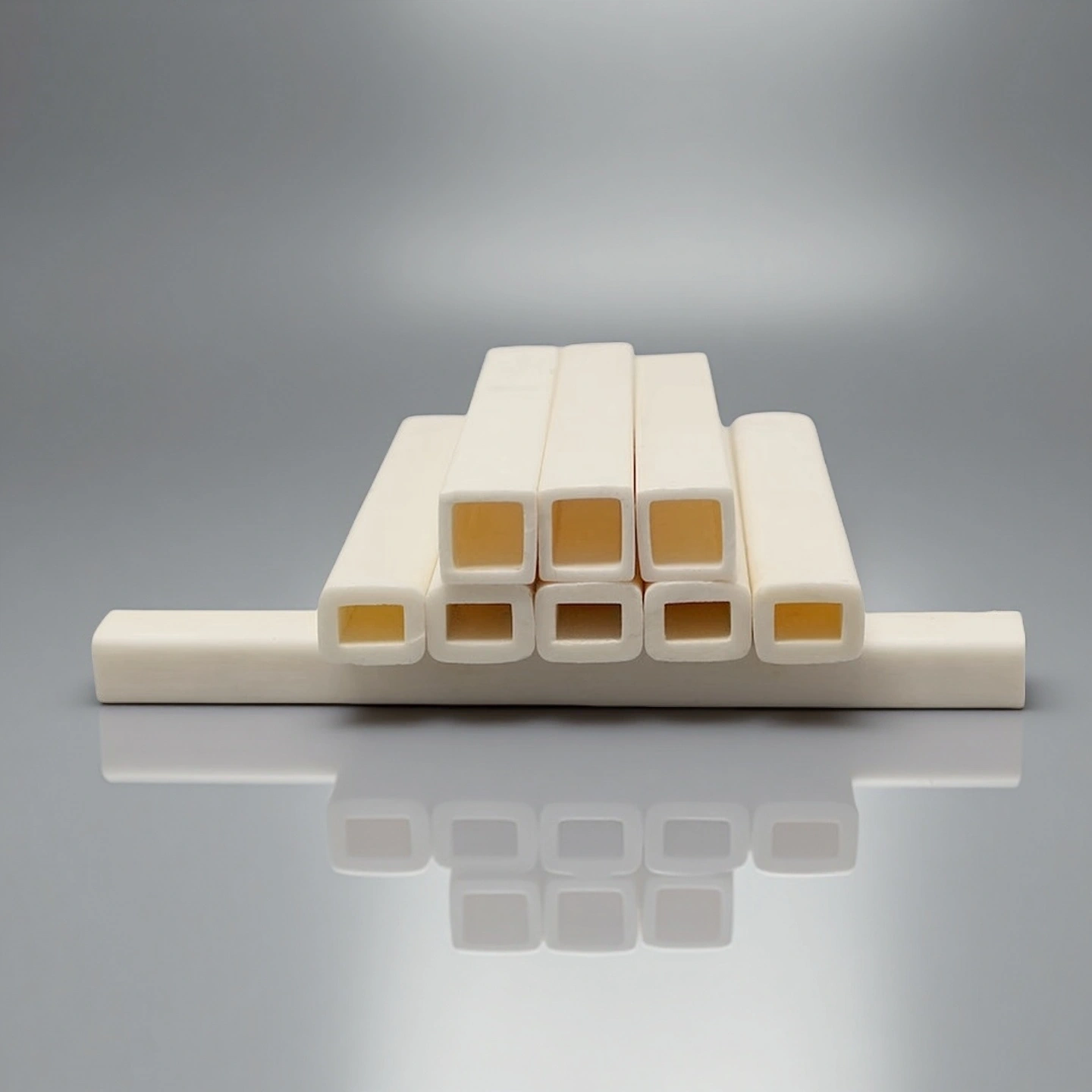

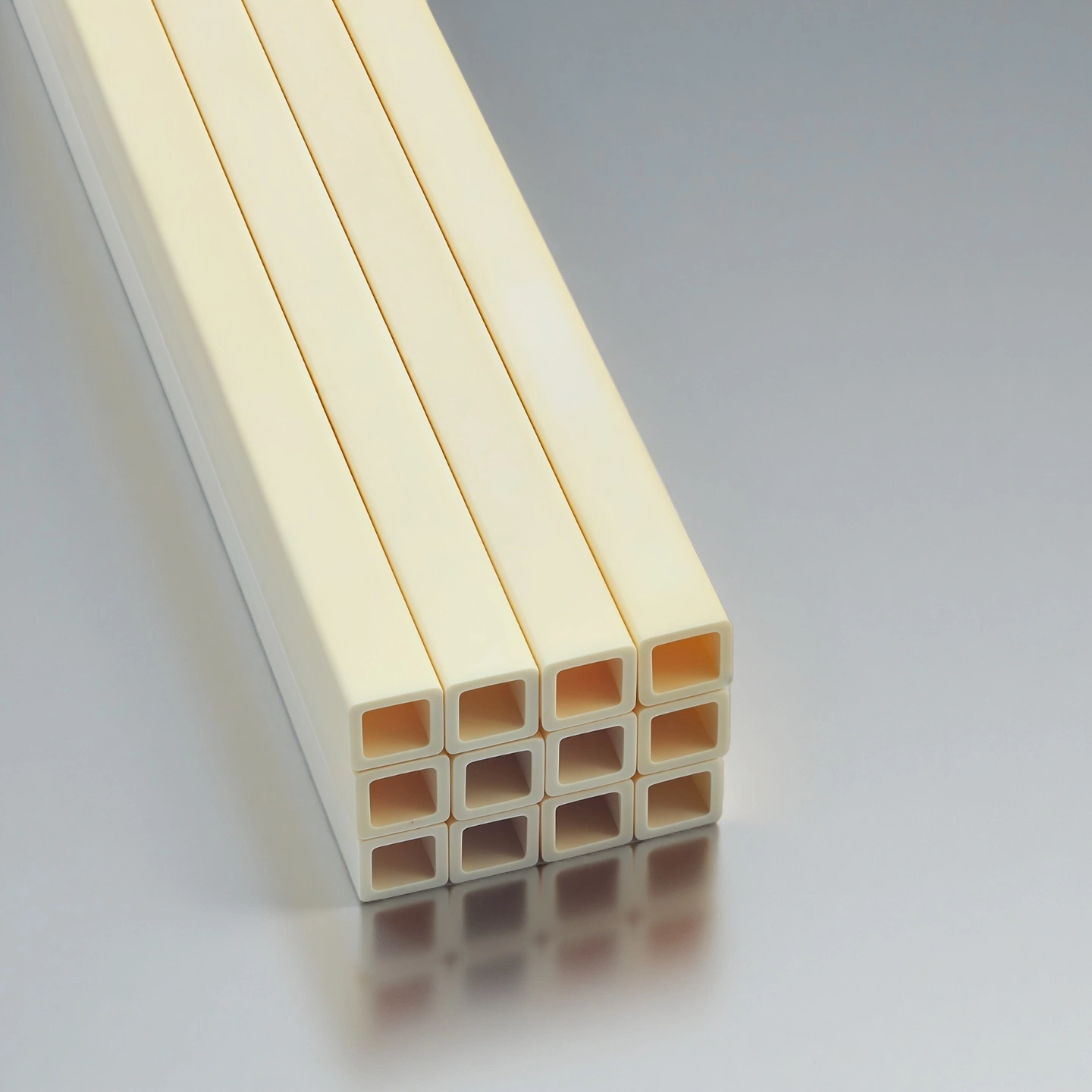

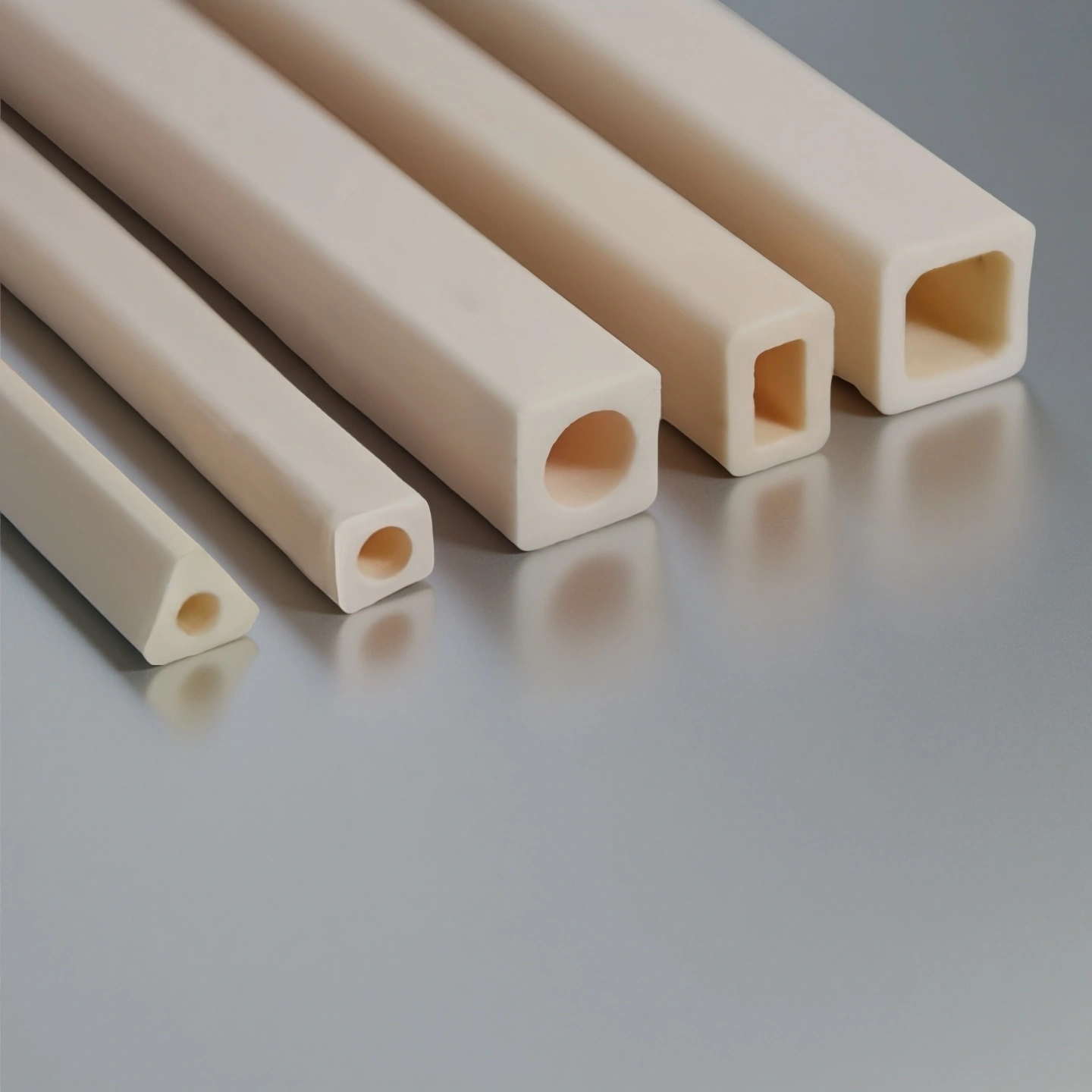

An alumina corundum square tube is a high-purity ceramic tube made from aluminum oxide (Al₂O₃), extruded or moulded into a square or rectangular cross-section. Often preferred in custom furnace designs where space efficiency or alignment matters. “Corundum” refers to crystalline alumina, known for its hardness and thermal stability.

Alumina Corundum Ceramic Square Tube Benefits

- Square cross-sections allow better packing density in multi-tube assemblies.

- Flat surfaces make mounting, alignment, or stacking easier compared to round tubes.

- High Thermal Stability: Withstands extreme temperatures (99.7% up to ~1730°C)

- Excellent Electrical Insulation: Non-conductive, ensuring safety in electrical and electronic components.

- Superior Chemical Resistance: Resists corrosion from acids, alkalis, and most chemicals, except hydrofluoric acid.

- High Mechanical Strength: Durable and resistant to wear, suitable for harsh environments.

- Low Thermal Expansion: Minimizes thermal stress, reducing cracking risks under temperature fluctuations.

Alumina Corundum Square Tube Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

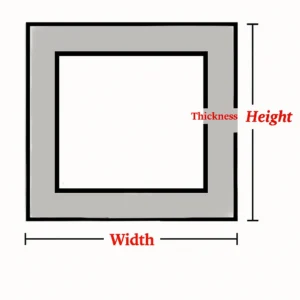

Specification of Alumina Corundum Square Tubes

Type 1-Al₂O₃ Corundum Square Tubes

| Item No. | Width(mm) | Height(mm) | Thickness(mm) | Length(mm) |

| TE-AT-50001 | 7 | 7 | 1.5 | ≤2000 |

| TE-AT-50002 | 8 | 6 | 1 | ≤2000 |

| TE-AT-50003 | 8.7 | 6.3 | 1.1 | ≤2000 |

| TE-AT-50004 | 9.5 | 9.5 | 2 | ≤2000 |

| TE-AT-50005 | 10 | 10 | 5 | ≤2000 |

| TE-AT-50006 | 11 | 8 | 2.5 | ≤2000 |

| TE-AT-50007 | 13 | 10 | 2 | ≤2000 |

| TE-AT-50008 | 15 | 15 | 4 | ≤2000 |

| TE-AT-50009 | 16.5 | 16.5 | 5 | ≤2000 |

| TE-AT-50010 | 23 | 16 | 3 | ≤2000 |

| TE-AT-50011 | 25 | 25 | 3.5 | ≤2000 |

| TE-AT-50012 | 32 | 27 | 3.5 | ≤2000 |

| TE-AT-50013 | 36 | 30 | 3 | ≤2000 |

| TE-AT-50014 | 40 | 30 | 3 | ≤2000 |

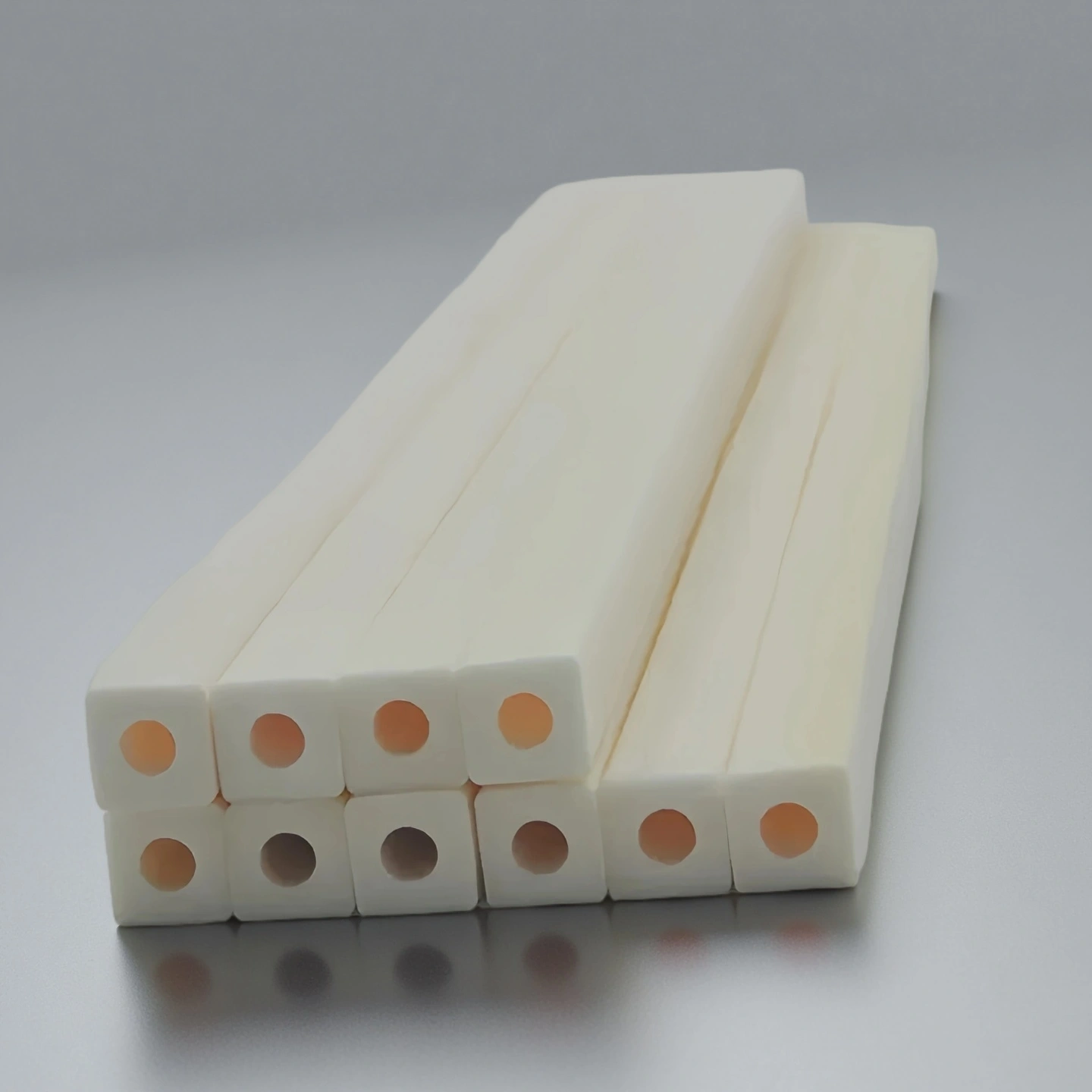

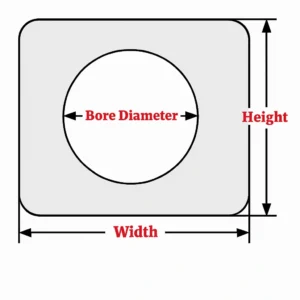

Type2-Al₂O₃ Corundum Square Tubes with Round Bore

| Item No. | Width(mm) | Height(mm) | Bore Dia(mm) | Length(mm) |

| TE-AT-50015 | 6 | 6 | 2.3 | ≤2000 |

| TE-AT-50016 | 8 | 8 | 4.5 | ≤2000 |

| TE-AT-50017 | 8 | 8 | 4 | ≤2000 |

| TE-AT-50018 | 9.5 | 9.5 | 5.2 | ≤2000 |

| TE-AT-50019 | 10 | 10 | 4.5 | ≤2000 |

| TE-AT-50020 | 10 | 10 | 7 | ≤2000 |

| TE-AT-50021 | 18 | 18 | 6 | ≤2000 |

| TE-AT-50022 | 23 | 23 | 8 | ≤2000 |

| TE-AT-50023 | 27 | 27 | 5.5 | ≤2000 |

| TE-AT-50024 | 32 | 32 | 10 | ≤2000 |

| TE-AT-50025 | 40 | 40 | 9 | ≤2000 |

| TE-AT-50013 | 36 | 30 | 3 | ≤2000 |

| TE-AT-50014 | 40 | 30 | 3 | ≤2000 |

*Note: The table above shows only some standard specifications. For more specifications, please refer to the complete product catalogue or contact us for customization.

Alumina Corundum Square Tube Packaging

Each alumina square tube is packed in shockproof foam and a reinforced carton.