ADCERAX® Zirconium Silicate Beads are medium-density ceramic grinding media designed for consistent milling of low to medium viscosity slurries. Their structure is free of pores and cavities, giving smooth surfaces and reducing wear by nearly half compared with conventional beads. These properties make them highly effective for dispersing coatings, inks, pigments, and agrochemicals where cost efficiency and stable performance are critical. ADCERAX® ensures reliable supply supported by factory inventory and engineering expertise.

Features of Zirconium Silicate Beads

- Zirconium Silicate Beads show a wear rate of <0.05 kg/T, which is nearly 50% lower than comparable ceramic beads. Each production run benefits from reduced bead loss and longer replacement cycles.

- With a crush strength of >1000 N (2 mm bead), they resist fracture during continuous operation, minimizing unplanned downtime. This performance is verified across multiple industrial milling applications.

- Their fine crystalline grains achieve a hardness of >900 HV, ensuring stability even under high-speed dispersion. This property reduces contamination risks during pigment milling.

- The density of Zirconium Silicate Beads is about 4.0 g/cm³, delivering balanced grinding energy. This figure allows efficient dispersion without overloading bead mills.

- A filled bulk density of >2.5 kg/L supports high packing ratios in disk-type mills, enabling consistent throughput. This helps maintain slurry flow across long production runs.

- Their moderate density achieves up to 15–20% energy savings compared with higher-density zirconia beads, making them cost-effective for coatings and agrochemical industries.

- Zirconium Silicate Beads maintain a roundness of ≥96%, which improves slurry circulation and narrows particle size distribution. This directly enhances product uniformity in inks and paints.

- Smooth polished surfaces reduce equipment wear by up to 30%, lowering maintenance costs. This also shortens cleaning time between color changes.

- Uniform bead diameter variation within ±0.1 mm minimizes internal friction, improving milling efficiency and extending media life in continuous processing lines.

Technical Properties for Zirconium Silicate Beads

The following section provides detailed technical specifications of Zirconium Silicate Beads, covering their physical, chemical, and mechanical properties. These parameters support industrial buyers in evaluating performance and align directly with the accompanying technical data and size specifications table.

| Property |

Specification |

| Density |

~4.0 g/cm³ (true), >2.5 kg/L (bulk) |

| Hardness |

>900 HV, Mohs hardness ~7.0 |

| Crush Strength |

>1000 N (2 mm bead) |

| Composition |

ZrO₂ 58–65%, SiO₂ 30–37%, Al₂O₃ ~5% |

| Wear Rate |

<0.05 kg/T slurry processed |

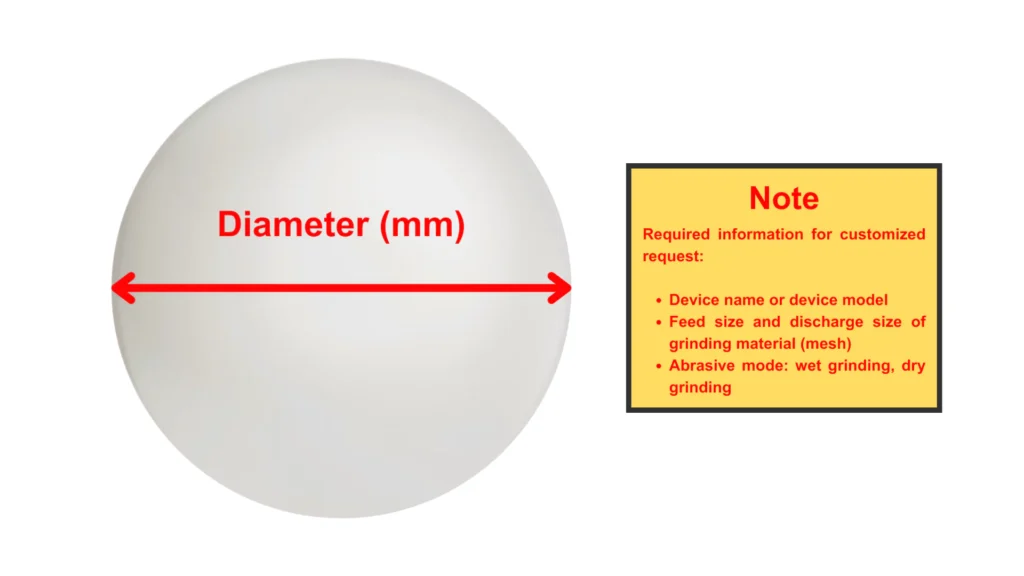

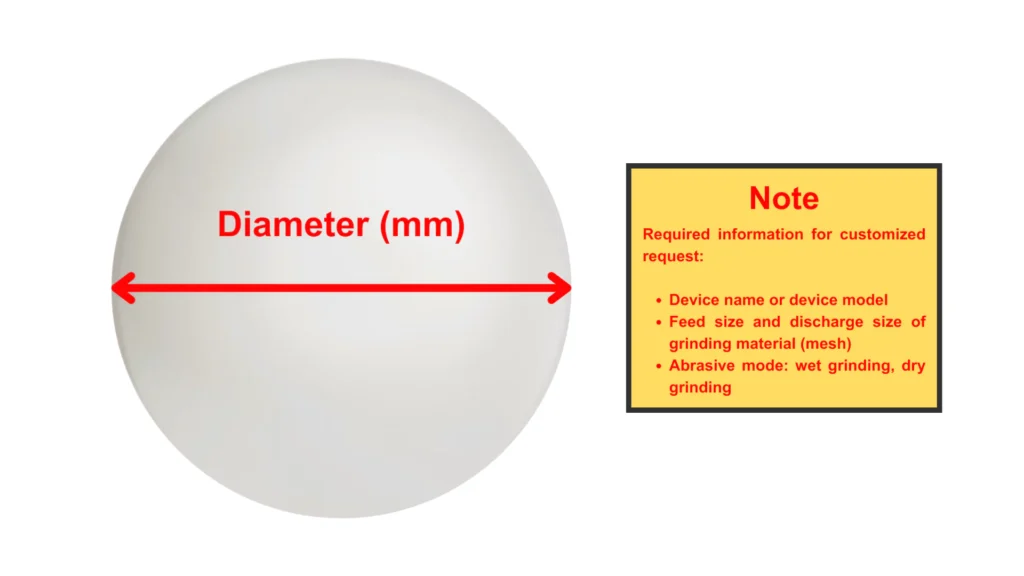

Specifications of Zirconium Silicate Beads

Packaging of Zirconium Silicate Beads

ADCERAX® offers multiple packaging solutions for Zirconium Silicate Beads, including jumbo bags, metal barrels, plastic barrels, and paper barrels. Smaller quantities of Zirconium Silicate Beads can be supplied in paper boxes, paper bags, textile bags, or aluminum foil vacuum packs. All packaging is designed to ensure safe transport, easy handling, and long-term storage of them.

Solving Application Challenges with ADCERAX® Zirconium Silicate Beads

Zirconium Silicate Beads are widely applied in sectors where medium density, low wear rate, and high sphericity are essential. By addressing industry-specific challenges, they ensure reliable milling, stable dispersions, and extended media lifespan.

-

Water-Based Architectural Coatings

✅Key Advantages

1. Low-wear, clean dispersion — Wear rate <0.05 kg/T cuts bead-derived debris vs common ceramic media by about half. Stable color and gloss are maintained over long runs.

2. High-sphericity flow — Sphericity ≥96% keeps slurry circulation uniform in large tanks. It supports consistent film build at production line speeds.

3. Balanced milling energy — Density ≈4.0 g/cm³ delivers effective grinding without torque spikes. Bulk density >2.5 kg/L enables efficient charge loading.

✅ ️Problem Solved

A high-volume paint line struggled with shade drift and frequent tank cleanups triggered by media wear. After switching to ADCERAX® Zirconium Silicate Beads (wear rate <0.05 kg/T, sphericity ≥96%), media-origin contamination events dropped in proportion to the ~2× lower wear. Coating batches held target color across extended runs while power stayed within spec thanks to the ≈4.0 g/cm³ density. The result was steadier output and fewer unplanned stoppages during color changeovers.

-

High-Opacity Titanium Dioxide Pigments

✅Key Advantages

1. Fracture-safe operation — Crush strength >1000 N (2 mm) prevents bead breakage under high TiO₂ loading. Milling stability improves in continuous duty.

2. Hard surface for narrow PSD — Hardness >900 HV resists micro-chipping that broadens particle tails. Supports tight opacity targets at standard disk-mill energy.

3. Geometry-driven uniformity — Sphericity ≥96% promotes even stress transfer to pigment agglomerates. Helps maintain narrow distribution windows batch to batch.

✅ ️Problem Solved

A pigment mill saw wide PSD spread and variable hiding power when irregular media chipped during long cycles. With ADCERAX® Zirconium Silicate Beads (hardness >900 HV, crush >1000 N, sphericity ≥96%), bead integrity held and stress input stayed consistent. TiO₂ agglomerates broke predictably, keeping distribution tight without raising power or residence time. Opacity targets were reached with stable throughput.

-

Pesticide Suspension Concentrates

✅Key Advantages

1. Corrosion-resistant media — Chemically stable in acidic, alkaline, and saline systems; bead structure remains intact through aggressive SC recipes.

2. Efficient packing and circulation — Bulk density >2.5 kg/L supports optimal bed loading. Uniform motion improves deagglomeration of actives and carriers.

3. Low-wear reliability — Wear rate <0.05 kg/T limits foreign solids that destabilize SCs. Runs remain consistent over extended cycles.

✅ ️Problem Solved

Formulators reported premature media breakdown and filter blockages in salt-rich SCs. Replacing legacy media with ADCERAX® Zirconium Silicate Beads (chemical-resistant matrix, wear <0.05 kg/T, bulk >2.5 kg/L) removed bead-origin fines from the system and stabilized dispersion quality. Mills held target viscosity without frequent screen changes, and corrosive batches no longer degraded the media during long campaigns.

User Guide for Zirconium Silicate Beads

Proper use of Zirconium Silicate Beads ensures stable milling efficiency, reduced wear, and longer service life. This section provides practical instructions on bead loading, operating conditions, cleaning routines, and replenishment practices to help customers achieve consistent results in coatings, pigments, agrochemicals, and other slurry applications.

-

Bead Loading Recommendations

1. Calculate optimal filling volume based on slurry viscosity and mill size. Overloading can increase wear, while underloading reduces grinding efficiency. Follow equipment guidelines for balanced results.

2. Match bead size distribution with target particle size. Smaller beads improve fine dispersion, while larger beads accelerate coarse milling. A mixed charge often balances energy transfer.

3. Ensure even distribution during loading. Uneven charging may cause vibration, reduce throughput, and increase stress on the mill components.

-

Operating Conditions and Speed

1. Maintain recommended rotor speed to avoid excessive bead collisions. Over-speeding raises wear rates, while under-speeding lowers dispersion quality. Balance is essential.

2. Control slurry temperature during milling. Excessive heat accelerates bead surface damage and may destabilize sensitive formulations. Use cooling systems where required.

3. Avoid dry running the mill. Proper slurry volume ensures bead cushioning, prevents fracture, and supports smooth particle size reduction.

-

Cleaning and Maintenance Practices

1. Perform regular cleaning cycles with water or compatible solvents. This prevents residue buildup that can contaminate future batches. Use filtered solutions for best results.

2. Inspect beads periodically for cracks, chipping, or discoloration. Damaged beads increase contamination risk and reduce efficiency. Replace when abnormalities are detected.

3. Use screening methods to separate broken beads from intact ones. Routine inspection extends service life and keeps slurry free from unwanted debris.

-

Replenishment and Storage Guidelines

1. Replenish bead volume regularly to maintain grinding efficiency. Long-term use naturally reduces total charge weight, affecting performance stability.

2. Screen before replenishment to remove fractured particles. Adding fresh beads without screening increases the risk of contamination and uneven wear.

3. Store Zirconium Silicate Beads in dry, sealed containers such as barrels or bags. Proper storage prevents moisture absorption and preserves material integrity.