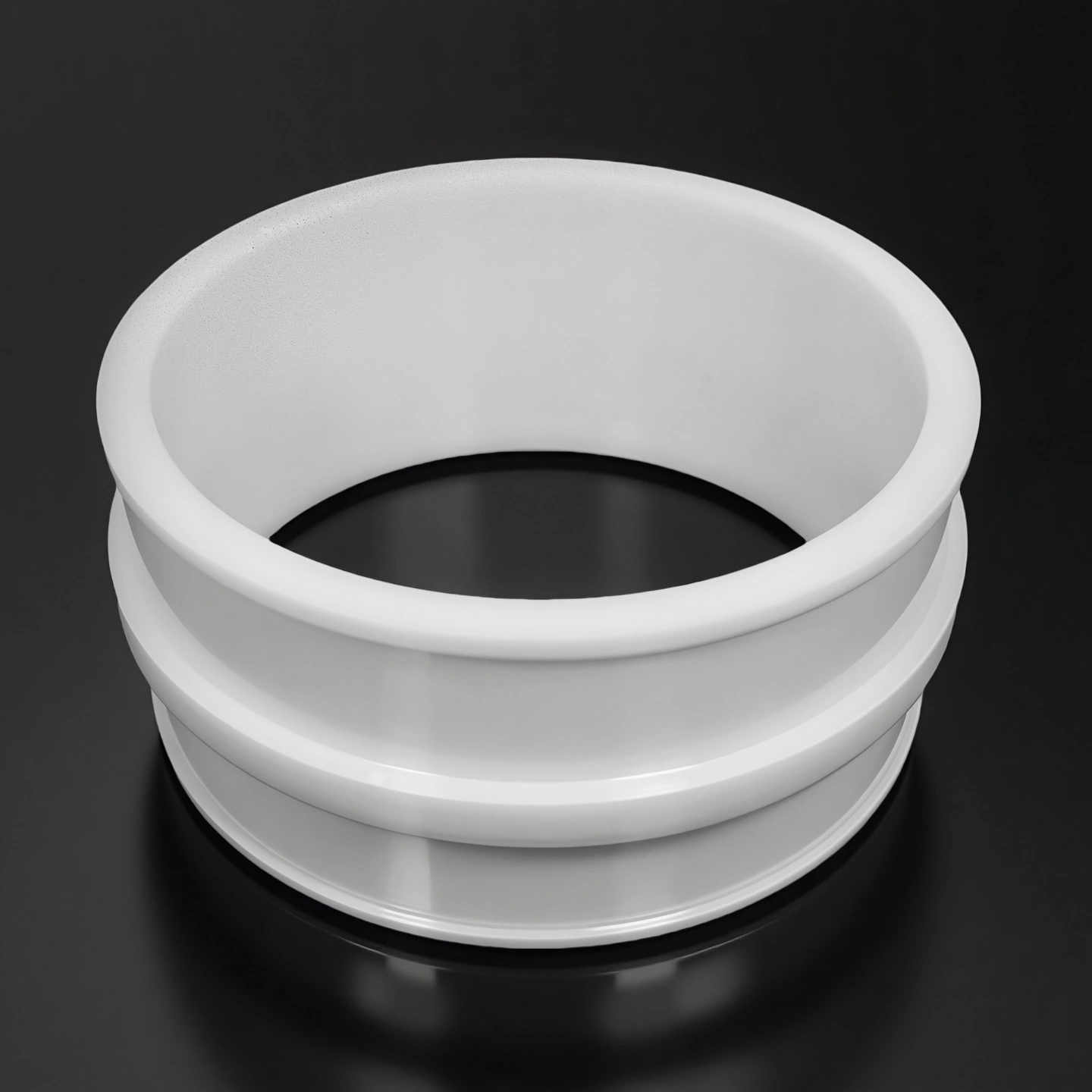

Zirconia-toughened alumina (ZTA) rings are advanced composite ceramic components made by combining alumina (Al₂O₃) with a controlled amount of zirconia (ZrO₂) to enhance mechanical strength and resistance to cracking. This material engineering approach—called transformation toughening—creates a ceramic ring that retains the hardness, wear resistance, and chemical stability of alumina, while gaining the impact resistance and fracture toughness of zirconia.

Zirconia Toughened Alumina Ring Benefits

- Balanced wear-plus-toughness: high hardness with improved crack resistance at edges and thin sections.

- Dimensional control: practical ID/OD tolerance in the ±0.02–0.05 mm band (size-dependent), with coaxiality and flatness matched to seal pairs.

- Polishable sealing faces: Ra ≤0.2–0.4 μm to support leak-tight startups and stable friction.

- Thermal fit stability: CTE near 8–9×10^−6/K helps keep interference/clearance predictable across temperature cycles.

- Media compatibility: ceramic matrix resists many acids, alkalis, and chlorides encountered in water processing and chemical service.

Zirconia Toughened Alumina Rings Properties

| Property | Unit | Alumina (99%) | ZTA (Zirconia Toughened Alumina) | Y-TZP Zirconia |

| Fracture Toughness (KIC) | MPa·m¹⁄² | 5 | 7 – 9 | 6 – 10 |

| Hardness (HV10) | GPa | 8.9 | 9 – 10 (≈ 90 HV) | 12 – 14 |

| Flexural Strength | MPa | 400 | 650 – 800 | 800 – 1200 |

| Density | g/cm³ | 3.9 | 4.0 – 4.3 | 6.0 |

| Relative Wear Rate | — | 1.0 | 0.45 – 0.55 | 0.2 |

| Thermal Expansion Coefficient (RT – 800 °C) | ×10⁻⁶ /K | 8.0 | 8.5 – 9.0 | 10 – 11 |

| Thermal Conductivity (RT) | W/m·K | 25 | 22 – 24 | 2 – 3 |

| Maximum Working Temperature | °C | 1600 | 1450 – 1500 | 1000 – 1200 |

| Dielectric Strength | kV/mm | 12 | 11 – 13 | 9 – 11 |

| Surface Roughness (Ground face) | µm Ra | 0.4 – 1.2 | 0.3 – 0.8 | 0.2 – 0.6 |

| Flatness (after grinding) | mm/300 mm | ≤ 0.4 | ≤ 0.3 | ≤ 0.2 |

ZTA Ring Specifications

| ZTA Ring | |||

| Item No. | Outer Diameter(mm) | Inner Diameter (mm) | Height(mm) |

| AT-ZTA-H1001 | 30 | 20 | 15 |

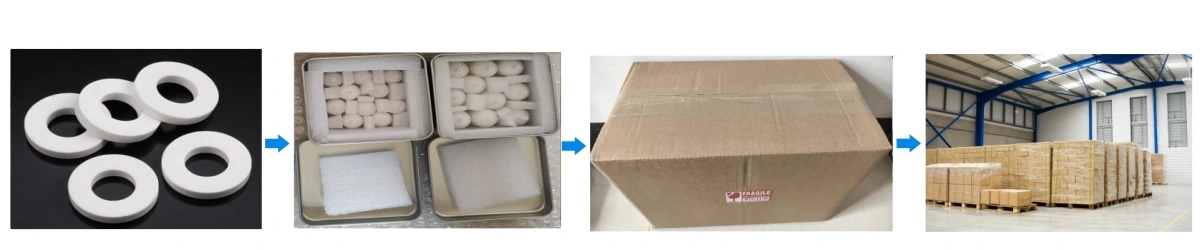

Zirconia Toughened Alumina Ring Packaging

Each Ring is encased in a polystyrene foam box and vacuum-sealed to prevent surface chipping during transit.