ADCERAX® Silicon Carbide Membrane Tube is engineered through high-temperature recrystallization, forming a uniform micro-porous network that enables precise clarification, separation, concentration, and purification of complex industrial fluids. Its structure allows clarified permeate to pass efficiently through a dense filtration layer while suspended solids, colloids, and large organic molecules are retained within interconnected microchannels, ensuring stable flux under demanding operating conditions. The membrane’s inherent mechanical strength, abrasion resistance, thermal endurance, and chemical inertness support long service life and reliable regeneration, making it suitable for continuous gas and liquid filtration across wastewater, chemical, food, and bioprocess applications.

Advanced Performance Characteristics of Silicon Carbide Membrane Tube

-

Pore Size Accuracy

The membrane achieves consistent clarification through a controlled pore structure with a nominal rating of 0.1 μm, ensuring reliable retention of suspended solids and colloidal matter under cross-flow and dead-end configurations. Its stable pore distribution maintains separation quality even when exposed to variable feed compositions.

-

Filtration Performance

A typical filtration efficiency above 95% allows the system to support high-clarity output across wastewater, chemical, and food applications. This throughput stability reduces downstream processing demands, improving overall system productivity.

-

Corrosion Immunity

The membrane withstands full-range chemical exposure from pH 0–14, including strong acids such as sulfuric and hydrochloric acids and strong bases like sodium hydroxide. This resistance preserves structural integrity where polymer and alumina membranes typically degrade.

-

High-Temperature Endurance

Operational reliability is maintained at temperatures up to 900 °C, enabling the membrane to process hot gases and high-temperature liquids without thermal deformation. This capability supports steam sterilization and high-temperature cleaning without performance loss.

-

Durable Operating Lifespan

Service life typically exceeds 5 years, depending on the feed composition and cleaning protocol. The membrane’s non-reactive material prevents surface degradation, extending replacement intervals and reducing total cost of ownership.

-

Cleaning and Regeneration Capacity

The structure accommodates aggressive chemical cleaning and extended backwash cycles while preserving permeability. After regeneration, permeability recovery is consistently above 95%, reducing operational interruptions and stabilizing long-term process efficiency.

Technical Specifications of Silicon Carbide Membrane Tube

The Silicon Carbide Membrane Tube is engineered with a recrystallized SiC microstructure that delivers stable filtration efficiency, mechanical reliability, and corrosion resistance across a wide range of industrial operating environments. Its thermal endurance, hydraulic strength, chemical robustness, and micro-porous architecture reflect the inherent properties of silicon carbide ceramics designed for long-term separation performance.

| Property |

Specification |

| Material |

Recrystallized SiC (SiC ≥ 98.5%) |

| Open Porosity |

35–45% interconnected microstructure |

| Pore Size Rating |

0.1–0.5 μm membrane layer |

| Density |

1.4–2.55 g/cm³ bulk range |

| Flexural Strength |

10–18 MPa |

| Compressive Strength |

25–45 MPa |

| Maximum Operating Pressure |

Up to 16 MPa |

| Maximum Operating Temperature |

Up to 900 °C |

| Thermal Shock Resistance |

ΔT > 500 °C tolerance |

| Chemical Resistance Range |

pH 0–14, including strong acids/alkalis |

| Oxidation Resistance |

Stable under NaClO / H₂O₂ exposure |

| Permeability Recovery After Cleaning |

≥ 95% |

| Microstructure Type |

Recrystallized, self-bonded SiC grains |

| Filtration Efficiency |

≥ 95% clarification efficiency |

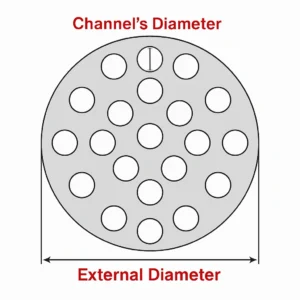

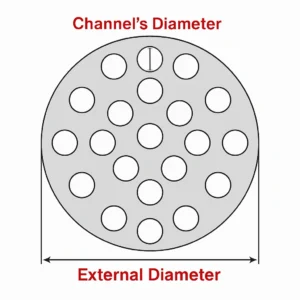

Dimensions of Silicon Carbide Membrane Tube

Type 1-Silicon Carbide Tubular Filtration Tube with Multiple Bore

Type 2-Porous Silicon Carbide Membrane Tube with Both Ends Open

Type 3-Silicon Carbide Membrane Tube Porous One End Closed

|

Item |

External Diameter(mm) |

Inner Diameter(mm) |

Length(mm) |

Filteration Accuracy (μm) |

|

AT-THG-MG022 |

60 |

40 |

200 |

0.1-20 |

|

AT-THG-MG023 |

60 |

40 |

1500 |

0.1-20 |

Type 4-Porous Silicon Carbide Membrane Tube One End Closed Flanged

|

Item |

External Diameter(mm) |

Inner Diameter(mm) |

Length(mm) |

Diameter of Flange

(mm) |

Filteration Accuracy (μm) |

|

AT-THG-MG024 |

60 |

40 |

1000 |

75 |

0.1-20 |

|

AT-THG-MG025 |

60 |

40 |

1500 |

75 |

0.1-20 |

|

AT-THG-MG026 |

70 |

44 |

1000 |

84 |

0.1-20 |

Packaging of Silicon Carbide Membrane Tube

Silicon Carbide Membrane Tube is secured in reinforced carton casings with protective internal padding to prevent vibration or point-impact damage during transit. Each unit is then consolidated into strapped multi-layer export cartons to maintain stability throughout long-distance handling. For overseas shipments, all cartons are finally fixed inside strengthened wooden frames to ensure structural protection under stacking, loading, and container transport conditions.

ADCERAX® Silicon Carbide Membrane Tube for High-Demand Industrial Separation Challenges

The Silicon Carbide Membrane Tube provides a high-stability filtration structure essential for industries that handle corrosive liquids, high-temperature streams, and particulate-rich mixtures. By combining chemical robustness, thermal endurance, and a uniform micro-porous architecture, it supports complex separation tasks where polymer and alumina membranes show rapid degradation.

ADCERAX® applies these characteristics to industrial scenarios that require reliable clarification, concentration, solvent recovery, and high-temperature fluid purification under continuous operation.

-

Silicon Carbide Membrane Tube in High-Salinity Brine Purification for Chlor-Alkali Processing

✅Key Advantages

1. Stable Flux Under Extreme Salinity

Content: In chlor-alkali brine circuits, ADCERAX® Silicon Carbide Membrane Tube maintains stable performance in high ionic strength media with total dissolved solids above typical chlor-alkali levels. Field data show flux decline below 10% over extended runs when operated with appropriate cross-flow velocity and periodic cleaning.

2. Full-Range pH and Oxidant Resistance

Content: The recrystallized SiC structure remains dimensionally stable across pH 0–14 and under continuous exposure to oxidants used in brine conditioning. Tests confirm no measurable loss of mechanical strength or pore-size integrity after repeated exposure to oxidizing cleaning agents and concentrated brine streams.

3. High-Clarity Brine for Downstream Electrolysis

Content: The membrane delivers brine clarification efficiencies above 95% for suspended solids and colloids that interfere with electrolysis cell performance. This level of solids removal supports more stable current efficiency and reduces the frequency of downstream equipment maintenance.

✅ ️Problem Solved

Chlor-alkali plants frequently report unstable brine quality, membrane corrosion, and repeated filtration shutdowns due to fouling in high-salinity and oxidizing environments. In one large-scale brine purification line, polymeric elements required frequent replacement and cleaning intervals shorter than one month, with significant loss of flux after each cycle. After adopting ADCERAX® Silicon Carbide Membrane Tube, the same line operated with flux recovery consistently above 95% after chemical cleaning and extended replacement intervals beyond five years of service. Process engineers reported a marked reduction in unplanned stops and more predictable operation of downstream electrolysis cells due to stable, clarified brine feed.

-

Silicon Carbide Membrane Tube in High-Temperature Flue Gas Condensate Recovery for Coal-Chemical Plants

✅Key Advantages

1. Thermal-Shock Resilience in Condensate Duty

Content: ADCERAX® Silicon Carbide Membrane Tube tolerates rapid temperature swings typical of flue gas condensate streams without cracking or loss of integrity. Laboratory simulations show the membrane structure remaining intact after repeated thermal cycles with temperature steps exceeding several hundred degrees Celsius.

2. Organic-Fouling Resistance and Easy Regeneration

Content: The SiC surface exhibits low affinity for tars and phenolic compounds, enabling fouling layers to be removed effectively by alkaline and oxidizing cleaning sequences. Plants using SiC elements report permeability recovery above 90–95% after regeneration, even when processing condensates rich in viscous organics.

3. Mechanical Stability Under Variable Hydraulic Load

Content: The high-strength support matrix maintains structural stability under fluctuating pressure differentials generated by variable condensate flow and gas load. Tests indicate reliable operation up to 16 MPa without structural deformation, supporting continuous recovery in demanding coal-chemical environments.

✅ ️Problem Solved

Coal-chemical operators often experience a combination of rapid fouling, membrane cracking, and unstable throughput when conventional elements are exposed to hot, organic-laden condensates. In a flue gas recovery unit handling condensate with significant tar and phenolic content, conventional ceramic modules showed crack failure rates above 10–15% after repeated thermal cycles, and flux recovery after cleaning remained below 70%. After replacement with ADCERAX® Silicon Carbide Membrane Tube modules, crack-related failures dropped to below 1%, and permeability recovery after standardized cleaning procedures remained in the 90–95% range. This improvement allowed the plant to extend operating campaigns between major maintenance events and stabilize condensate recovery performance.

-

Silicon Carbide Membrane Tube in Fermentation-Broth Clarification for Bio-Processing Concentration Systems

✅Key Advantages

1. Consistent Biomass and Macromolecule Retention

Content: The controlled pore rating of 0.1–0.5 μm in ADCERAX® Silicon Carbide Membrane Tube supports reliable retention of microbial cells and large macromolecules while allowing clarified permeate to pass. Trials in fermentation clarification show suspended solids removal efficiencies exceeding 95%, with stable cut-off behavior across multiple batches.

2. Steam-Sterilization Compatibility Over Repeated Cycles

Content: The SiC membrane structure tolerates repeated steam-in-place sterilization cycles in the 121–135 °C range without pore-collapse or matrix degradation. Long-term endurance tests demonstrate stable flux and retention characteristics after more than 200 sterilization and cleaning cycles.

3. High-Flux Operation in Viscous Broths

Content: The open microchannel architecture supports cross-flow operation in broths with viscosities significantly higher than water without excessive pressure build-up. In pilot systems handling fermentation media with elevated solids and viscosity, flux recovery after cleaning remains above 90–95%, enabling extended production runs with fewer membrane changeouts.

✅ ️Problem Solved

Bio-processing plants frequently struggle with rapid flux decline, irreversible fouling, and instability during sterilization when clarifying dense fermentation broths. In one fermentation-based production line, polymeric membranes showed significant loss of capacity after fewer than 50 steam-sterilization cycles, and flux recovery after cleaning remained below 70%, forcing frequent membrane replacement. After installing ADCERAX® Silicon Carbide Membrane Tubes, the same line sustained clarification performance over more than 200 operating and sterilization cycles with flux recovery above 90–95%. This change reduced membrane-associated interruptions and stabilized upstream clarification feeding downstream concentration and purification steps.

ADCERAX® Silicon Carbide Membrane Tube User Guide for Stable, Safe, and Efficient Operation

This section provides practical guidance for ensuring consistent performance and long-term reliability when operating Silicon Carbide Membrane Tube systems across industrial filtration lines. The recommendations below help users maintain stable flux, protect membrane integrity, and achieve predictable clarification results under demanding chemical, thermal, and mechanical conditions.

-

Installation Requirements for System Integration

1. Proper Inlet Conditioning

Feed streams should be screened to remove oversized particulates that may cause uneven loading at the membrane entrance. Stable inlet pressure must be maintained to avoid hydraulic shocks that can affect early-stage permeation consistency. Uniform flow distribution improves cross-flow efficiency and minimizes localized fouling.

2. Controlled Mechanical Support

Secure mounting structures should be used to prevent vibration and bending stress during operation. Support fixtures must avoid point contact that could create concentrated mechanical loads over extended run time. Ensuring balanced alignment enhances flow uniformity within all membrane channels.

3. Safe Connection Practices

Sealing interfaces should be fitted using compatible gasket or clamp materials resistant to process chemistry. Over-tightening should be avoided to prevent structural stress at the tube ends during long-term cycling. Flow direction indicators and assembly orientation should be checked prior to commissioning for predictable operation.

-

Operating Conditions for Stable Clarification

1. Controlled Pressure Operation

Operating pressure should remain within validated limits to maintain stable flux performance and prevent unnecessary membrane fatigue. Pressure fluctuations in high-salinity or viscous media can accelerate fouling, requiring additional adjustment or process buffering. Gradual ramp-up improves system stability during startup.

2. Temperature Management

Feed temperature must be kept within thermal stability allowances to avoid rapid expansion stresses and performance drift. High-temperature applications should ensure a controlled gradient to protect the membrane’s micro-porous network. Consistent temperature helps maintain predictable permeate behavior.

3. Chemical Compatibility Handling

Incoming fluid chemistry must fall within recommended acid, alkali, or oxidizing ranges to ensure long service life of the filtration layer. Sudden pH shifts or oxidant surges may require buffer zones or automated dosing adjustments. Maintaining chemical stability extends runtime between cleaning cycles.

-

Cleaning and Regeneration Protocols

1. Periodic Backwashing Strategy

Backwash cycles should be scheduled according to feed characteristics to remove accumulated solids from the inner channels. Controlled flow reversal prevents excessive impact force while helping restore permeate recovery. Regular intervals improve long-term operational consistency.

2. Chemical Cleaning Recommendations

Cleaning agents must be matched to the foulant category—organic, inorganic, or biological—to prevent surface damage. Temperature-controlled cleaning solutions improve solubility of deposits without compromising structural strength. Proper neutralization should follow before returning the system to production.

3. Thermal Sterilization Guidelines

High-temperature sanitation should be introduced gradually to avoid thermal shock. Steam cycles must stay within the allowable heat range to preserve membrane geometry and pore distribution. Alternating between heating and cooling phases should follow recommended timing to protect microstructural integrity.

-

Storage, Handling, and Transportation Care

1. Safe Storage Environment

Membrane tubes should be stored in clean, dry conditions to avoid moisture absorption that can cause unexpected thermal behavior during later operation. Storage racks must prevent bending or torsional stress over prolonged periods. Protective coverings help reduce exposure to airborne contaminants.

2. Careful Handling Procedures

Handling should follow two-point support to avoid concentrated stress at the tube ends. Impact or rolling should be strictly avoided as micro-cracks may propagate under high-pressure use. Team lifting is advised for multi-unit assemblies to ensure structural safety.

3. Optimized Transport Protection

For long-distance shipment, units should be packed using rigid crates, foam-lined cartons, or reinforced frames to maintain impact resistance throughout transit. Vibration control materials reduce transportation fatigue during overseas movement. All packaging must be clearly labeled for upright orientation and fragile handling.

![]()

![]()

![]()

![]()