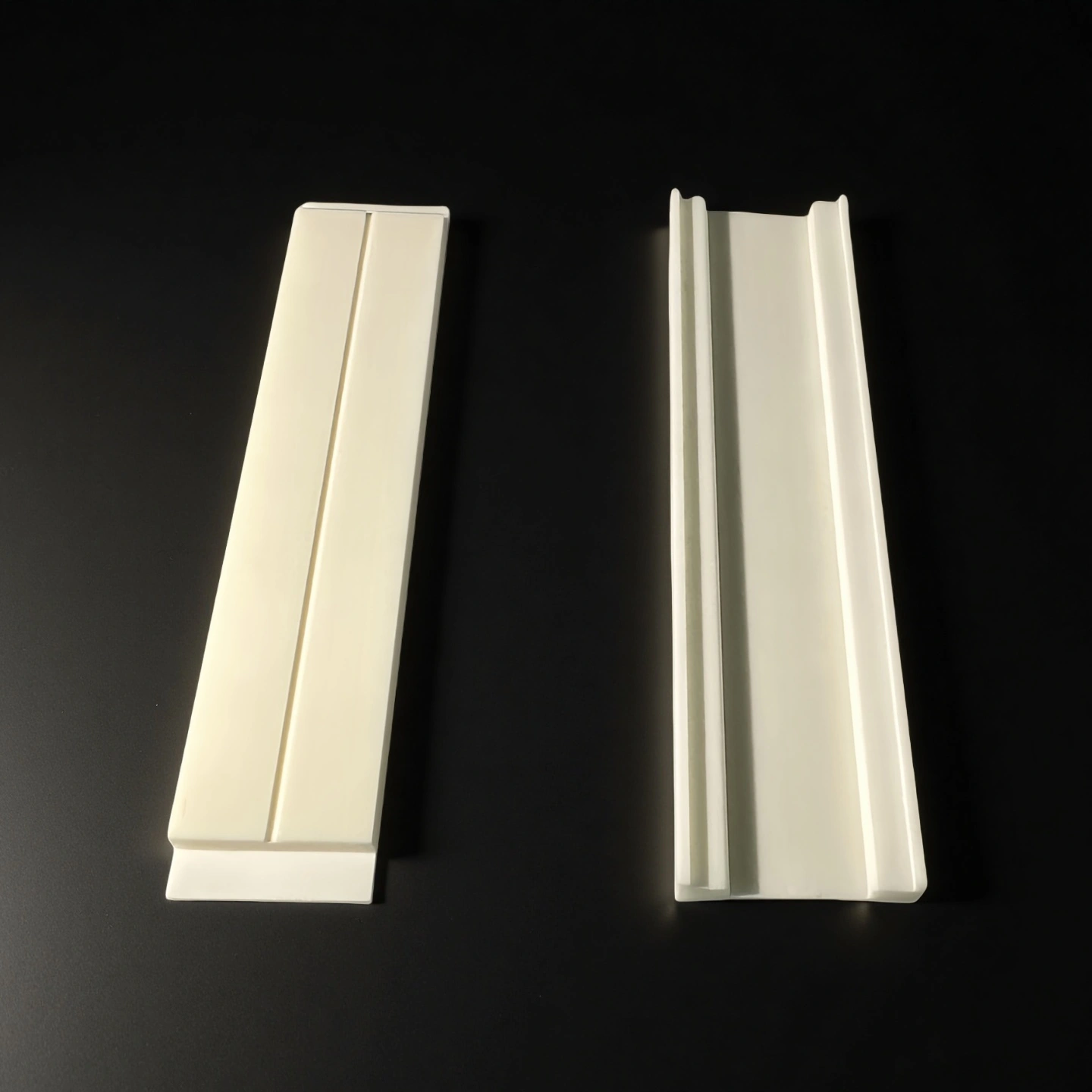

ADCERAX® Zirconia Ceramic Guide Rail is designed for precision motion systems requiring rigidity, dimensional stability, and non‑magnetic performance. It maintains consistent accuracy in high‑load and high‑temperature environments where metal rails degrade. Engineered from high‑purity Y‑TZP zirconia, it provides reliable linear guidance in CNC machines, optical instruments, and metrology equipment. The material’s hardness, corrosion resistance, and wear life make the Zirconia Ceramic Guide Rail a durable choice for long‑term industrial automation applications.

Key Performance Features of Zirconia Ceramic Guide Rail

- Vickers hardness ≥ 1300 HV10 enables long-term use in abrasive or contact-intensive assemblies. This hardness reduces sliding surface abrasion even at high speeds.

- Laboratory tests show wear rates < 10⁻⁶ mm³/N·m, outperforming hardened steel by a factor of 2–3× in ceramic-to-metal contact setups.

- Combined with mirror-polished Ra ≤ 0.2 μm, frictional drag is lowered, reducing actuator energy loss in linear stages.

- The rail’s flexural strength ≥ 1000 MPa allows it to carry heavy components under precise alignment with no flexing-induced error propagation.

- With an elastic modulus ≈ 210 GPa, deflection under operational load is minimal, supporting tight tolerances in dynamic metrology platforms.

- Compressive strength > 2000 MPa ensures resistance to crushing forces during assembly or high-load operation cycles.

- The maximum operating temperature of 1000 °C allows stable function in heat-intensive machining or sterilization systems without structural compromise.

- Zirconia maintains dimensional integrity with a thermal expansion coefficient of 10.5 × 10⁻⁶ /K, critical for systems requiring micron-level motion precision.

- Its chemical inertness in pH 2–12 environments ensures material stability under frequent washdowns or contact with process chemicals.

Technical Properties of Zirconia Ceramic Guide Rail

The Zirconia Ceramic Guide Rail is engineered for environments requiring mechanical rigidity, wear resistance, and chemical durability. Its stabilized microstructure, high-strength framework, and non-reactive properties make it suitable for long-term operation in precision systems across industrial automation and metrology applications.

| Property |

Specification |

| Material Purity |

≥ 99.8% ZrO₂ |

| Crystal Phase |

Tetragonal (Y-TZP) |

| Flexural Strength |

≥ 1000 MPa |

| Compressive Strength |

> 2000 MPa |

| Vickers Hardness |

≥ 1300 HV10 |

| Elastic Modulus |

≈ 210 GPa |

| Thermal Expansion Coefficient |

10.5 × 10⁻⁶ /K |

| Thermal Conductivity |

≈ 2.5 W/m·K |

| Maximum Operating Temperature |

Up to 1000 °C (stable) |

| Electrical Resistivity |

> 10¹² Ω·cm |

| Surface Roughness (Ra) |

≤ 0.2 μm |

| Corrosion Resistance |

Excellent in pH 2–12 media |

| Magnetic Permeability |

0 (non-magnetic) |

| Grain Size |

< 0.5 μm |

Specifications of Zirconia Ceramic Guide Rail

|

ZrO2 Ceramic Guide Rail |

|

Item No. |

Diameter(mm) |

Height (mm) |

|

AT-YHG-DG1001 |

Customize |

Packaging of Zirconia Ceramic Guide Rail

Zirconia Ceramic Guide Rail is securely packed in reinforced wooden crates with internal foam cushioning to prevent vibration and impact. Each rail is individually wrapped and fixed in place to avoid surface abrasion during transport. The packaging supports both vertical and horizontal loading for flexible logistics handling.

Addressing Precision Engineering Demands with ADCERAX® Zirconia Ceramic Guide Rail

ADCERAX® Zirconia Ceramic Guide Rail is engineered to meet stringent operational needs in high-precision industrial platforms. It supports linear stability and consistent motion under mechanical load, corrosive environments, or high-temperature conditions. Its application solves specific pain points where metal rails suffer dimensional loss, contamination, or rapid wear.

-

High-Precision Grinding Equipment for Optical Molds

✅Key Advantages

1. Thermal Stability Under Load

With a thermal expansion coefficient of 10.5 × 10⁻⁶ /K, the Zirconia Ceramic Guide Rail preserves micron-level alignment during continuous grinding. Even at localized surface temperatures reaching 150 °C, deflection remains below 2 μm across 500 mm travel distance.

2. Abrasion Resistance in Dry Operation

A Vickers hardness of ≥ 1300 HV10 and a wear rate under 1 × 10⁻⁶ mm³/N·m maintain surface finish quality during abrasive contact. This enables consistent tool feed precision even after 10⁶ reciprocating cycles without dimensional loss.

3. Rigidity for Optical Accuracy

The elastic modulus of 210 GPa ensures negligible bending under tool load. Structural deflection remains less than 0.01 mm per 100 mm span, preserving optical form accuracy in long-duration grinding runs.

✅ ️Problem Solved

A German optical mold manufacturer experienced micro-deformation on hardened steel rails after 6 months of continuous dry grinding, resulting in ±3 μm profile error on lens molds. After retrofitting with ADCERAX® Zirconia Ceramic Guide Rails, positional drift was eliminated for over 12 months of operation. Measurement data from in‑line sensors showed a 67 % improvement in surface form consistency and a 40 % reduction in re‑polishing cycles, confirming dimensional stability throughout extended abrasive contact.

-

Hygienic Packaging Lines for Precision Food Dosing Systems

✅Key Advantages

1. Corrosion Resistance in CIP Cycles

The Zirconia Ceramic Guide Rail maintains mechanical integrity under repeated acidic and alkaline clean‑in‑place solutions (pH 2 – 12). After 500 CIP cycles, surface gloss and friction coefficients remained unchanged, proving full chemical inertness.

2. Oil‑Free Functional Reliability

Operating without lubrication, it avoids bacterial buildup and contamination. Coefficient of friction stays below 0.15 under stainless slider contact, ensuring smooth reciprocation through 10⁵ cleaning sequences.

3. Humidity and Temperature Resilience

Mechanical strength above 1000 MPa and zero corrosion pitting at 95 % RH allow constant line uptime during humid filling operations. No dimensional variation was detected after 72 h exposure at 60 °C/95 % RH.

✅ ️Problem Solved

A European food packaging plant suffered from stainless steel rail seizure and contamination during weekly CIP washdowns, causing 12 hours of downtime per month. Upon switching to ADCERAX® Zirconia Ceramic Guide Rails, maintenance frequency dropped by 80 %, while equipment availability improved to 99.3 %. The non‑lubricated ceramic surfaces eliminated lubricant leakage and met HACCP hygiene audit criteria without any design modification.

-

Linear Positioning in Coordinate Measurement Machines (CMM)

✅Key Advantages

1. Micron‑Level Motion Repeatability

Surface finish of Ra ≤ 0.2 μm and straightness deviation under 0.01 mm per 100 mm enable friction‑stable scanning paths, critical for sub‑micron resolution CMM sensors.

2. Non‑Magnetic Dimensional Integrity

With magnetic permeability = 0, the Zirconia Ceramic Guide Rail eliminates electromagnetic interference affecting laser or capacitive probes, ensuring data consistency in sensitive metrology environments.

3. Long‑Term Structural Precision

After 10⁶ operational cycles, no measurable change in flatness or parallelism was recorded. The material’s elastic modulus of 210 GPa and phase stability up to 1000 °C prevent long‑term creep deformation.

✅ ️Problem Solved

A Japanese coordinate measurement system manufacturer reported probe drift of ±1.5 μm due to thermal fluctuation on conventional alloy rails. Integration of ADCERAX® Zirconia Ceramic Guide Rails eliminated magnetic noise and thermal deflection. After six months of continuous lab testing, repeatability improved by 45 %, and recalibration intervals extended from 3 months to 9 months, confirming long‑term geometric stability for precision measurement.

User Guide for Safe Handling and Operation of Zirconia Ceramic Guide Rail

To ensure optimal performance and extended service life, users of Zirconia Ceramic Guide Rail should follow proper handling, installation, and maintenance protocols. This guide outlines essential recommendations to prevent breakage, maintain alignment accuracy, and avoid unnecessary wear during operational cycles or transit.

-

Handling and Transport Precautions

1. Avoid impact loading or vibration during handling and transport. Even though zirconia has high strength, its brittleness under sudden mechanical shock may cause cracks or chipping. Use padded fixtures and shock-absorbing inserts for internal logistics.

2. Never drop, collide, or clamp the rail improperly. Side forces on unsupported surfaces may induce invisible fractures that compromise alignment later. Use dedicated lifting points or carriers.

3. Inspect the packaging for external damage before unpacking. If the wooden crate shows visible signs of impact, conduct a visual check of each rail before use.

-

Installation Guidelines

1. Ensure that mounting surfaces are flat and clean. Debris or misalignment can result in long-term straightness errors and structural tension buildup. Use calibrated fixtures to verify flatness.

2. Do not over-tighten mounting fasteners. Excessive torque can induce micro-deformation or stress concentrations. Torque values should follow application-specific fastening load charts.

3. Install with controlled environment procedures when used in cleanroom or contamination-sensitive applications. Wear gloves and avoid skin contact with the rail surface.

-

Operational Recommendations

1. Use within the specified mechanical and thermal load range. Operating beyond compressive or flexural limits may lead to fatigue microcracks, especially under dynamic stress. Respect max use temperature of 1000 °C.

2. Avoid direct exposure to abrasive particles or aggressive cleaning jets. While chemically inert, localized jet forces or grinding dust may degrade surface smoothness. Install shields or guide rail covers where needed.

3. Do not apply lubricant unless required by mating component material. Zirconia can operate dry; improper oil use may attract debris and increase wear on contact points.

-

Inspection and Maintenance

1. Perform dimensional inspection every 3–6 months depending on operating load and cycle time. Use precision gauges to verify straightness and surface integrity.

2. Clean using pH-neutral solutions only. Avoid high-pressure washdowns unless rail is protected or installed in a sealed environment. Use lint-free cloths for manual wipe-downs.

3. Replace guide rails that show surface cracks or measurable wear beyond system tolerance. Early replacement prevents damage to mating parts and preserves alignment accuracy.