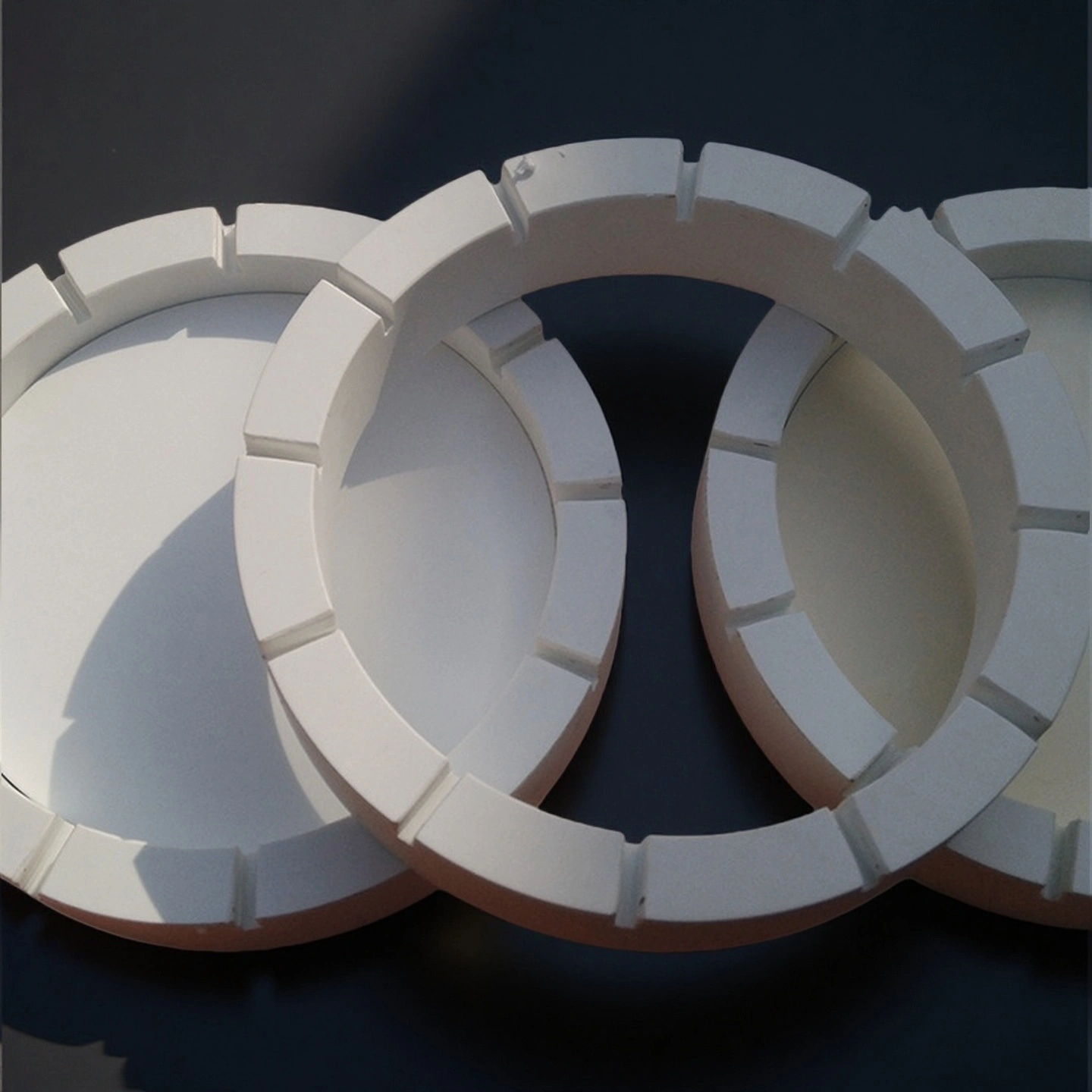

An alumina ceramic retaining ring is a high-purity ceramic component engineered for precision grinding, lapping, and polishing systems. Manufactured from 99% or higher aluminum oxide, these rings provide exceptional hardness, dimensional stability, and chemical inertness, which are critical for processing semiconductor wafers, optical components, and other hard materials. Their primary function is to guide and secure workpieces within a lapping carrier, ensuring uniform material removal and achieving sub-micron surface finishes.

Alumina Ceramic Retaining Ring Benefits

- Sub-Micron Dimensional Control: Manufactured with high-stiffness material and precision-machined geometry, achieving tolerances as tight as ±0.01mm for superior flatness and thickness consistency.

- Exceptional Wear Resistance: With a Vickers hardness exceeding 15 GPa, the rings exhibit minimal wear when used with abrasive slurries, ensuring a long and predictable component lifespan.

- High Material Purity: Made from ≥99.5% pure Al₂O₃, the material is chemically inert and prevents leaching or reaction with polishing slurries, ensuring no microscopic surface contamination.

Alumina Ceramic Retaining Ring Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Specifications of Alumina Ceramic Retaining Ring

| Item | Outer Diameter( mm) | Inner Diameter(mm) | Height(mm) | Purity(%) |

| AT-YHL-YMH001 | 130 | 109 | 40 | 96-99 |

| AT-YHL-YMH002 | 143 | 110 | 40 | 96-99 |

| AT-YHL-YMH003 | 148 | 120 | 38 | 96-99 |

| AT-YHL-YMH004 | 160 | 140 | 43 | 96-99 |

| AT-YHL-YMH005 | 170 | 140 | 40 | 96-99 |

| AT-YHL-YMH006 | 178 | 140 | 45 | 96-99 |

| AT-YHL-YMH007 | 200 | 169 | 45 | 96-99 |

| AT-YHL-YMH008 | 205 | 167 | 45 | 96-99 |

| AT-YHL-YMH009 | 220 | 182 | 50 | 96-99 |

| AT-YHL-YMH010 | 239 | 201 | 45 | 96-99 |

| AT-YHL-YMH011 | 273 | 230 | 40 | 96-99 |

| AT-YHL-YMH012 | 273 | 241 | 45 | 96-99 |

| AT-YHL-YMH013 | 285 | 250 | 55 | 96-99 |

| AT-YHL-YMH014 | 290 | 249 | 45 | 96-99 |

| AT-YHL-YMH015 | 296 | 251 | 50 | 96-99 |

| AT-YHL-YMH016 | 338 | 306 | 40 | 96-99 |

| AT-YHL-YMH017 | 340 | 306 | 50 | 96-99 |

| AT-YHL-YMH018 | 353 | 315 | 52 | 96-99 |

| AT-YHL-YMH019 | 360 | 322 | 60 | 96-99 |

| AT-YHL-YMH020 | 380 | 340 | 55 | 96-99 |

| AT-YHL-YMH021 | 395 | 362 | 55 | 96-99 |

| AT-YHL-YMH022 | 400 | 352 | 60 | 96-99 |

| AT-YHL-YMH023 | 420 | 388 | 60 | 96-99 |

| AT-YHL-YMH024 | 440 | 388 | 60 | 96-99 |

| AT-YHL-YMH025 | 525 | 486 | 60 | 96-99 |

Alumina Ceramic Retaining Ring Packaging

- Each alumina ceramic retaining ring is individually cleaned and sealed in a dust-free PE bag. Rings are then placed in custom-cut EPE foam inserts within a double-walled corrugated carton to prevent any movement or impact during international transit.