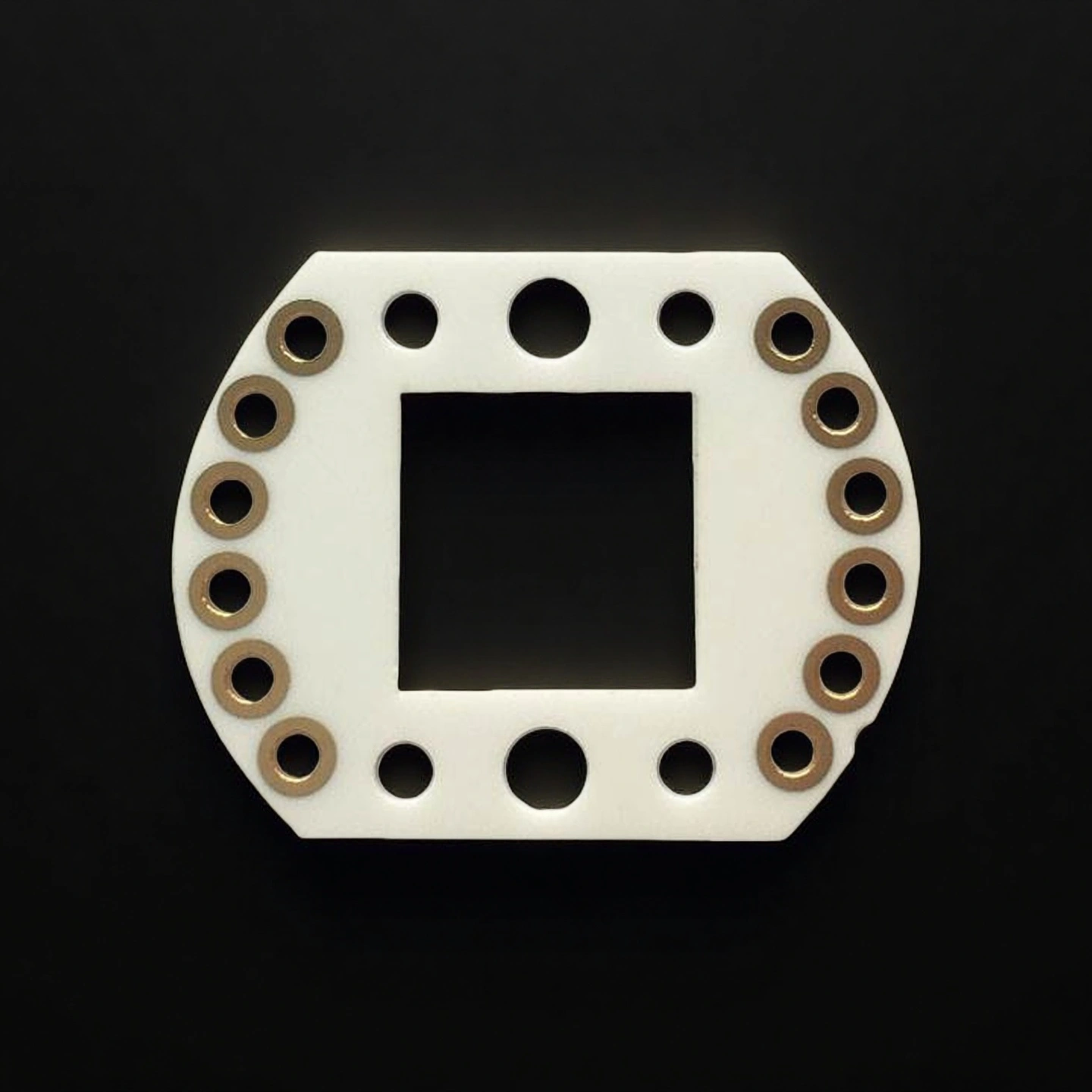

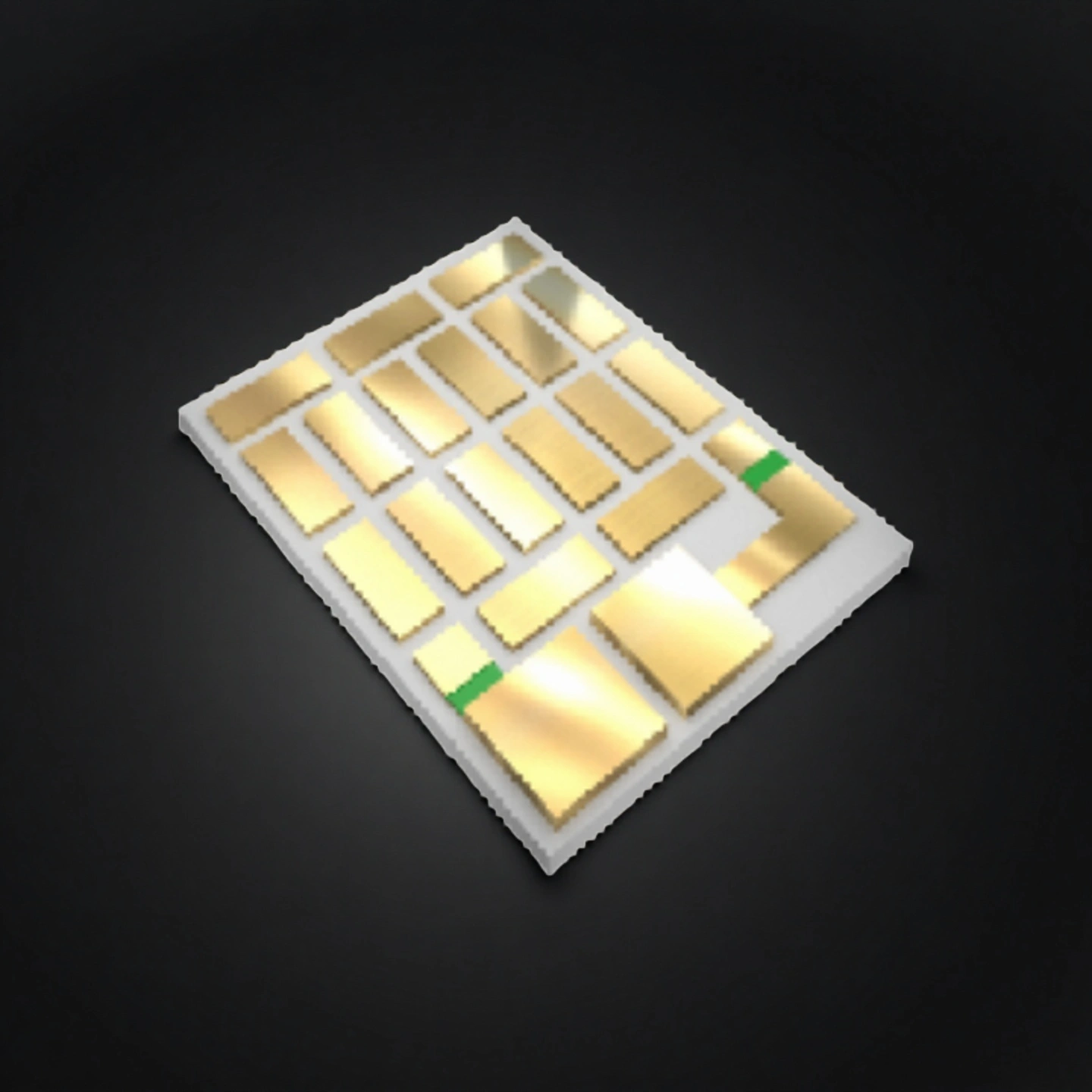

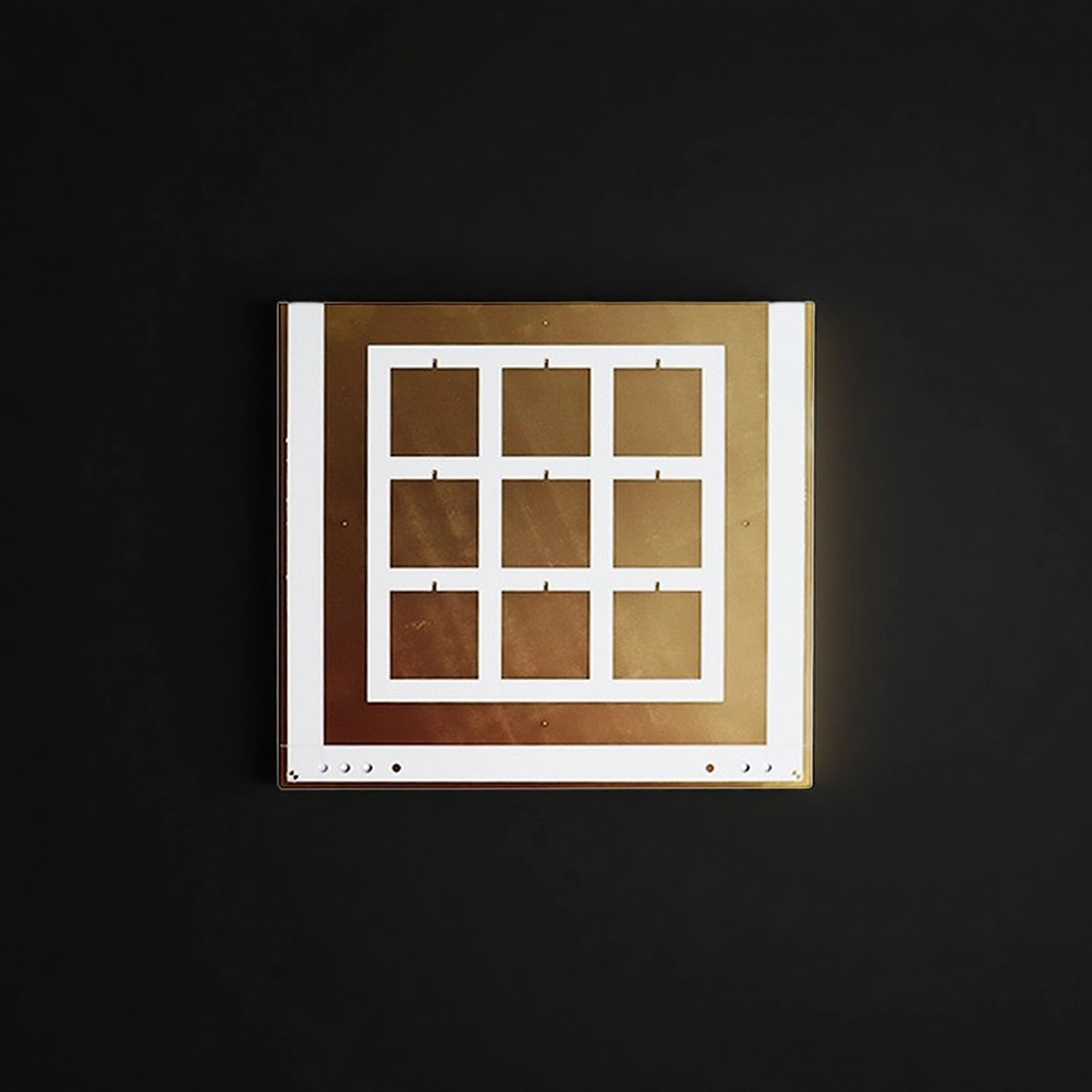

Metalized alumina substrate is a high-performance component used in electronics, as a small, flat tile made of alumina ceramic—a very hard, white material that is an excellent electrical insulator but also conducts heat well—onto which a thin layer of metal, usually copper, is bonded in a specific pattern, similar to the printed wires on a traditional circuit board.

Alumina Metalized Ceramic Substrate Benefits

- Exceptional Thermal Dissipation: Constructed from 96% or 99.6% purity alumina (Al₂O₃), our substrates conduct heat away from critical components like IGBTs and LEDs, preventing thermal failure and extending device lifespan.

- Stable Electrical Performance: The high dielectric strength and low dielectric loss of alumina ensure reliable electrical isolation at high voltages and maintain signal integrity in high-frequency RF applications.

- Strong Metallization Adhesion: Utilizing advanced metallization processes (DBC, DPC, Thick Film), the copper and refractory metal layers form a permanent bond with the ceramic, withstanding severe thermal cycling and mechanical stress without delamination.

- Precision Patterning: Laser processing and photolithography enable circuit trace and space resolution down to 30μm, facilitating the design of dense and complex electronic modules

Metalized Alumina Substrate Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Al2O3 Metalized Ceramic Substrate Specifications

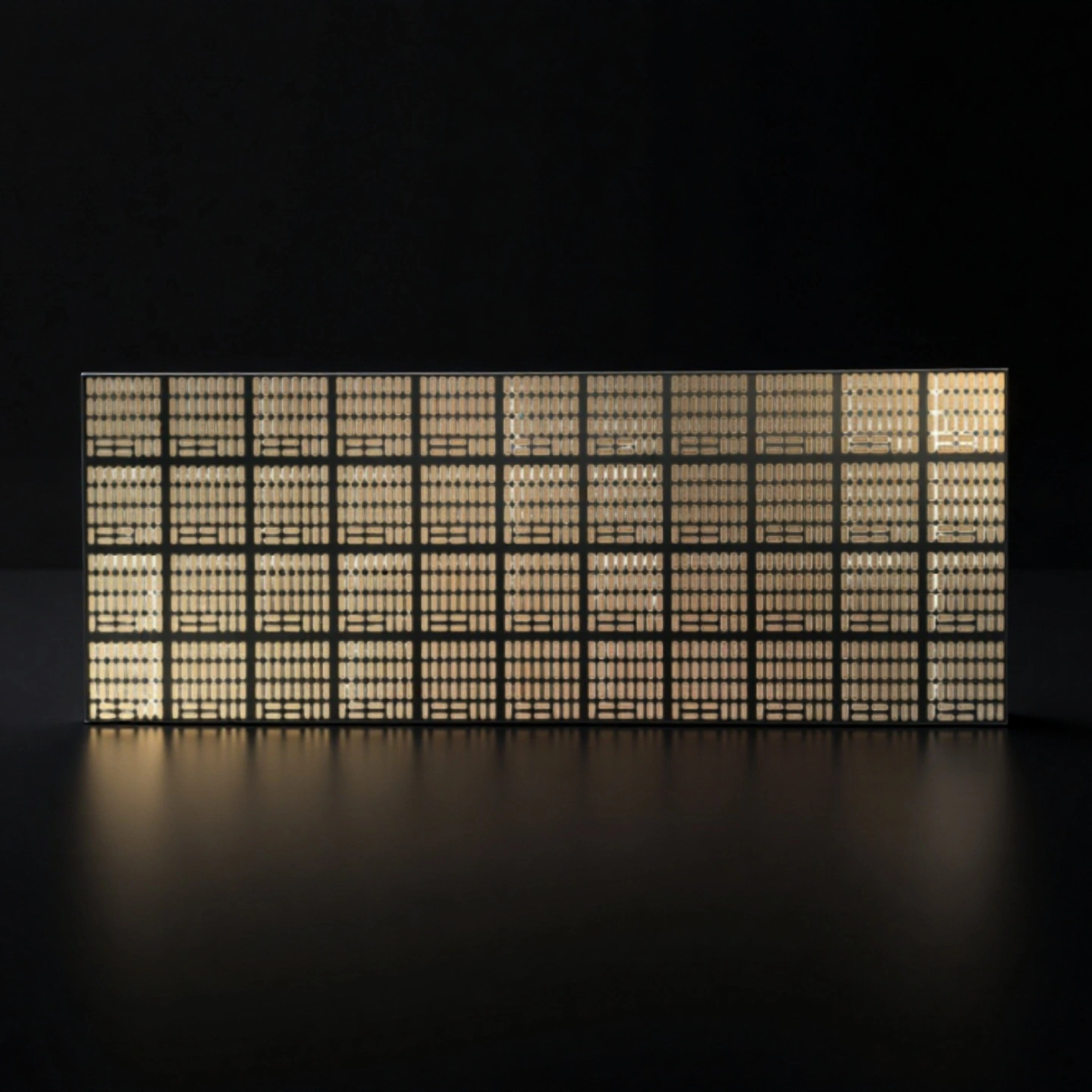

Type 1: Rectangle Alumina Metalized Ceramic Substrate

| Rectangle Alumina Metalized Ceramic Substrate | ||||||

| Item No. | Length(mm) | Width(mm) | Thickness(mm) | Copper foil thickness (mm) | Copper clad thickness(mm) | Purity(%) |

| AT-DBC-C001 | 10 | 5 | 0.25 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| AT-DBC-C002 | 18 | 11 | 0.25 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| AT-DBC-C003 | 20 | 15 | 0.38 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| AT-DBC-C004 | 28 | 9 | 0.635 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| AT-DBC-C005 | 32 | 24 | 0.55 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| AT-DBC-C006 | 55 | 30 | 6 | 0.1-0.6 | 0.035 | 96 |

| AT-DBC-C007 | 70 | 52 | 0.76 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| AT-DBC-C008 | 84 | 35 | 1 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| AT-DBC-C009 | 103 | 90 | 0.635 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| AT-DBC-C010 | 127 | 105 | 2 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| AT-DBC-C011 | 156 | 84 | 3 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| AT-DBC-C012 | 178 | 138 | 5 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| AT-DBC-C013 | 188 | 138 | 4.6 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

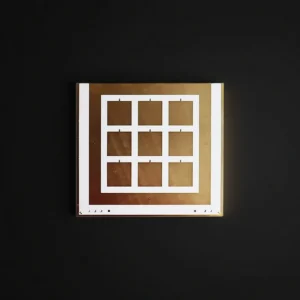

Type 2: Square Alumina Metalized Ceramic Substrate

| Square Alumina Metalized Ceramic Substrate | ||||||

| Item No. | Length(mm) | Width(mm) | Thickness(mm) | Copper foil thickness (mm) | Copper clad thickness(mm) | Purity(%) |

| AT-DBC-Z001 | 10 | 10 | 0.25 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| AT-DBC-Z002 | 15 | 15 | 0.25 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| AT-DBC-Z003 | 18 | 18 | 0.25 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| AT-DBC-Z004 | 25 | 25 | 0.38 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| AT-DBC-Z005 | 31.5 | 31.5 | 0.635 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| AT-DBC-Z006 | 33 | 33 | 0.76 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| AT-DBC-Z007 | 40 | 40 | 0.76 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| AT-DBC-Z008 | 60 | 60 | 1 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| AT-DBC-Z009 | 72 | 72 | 1 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| AT-DBC-Z010 | 100 | 100 | 3 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

| AT-DBC-Z011 | 127 | 127 | 1 | 0.1-0.6 | 0.035 | 99.7 |

| AT-DBC-Z012 | 138 | 138 | 5 | 0.1-0.6 | 0.075-0.1 | 96-99.7 |

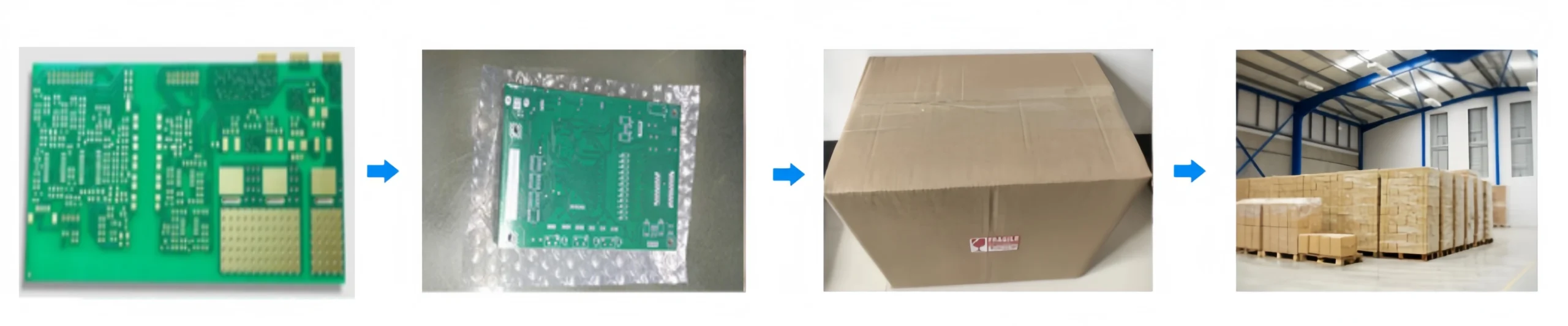

Metalized Alumina Substrate Packaging

- Each metalized ceramic part is sealed, packed, and placed in anti-static trays with moisture-proof bags. Shock-resistant outer cartons ensure integrity during transport.