) | 0.132 ( 800°C) | 0.132 ( 800°C) | 0.132 ( 800°C) | 0.132 ( 800°C) | |

| 0.180 (1000°C) | 0.180 (1000°C) | 0.180 (1000°C) | 0.180 (1000°C) | ||

| Tensile Strength (MPa) (bulk density 128 kg/m³) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Chemical Composition (wt%) | |||||

| Al₂O₃ | 44 | 46 | 47–49 | 52–55 | 39–40 |

| Al₂O₃ + SiO₂ | 96 | 97 | 99 | 99 | – |

| Al₂O₃ + SiO₂ + ZrO₂ | – | – | – | – | 99 |

| ZrO₂ | – | – | – | – | 15–17 |

| Fe₂O₃ | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 |

| Na₂O + K₂O | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 |

Aluminum Silicate Fiber Paper Specifications

| Item | Thickness(mm) | Length*Width(m) | Classification Temperature(℃) |

| AT-GSL-Z1001 | 2 | 1*0.61 | 1260 |

| AT-GSL-Z1002 | 3 | 1*0.61 | 1260 |

| AT-GSL-Z1003 | 4 | 1*0.61 | 1260 |

| AT-GSL-Z1004 | 5 | 1*0.61 | 1260 |

| AT-GSL-Z1005 | 6 | 1*0.61 | 1260 |

| AT-GSL-Z1006 | 8 | 1*0.61 | 1260 |

| AT-GSL-Z1007 | 10 | 1*0.61 | 1260 |

| AT-GSL-Z1008 | 0.5 | 6*0.61 | 1260 |

| AT-GSL-Z1009 | 1 | 60*0.61 | 1260 |

| AT-GSL-Z1010 | 2 | 30*0.61 | 1260 |

| AT-GSL-Z1011 | 3 | 20*0.61 | 1260 |

| AT-GSL-Z1012 | 4 | 15*0.61 | 1260 |

| AT-GSL-Z1013 | 5 | 12*0.61 | 1260 |

| AT-GSL-Z1014 | 6 | 10*0.61 | 1260 |

| AT-GSL-Z1015 | 8 | 7.5*0.61 | 1260 |

| AT-GSL-Z1016 | 10 | 6*0.61 | 1260 |

| AT-GSL-Z1017 | 0.5 | 6*0.22 | 1260 |

| AT-GSL-Z1018 | 1 | 60*1.22 | 1260 |

| AT-GSL-Z1019 | 2 | 30*1.22 | 1260 |

| AT-GSL-Z1020 | 3 | 20*1.22 | 1260 |

| AT-GSL-Z1021 | 4 | 15*1.22 | 1260 |

| AT-GSL-Z1022 | 5 | 12*1.22 | 1260 |

| AT-GSL-Z1023 | 6 | 10*1.22 | 1260 |

| AT-GSL-Z1024 | 8 | 7.5*1.22 | 1260 |

| AT-GSL-Z1025 | 10 | 6*1.22 | 1260 |

Aluminum Silicate Fiber Paper Packaging