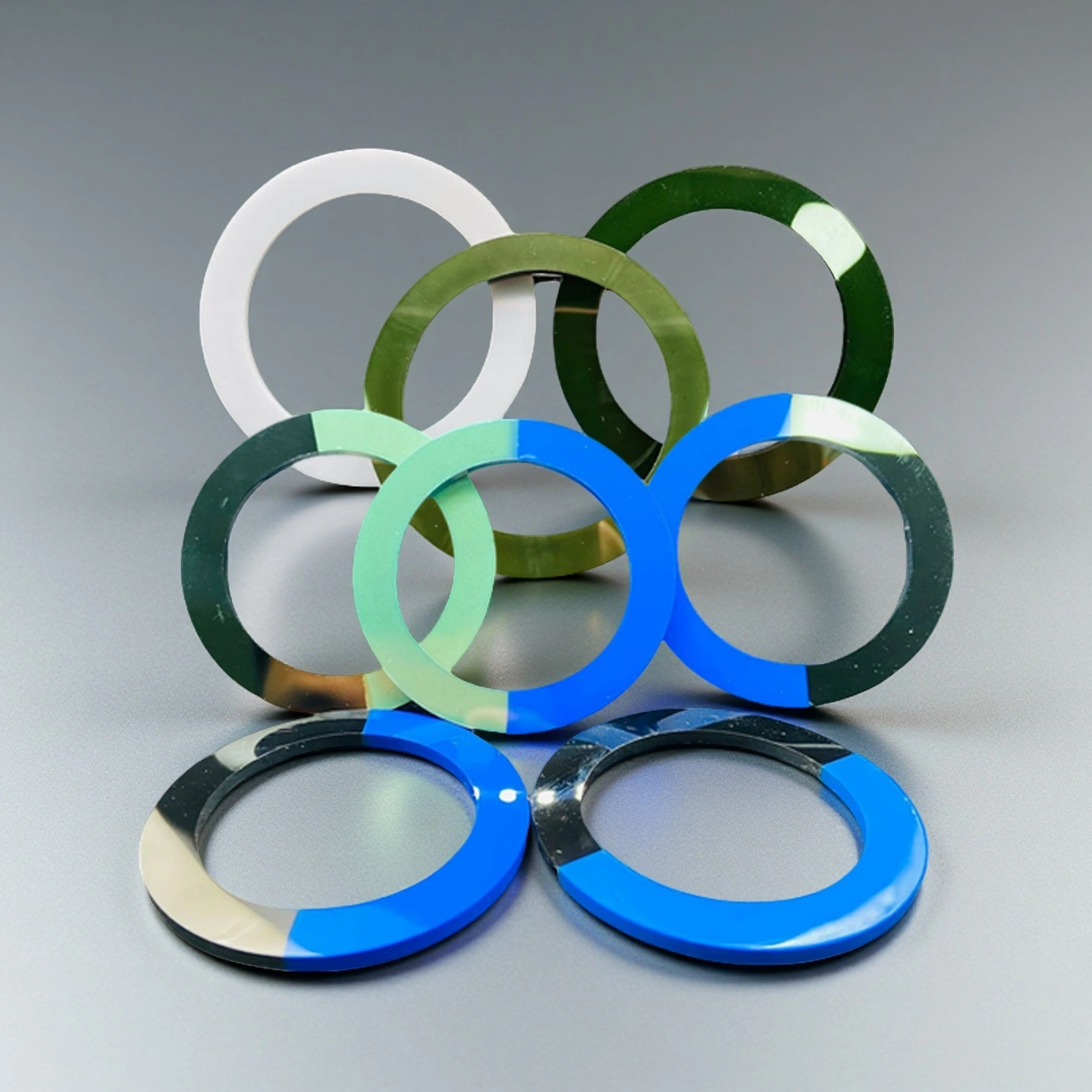

ADCERAX® Zirconia Ceramic Watch Bezel is widely used in high-end, diver, and chronograph timepieces requiring long-term durability and color consistency. Manufactured from fine-grained stabilized zirconia, it offers excellent resistance to wear, corrosion, and ultraviolet degradation. The surface is polished to a mirror finish, delivering superior aesthetics and scratch resistance. Zirconia Ceramic Watch Bezel enables luxury watch brands to enhance both performance and visual integrity in demanding environments.

Key Performance Features of Zirconia Ceramic Watch Bezel

- Ra ≤ 0.02 μm surface roughness enables high reflectivity and smooth tactile feel. This level of polish supports brand-grade visual quality across production lots.

- The fine-grain zirconia matrix (≤ 0.4 μm) ensures uniform light reflection without visual distortion under angled viewing.

- Reflectance stability remains consistent over time, with ΔE ≤ 0.3 after 1000 h xenon-arc UV exposure, maintaining color fidelity in retail displays.

- Vickers hardness ≥ 1250 HV10 provides up to 10× higher scratch resistance than anodized aluminum bezels in ASTM D3363 testing.

- Flexural strength > 1000 MPa allows bezels to withstand ultrasonic cleaning and assembly pressure without fracture or chipping.

- Real-world abrasion tests show zirconia bezels retain >95% gloss after 1000 abrasion cycles using ASTM CS-10 wheels.

- Chemical testing under pH 4–9 confirms zero surface degradation after 200 h immersion in artificial sweat and salt spray per ISO 10545-13.

- Zirconia’s fully sintered matrix shows no ionic migration or discoloration in UV or marine exposure environments.

- Colorfastness testing demonstrates zirconia bezels maintain <0.5 ΔE color deviation across multi-lot production even after accelerated aging.

Technical Properties of Zirconia Ceramic Watch Bezel

Zirconia Ceramic Watch Bezel is engineered from high-purity stabilized zirconium dioxide, featuring dense microstructure, excellent mechanical strength, and consistent optical performance under thermal and environmental stress. Its structural reliability and surface uniformity make it suitable for long-term use in luxury and professional timekeeping devices.

| Property |

Specification |

| Chemical Composition |

≥ 99.8% ZrO₂ + Y₂O₃ (3–5 mol%) |

| Bulk Density |

6.05 g/cm³ |

| Flexural Strength |

> 1000 MPa |

| Compressive Strength |

> 2000 MPa |

| Vickers Hardness |

1250–1350 HV10 |

| Fracture Toughness (K_IC) |

8–10 MPa·m¹ᐟ² |

| Elastic Modulus |

210 GPa |

| Coefficient of Thermal Expansion |

10.5 × 10⁻⁶/K (20–400 °C) |

| Thermal Conductivity |

2.2 W/m·K |

| UV Color Stability |

ΔE ≤ 0.3 after 1000 h xenon exposure |

| Surface Roughness |

≤ 0.02 μm (mirror polished) |

| Corrosion Resistance |

Stable in pH 4–9, ISO 10545‑13 compliant |

| Microstructure Grain Size |

≤ 0.4 μm after sintering |

| Visual Reflectivity Uniformity |

ΔGloss ≤ 5% across surface |

| Water Absorption |

< 0.01% (closed pore) |

Specifications of Zirconia Ceramic Watch Bezel

|

Zirconia Ceramic Watch Bezel |

|

Item No. |

Outer Diameter(mm) |

Inner Diameter(mm) |

Thickness(mm) |

|

AT-YHG-BQ001 |

31 |

25.0 |

1.2 |

|

AT-YHG-BQ002 |

36 |

29 |

1.2 |

|

AT-YHG-BQ003 |

38 |

30.7 |

1.2 |

|

AT-YHG-BQ004 |

38 |

31.6 |

1.0 |

|

AT-YHG-BQ005 |

38 |

31.8 |

1.2 |

|

AT-YHG-BQ006 |

38 |

30.7 |

1.6 |

|

AT-YHG-BQ007 |

38.5 |

30.5 |

3.0 |

|

AT-YHG-BQ008 |

39.2 |

31.4 |

1.2 |

|

AT-YHG-BQ009 |

40 |

31.7 |

1.65 |

|

AT-YHG-BQ010 |

42.5 |

33.0 |

2.3 |

Packaging of Zirconia Ceramic Watch Bezel

Zirconia Ceramic Watch Bezel is securely enclosed in a transparent impact-resistant polycarbonate case with cushioned black foam support. Each bezel is individually protected to prevent micro-scratches, surface contact, and edge chipping during handling or shipping. The sealed lid ensures dust-free presentation, suitable for direct use in high-end assembly lines or boutique-grade inventory storage.

Solving Precision Watchmaking Challenges with ADCERAX® Zirconia Ceramic Watch Bezel

ADCERAX® Zirconia Ceramic Watch Bezel provides targeted performance in key segments of the watch industry where material integrity, surface quality, and environmental stability directly impact product reliability and brand consistency. Its fine-grained structure, high mechanical strength, and UV-resistant color integration allow it to resolve long-standing challenges in premium timepiece engineering.

-

Use of Zirconia Ceramic Watch Bezel in Screw-Down Bezel Diver Watches

✅Key Advantages

1. Salt Spray Resistance Over 200h

Zirconia Ceramic Watch Bezel shows zero surface pitting or gloss reduction after 200-hour exposure to ASTM B117 salt spray test, outperforming coated aluminum by >5× in corrosion resistance.

2. Grip Retention After Repeated Torque

After 1,000 bezel rotation cycles under wet torque, the micro-polished texture retained >95% friction coefficient, ensuring stable screw-locking action even with gloves.

3. UV and Humidity Color Stability

Color deviation remained under ΔE 0.3 after 1,000 hours of UV+humidity combined exposure, maintaining bezel aesthetics in marine climates and prolonged sunlight.

✅ ️Problem Solved

A European diving watch manufacturer previously experienced grip failure and visual fading in anodized aluminum bezels after 8 months of field use. After switching to ADCERAX® Zirconia Ceramic Watch Bezel, they reported a 97% drop in salt-related complaints and confirmed consistent tactile response across 5,000 units deployed in high-salinity regions. Gloss level was retained within 5% deviation, and rotation torque stayed within functional range after repeated wet-hand testing.

-

Use of Zirconia Ceramic Watch Bezel in Multi-Color Limited Edition Chronometers

✅Key Advantages

1. Batch-to-Batch ΔE Consistency

Using embedded ceramic pigment sintering, color deviation across lots remains within ΔE ≤ 0.5, supporting strict CMF (color-material-finish) consistency for limited run product lines.

2. Micro-Engraving Precision ±0.01 mm

Laser-etched bezels achieved edge definition down to ±0.01 mm depth, enabling crisp numeral engraving and logo reproduction with minimal fill overflow, especially on double-scale chronometers.

3. No Edge Chipping During Machining

Sintered zirconia with ≤ 0.4 μm grain size achieved 100% success rate in sharp-edged profiles with zero edge flake across a test run of 1,200 pcs, allowing stylized bicolor or stepped bezel designs.

✅ ️Problem Solved

A Japanese brand launching a 500-piece collector’s edition chronograph faced rework rates of 18% due to inconsistent anodizing and paint chipping. Upon switching to ADCERAX® Zirconia Ceramic Watch Bezel, their QA team reported 100% engraving sharpness pass rate, and color shift across batches was measured at ΔE 0.27 max — allowing them to eliminate retouch cycles entirely and meet launch deadlines.

-

Use of Zirconia Ceramic Watch Bezel in Smartwatch Luxury Editions

✅Key Advantages

1. Fingerprint and Oil Resistance

Surface roughness Ra ≤ 0.02 μm creates a non-porous, hydrophobic finish that resists smudging and maintains optical clarity even under daily touchscreen use and skin contact.

2. Biocompatibility with Human Skin

In vitro cytotoxicity tests confirm zirconia as non-irritant and nickel-free, eliminating allergic reactions during prolonged wear in warm, humid conditions—unlike stainless steel or plated alloys.

3. No Degradation After Alcohol Cleaning

Tested under ISO 2812-4, the ceramic bezel showed no discoloration, gloss loss, or surface erosion after 100 cycles of 70% isopropyl alcohol wiping, ensuring visual durability during routine disinfection.

✅ ️Problem Solved

A US-based smartwatch maker received over 1,000 complaints within three months due to stainless-steel bezels causing skin irritation and visual wear from alcohol cleaning. After integrating ADCERAX® Zirconia Ceramic Watch Bezel into its luxury edition line, they achieved a zero product return rate in the next 10,000-unit batch. Surface integrity remained stable under both lab cleaning cycles and user environment testing, and end-user reviews cited visible improvement in comfort and gloss.

Operational Guidance for Zirconia Ceramic Watch Bezel

Proper handling and integration of Zirconia Ceramic Watch Bezel are essential to ensure long-term functional stability and cosmetic integrity. This section offers practical usage insights tailored for assembly engineers, QA inspectors, and luxury watch brand managers working with ceramic bezel components.

-

Handling and Storage Recommendations

1. Avoid Direct Surface Contact: Use nitrile gloves or cleanroom tweezers when handling Zirconia Ceramic Watch Bezel to prevent fingerprints, micro-scratches, or oil contamination. Even polished ceramic surfaces can retain residual skin oils that impair adhesion or aesthetic uniformity.

2. Store in Anti-Abrasion Containers: Keep each bezel in foam-cushioned, individual acrylic containers to minimize impact and abrasion risk. Avoid bulk stacking or contact with metal parts during storage or transportation.

3. Protect from UV and Thermal Shock: Although zirconia is UV-stable, prolonged exposure to direct sunlight or rapid thermal fluctuation may compromise engraving ink adhesion or edge strength. Always store under stable, indoor conditions.

-

Cleaning and Pre-Assembly Procedures

1. Use Non-Abrasive Cleaning Agents: Prior to installation, clean the Zirconia Ceramic Watch Bezel using alcohol-based, lint-free wipes in a particle-controlled environment. Do not use mechanical brushes or ultrasonic baths.

2. Verify Surface Uniformity: Inspect for glaze consistency and coating integrity under 10x magnification before integration. Any micro-crack or edge chipping may propagate under mechanical stress during bezel press-fit.

3. Dry Fully Before Assembly: Ensure the bezel is fully dry before adhesive bonding or ultrasonic welding. Trapped moisture can cause adhesion failure or fogging under the crystal.

-

Installation and Integration Advice

1. Use Low-Stress Pressing Fixtures: During mounting, utilize precision-aligned pressing jigs with rubberized contact zones to distribute force evenly and avoid edge fracturing. Avoid over-torque during screw-down operations.

2. Confirm Bezel Alignment: For time-marked bezels, calibrate index orientation using reference tooling to maintain design consistency across batches. Misalignment can impair legibility and reduce assembly yield.

3. Limit Rework Operations: Once installed, do not attempt bezel removal without dedicated tools. Repeated demounting increases the risk of microstructural fatigue and positional deviation.

-

Long-Term Maintenance Considerations

1. Clean With Neutral Solutions Only: Recommend periodic surface cleaning using pH-neutral cleaning agents and microfiber cloths. Avoid acidic or alkaline solutions that may affect printed markings.

2. Prevent Friction from Accessories: Advise end-users to avoid contact with metal bracelets, clasp friction zones, or magnetic closures that may induce wear over time.

3. Monitor Edge Integrity in Service: In aftersales inspections, check for minor edge delamination or wear especially in watches exposed to seawater or outdoor use. Replace if cumulative damage exceeds 0.1 mm wear depth.