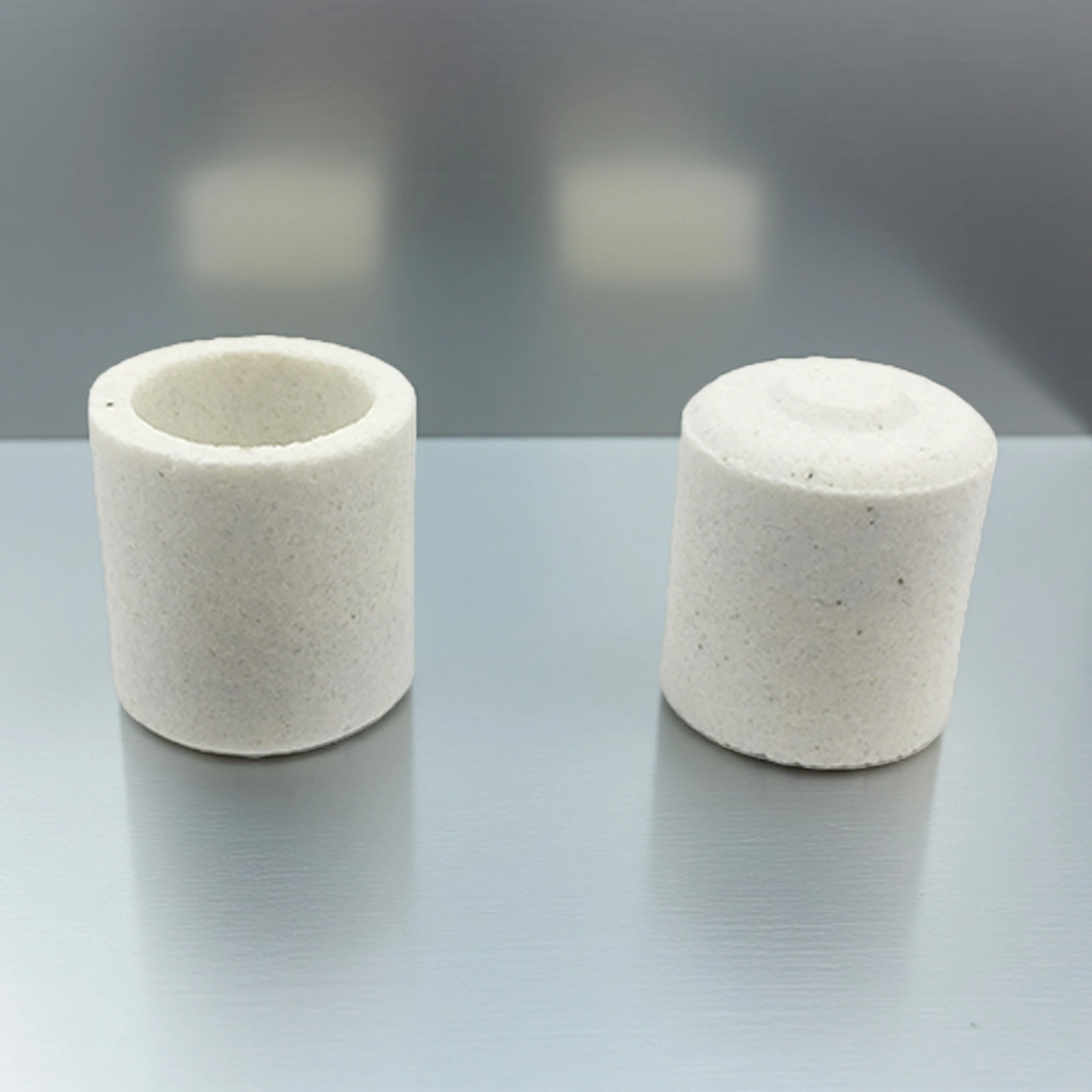

Carbon sulfur ceramic crucible is a high-temperature ceramic consumable used in carbon & sulfur (C/S) analyzers (typically combustion + infrared detection). It holds the sample (often steel, iron, alloys, ores, cement, or carbon materials) during combustion so the instrument can measure carbon and sulfur content reliably.

Carbon sulfur ceramic crucible Benefits

-

Low-blank grade control (C/S background): Low-blank targets such as C < 3 ppm and S < 2 ppm help reduce baseline contribution, improving repeatability for ppm-level reporting and lowering the need for confirmation burns.

-

Dimensional repeatability for autosampler seating: Stable OD/height/rim geometry supports consistent pickup, transfer, and seating in analyzer crucible trays, reducing mis-seating and intermittent run stops during long queues.

-

Preheat-ready consistency: Designed to stay consistent through workflows that use a preheat step around 1100°C for ~10 minutes, helping maintain predictable burn initiation and reducing variation between early and late runs.

-

Lid-fit consistency (cover + vent options): Controlled lid seating and optional hole configurations help standardize combustion conditions when covers are used, improving method-to-method comparability and limiting run-to-run drift.

-

Lot-to-lot repeatability for faster qualification: Consistent batch behavior supports second-source approval with fewer internal checks, making it easier to lock one consumable baseline across routine testing cycles.

Carbon Sulfur Ceramic Crucible Properties & Specifications

- Dimension: 25mm × 25mm

- Main Material: Fused Quartz/Al2o3+Sio2

- Blank Value of Carbon & Sulfur: C < 5 ppm, S < 5 ppm

- Max. Working Temperature: 1400°C

- Max. Temperature of Rapid Changes: Up to 350°C

- Max. Physical Pressure: 45,000 psi

- Product Quantity: 1000 PCS / CTN

- Product Sample Service: Free Offer

- Compatible Instruments Consumables No.:Bruker G4 Icarus CS Bruker: JW-N009250423

Carbon Sulfur Ceramic Crucible Packaging

- Sealed clean packaging to limit dust transfer during storage and bench handling