Boron Carbide (B4C) Ceramic | Ultra-Hard, Lightweight Material for Extreme Wear Applications

ADCERAX is an advanced ceramic properties manufacturer in China specializing in custom boron carbide (B4C) components with tight tolerances, stable quality, and fast delivery. We provide both standard stock and drawing-based parts—including sandblasting nozzles, waterjet mixing tubes, valve seats, and wear inserts—widely used in surface treatment, coating, and precision machinery industries.

👉Get a fast quote or upload your drawing to start your custom B4C ceramic solution with ADCERAX.

- Factory-direct

- Engineering support

- Small-batch friendly

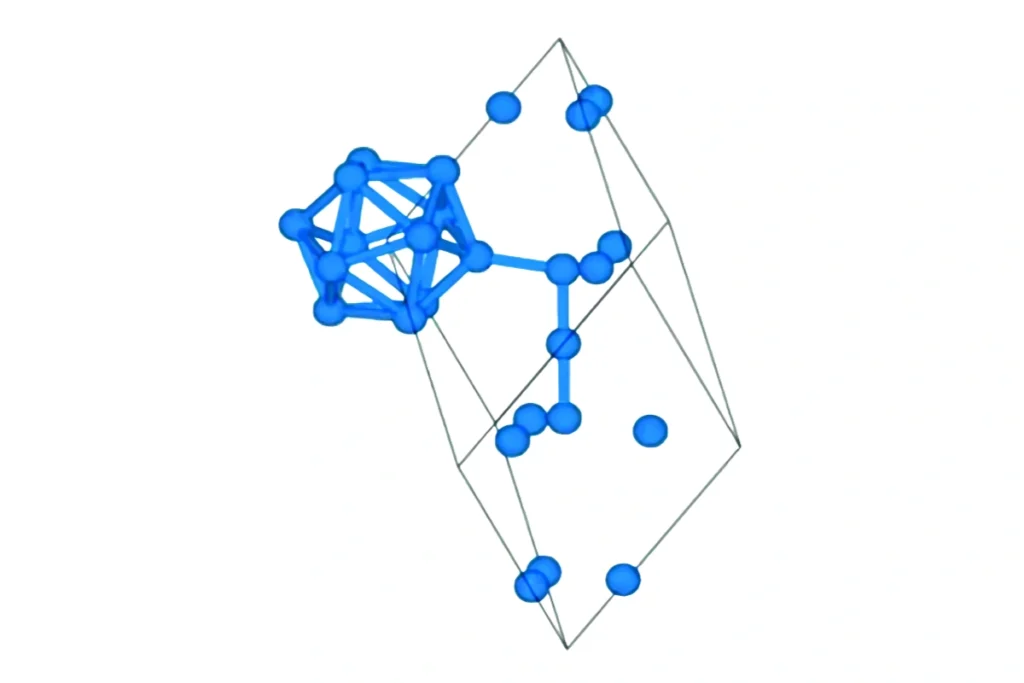

What is Boron Carbide (B4C )Ceramic?

Is Boron Carbide (B4C) a Ceramic ?

Yes — boron carbide (B₄C) is used as an advanced ceramic material, characterized by its covalent bonding, crystalline microstructure, and exceptional mechanical stability. It is one of the lightest and hardest structural ceramics available today, combining extreme hardness (≈9.3 on the Mohs scale) with remarkably low density (~2.5 g/cm³).

At the atomic level, boron and carbon form a strong B–C lattice network, resulting in outstanding wear resistance, corrosion resistance, and dimensional stability under abrasive or high-temperature conditions.

Boron Carbide Ceramic vs Metal Ceramic (Cermet) vs Polymer

| Property | Boron Carbide (B4C) Ceramic | Metal Ceramic (Cermet — TiC–Ni / WC–Co) | Polymer (e.g., Nylon, PEEK) |

| Density (g/cm³) | ~2.5 (very light) | 6.0–7.0 (medium) | 1.1–1.4 (light) |

| Hardness (Mohs) | 9.3 (near diamond) | 7–8 | <3 |

| Temperature Resistance (°C) | Up to 1800–2000 | Up to 1000–1200 | Below 250 |

| Elastic Modulus (GPa) | 450–480 | 300–350 | <5 |

| Wear Resistance | Excellent — minimal erosion | Good — moderate wear | Poor — softens quickly |

| Thermal Expansion (×10⁻⁶/K) | 4–5 | 8–10 | 60–100 |

| Cost Level (Relative) | $$$ — High precision, long lifespan | $$ — Balanced cost-performance | $ — Low-cost, short lifespan |

Boron Carbide is not a Metal Ceramic or Polymer

metals deform plastically under stress, while polymers soften with temperature. In contrast, B4C retains its rigidity, stiffness, and thermal stability even above 1800 °C, exhibiting the inherent brittleness and resilience typical of technical ceramics.

In short, boron carbide ceramic combines the near-diamond hardness of covalent compounds with the lightweight efficiency of modern engineering ceramics, making it a top-tier material for high-wear and high-temperature systems.

Boron Carbide Ceramic Properties and Data

Boron carbide (B4C) ceramics feature ultra-high hardness, low density, and excellent wear resistance, ranking among the lightest and hardest structural ceramics. As one of the leading suppliers of boron carbide ceramic properties in China, ADCERAX ensures consistent chemical stability and thermal resistance even under extreme industrial conditions.

| Property | Typical Value | Unit | Description / Notes |

|---|---|---|---|

| Flexural Strength | 350 – 450 | MPa | High bending resistance for wear and structural parts. |

| Compressive Strength | 2,800 – 3,200 | MPa | Handles extreme load and pressure without deformation. |

| Fracture Toughness (KIC) | 3.5 – 4.0 | MPa·m¹ᐟ² | Ensures good resistance to microcrack propagation under impact. |

| Young’s Modulus | 420 – 460 | GPa | Provides rigidity and dimensional stability at high temperatures. |

| Electrical Resistivity | 1 × 10³ – 1 × 10⁴ | Ω·cm | Excellent insulation; suitable for electrical isolation components. |

| Thermal Expansion Coefficient (CTE) | 4.5 × 10⁻⁶ | /K | Ensures low thermal stress when paired with metals or composites. |

| Chemical Stability | Excellent | — | Resistant to acids, alkalis, and molten metal corrosion. |

Mechanical Strength and Wear Resistance

Boron carbide ceramics combine ultra-high hardness and low density for superior wear and impact resistance.

- Vickers hardness: 30–38 GPa, among the hardest engineering materials.

- Low density: 2.5 g/cm³ allows high stiffness with minimal weight.

- Proven wear rate < 3 × 10⁻⁷ mm³/N·m, extending component service life.

Thermal Stability and Heat Resistance

B4C maintains its strength and dimensional accuracy at high temperatures, ensuring durability in severe environments.

- Working temperature: up to 1200 °C in air / 2000 °C in inert gas.

- Excellent thermal conductivity (30–60 W/m·K) for uniform heat dissipation.

- Stable structure under rapid thermal cycling and mechanical shock.

Chemical Inertness and Corrosion Protection

The covalent B–C bonding network gives boron carbide superior chemical and oxidation resistance.

- Inert to most acids, alkalis, and molten metals below 1000 °C.

- No structural degradation in H₂, CO, or vacuum atmospheres.

- Ideal for use in abrasive, corrosive, or chemically reactive environments.

Electrical Insulation and Functional Reliability

B4C provides excellent electrical insulation while maintaining high thermal performance and mechanical strength.

- Electrical resistivity: ~10¹² Ω·cm ensures stable insulation.

- Low dielectric loss supports safe operation in high-voltage systems.

- Reliable performance for plasma, coating, and sensor protection components.

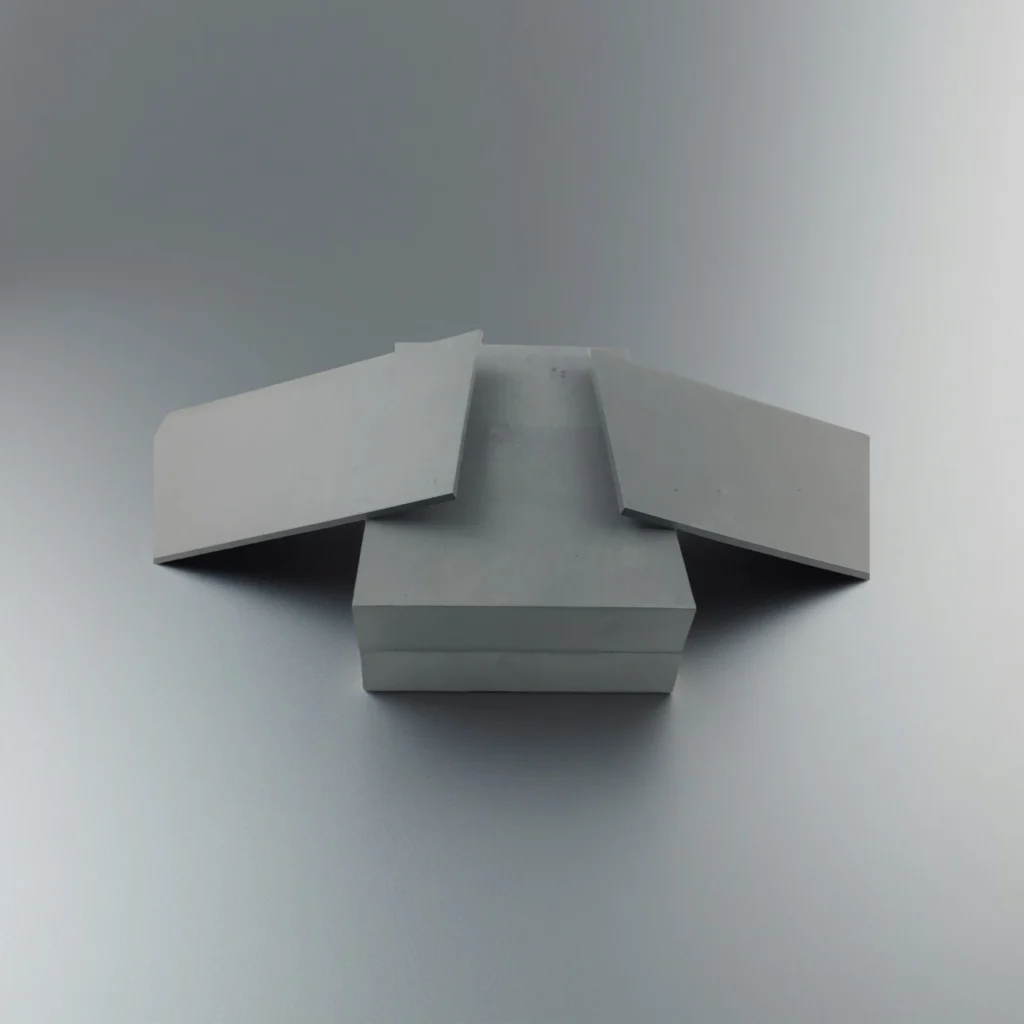

Wear-resistant Boron Carbide B4C Ceramic Components

ADCERAX supplies boron carbide (B4C) ceramic plates, nozzles, rings, and rods built for extreme wear, impact, and temperature resistance. With ultra-high hardness, low density, and chemical stability, these components ensure long life and precision performance in sandblasting, cutting, and protective applications.

Boron carbide plates offer outstanding hardness, light weight, and thermal stability for demanding wear and protection environments.

- Performs reliably up to 1200 °C in air and 2000 °C in inert gas.

- Provides superior wear and erosion resistance against abrasive media.

- Ensures long service life and stability in high-load and thermal cycling systems.

Boron carbide nozzles deliver extreme hardness, low density, and exceptional wear resistance for sandblasting.

- Operates steadily up to 1200 °C without deformation or erosion.

- Provides wear life 5–10× longer than tungsten carbide nozzles.

- Ensures precise jet control and energy-efficient blasting performance.

Boron carbide rings provide exceptional hardness, low density, and thermal stability for precision alignment and sealing applications.

- Maintains dimensional accuracy and surface smoothness under load.

- Offers excellent wear and erosion resistance for rotating assemblies.

- Performs reliably up to 1200 °C, ensuring stable operation and long service life.

👉 Harder Than Steel. Lighter Than Aluminum. Powered by ADCERAX Boron Carbide Ceramics.

ADCERAX is a China-based boron carbide ceramic manufacturer providing custom B4C solutions for industrial applications. From sandblasting nozzles to wear plates, our B4C ceramics combine extreme hardness with thermal stability to outlast conventional materials.

Boron Carbide (B4C) Ceramic Applications

Boron carbide ceramics are widely used in surface treatment, semiconductor, precision machinery, and energy industries. Their high hardness, wear resistance, and thermal stability make them ideal for sandblasting nozzles, valve seats, cutting tools, and wear-resistant liners, ensuring long-term reliability under harsh industrial conditions.

Chemical & Petrochemical Processing

Application: Flow control components, spray nozzles, and wear-resistant liners in acid, alkali, and abrasive fluid systems.

Challenges: Metal and silicon carbide parts corrode or erode rapidly in aggressive chemical environments, increasing maintenance frequency.

- 🧩 ADCERAX Solution: Boron carbide ceramics exhibit excellent chemical inertness and extreme hardness (Mohs 9.5), remaining dimensionally stable in acidic, chloride-rich, and high-flow conditions.

- 🔹Case Example:

A French petrochemical refinery using sulfuric acid scrubbers replaced SiC spray nozzles with ADCERAX B4C ones. After 9 months, wear loss was only 0.08 mm, compared to 0.54 mm on SiC. Component life extended from 3 to 15 months, cutting annual maintenance costs by €62,000 and eliminating one scheduled shutdown per year.

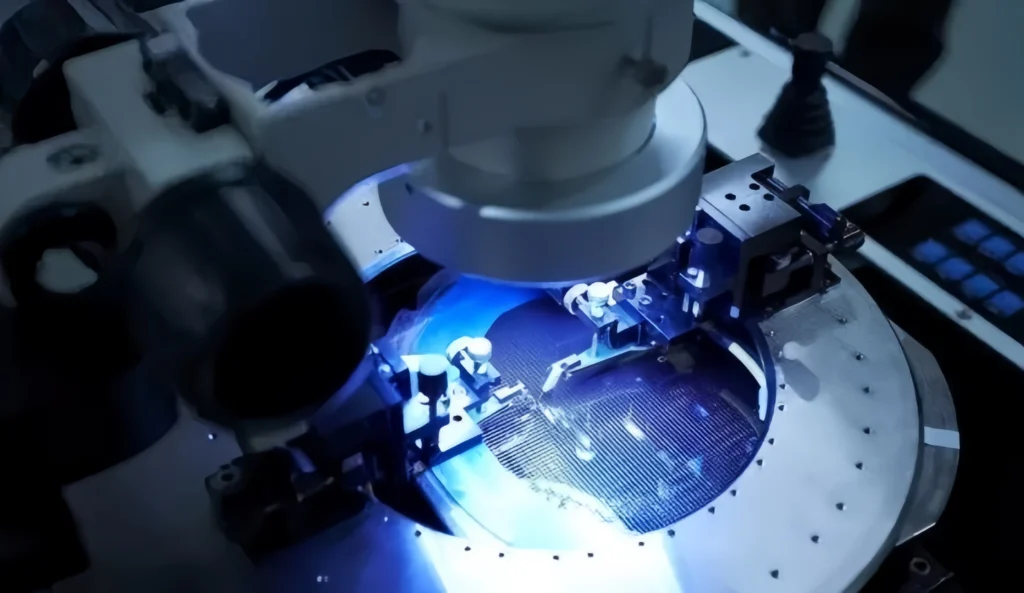

Semiconductor & Precision Equipment

Application: Wafer handling rings, valve seats, plasma-resistant shields, and precision positioning guides in CVD and ALD systems.

Challenges: Quartz and SiC parts deform or release micro-particles under plasma exposure above 800 °C, leading to wafer contamination and yield loss.

- 🧩 ADCERAX Solution: B4C ceramics offer ultra-low particle generation, thermal stability up to 1200 °C, and high dimensional precision (±0.05 mm), ensuring stable operation in cleanroom-grade environments.

- 🔹Case Example:

A Korean semiconductor equipment OEM integrated ADCERAX B4C valve inserts into a wafer gas delivery module. After 1 year, particle generation was reduced by 43%, wafer defect rate dropped from 0.32% to 0.18%, and tool uptime improved by 29%. The client standardized ADCERAX B4C components for all 300 mm wafer tools, achieving consistent yield improvement across production lines.

Industrial Machinery & Energy Systems

Application: Pump liners, valve plates, mechanical seals, and wear rings in slurry pumps, power plant condensate systems, and chemical compressors.

Challenges: High-velocity particles and corrosive fluids rapidly degrade metallic and WC parts, leading to leakage, vibration, and efficiency loss.

- 🧩 ADCERAX Solution: B4C ceramics deliver 5–8× longer wear life than metal or carbide parts, maintaining strength and geometry even after 10,000+ operating hours in abrasive environments.

- 🔹Case Example:

A U.S. energy equipment supplier used ADCERAX B4C valve seats in their circulating water pumps. After 16 months of operation in 700 ppm silica slurry, the wear depth was less than 0.15 mm, compared to 1.2 mm on tungsten carbide. Pump efficiency improved by 11%, annual maintenance downtime decreased by 41%, saving an estimated $52,800 per unit per year.

Powder Processing & Material Conveying

Application: Venturi tubes, elbows, and liners in pneumatic conveying systems for catalysts, abrasives, ceramics, and powder coatings.

Challenges: Continuous particle impact at speeds above 40 m/s causes severe erosion in alumina and steel liners, increasing material loss and air pressure drop.

- 🧩 ADCERAX Solution: ADCERAX B4C liners provide exceptional wear resistance and smooth surface finish (Ra < 0.4 μm), minimizing friction loss and preventing contamination in high-purity powder transport.

- 🔹Case Example:

A German powder processing plant transporting alumina powders upgraded its steel venturi elbows to ADCERAX B4C ceramics. After 18 months, no visible erosion or clogging occurred. Air pressure stability improved by 16%, conveying efficiency increased by 22%, and total maintenance interventions dropped from 8 to 2 times per year, reducing operating costs by €45,000 annually.

Custom Boron Carbide Ceramic Factory

ADCERAX is a boron carbide ceramic properties supplier in China, offering custom-made boron carbide components built to your drawings or samples.We provide flexible sizing, complex shapes, and stable quality with typical delivery in 3–9 weeks.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

ADCERAX – Boron Carbide Ceramic Properties Wholesaler

ADCERAX is a boron carbide used as ceramic materials manufacturer in China, providing high-performance boron carbide ceramics made through advanced sintering and precision machining. With in-house production and quality control, we ensure stable performance, reliable consistency, and flexible supply for both prototype and mass-production orders.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

ADCERAX integrates boron carbide ceramic forming, precision machining, and inspection into a unified workflow. Our one-stop production system supports custom shapes, tight tolerances, and consistent quality—from prototype development to mass production.

-

Precision Machining & Dimensional Control:

Each boron carbide part is manufactured under strict process control to maintain uniform density, fine microstructure, and accurate geometry—ensuring high hardness and reliable wear resistance in demanding environments. -

Batch Stability & Quality Assurance:

Every batch undergoes density, hardness, and surface inspection to ensure stable performance in high-temperature, ballistic, and abrasive applications. -

Customization & Engineering Support:

We provide design support for complex boron carbide components, including custom sizes, hole patterns, and assembly interfaces, to meet the specific needs of defense, nuclear, and industrial customers.

ADCERAX specializes in boron carbide ceramics production, integrating precision forming, hot pressing, and ultra-fine machining. Each component is engineered for high hardness, low density, and superior wear resistance, ensuring stable performance in ballistic, nuclear, and industrial environments.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Capability Item | Typical Value / Description | ||

| Material Grades | Hot-Pressed (HP-B₄C), Pressureless Sintered (PS-B₄C), Reaction-Bonded (RB-B₄C), and Composite B₄C–SiC / B₄C–Al₂O₃ hybrid ceramics for enhanced toughness. | ||

| Precision Machining | CNC diamond grinding, ultrasonic milling, laser cutting, and EDM trimming for tight tolerance features (±0.02 mm typical). | ||

| Forming & Shaping | Cold Isostatic Pressing (CIP), slip casting, die pressing, and CNC preform shaping before sintering to achieve complex contours and minimized machining loss. | ||

| Microstructure Control | Fine powder processing (<0.5 µm), controlled grain growth, and binder optimization to achieve homogeneous microstructure and high fracture resistance. | ||

| Surface Treatment | Polishing, lapping, and CVD/PVD coating for improved wear resistance, reflectivity, or adhesion for functional interfaces. | ||

FAQ

Boron carbide is a ceramic because it is built on strong covalent bonds between boron and carbon atoms, giving it exceptional hardness, low density, and chemical stability. Unlike metals or polymers, it lacks ductility and electrical conductivity, performing as a rigid, heat-resistant structural ceramic ideal for high-temperature and wear-intensive applications.

Also it is a non-oxide ceramic, containing no oxygen and maintains excellent oxidation resistance and thermal stability even at high temperatures.

Here's a how Adcerax control Boron Carbide product quality:

Superior Materials: We use only the purest Boron Carbide powder with consistent particle sizes.

Smart Manufacturing: Our advanced shaping and heating processes create strong, uniform products.

Precise Shaping: We use high-accuracy methods to meet exact size and surface needs.

Strict Checks: Every batch is thoroughly tested for size, density, hardness, strength, and other important properties.

Constant Improvement: We continuously research and refine our methods to make even better products.

Expert Team: Our skilled quality team carefully monitors every step of production.

This careful approach guarantees high-quality, high-performance Boron Carbide products for our customers.

To order custom Boron Carbide ceramic products, provide us with:

- Detailed Drawings/3D Models:

- Precise dimensions, tolerances, and geometric features.

- 3D CAD model (e.g., STEP, IGES) preferred.

- Material Specifications:

- Boron Carbide grade, purity, B:C ratio, and additives (if needed).

- Performance Requirements:

- Hardness, strength, toughness, wear resistance.

- Density, porosity, thermal properties.

- Surface finish (e.g., Ra value).

- Operating conditions (temperature, chemicals, loads).

- Quantity & Timeline:

- Order volume, target price, delivery schedule

Clear, precise information ensures accurate production, minimizes errors, and streamlines the process.

Here's a table of the key properties of boron carbide ceramics and silicon carbide ceramics:

| Property | Boron Carbide Ceramics | Silicon Carbide Ceramics |

|---|---|---|

| Density (g/cm³) | Low, only 2.52 | Relatively low, theoretical density is 3.2 |

| Hardness (Vickers Hardness GPa) | High, up to 35-45 | High, typically 28-34 at room temperature |

| Elastic Modulus (GPa) | High, 450 | High |

| Melting Point (°C) | Approximately 2447-2450 | Up to 2750-2830 |

| Thermal Expansion Coefficient | Low | Small |

| Thermal Conductivity | High | Very High |

| Chemical Stability | Good, resistant to acid and alkali corrosion. Does not react with acids, alkalis, and most inorganic liquids at room temperature. Slow corrosion in hydrofluoric acid-sulfuric acid and hydrofluoric acid-nitric acid mixtures. | Good, stable below 1000°C. A protective silica film forms on the surface at 1000°C. Oxidation resistance diminishes at 1600°C. |

| Oxidation Resistance | Begins to oxidize around 600°C, significant oxidation above 800°C. Prone to reacting with metals. | Superior to boron carbide ceramics, good stability below 1000°C. |

| Fracture Toughness | Low, less than 2.2 MPa*m^(1/2) | Relatively high |

| Price | Expensive, about 10 times the price of alumina | Moderate, cost-effective |

| Main Applications | Military armor, aerospace, neutron absorption, and radiation shielding | Abrasives, ballistic materials, high-temperature applications, anti-corrosion coatings, and sealant fillers. |

Boron carbide ceramic is lightweight, ultra-hard, thermally conductive, and chemically stable but brittle with poor oxidation resistance, priced high, ideal for armor, space, and radiation shielding.

Silicon carbide ceramic offers moderate hardness, excellent oxidation resistance, high thermal conductivity, and toughness at a lower cost, suitable for abrasives, bulletproofing, and high-temperature applications.

Boron carbide ceramics differ from alumina and zirconia mainly in density, hardness, and wear performance.

They are much lighter while maintaining exceptional hardness and chemical stability, making them suitable for high-wear, weight-sensitive, and high-temperature applications.

| Property | Boron Carbide (B₄C) | Alumina (Al₂O₃) | Zirconia (ZrO₂) |

|---|---|---|---|

| Density (g/cm³) | 2.5 | 3.9 | 6.0 |

| Hardness (GPa) | 30–35 | 18–20 | 12–15 |

| Flexural Strength (MPa) | 400–450 | 300–400 | 800–1000 |

| Fracture Toughness (MPa·m¹ᐟ²) | 3–4 | 4 | 8–10 |

| Thermal Conductivity (W/m·K) | 30–45 | 25 | 2–3 |

| Chemical Resistance | Excellent | Excellent | Good |

| Key Advantage | Highest hardness & lowest weight | Cost-effective & stable | High toughness & shock resistance |

Boron carbide offers the best hardness-to-weight ratio and superior wear resistance, while alumina is more economical and zirconia provides higher toughness for impact-prone conditions.

ADCERAX is one such boron carbide ceramic properties manufacturer and wholesaler in China, offering hot-pressed and pressureless-sintered boron carbide parts with full in-house forming, machining, and inspection.

We support both prototype and mass production, providing consistent density, surface quality, and material certification for industrial applications.

ADCERAX offers Hot-Pressed (HP-B₄C), Pressureless Sintered (PS-B₄C), and Reaction-Bonded B₄C ceramics to meet different strength, density, and cost requirements.

Yes. ADCERAX has over 20 years of experience in producing boron carbide B₄C ceramic made in China, serving international customers with consistent quality and precision manufacturing.

Our boron carbide ceramics are exported to the United States, Japan, Australia, Germany, and other global markets, supported by reliable logistics for DDP, CIF, and EXW terms.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Looking for a Reliable Boron Carbide Ceramic Manufacturer in China?

ADCERAX delivers custom B4C ceramics with extreme hardness, low density, and wear resistance.

We support precision machining and tailored designs for sandblasting, cutting, and protective applications worldwide.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours