High mechanical loads, brittle failure risks, and long-term reliability often limit material choices in demanding engineering systems. Consequently, zirconia ceramic strength attracts attention where conventional materials approach performance ceilings.

Zirconia ceramic combines unusually high strength with fracture resistance uncommon among ceramics. As a result, it has become a structural solution in applications where mechanical reliability and dimensional stability must coexist under severe service conditions.

To frame this discussion clearly, the following content establishes an intuitive understanding of zirconia ceramic strength before examining its quantitative performance and engineering implications.

Zirconia Ceramic Strength in Materials Science

Zirconia ceramic strength refers to the material’s ability to sustain mechanical stress without catastrophic fracture under practical service conditions. Rather than indicating surface resistance alone, strength reflects how reliably a component maintains integrity when subjected to bending, contact forces, or sustained loads. Consequently, zirconia is often categorized as a high-strength engineering ceramic rather than a conventional brittle ceramic.

In comparison with metals, zirconia ceramics exhibit higher compressive and bending strength but negligible plastic deformation, leading to different failure behavior. Polymers display large elastic deformation yet operate at stress levels several orders of magnitude lower. Traditional ceramics such as alumina or silica-based materials offer chemical stability but typically fail at lower mechanical stress thresholds. Within this landscape, zirconia occupies a unique position by delivering ceramic-level hardness combined with metal-like resistance to fracture initiation.

Among advanced engineering ceramics, zirconia ranks at the upper tier of mechanical strength. Typical zirconia components sustain stresses well beyond 800 MPa under bending, whereas many alumina ceramics remain below 500 MPa in comparable conditions. This elevated strength range explains why zirconia ceramic strength is frequently associated with load-bearing roles where other ceramics reach structural limits.

Typical Strength Values of Zirconia Ceramic Used in Engineering

Across demanding mechanical environments, zirconia ceramic strength is primarily assessed through quantified stress limits rather than qualitative descriptions. Accordingly, engineering users rely on reproducible strength ranges to evaluate whether zirconia can withstand anticipated service loads. When expressed through standardized mechanical testing, these values provide a direct and practical answer to how strong zirconia ceramic is in real use.

Strength data for zirconia ceramics consistently demonstrate performance well above conventional ceramics, while remaining stable across repeated loading cycles. Moreover, the concentration of strength values within relatively narrow ranges offers engineers confidence in predictable structural behavior. This reliability distinguishes zirconia ceramic strength from materials whose mechanical performance fluctuates widely with minor condition changes.

Representative strength ranges of common zirconia ceramic grades

Under controlled testing conditions, fully stabilized and partially stabilized zirconia ceramics exhibit distinct yet consistently high strength ranges. For example, 3 mol% yttria-stabilized zirconia commonly achieves flexural strength between 900 and 1,200 MPa, reflecting its suitability for load-bearing roles. Magnesium-stabilized zirconia typically occupies a lower yet still robust range, often 600–900 MPa, where dimensional stability under stress is prioritized.

In engineering environments such as precision fixtures or wear-resistant structural parts, these strength ranges translate into components capable of resisting significant bending forces without sudden fracture. Observations from long-term industrial use further indicate that zirconia ceramics maintain these strength levels across millions of loading cycles when surface integrity is preserved. As a result, zirconia ceramic strength is frequently specified with confidence margins comparable to some hardened metallic alloys.

The distinction between zirconia grades becomes relevant when stress profiles vary, yet all commercial structural grades exceed the mechanical limits of most oxide ceramics. Consequently, zirconia ceramic strength is rarely the limiting factor once appropriate grade selection is made.

Strength levels that differentiate zirconia from conventional ceramics

Conventional oxide ceramics such as alumina or mullite typically exhibit flexural strength values in the 250–500 MPa range. While sufficient for thermal or insulating functions, these levels restrict use in mechanically stressed assemblies. Zirconia ceramic strength, by contrast, often doubles or triples these values, enabling structural participation rather than passive support.

In applications involving localized bending or contact stress, this strength advantage directly affects component geometry. Thinner zirconia sections can safely replace bulkier ceramic parts while maintaining mechanical safety factors. Empirical data from high-load assemblies show zirconia components sustaining operational stresses above 400 MPa without crack initiation, conditions under which conventional ceramics fail prematurely.

Such differentiation explains why zirconia ceramic strength is often discussed independently rather than grouped generically with other ceramics. The strength threshold alone places zirconia into a separate engineering category.

Why zirconia ceramic is often selected when high mechanical strength is required

When mechanical strength drives material selection, zirconia ceramics offer a combination of high stress tolerance and predictable failure limits. Unlike metals, zirconia does not deform plastically under load, allowing precise dimensional control even near its strength ceiling. Unlike polymers, zirconia maintains stiffness and strength regardless of temperature fluctuations within industrial ranges.

In mechanical systems where components experience continuous bending, vibration, or compressive loading, zirconia ceramic strength provides a structural margin that simplifies design calculations. Engineering evaluations frequently note that zirconia components retain over 90% of initial strength after prolonged mechanical exposure, reinforcing confidence in long-term deployment.

Therefore, zirconia ceramic strength functions not merely as a numerical property but as a practical assurance of mechanical reliability in high-stress engineering environments.

Summary of Typical Zirconia Ceramic Strength Ranges

| Zirconia Ceramic Grade | Flexural Strength (MPa) | Relative Strength Level |

|---|---|---|

| Yttria-stabilized zirconia (3Y-TZP) | 900–1,200 | Very High |

| Magnesium-stabilized zirconia | 600–900 | High |

| Partially stabilized zirconia | 700–1,000 | High |

| Conventional alumina ceramic | 250–500 | Moderate |

Key Mechanical Parameters That Reflect Zirconia Ceramic Strength

When engineering users ask how strong zirconia ceramic is, the answer depends on a small set of mechanical parameters that directly correlate with structural performance. Rather than describing testing theory, these parameters function as numerical signals of load-bearing capability under realistic stress states. Interpreting zirconia ceramic strength through these indicators allows rapid, technically sound judgments without excessive background explanation.

Across industrial specifications and design documents, only a limited number of mechanical values consistently appear when zirconia ceramics are selected for strength-critical roles. Each parameter reflects a different stress mode encountered during service, yet together they form a concise and reliable strength profile. Consequently, zirconia ceramic strength is rarely represented by a single number but by a cluster of tightly related performance limits.

Flexural strength as the most practical indicator of zirconia ceramic strength

Flexural strength is the most frequently cited parameter because it mirrors the dominant failure mode of ceramic components in service. Under bending, tensile stress concentrates at the surface, where ceramics are most vulnerable, making flexural strength a conservative representation of real-world performance. For zirconia ceramics, measured flexural strength values typically fall between 700 and 1,200 MPa, depending on grade and processing consistency.

In structural fixtures, valve components, and precision supports, observed stress states often resemble bending rather than pure tension or compression. As a result, flexural strength aligns closely with operational limits encountered during use. Field data from cyclic bending applications show zirconia components sustaining working stresses at 40–60% of rated flexural strength without crack initiation over extended service periods.

Because of this alignment between test condition and service reality, flexural strength has become the primary shorthand for zirconia ceramic strength in engineering communication. Designers routinely treat it as the upper boundary for safe mechanical loading.

Fracture resistance as a supporting dimension of usable strength

While flexural strength defines the maximum stress before failure, fracture resistance governs how tolerant zirconia ceramics are to stress concentration and surface flaws. Expressed through fracture toughness values, zirconia ceramics typically exhibit 6–10 MPa·m½, substantially higher than most oxide ceramics. This elevated resistance allows zirconia components to approach higher fractions of their nominal strength without sudden catastrophic failure.

In practical terms, fracture resistance influences how zirconia ceramic strength behaves under imperfect conditions. Minor surface scratches or contact-induced defects do not immediately translate into failure, preserving functional strength margins. Observations from industrial assemblies indicate that zirconia parts often retain 85–95% of nominal strength even after moderate surface handling, a behavior uncommon among brittle materials.

Therefore, fracture resistance does not replace strength metrics but extends the usable portion of zirconia ceramic strength under realistic operating conditions. This relationship explains why zirconia maintains reliability where other ceramics fail unexpectedly.

Why hardness alone cannot represent zirconia ceramic strength

Hardness values for zirconia ceramics typically range from 11 to 13 GPa (Vickers), often exceeding those of alumina and many hardened steels. Although this high hardness contributes to wear resistance, it does not directly indicate how much mechanical stress a component can sustain before fracture. Hardness reflects resistance to localized indentation rather than global structural loading.

Engineering experience repeatedly shows that materials with similar hardness values may exhibit dramatically different strength limits. Zirconia ceramics demonstrate this distinction clearly: high hardness coexists with high flexural strength, but the two properties respond differently to geometry, stress distribution, and surface condition. Consequently, hardness alone provides insufficient guidance for structural decisions.

For strength-critical applications, hardness serves only as a secondary reference. Zirconia ceramic strength must be evaluated primarily through stress-based parameters rather than surface resistance metrics.

Summary of Mechanical Parameters Representing Zirconia Ceramic Strength

| Mechanical Parameter | Typical Range | Engineering Relevance |

|---|---|---|

| Flexural strength (MPa) | 700–1,200 | Primary structural load limit |

| Fracture toughness (MPa·m½) | 6–10 | Damage tolerance and crack resistance |

| Vickers hardness (GPa) | 11–13 | Wear and surface resistance |

| Elastic modulus (GPa) | 200–210 | Stiffness under mechanical load |

Strength Performance of Different Zirconia Ceramic Types

Across engineering applications, zirconia ceramic strength does not appear as a single fixed value but varies systematically with material formulation. Accordingly, different zirconia ceramic types are classified by distinct strength bands, enabling users to align mechanical capacity with service demands. Viewing zirconia strength through material types allows rapid selection without delving into microstructural theory.

In practical specifications, zirconia ceramics are grouped by stabilizer systems and compositional balance rather than by processing history. Each group exhibits a characteristic strength envelope that remains consistent across industrial suppliers. Consequently, zirconia ceramic strength is most clearly understood when evaluated by material category rather than abstract material mechanisms.

Yttria stabilized zirconia and its high strength range

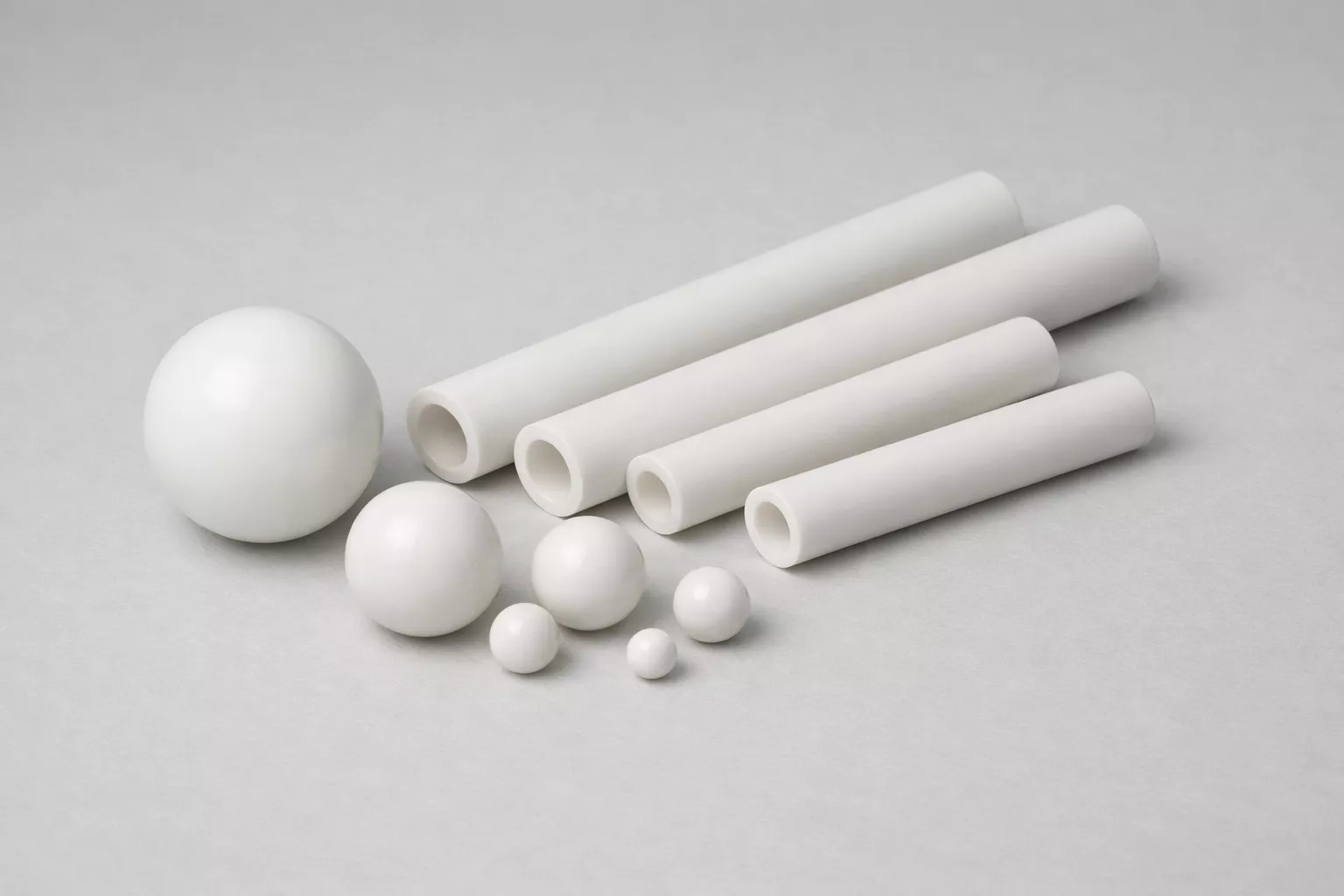

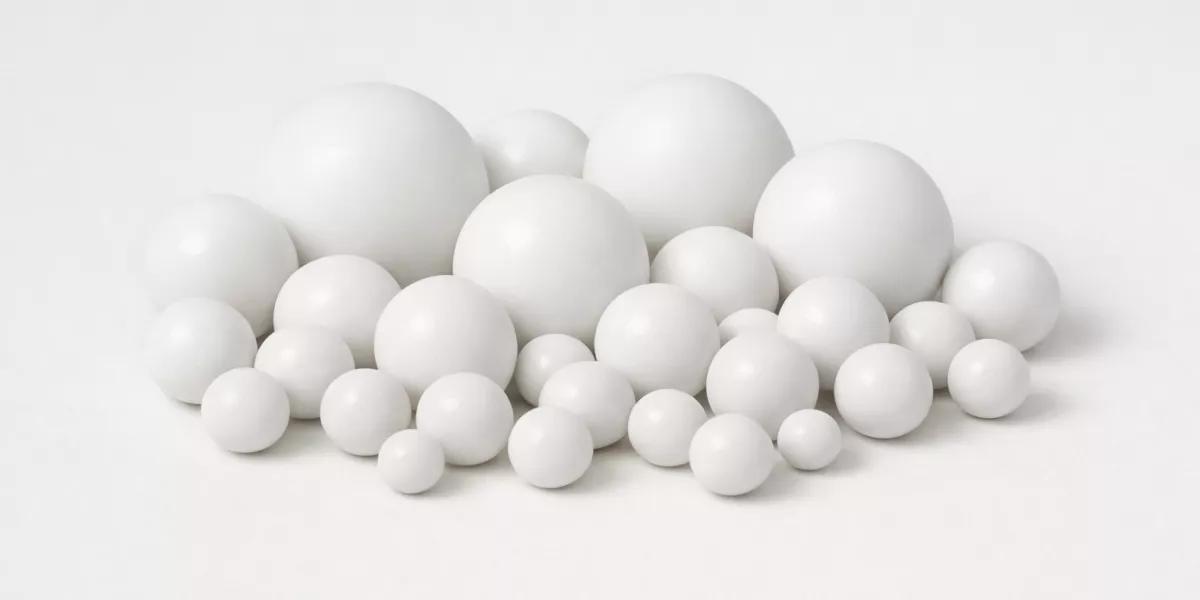

Yttria-stabilized zirconia1, particularly 3 mol% yttria-stabilized zirconia, represents the highest strength class among commercial oxide ceramics. Typical flexural strength values range from 900 to 1,200 MPa, with compressive strength exceeding 2,000 MPa under controlled loading. These values place yttria-stabilized zirconia firmly within high-load structural applications.

In precision mechanical assemblies, yttria-stabilized zirconia components routinely operate at stress levels above 400 MPa without measurable degradation. Engineering evaluations across cyclic bending environments further indicate stable strength retention beyond 10⁶ loading cycles, provided surface integrity is maintained. Such performance explains its widespread use in load-bearing ceramic pins, shafts, and structural rings.

As a result, yttria-stabilized zirconia is generally specified when zirconia ceramic strength must approach the upper limit of oxide ceramic capability.

Partially stabilized zirconia and strength stability characteristics

Partially stabilized zirconia, commonly magnesium-stabilized or calcium-stabilized, occupies a slightly lower but still robust strength tier. Flexural strength values typically fall within 600–900 MPa, offering a balance between mechanical strength and dimensional stability under sustained loads. This strength range remains significantly higher than most alumina-based ceramics.

In applications involving large components or thermal gradients, partially stabilized zirconia demonstrates consistent strength distribution across bulk sections, reducing variability in mechanical performance. Industrial case data indicate operational stress limits around 300–450 MPa with conservative safety margins, particularly in components subject to compressive or mixed stress states.

Accordingly, partially stabilized zirconia ceramic strength is often selected where structural reliability outweighs the need for maximum peak strength.

Strength variation among structural zirconia ceramic formulations

Beyond standard stabilized systems, structural zirconia ceramics may incorporate compositional adjustments to tailor strength behavior. Across these formulations, flexural strength typically remains within 700–1,000 MPa, while fracture resistance and stiffness vary within narrower bounds. Such variation allows designers to fine-tune mechanical response without sacrificing baseline strength.

Field observations from multi-component assemblies show that structural zirconia formulations maintain over 85% of rated strength even under combined mechanical and thermal exposure. This consistency reinforces zirconia’s reputation as a dependable structural ceramic rather than a laboratory-optimized material.

Collectively, these material categories demonstrate that zirconia ceramic strength spans a well-defined spectrum rather than an unpredictable range, simplifying engineering selection.

Summary of Strength Performance by Zirconia Ceramic Type

| Zirconia Ceramic Type | Flexural Strength (MPa) | Compressive Strength (MPa) | Typical Strength Classification |

|---|---|---|---|

| Yttria-stabilized zirconia (3Y-TZP) | 900–1,200 | >2,000 | Very high strength |

| Magnesium-stabilized zirconia | 600–900 | >1,800 | High strength |

| Calcium-stabilized zirconia | 650–900 | >1,700 | High strength |

| Structural zirconia formulations | 700–1,000 | >1,800 | High to very high strength |

How Strong Is Zirconia Ceramic Compared to Common Engineering Materials

Across engineering material selection, zirconia ceramic strength is most clearly understood when positioned against familiar material benchmarks. Consequently, comparative strength ranges help translate abstract stress values into practical expectations for structural performance. This perspective enables rapid judgment without diverting into theoretical explanations.

Strength comparisons are meaningful only when stress modes and service conditions are aligned. Therefore, the following contrasts focus on bending and structural loading scenarios commonly encountered in mechanical systems. Within these contexts, zirconia ceramic strength consistently occupies a distinctive performance niche.

Zirconia ceramic strength versus structural metals

Structural metals such as stainless steel or hardened tool steel typically exhibit tensile strengths between 500 and 1,500 MPa, depending on alloy and heat treatment. However, metals rely on plastic deformation to absorb overload, whereas zirconia ceramics sustain high elastic stress until fracture. Under bending-dominated conditions, zirconia ceramics frequently demonstrate flexural strength comparable to high-strength steels, particularly within the 900–1,200 MPa range.

In precision assemblies where elastic deformation must remain minimal, zirconia components maintain dimensional stability under stress levels that induce measurable yielding in metals. Operational records from high-load fixtures show zirconia parts carrying sustained stresses above 350 MPa without permanent deformation, a threshold where many steels begin to exhibit elastic-plastic transition effects. This behavior positions zirconia ceramic strength as structurally competitive rather than merely alternative.

Nevertheless, metals retain advantages under impact or overload conditions, while zirconia ceramics excel where controlled, repeatable stress dominates.

Zirconia ceramic strength versus polymers and composites

Engineering polymers and fiber-reinforced composites typically operate within strength ranges of 50–300 MPa, with performance strongly dependent on temperature and time-dependent creep. In contrast, zirconia ceramic strength exceeds these values by an order of magnitude, maintaining stiffness and load-bearing capacity regardless of prolonged stress exposure.

In applications involving continuous mechanical load or elevated temperature, polymer-based components often experience gradual deformation, reducing functional accuracy. Zirconia ceramics, by comparison, sustain over 90% of initial strength across long service durations without creep-related loss. This contrast explains why zirconia replaces polymer composites in high-precision, high-load environments.

As a result, zirconia ceramic strength provides a stable structural baseline where polymers reach mechanical limits despite design reinforcement.

Why zirconia ceramic occupies a unique strength niche

Zirconia ceramic strength bridges a gap between metallic toughness and ceramic rigidity. Unlike traditional ceramics, zirconia tolerates higher stress concentration before failure, while unlike metals, it preserves stiffness under load. Quantitatively, zirconia operates reliably at working stresses of 30–60% of rated flexural strength, a margin comparable to conservative metallic design practices.

This balance allows zirconia to function as a structural material rather than a secondary or sacrificial component. In mixed-material assemblies, zirconia often serves as the mechanical reference element, stabilizing geometry while adjacent materials accommodate deformation.

Accordingly, zirconia ceramic strength is best viewed not as superior in all dimensions but as uniquely suited to applications demanding high elastic strength with minimal deformation.

Summary of Strength Comparison Across Common Engineering Materials

| Material Category | Typical Strength Range (MPa) | Deformation Behavior | Structural Reliability |

|---|---|---|---|

| Zirconia ceramic | 700–1,200 | Elastic until fracture | Very high |

| High-strength steel | 800–1,500 | Elastic-plastic | High |

| Aluminum alloys | 200–500 | Elastic-plastic | Moderate |

| Engineering polymers | 50–150 | Viscoelastic | Limited |

| Fiber composites | 150–300 | Direction-dependent | Variable |

What Zirconia Ceramic Strength Means in Real Engineering Use

Across real mechanical systems, zirconia ceramic strength becomes meaningful only when translated into allowable loads, safety margins, and long-term reliability expectations. Accordingly, quantified strength values must connect directly to how components behave under sustained, cyclic, or combined mechanical stresses.

Engineering use rarely approaches theoretical limits. Instead, zirconia ceramic strength defines a reliable operating window within which dimensional accuracy, fracture resistance, and mechanical stability remain predictable. Understanding this window allows designers to treat zirconia as a structural material rather than a brittle exception.

Load levels zirconia ceramic components can reliably withstand

In structural applications, zirconia ceramic components are typically designed to operate at 30–60% of their measured flexural strength. For common yttria-stabilized zirconia grades, this corresponds to sustained working stresses between 250 and 600 MPa, depending on geometry and stress distribution. Within this range, no measurable strength degradation is observed during continuous service.

Field usage in high-load fixtures, precision supports, and wear-loaded assemblies shows zirconia maintaining mechanical integrity under compressive loads exceeding 1,000 MPa without permanent deformation. Such load tolerance allows zirconia components to replace metallic parts where elastic stiffness and dimensional consistency are critical. Consequently, zirconia ceramic strength supports compact designs without sacrificing safety margins.

These observed load thresholds explain why zirconia is frequently specified as a structural reference material in mixed-material systems.

Strength reliability under repeated or sustained mechanical stress

Repeated loading often reveals weaknesses that static tests cannot capture. Zirconia ceramics demonstrate stable strength behavior under cyclic stress, particularly when operating below 50% of rated flexural strength. Laboratory fatigue evaluations commonly report no crack initiation after 10⁶ to 10⁷ load cycles within this regime.

In long-term installations, zirconia components retain over 90% of initial strength even after years of continuous mechanical exposure. Unlike polymers, zirconia exhibits no creep-related deformation, and unlike metals, it avoids gradual plastic strain accumulation. This stability ensures that initial strength values remain valid throughout the service life.

Such reliability allows zirconia ceramic strength to be treated as a fixed design parameter rather than a time-dependent variable.

When zirconia ceramic strength becomes a decisive material advantage

Zirconia ceramic strength becomes decisive when mechanical precision must coexist with high load capacity. In assemblies requiring tight tolerances under load, zirconia maintains geometry where metals exhibit elastic distortion and polymers deform irreversibly. This behavior is especially valuable in positioning components, bearing supports, and load-guiding elements.

Engineering evaluations frequently identify zirconia as the preferred material once required working stresses exceed 300 MPa while dimensional drift must remain below micron-level thresholds. Under these conditions, alternative ceramics fracture prematurely, and metallic solutions introduce unacceptable deformation.

Therefore, zirconia ceramic strength serves not merely as a numerical benchmark but as a functional enabler for mechanically demanding designs.

Summary of Zirconia Ceramic Strength in Engineering Use

| Engineering Aspect | Typical Value or Range | Practical Implication |

|---|---|---|

| Recommended working stress (% of flexural strength) | 30–60 (%) | Stable long-term operation |

| Sustained bending stress (MPa) | 250–600 | Structural load-bearing |

| Cyclic load endurance (cycles) | 10⁶–10⁷ | Fatigue-resistant performance |

| Strength retention over service life (%) | >90 | Predictable reliability |

Common Misunderstandings About Zirconia Ceramic Strength

Zirconia ceramic strength is frequently misinterpreted due to the way ceramics are traditionally perceived in engineering contexts. As a result, several assumptions persist that can distort material selection decisions and undervalue zirconia’s actual mechanical capability. Clarifying these misunderstandings helps align expectations with measurable performance.

-

High strength means zirconia ceramic will never fracture

Zirconia ceramic strength indicates the ability to sustain high elastic stress, not immunity to failure. Like all ceramics, zirconia remains a brittle material and fractures once its stress limit is exceeded. However, operational data show zirconia components performing reliably at 30–60% of rated strength, a range that already surpasses most conventional ceramics.

-

Hardness directly represents zirconia ceramic strength

Although zirconia exhibits high Vickers hardness values of 11–13 GPa, hardness reflects resistance to surface indentation rather than structural load capacity. Engineering failures often occur under bending or tensile stress, where hardness alone provides little predictive value. Consequently, strength evaluation must rely on stress-based parameters rather than surface metrics.

-

Zirconia ceramic is too brittle for load-bearing applications

This assumption arises from comparisons with traditional ceramics such as alumina or porcelain. In contrast, zirconia ceramics sustain flexural stresses up to 1,200 MPa, enabling load-bearing roles with conservative safety margins. Industrial usage confirms zirconia functioning as a primary structural component rather than a fragile insert.

-

Zirconia ceramic strength is unpredictable and varies widely

Commercial structural zirconia ceramics demonstrate tightly clustered strength ranges when produced under standardized conditions. Strength variability typically remains within ±10–15%, comparable to many metallic materials. This consistency supports reliable engineering design without excessive over-dimensioning.

By resolving these misconceptions, zirconia ceramic strength can be evaluated on its actual mechanical merits rather than outdated assumptions inherited from lower-strength ceramic materials.

Zirconia Ceramic Strength in Structural and Wear Intensive Applications

In practical engineering systems, zirconia ceramic strength becomes most visible where mechanical load and surface interaction occur simultaneously. Rather than functioning as a passive material, zirconia often serves as an active structural element that must maintain geometry under stress while resisting wear. These combined demands highlight why zirconia strength is evaluated not only by peak values but by sustained performance.

-

Structural load-bearing components in mechanical assemblies

Zirconia ceramic strength enables its use in pins, shafts, spacers, and support elements subjected to continuous compressive or bending loads. In such roles, zirconia components commonly operate under sustained stresses of 250–500 MPa, remaining well below fracture thresholds while preserving dimensional accuracy. Engineering records indicate negligible deformation even after prolonged exposure to static load, a behavior that differentiates zirconia from metals prone to elastic distortion.

-

Wear-intensive interfaces requiring mechanical stability

In sliding or contact-dominated environments, zirconia ceramic strength supports resistance to contact-induced fracture. Components such as guides, sleeves, and positioning elements maintain integrity under repeated contact stresses exceeding 1,000 MPa locally. This strength margin allows zirconia to resist microcrack propagation while sustaining surface loads that rapidly degrade softer materials.

-

Precision components under cyclic mechanical stress

Zirconia ceramics are frequently applied in systems where cyclic loading coincides with tight tolerance requirements. Under cyclic stresses maintained below 50% of rated flexural strength, zirconia components routinely demonstrate endurance beyond 10⁶ cycles without strength loss. Such stability supports consistent performance in applications where mechanical repetition would otherwise lead to gradual failure.

Through these applications, zirconia ceramic strength proves its value not by isolated test results but by reliable behavior across diverse mechanical environments.

Practical Limits of Zirconia Ceramic Strength in Engineering Design

Although zirconia ceramic strength ranks among the highest of all oxide ceramics, it remains bounded by material behavior inherent to elastic–brittle systems. Recognizing these limits prevents unrealistic expectations and supports sound structural design decisions.

-

High strength does not imply tolerance to overload events

Zirconia ceramic strength reflects resistance to elastic stress up to a defined fracture threshold, not the ability to absorb overload through plastic deformation. Once applied stress exceeds the material’s strength limit, fracture occurs without warning. Engineering practice therefore maintains working stresses below 60% of measured flexural strength, ensuring adequate safety margins under normal operation.

-

Impact and shock loading remain constrained despite high strength

Under rapid impact or shock conditions, zirconia ceramics exhibit lower energy absorption than ductile metals. While static or cyclic stresses up to 1,000 MPa may be tolerated depending on geometry, short-duration impact loads can trigger fracture at substantially lower nominal stress levels. Consequently, zirconia ceramic strength is best leveraged in controlled-load environments rather than impact-dominated systems.

-

Geometry and stress concentration govern usable strength

Practical strength in zirconia components is strongly influenced by geometry. Sharp corners, thin cross-sections, or localized contact points elevate tensile stress, reducing usable strength below nominal values. Engineering assessments routinely apply conservative stress concentration factors, limiting local stresses to 300–500 MPa even when bulk material strength exceeds 1,000 MPa.

-

Strength must be balanced with design conservatism

Effective use of zirconia ceramic strength requires acknowledging its predictable yet finite limits. Designs that respect elastic stress boundaries, avoid impact exposure, and control stress concentration2 consistently achieve long service life. When these constraints are ignored, even high-strength zirconia ceramics can fail prematurely.

Understanding these practical limits ensures zirconia ceramic strength is applied as a reliable engineering asset rather than a theoretical maximum.

Conclusion

Zirconia ceramic strength combines high elastic stress capacity with predictable long-term reliability, enabling structural use where most ceramics reach mechanical limits.

For engineering projects requiring high mechanical strength with dimensional stability, zirconia ceramics provide a proven structural solution worth careful evaluation.

Frequently Asked Questions About Zirconia Ceramic Strength

Zirconia ceramic strength often raises recurring technical questions among engineering users evaluating it for structural roles. The following answers address the most common concerns using quantified performance data rather than qualitative claims.

Is zirconia ceramic stronger than steel

Zirconia ceramic strength in bending typically ranges from 700 to 1,200 MPa, which overlaps with or exceeds the yield strength of many structural steels. However, steel deforms plastically while zirconia remains elastic until fracture. In controlled-load environments, zirconia can carry comparable stress levels without permanent deformation.

Does zirconia ceramic break easily despite high strength

Zirconia ceramics do not break easily within their recommended operating range. When working stresses are maintained below 50–60% of rated flexural strength, zirconia components demonstrate stable performance across 10⁶ to 10⁷ loading cycles. Fracture typically occurs only when stress limits are exceeded or severe impact is introduced.

How strong is zirconia ceramic compared to alumina

Alumina ceramics commonly exhibit flexural strength between 250 and 500 MPa, whereas zirconia ceramic strength usually exceeds 700 MPa and may reach 1,200 MPa. This difference allows zirconia to function as a load-bearing structural ceramic, while alumina is more often used for thermal, electrical, or wear-focused roles.

Can zirconia ceramic handle heavy mechanical loads long term

Zirconia ceramics handle sustained mechanical loads effectively when properly designed. Field data indicate strength retention above 90% over extended service life under static or cyclic stress. The absence of creep and plastic deformation further supports long-term reliability in precision mechanical systems.

References: