The alumina Ceramic Ball Valve is a precision-engineered industrial valve that uses high-purity alumina ceramic (Al₂O₃) for its key internal components—typically the ball, seat, and lining. Unlike conventional metal valves, which degrade quickly when exposed to abrasive slurries or corrosive chemicals, alumina ceramic valves maintain tight shutoff and stable torque through extreme wear and chemical attack.

Alumina Ceramic Ball Valve Benefits

- Ceramic sealing pair: Al₂O₃ ball/seat interface supports tight shutoff under abrasive load.

- Slurry-tolerant flow path: Full-bore option and erosion-aware geometry help mitigate choke points in particle-rich media.

- Mixed-media compatibility: Alumina’s chemical stability suits alternating acid/alkali wash cycles.

- Repeatable torque: Stable friction profile aids accurate actuator sizing and control loop tuning.

- Field serviceability: Cartridge-style trim options simplify inspection and replacement.

Alumina Ceramic Ball Valve Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina Ceramic Ball Valve Specifications

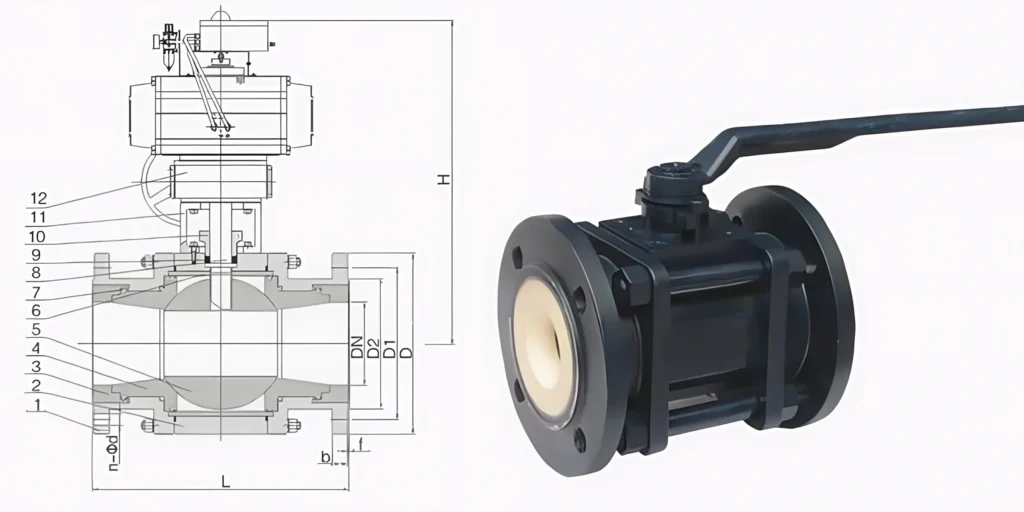

| Part No. | Parts | Material |

|---|---|---|

| 1 | Valve Body | WCB |

| 2 | Middle Body | WCB |

| 3 | Gland Flang | Engineering Ceramic |

| 4 | Valve Seat | Engineering Ceramic |

| 5 | Ball | Engineering Ceramic |

| 6 | Bushing | Engineering Ceramic |

| 7 | Stem | 2Cr13 |

| 8 | Packing | Flexible Graphite |

| 9 | Packing Gland | WCB |

| 10 | Lever | WCB |

Type 1: Alumina Ceramic Lined O Type Ball Valve

| Alumina Ceramic Lined O Type Ball Valve | ||||||||

| Item NO. | DN | PH (Mpa) | D (mm) | D1 (mm) | D2 (mm) | C (mm) | H (mm) | n-d |

| AT-CVO-001 | 15 | 1.6 | 130 | 95 | 45 | 14 | 180 | 4-∅14 |

| AT-CVO-002 | 20 | 1.6 | 140 | 105 | 55 | 16 | 190 | 4-∅14 |

| AT-CVO-003 | 25 | 1.6 | 150 | 115 | 65 | 16 | 220 | 4-∅14 |

| AT-CVO-004 | 32 | 1.6 | 165 | 135 | 75 | 18 | 235 | 4-∅18 |

| AT-CVO-005 | 40 | 1.6 | 180 | 145 | 85 | 18 | 255 | 4-∅18 |

| AT-CVO-006 | 50 | 1.6 | 203 | 160 | 100 | 20 | 270 | 4-∅18 |

| AT-CVO-007 | 65 | 1.6 | 220 | 180 | 120 | 20 | 310 | 4-∅18 |

| AT-CVO-008 | 80 | 1.6 | 250 | 195 | 135 | 20 | 370 | 8-∅18 |

| AT-CVO-009 | 100 | 1.6 | 280 | 215 | 155 | 22 | 430 | 8-∅18 |

| AT-CVO-010 | 125 | 1.6 | 320 | 245 | 185 | 22 | 510 | 8-∅18 |

| AT-CVO-011 | 150 | 1.6 | 394 | 280 | 210 | 24 | 590 | 8-∅23 |

| AT-CVO-012 | 200 | 1.6 | 457 | 335 | 265 | 24 | 750 | 8-∅23 |

| AT-CVO-013 | 250 | 1.6 | 533 | 506 | 320 | 26 | 850 | 12-∅23 |

| AT-CVO-014 | 300 | 1.6 | 610 | 460 | 375 | 30 | 920 | 12-∅25 |

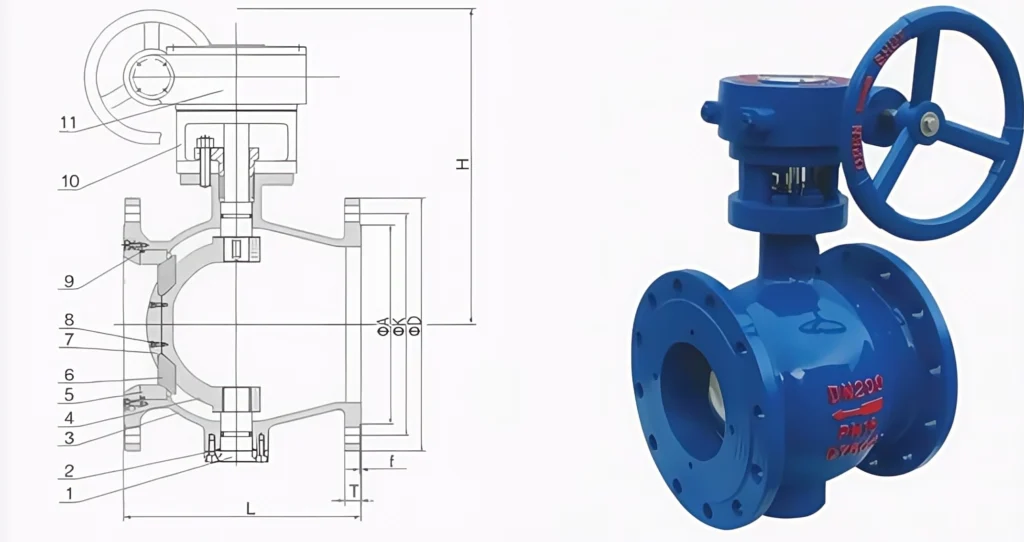

Type 2: Alumina Ceramic Lined Eccentric Half Ball Valve

| Alumina Ceramic Lined Eccentric Half Ball Valve | ||||||||||

| Item NO. | DN | PN (Mpa) | H (mm) | L (mm) | D (mm) | D1 (mm) | D2 (mm) | n-d | C (mm) | F (mm) |

| AT-CVP1-001 | 50 | 1.6 | 230 | 124 | 165 | 125 | 100 | 4-∅18 | 16 | 3 |

| AT-CVP1-002 | 65 | 1.6 | 237 | 145 | 185 | 145 | 120 | 4-∅18 | 18 | 3 |

| AT-CVP1-003 | 80 | 1.6 | 260 | 165 | 200 | 160 | 135 | 8-∅18 | 20 | 3 |

| AT-CVP1-004 | 100 | 1.6 | 270 | 194 | 220 | 180 | 156 | 8-∅18 | 20 | 3 |

| AT-CVP1-005 | 125 | 1.6 | 320 | 210 | 250 | 210 | 185 | 8-∅22 | 22 | 3 |

| AT-CVP1-006 | 150 | 1.6 | 340 | 229 | 285 | 240 | 211 | 8-∅22 | 26 | 3 |

| AT-CVP1-007 | 200 | 1.6 | 390 | 243 | 340 | 295 | 265 | 8-∅23 | 26 | 3 |

| AT-CVP1-008 | 250 | 1.6 | 420 | 297 | 405 | 355 | 319 | 8-∅26 | 30 | 3 |

| AT-CVP1-009 | 300 | 1.6 | 510 | 338 | 460 | 410 | 375 | 8-∅26 | 30 | 4 |

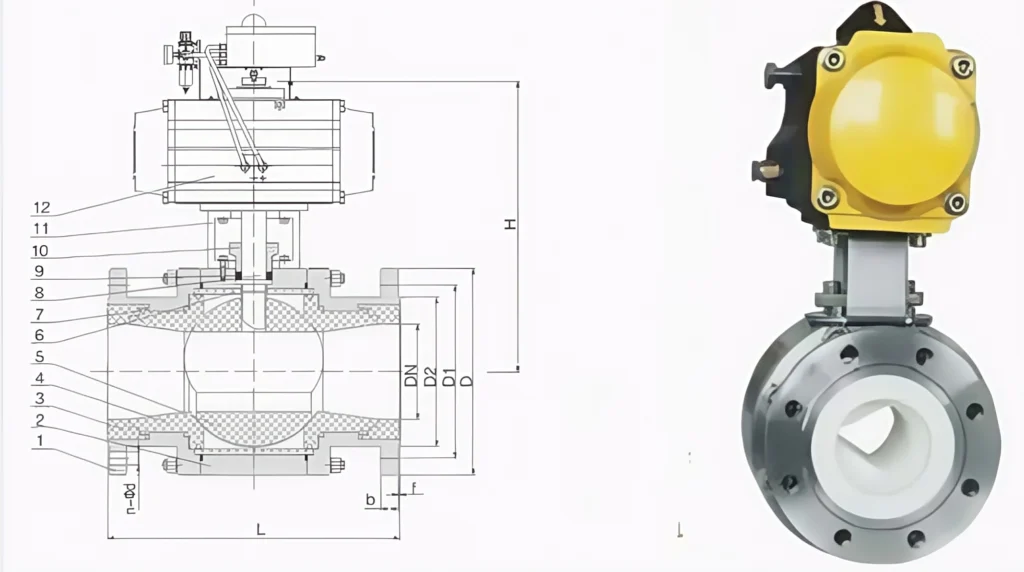

Type 3: Alumina Ceramic Lined V Ball Control Valve

| Alumina Ceramic Lined V Ball Control Valve | ||||||||||

| Item No. | DN | NPS | H (mm) | L (mm) | D (mm) | D1 (mm) | D2 (mm) | n-d | b (mm) | f (mm) |

| AT-CVV1-001 | 15 | 1 2" | 170 | 108 | 90 | 60.3 | 34.9 | 4-M12 | 11.6 | 2 |

| AT-CVV1-002 | 20 | 3 /4" | 180 | 117 | 100 | 69.9 | 42.9 | 4-M12 | 13.2 | 2 |

| AT-CVV1-003 | 25 | 1" | 185 | 127 | 110 | 79.4 | 50.8 | 4-M12 | 14.7 | 2 |

| AT-CVV1-004 | 32 | 1-1/4" | 220 | 140 | 115 | 88.9 | 63.5 | 4-M12 | 16.3 | 2 |

| AT-CVV1-005 | 40 | 1-1/2" | 230 | 165 | 125 | 98.4 | 73 | 4-M12 | 17.9 | 2 |

| AT-CVV1-006 | 50 | 2" | 247 | 178 | 150 | 120.7 | 92.1 | 4-M16 | 19.5 | 2 |

| AT-CVV1-007 | 65 | 2-1/2" | 270 | 190 | 180 | 139.7 | 104.8 | 4-M16 | 22.7 | 2 |

| AT-CVV1-008 | 80 | 3" | 310 | 203 | 190 | 152.4 | 127 | 4-M16 | 24.3 | 2 |

| AT-CVV1-009 | 100 | 4" | 355 | 229 | 230 | 190.5 | 139.7 | 4-M16 | 24.3 | 2 |

| AT-CVV1-010 | 125 | 5" | 430 | 356 | 255 | 215.9 | 157.2 | 4-M20 | 24.3 | 2 |

| AT-CVV1-011 | 150 | 6" | 490 | 394 | 280 | 241.3 | 185.7 | 4-M21 | 25.9 | 2 |

| AT-CVV1-012 | 200 | 8" | 590 | 457 | 345 | 298.5 | 215.9 | 4-M22 | 29 | 2 |

Alumina Ball Valve Packaging

- Each valve unit is carefully packed with the foam-injected crate.

- Anti-fracture reinforced outer box aligned with the valves' dimensions.