An alumina high-pressure sodium (HPS) lamp arc tube is the ceramic “discharge chamber” inside an HPS (HID) lamp where the electrical arc forms and light is generated. It is typically made from PCA (polycrystalline alumina) so it can withstand high operating temperature, high internal pressure, and corrosive sodium vapor during repeated lamp start/stop cycles.

Alumina High Pressure Sodium Lamp Arc Tube Advantages

-

Translucent PCA tube body for stable arc-chamber performance: the alumina HPS arc tube maintains a consistent optical path under high temperature and pressure, helping keep lamp-to-lamp output behavior predictable across production batches.

-

End-geometry consistency that matches real lamp sealing interfaces: open/closed/domed end options can be held to your functional seating reference, reducing electrode/seal misalignment risk caused by small end-face or land variations.

-

Tight dimensional control for repeatable fit-up in jigs and fixtures: controlled OD/ID and length reduce “force-fit” assembly behavior, improve kitting compatibility, and support faster incoming inspection with defined critical checkpoints.

-

Low-variation straightness and concentricity targets to cut build rework: improved tube linearity and center alignment reduce fixture interference and reduce adjustment during electrode positioning and sealing steps in lamp assembly.

-

Controlled surface condition for consistent handling and inspection: defined surface zones (as-sintered, ground, or polished where needed) help stabilize seating, reduce micro-chipping during handling, and make visual/measurement checks more repeatable.

Alumina High Pressure Sodium Lamp Arc Tube Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina High Pressure Sodium Lamp Arc Tube Specifications

| Alumina High Pressure Sodium Lamp Arc Tube | ||

| Item No. | Diameter (mm) | Length (mm) |

| AT-AO-DG1001 | 4 | 43.2 |

| AT-AO-DG1002 | 4 | 44.4 |

| AT-AO-DG1003 | 4 | 52.5 |

| AT-AO-DG1004 | 5 | 58 |

| AT-AO-DG1005 | 5.8 | 70 |

| AT-AO-DG1006 | 7.4 | 230 |

| AT-AO-DG1007 | 7.8 | 162 |

| AT-AO-DG1008 | 11 | 184 |

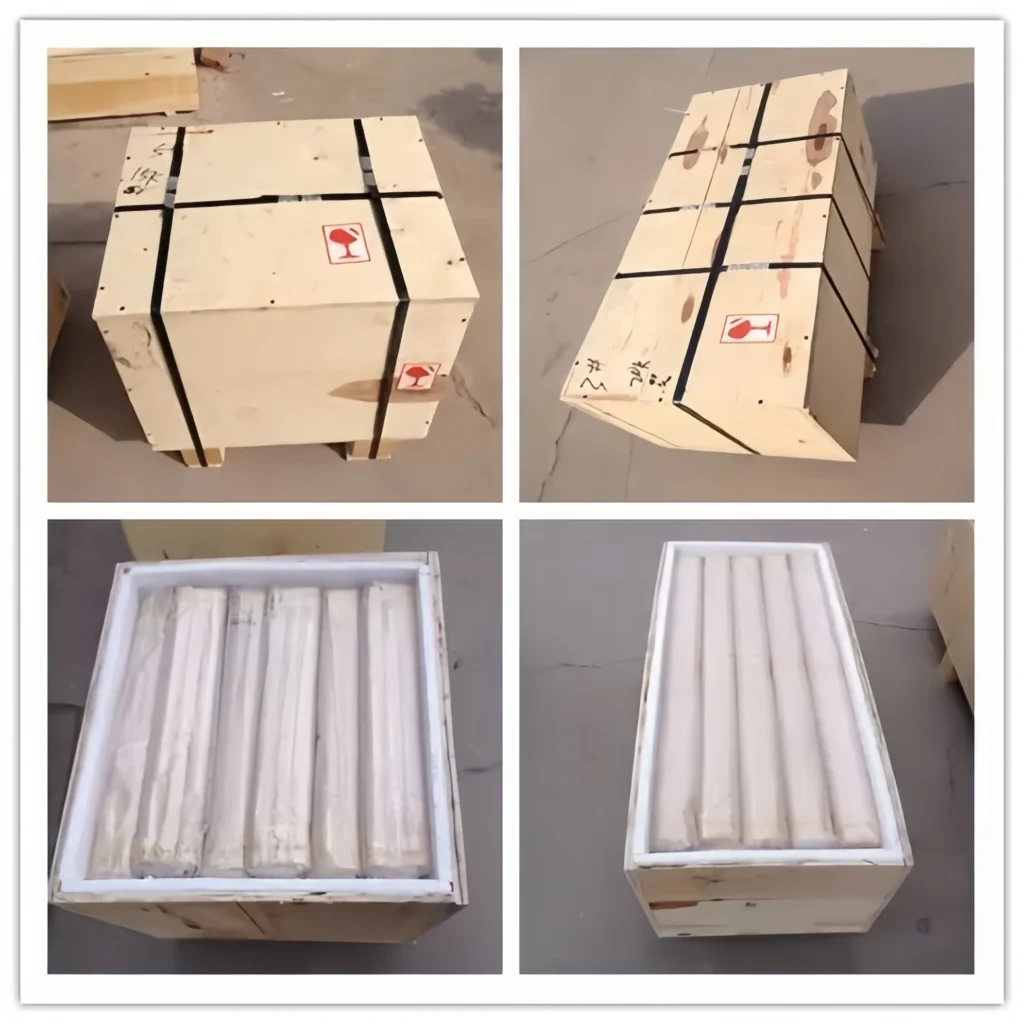

Alumina High Pressure Sodium Lamp Arc Tube Packaging

- Individual slot or partitioned tray to prevent tube-to-tube contact

- Shock-absorbing foam layers for end protection during transit