Transparent Ceramic Solutions for Industrial and Optical Markets

We specialize in ALON, spinel, and transparent alumina ceramics, delivering precision-engineered windows, domes, plates, and protective optics for laser, infrared, and high-temperature applications. Our factory team provides end-to-end support—from material selection and drawing review to precision machining, polishing, and advanced AR/DLC coatings—ensuring every part achieves superior clarity, mechanical strength, and thermal stability.

🏭At ADCERAX, we bring over 20 years of manufacturing experience in transparent ceramics, mastering multiple forming, sintering, and finishing techniques to customize complex optical components that meet diverse industrial needs.

👉Discover how our custom transparent ceramic solutions can redefine your optical performance and project success.

What is Transparent Ceramic?

Transparent Ceramics Definition

Transparent ceramic is a polycrystalline optical material engineered to combine glass-like transparency with the mechanical strength and thermal stability of advanced ceramics. Unlike conventional glass, it is formed by precisely controlling grain size, density, and impurities during sintering—eliminating light-scattering defects and allowing visible, infrared, or ultraviolet transmission.

Transparent Ceramic Materials

Transparent ceramics can be produced from several advanced oxide and oxynitride materials.

The most common include ALON (aluminum oxynitride), spinel (MgAl₂O₄), transparent alumina (Al₂O₃), and yttria (Y₂O₃).

Each material offers different optical and mechanical characteristics suitable for laser systems, infrared sensing, lighting optics, and structural protection.

At ADCERAX, we provide these four major transparent ceramic materials, along with custom composite formulations, to support various industrial and research requirements.

| Material Type | Chemical Composition | Laser/IR/Lighting/Structural |

| ALON Transparent Ceramic | Aluminum Oxynitride (Al₍₂₃₎O₂₇N₅) | Infrared domes, transparent armor windows, optical sensor protection, aerospace optics |

| Transparent Spinel Ceramic | Magnesium Aluminate (MgAl₂O₄) | Laser-grade windows, electro-optical housings, visible–NIR sensor covers, optical protection plates |

| Transparent Alumina Ceramic | Aluminum Oxide (Al₂O₃) | High-temperature viewing windows, lighting optics, furnace sight glasses, protective covers |

| Yttria Transparent Ceramic | Yttrium Oxide (Y₂O₃) | Mid-infrared optics, laser gain media, high-heat resistant optical components, precision instruments |

Transparent Ceramic Manufacture

From high-purity alumina and oxynitride powders to precision-polished optical components, ADCERAX controls every stage of transparent ceramic manufacture. Our in-house process covers forming, sintering, polishing, and coating preparation, ensuring optical-grade clarity, uniform density, and mechanical strength across all transparent ceramic parts.

Selection and blending of high-purity oxide or oxynitride powders to ensure uniform composition and particle size.

Compacting powders through pressing, slip casting, or isostatic forming into pre-sintered shapes.

Densification under controlled temperature and atmosphere to eliminate internal pores and improve transparency.

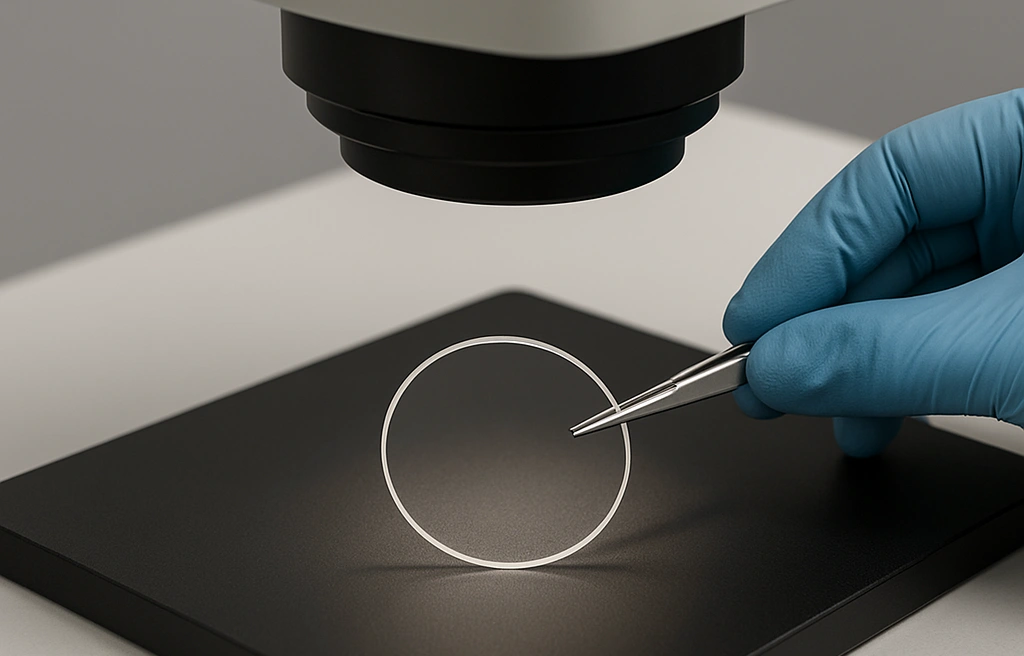

Precision grinding and multi-stage polishing to achieve flatness, figure, and surface roughness for optical use.

Cleaning and surface activation for AR/DLC or hydrophobic coatings.

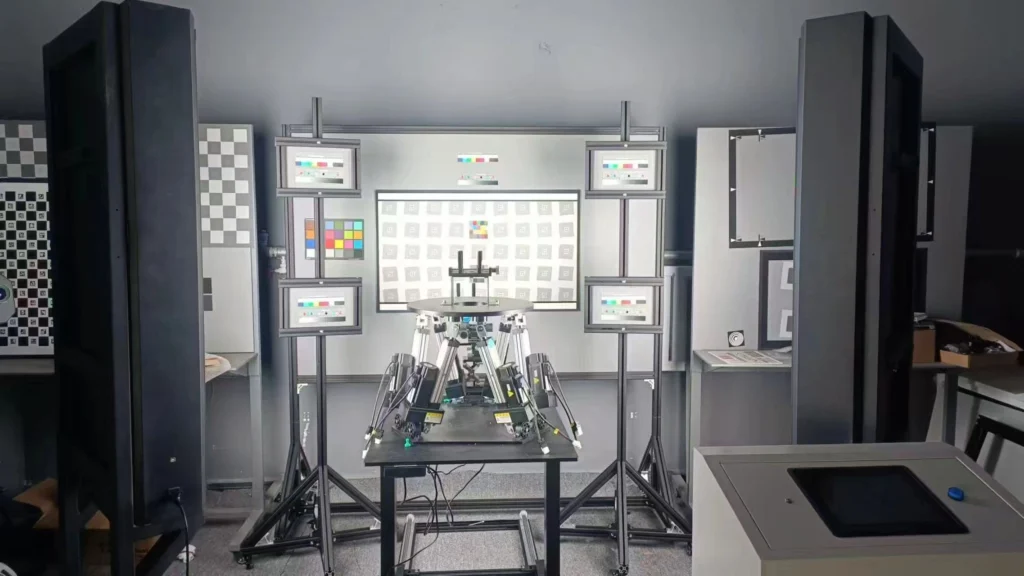

Transmission, haze, and dimension inspection under controlled conditions.

Transparent Ceramic Properties

Each transparent ceramic material demonstrates a unique performance balance between optical clarity, strength, and temperature resistance.

ADCERAX ensures these parameters are precisely controlled during production—providing dependable, repeatable results for laser optics, infrared domes, and protective optical components worldwide.

⚡Transparent Aluminum Oxide Ceramic

Transparent alumina ceramic (Al₂O₃) combines excellent clarity with extreme hardness and thermal shock resistance. It is widely used for high-temperature viewing ports, lighting optics, and protective covers.

| Property | Typical Value / Range | Performance Highlights / Notes |

|---|---|---|

| Optical Transmission | 75–80% (0.6–4 μm) | High clarity in visible–IR range |

| Refractive Index (n) | 1.76 | Stable refractive behavior at elevated temperature |

| Hardness (Vickers) | 1900 HV | Excellent wear and abrasion resistance |

| Flexural Strength | 400–600 MPa | High load-bearing strength |

| Thermal Expansion (CTE) | 8.1 ×10⁻⁶ /K | Compatible with metal housings |

| Working Temperature | up to 1500 °C | Excellent thermal shock resistance |

| Density | 3.9 g/cm³ | High mechanical stability |

| Dielectric Strength | 12 kV/mm | Superior electrical insulation properties |

🔥Transparent AlN Ceramic (Aluminum Nitride)

AlN Transparent ceramic (aluminum nitride) offers high thermal conductivity, electrical insulation, and optical transparency in the infrared range. It is ideal for laser components, infrared windows, and high-power electronic packaging requiring both heat dissipation and optical clarity.

| Property | Typical Value / Range | Performance Highlights / Notes |

|---|---|---|

| Optical Transmission | 70–80% (0.8–5 μm) | Excellent infrared transparency |

| Refractive Index (n) | 2.12 | Stable optical properties across IR spectrum |

| Hardness (Vickers) | 1100 HV | Moderate hardness with excellent polishability |

| Flexural Strength | 300–450 MPa | Maintains strength under thermal load |

| Thermal Expansion (CTE) | 4.5 ×10⁻⁶ /K | Excellent dimensional stability |

| Working Temperature | up to 1000 °C | Reliable for high-heat optical environments |

| Density | 3.3 g/cm³ | High purity, fully dense sintered structure |

| Thermal Conductivity | 170–200 W/m·K | Exceptional heat dissipation performance |

⚙️Yttria Transparent Ceramic (Y₂O₃)

Yttria transparent ceramic (Y₂O₃) delivers superior infrared transmission and outstanding heat tolerance. It is suited for laser gain media, IR optics, and precision optical instruments.

| Property | Typical Value / Range | Performance Highlights / Notes |

|---|---|---|

| Optical Transmission | 78–85% (0.6–6 μm) | Outstanding mid-IR transparency |

| Refractive Index (n) | 1.84 | High refractive index for IR optics |

| Hardness (Vickers) | 650 HV | Softer, easy to machine and polish |

| Flexural Strength | 150–250 MPa | Stable performance for optical assemblies |

| Thermal Expansion (CTE) | 7.7 ×10⁻⁶ /K | Good compatibility with IR mounts |

| Working Temperature | up to 1900 °C | Excellent oxidation and heat resistance |

| Density | 5.0 g/cm³ | High optical density and stability |

| Dielectric Strength | 11 kV/mm | Reliable for high-power IR laser systems |

🔧ALON Transparent Ceramic (Aluminum Oxynitride)

ALON transparent ceramic (aluminum oxynitride) offers high optical clarity, strength, and heat resistance. Its dense microstructure ensures durability and scratch resistance for infrared domes, armor, and optical windows.

| Property | Typical Value / Range | Performance Highlights / Notes |

|---|---|---|

| Optical Transmission | 80–85% (0.4–5 μm) | Broad VIS–IR transmission; minimal scattering |

| Refractive Index (n) | 1.79 | Stable index across optical wavelengths |

| Hardness (Vickers) | ~1800 HV | Extremely hard; ideal for transparent armor |

| Flexural Strength | 350–550 MPa | Maintains strength under thermal stress |

| Thermal Expansion (CTE) | 8.0 ×10⁻⁶ /K | Compatible with optical coatings and metals |

| Working Temperature | up to 1200 °C | Reliable clarity under high heat |

| Density | 3.7 g/cm³ | Fully dense microstructure; no pores |

| Dielectric Strength | 10 kV/mm | Stable insulation for optical windows |

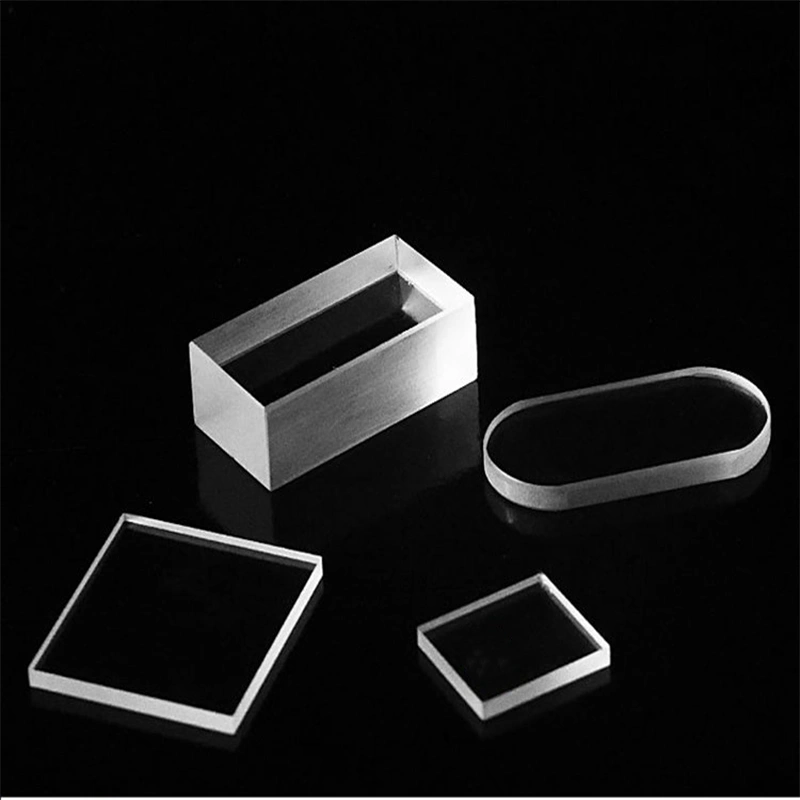

Transparent Ceramic Products

ADCERAX supplies transparent ceramic and sapphire optics—including substrates, optical windows, tubes, and yttria covers—engineered for laser and IR systems. Every component is verified for transmission and haze and ships with full dimensional inspection for stable, repeatable performance.

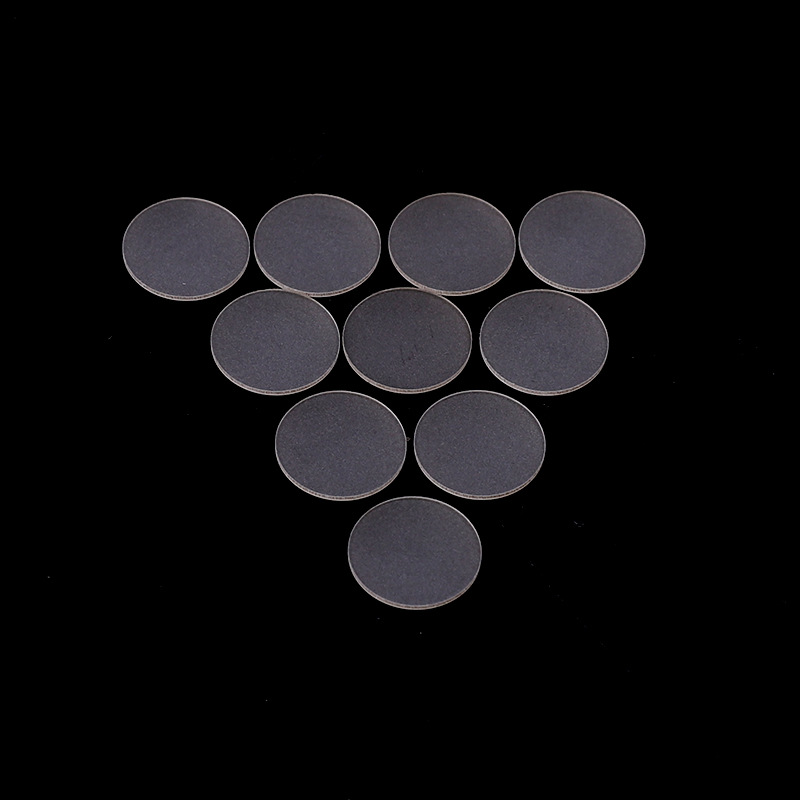

Transparent alumina ceramic substrates offer outstanding optical clarity, hardness, and thermal stability for high-power and optical systems.

- 🔹Surface flatness: ≤ 2 µm for precision optical alignment

- 🔹Hardness: rated 9 on Mohs scale for superior scratch resistance

- 🔹Refractive index: 1.76 for high optical transmission and clarity

Sapphire optical glass windows deliver high transparency, hardness, and stability for optical and industrial systems. They ensure consistent clarity and performance under heat, pressure, and vacuum conditions.

- 🔹Optical transmission: 85–90% from 0.2–5 μm wavelength range

- 🔹Refractive index: 1.76 ensures stable clarity across UV–IR spectrum

- 🔹Hardness: 9 on Mohs scale for extreme scratch and impact resistance

Transparent aluminum oxide ceramic tubes offer high hardness, clarity, and heat resistance for optical and thermal systems. They maintain precision and insulation under extreme temperatures.

- 🔹Surface finish: polished bore Ra < 10 nm for clean flow and IR clarity

- 🔹Excellent dielectric and chemical stability for heaters and sensors

- 🔹Insulation: dielectric strength ≈ 9 kV/mm for safe high-voltage use

Yttrium oxide transparent ceramic covers offer high IR clarity, strength, and insulation under extreme temperatures.

- 🔹 Optical transmission: 80–85% in the 0.6–6 μm range

- 🔹 Thermal conductivity: about 12 W/m·K for stable heat dispersion

- 🔹 Dielectric strength: around 11 kV/mm for safe insulation integrity

💡Clear Strength. Optical Precision. ADCERAX Transparent Ceramic Solutions.

Every ADCERAX clear ceramic is engineered for clarity, strength, and performance —delivering superior transmission, tighter tolerance, and higher heat stability in the world’s toughest optical and industrial applications.

Transparent Ceramics Applications

Transparent ceramic glass is widely applied across industries where visibility, durability, and precision alignment are critical. They are used in laser and optical systems, aerospace and defense optics, semiconductor processing equipment, high-temperature furnaces, and scientific instruments.

🏭 Laser and Optical Systems

Application: Laser gain media, optical windows, sensor domes, and beam alignment lenses.

Challenges: High-energy lasers generate extreme heat and stress, often causing deformation or optical distortion in glass components.

- 🧩 ADCERAX Solution:

By using ALON and Yttria transparent ceramics, ADCERAX ensures thermal stability above 1800 °C, minimal refractive deviation (<0.5%), and long-term clarity even after repeated pulse exposure.

- 🌐Transparent Ceramics examples:

A German precision laser equipment OEM adopted ADCERAX transparent ALON windows to replace quartz glass in high-power cutting systems.

After 9 months of 24-hour operation, transmission stability improved by 21 %, and optical distortion decreased below 0.3 mrad.

Component lifetime extended 3.2×, reducing maintenance interruptions by 43 % and improving system uptime.

🔥 Semiconductor & High-Temperature Equipment

Application: Transparent furnace viewports, process monitoring windows, and protective sight glasses.

Challenges: Furnace environments exceeding 1700 °C cause ordinary materials to devitrify or contaminate optical paths.

- 🧩 ADCERAX Solution:

ADCERAX transparent alumina ceramics offer thermal stability up to 1900 °C and maintain purity > 99.9 %, ensuring consistent process visibility.

- 🌐Transparent Ceramics Examples:

A Japanese furnace manufacturer integrated ADCERAX transparent alumina viewports for real-time wafer inspection at 1900 °C. Window failure rates dropped from 18 % to 2 %, and visual accuracy improved by 11 % in automated detection systems.The transparent ceramics maintained optical clarity after 1,000+ heating cycles, supporting uninterrupted production for over a year.

💡Lighting and Energy Systems

Application: High-intensity discharge lamps, LED encapsulation lenses, and IR-transparent covers.

Challenges: Long exposure to high heat and UV leads to discolouration, cracking, and reduced luminous efficiency.

- 🧩 ADCERAX Solution:

ADCERAX’s yttrium-based transparent ceramics maintain > 90 % light transmittance and resist thermal degradation up to 1600 °C, ensuring long-term optical stability.

- 🌐Transparent Ceramics examples:

An Italian infrared lighting producer replaced quartz covers with ADCERAX yttria-based transparent ceramics in 1 kW lamp modules.

After 2,000 hours of continuous operation, light transmission loss was only 4 %, compared with 17 % for fused silica.

Component life doubled, and replacement costs were reduced by 35 %, improving total energy efficiency and reliability.

🔬 Scientific & Analytical Instruments

Application: Spectroscopy cells, optical windows, and radiation shields.

Challenges: Demand for precise optical calibration and zero interference from material defects.

- 🧩 ADCERAX Solution:

ADCERAX transparent ceramics offer surface roughness < 0.05 μm and optical uniformity > 99.8 %, meeting research-grade performance standards.

- 🌐Transparent Ceramics examples:

A European laboratory adopted ADCERAX Y₂O₃ clear windows for high-temperature Raman spectrometry. After 600 thermal cycles, optical clarity remained stable with no haze formation or refractive shift above 0.1 %.

Signal-to-noise ratio improved by 23 %, enhancing precision in spectroscopic calibration and analytical consistency.

Customize Transparent Ceramic Supplier

ADCERAX specializes in custom transparent ceramics, offering precision machining, optical polishing, and coating-ready finishes. Parts are made to your drawings or samples with tight tolerances and delivered within 3–7 weeks under full inspection.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

ADCERAX – Precision Transparent Ceramic Manufacturer

ADCERAX is a trusted transparent ceramics factory, supplying high-purity optical components for laser and industrial use. We provide standard and custom parts with exceptional clarity, precision, and stability.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

ADCERAX integrates optical machining, polishing, coating preparation, and quality inspection into a unified workflow. Our one-stop approach ensures optical-grade clarity, precision fit, and faster delivery from prototype to production for high-performance transparent ceramics.

-

Precision Optical Manufacturing:

Each transparent ceramic part is produced to tight optical and dimensional tolerances (±0.05 mm),featuring fine-grain density and mirror-quality surfaces for laser, infrared, and sensor applications. -

Optical & Dimensional Consistency:

Every batch undergoes strict testing for transmission rate, haze, flatness, and refractive accuracy, ensuring uniform clarity and mechanical stability across all custom and standard parts. -

Engineering & Application Support:

ADCERAX engineers assist clients with material selection, coating preparation, and optical design compatibility, helping optimize performance, reliability, and alignment in advanced optical and industrial systems.

ADCERAX specializes in producing high-purity transparent ceramics, combining advanced optical forming, sintering, and polishing technologies with precision CNC machining and stringent inspection control. Each component is engineered for optical clarity, density consistency, and structural stability, ensuring reliability in laser, infrared, and high-temperature optical applications.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Capability Item | Typical Value / Description | ||

| Material Grades | High-purity ALON, Spinel, Yttria, and Transparent Alumina with ≥99.9% density and fine-grain structure for optical-grade transmission. | ||

| Dimension Range | Custom components from precision lenses and domes to large windows and tubes, machined to ±0.05–0.2 mm tolerance. | ||

| Forming Methods | Hot pressing, isostatic pressing (HIP/CIP), CNC machining, and optical polishing for stable microstructure and clarity. | ||

| Processing | Controlled sintering up to 1900 °C ensures full transparency, minimal porosity, and uniform optical properties. | ||

| Surface Finish | Optical polishing achieves surface roughness below Ra < 0.02 μm, suitable for AR/DLC coatings and optical assembly. | ||

FAQ

Transparent glass ceramics are materials formed by controlled crystallization of glass, combining glass-like transparency with ceramic-level strength and stability. They are considered among the toughest transparent ceramics, offering superior hardness and thermal resistance over conventional glass.

Most ceramics are opaque because of internal pores and grain boundaries that scatter light.

However, when produced with high-purity materials, fine grains, and controlled sintering, certain types become transparent ceramics—allowing light to pass through like glass.

These transparent ceramics combine optical clarity, strength, and heat resistance, making them suitable for high-performance optical and industrial applications.

Clear ceramics are stronger than glass because their atoms are arranged in a very organized, tight way like a brick wall. Glass atoms are messy, like a pile of sand.

- Organized Atoms: In ceramics, atoms link up strongly in a repeating pattern, making it hard for cracks to start and spread.

- Messy Atoms: In glass, atoms are jumbled, creating weak spots where cracks can easily form and cause shattering.

- Tiny Crystals: Many clear ceramics are made of tiny, tightly packed crystals. The borders between these crystals also help block cracks.

So, the orderly, strong way the atoms are connected in clear ceramics is why they can handle much more stress than the disorganized atoms in glass.

es, clear ceramics can be shaped and made smooth, but it takes special methods because they're so hard.

Machining:

- Lasers: Can precisely cut and drill without much stress.

- Diamond Grinding: Uses diamond tools to grind the material carefully.

- Ultrasonic: Uses vibrations and grit to slowly shape it.

Polishing:

- Diamond Polishing: Uses finer and finer diamond particles.

- Silica Polishing: Uses tiny silica bits in liquid to smooth the surface chemically.

- Lapping: Rubs the ceramic with grit to make it flat and smooth.

The best way to shape and smooth them depends on the specific ceramic and what it's being used for. Getting a really clear finish often means using this steps.

Transparent ceramics combine optical clarity with exceptional strength and heat resistance, outperforming glass and plastic in demanding environments.

Compared with glass, they offer higher hardness, thermal shock resistance, and longer service life under mechanical or thermal stress.

Compared with plastic optics, they maintain optical precision and transparency even above 1000 °C, where polymers degrade.

Transparent Ceramic vs. Other Transparent Materials:

| Feature | Transparent Ceramic | Glass | Plastics |

|---|---|---|---|

| Mechanical Strength | Very High (Excellent resistance to impact & abrasion) | Moderate (Prone to shattering) | Low (Easily scratched & damaged) |

| Thermal Stability | Excellent (High operating temperatures) | Moderate (Limited temperature resistance) | Low (Deforms at relatively low temperatures) |

| Optical Transmission | Broadband (UV to IR) | Visible Spectrum | Limited Spectrum |

| Chemical Resistance | Excellent (Inert to most chemicals) | Good (Susceptible to some chemicals) | Fair (Affected by many solvents) |

| Customizability | High (Complex shapes & tight tolerances) | Moderate (Limited shape complexity) | High (Easy to mold, but lower precision) |

| Maximum Use Temperature | Up to 2400°C | Up to 1500°C | Up to 300°C |

| Wear Resistance | Excellent | Ordinary | Poor |

This makes transparent ceramics ideal for infrared domes, laser optics, and high-temperature viewing systems where both clarity and durability are critical.

Depending on material type:

ALON transmits from 0.2–5 µm,

Spinel from 0.2–6 µm,

Yttria from 0.25–7 µm,

covering UV–IR bands ideal for sensor and laser optics.

Please provide material type, dimensions (OD/ID/Thickness), tolerance, surface finish, quantity, and drawing or sample. Our engineering team can assist with material selection and optical design matching before quotation.

Transparent ceramics can be used wherever optical clarity and mechanical strength are both required.

They serve as protective windows, lenses, domes, and covers in systems exposed to high temperature, pressure, or radiation, ensuring long-term optical performance and durability.

Transparent optical ceramics are high-performance materials designed for laser, infrared, and optical systems, offering superior transmission, hardness, and thermal stability.

At ADCERAX, a professional transparent ceramics manufacturer from China, we provide transparent ceramics for sale in both standard and custom sizes, ensuring optical-grade quality and full inspection before shipment.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Searching for a Trusted Transparent Ceramics Manufacturer in China?

Partner with ADCERAX for precision-engineered transparent ceramics, tailored to your drawings with full optical inspection, technical support, and fast global delivery.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours