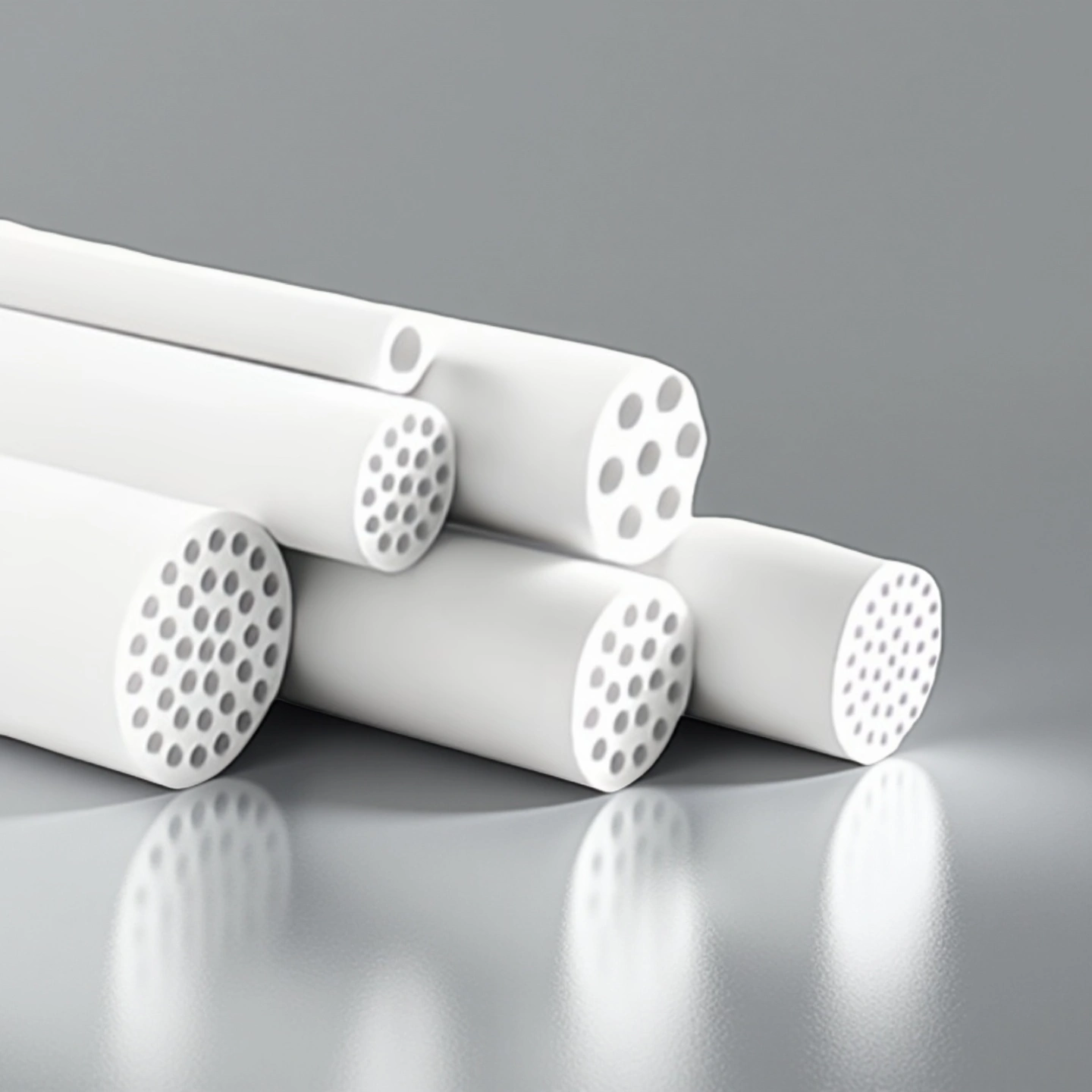

ADCERAX® Zirconia Ceramic Membrane Tube is a high-performance filtration component designed for demanding industrial processes across food processing, wastewater treatment, biopharmaceutical separation, and chemical production. With exceptional resistance to extreme pH environments and thermal cycling, it enables stable filtration under CIP/SIP protocols. The micro-structured zirconia matrix ensures consistent flux, minimal fouling, and long operational life. Zirconia Ceramic Membrane Tube is widely adopted in global facilities requiring high reliability and efficient liquid-solid separation.

Performance-Driven Features of Zirconia Ceramic Membrane Tube in Industrial Filtration

- Zirconia Ceramic Membrane Tube ensures stable filtration rates across continuous operations. Pure water flux reaches 800 L/m²·h·bar at 25 °C, enabling high-throughput processing in milk clarification and chemical recovery systems.

- Its asymmetric pore structure minimizes hydraulic resistance and supports fast molecular separation. Up to 98% separation efficiency has been achieved in pilot trials involving fruit juice and catalyst slurries.

- Under steady TMP conditions, the membrane maintains over 95% flux consistency after 100 CIP cycles, reducing downtime and improving processing continuity.

- The membrane resists strong acids and alkalis, with full pH range tolerance from 0 to 14, making it suitable for corrosive chemical and wastewater environments.

- Zirconia’s inert surface prevents leaching or ion exchange, supporting safe use in pharmaceutical-grade and food-contact filtration lines.

- It withstands repeated exposure to sodium hypochlorite, sulfuric acid, and ethanol with no degradation in membrane integrity, as verified by SEM imaging after 200 cleaning cycles.

- Unlike disposable filters, the Zirconia Ceramic Membrane Tube can be reused for up to 5 years in moderate industrial duty cycles, reducing waste and long-term replacement needs.

- Routine CIP/SIP protocols restore over 90% of initial flux performance without altering pore structure, as validated by independent testing after sterilization runs.

- Filtration systems equipped with zirconia membranes eliminate the need for single-use filter cloths, saving 30–40% on annual maintenance and consumable costs.

Technical Properties of Zirconia Ceramic Membrane Tube

Zirconia Ceramic Membrane Tube delivers reliable filtration under extreme thermal, chemical, and mechanical conditions, making it suitable for use in continuous processing lines and corrosive liquid environments across industrial sectors.

| Property |

Specification |

| Material Composition |

≥99.8% zirconium dioxide (ZrO₂), stabilized with Y₂O₃ or MgO |

| Membrane Structure |

Asymmetric multilayer (support + selective skin) |

| Open Porosity |

35–45% |

| Mean Pore Size |

0.01–0.1 µm (UF/MF range) |

| Pure Water Flux |

400–800 L/m²·h·bar at 25 °C |

| Flexural Strength |

≥800 MPa |

| Compressive Strength |

≤1500 MPa |

| Thermal Operating Range |

5 °C to 850 °C (dry), ≤350 °C (wet) |

| Thermal Expansion Coefficient |

10.5 × 10⁻⁶ K⁻¹ |

| pH Resistance Range |

0–14 (continuous exposure) |

| Chemical Resistance |

Stable in H₂SO₄, NaOH, NaClO, ethanol, acetone |

| Surface Roughness (Ra) |

≤0.2 µm (top layer) |

| Backwash Pressure Tolerance |

≤6 bar |

| Cleaning Compatibility |

CIP/SIP, autoclave, NaOH, HNO₃, steam ≤150 °C |

| Service Life |

>5 years in standard industrial duty |

Specifications of Zirconia Ceramic Membrane Tube

|

Zirconia Ceramic Membrane Filter Tube |

|

Item No. |

Bore Quantities |

Picture |

Bore Diameter (mm) |

Membrane Area |

Size |

Micro filter |

Super filter |

Fine ultrafiltration |

|

AT-YHG-MG1001 |

19 |

|

3.5mm |

0.05 m2 |

Outer Diameter:25mm,Length :250mm |

0.14μm,0.2μm,0.45μm,0.8μm,1.4μm |

15KD,50 KD,150KD,300KD |

1 KD,3KD,5KD,8KD |

|

AT-YHG-MG1002 |

23 |

|

3.5mm |

|

AT-YHG-MG1003 |

7 |

|

6mm |

0.16m2 |

|

AT-YHG-MG1004 |

8 |

|

6mm |

|

AT-YHG-MG1005 |

19 |

|

3.5mm |

|

AT-YHG-MG1006 |

23 |

|

3.5mm |

|

AT-YHG-MG1007 |

49 |

|

2.5mm |

|

AT-YHG-MG1008 |

19 |

|

6mm |

0.35m2 |

|

AT-YHG-MG1009 |

25 |

|

5.5mm |

|

AT-YHG-MG1010 |

37 |

|

3.6mm |

Packaging of Zirconia Ceramic Membrane Tube

Zirconia Ceramic Membrane Tube is securely packed in foam-lined wooden crates to prevent damage during international transit. Each tube is individually wrapped with shock-resistant cushioning to avoid surface scratches or impact stress. Custom-fit compartments ensure stability and separation throughout handling and shipping.

Solving Application Challenges with ADCERAX® Zirconia Ceramic Membrane Tube in Industrial Liquid Processing

ADCERAX® Zirconia Ceramic Membrane Tube is specifically engineered to address filtration challenges in industries requiring stable throughput, chemical durability, and consistent purity. Its micro-porous structure and strong mechanical stability enable reliable separation and purification in diverse continuous-flow systems.

-

Clarification of Dairy and Beverage Streams Using Zirconia Ceramic Membrane Tube

✅Key Advantages

1. High Flux Retention under CIP Cleaning

Zirconia Ceramic Membrane Tube maintains over 95% of its initial flux after 100 alkaline and steam cleaning cycles, verified under pH 12 CIP conditions. This stability enables continuous milk and juice clarification without frequent shutdowns for membrane replacement.

2. Cold Filtration Capability for Heat‑Sensitive Liquids

The membrane structure supports efficient separation at below 40 °C, ensuring the preservation of natural enzymes and vitamins in dairy and beverage products. Its non‑reactive zirconia matrix avoids taste or odor alteration during processing.

3. Long Operational Lifetime in Beverage Lines

Laboratory validation and industrial trials confirm a service life of >5 years in continuous fruit‑juice production, with fouling resistance reducing cleaning frequency by 30 % compared to polymeric membranes.

✅ ️Problem Solved

A European dairy processor reported severe flux decay of polymeric membranes after three months of daily CIP cleaning, causing batch delays and product waste. After switching to ADCERAX® Zirconia Ceramic Membrane Tube, the line operated continuously for 18 months with stable throughput and no chemical degradation. Filtration clarity improved by 25 %, and annual membrane replacement costs dropped by 40 %, proving long‑term reliability in cold beverage clarification systems.

-

Solvent Recovery and Catalyst Separation in Fine Chemical Production

✅Key Advantages

1. Corrosion Resistance in Strong Solvent Media

Zirconia Ceramic Membrane Tube remains structurally stable in 10 wt % H₂SO₄ and 5 wt % NaOH environments, verified after 200 hours of immersion testing. It delivers steady filtration performance even when exposed to reactive organic solvents such as ethanol and acetone.

2. Consistent Particle Retention for Catalyst Recovery

In catalyst‑laden streams, the membrane achieves 98 % separation efficiency with minimal flux loss across multiple reaction cycles. The controlled pore geometry ensures effective recovery of catalyst particles sized 0.02–0.1 µm.

3. Reduced Downtime through Chemical‑Cleaning Endurance

After repeated solvent wash cycles, zirconia membranes maintain >90 % permeability recovery, minimizing maintenance interruptions. Plants report a 25 % reduction in total process downtime per year compared with polymeric systems.

✅ ️Problem Solved

A fine‑chemical producer in Japan faced recurring shutdowns due to swelling and cracking of PTFE membranes during acidic catalyst filtration. ADCERAX® Zirconia Ceramic Membrane Tube replaced these modules, sustaining operation in a pH 1–13 solvent loop for over 14 months. Catalyst recovery efficiency increased from 89 % to 98 %, solvent purity improved to <50 ppm residuals, and annual filter‑replacement costs were cut by over 60 %.

-

Treatment of High‑COD Oily Wastewater with Zirconia Ceramic Membrane Tube

✅Key Advantages

1. High COD and Oil Rejection Efficiency

In pilot wastewater tests, Zirconia Ceramic Membrane Tube achieved >90 % COD reduction and 99 % oil removal, maintaining stable flux under trans‑membrane pressure of 3 bar. Its fine pore structure effectively separates emulsified oils and suspended solids.

2. Oxidative Cleaning Compatibility

The zirconia membrane withstands NaClO 5000 ppm oxidative cleaning without surface corrosion or loss of integrity after 200 cycles, verified through SEM surface inspection. This enables aggressive chemical regeneration without membrane failure.

3. Mechanical Strength for Backwash Operations

The tube endures 6 bar reverse‑pressure backwashing, allowing operators to restore >85 % of original flux in a single cycle. Its mechanical stability reduces filter‑change frequency by 50 % in continuous wastewater systems.

✅ ️Problem Solved

A textile wastewater plant in South Korea experienced rapid clogging and chemical degradation of polymer membranes, causing unplanned downtime every two weeks. After integrating ADCERAX® Zirconia Ceramic Membrane Tube, COD levels in discharge fell from 900 mg/L to <80 mg/L, while cleaning frequency was extended to once every 45 days. Operational uptime improved by 35 %, and annual maintenance costs dropped by 28 %, demonstrating the tube’s durability and cleaning efficiency in high‑COD effluent treatment.

Practical User Guide for Zirconia Ceramic Membrane Tube

To ensure stable performance, long service life, and optimal separation results, Zirconia Ceramic Membrane Tube users must follow proper operational and maintenance guidelines. This section outlines key precautions and best practices during installation, cleaning, storage, and system integration for industrial process users.

-

Installation Guidelines

1. Support Structure: A rigid frame or housing must be used to secure the membrane without bending stress. Improper alignment may lead to hairline cracks or seal failure under pressure.

2. Sealing Integrity: Use compatible gaskets or O-rings that withstand CIP chemicals and elevated temperatures. Avoid metal-to-ceramic point loads which may cause microfractures.

3. Orientation & Flow: Install with correct flow direction marked on the module. Reverse installation may disrupt pore gradient performance and reduce filtration efficiency.

-

Cleaning and Maintenance

1. Cleaning Agents: Use alkaline (NaOH) or oxidizing agents (NaClO ≤500 ppm) for periodic flushing. Avoid strong acids which degrade seals and mounting.

2. Backflushing Frequency: Apply reverse pressure pulses every 8–12 hours of continuous use. This restores flux performance and minimizes membrane compaction.

3. Drying Process: Before storage, dry membranes with filtered compressed air or ambient heat under 60°C. Avoid direct flame or sunlight exposure.

-

Operation Parameters

1. Pressure Control: Keep transmembrane pressure (TMP) below 0.4 MPa during normal operation. Overpressure can cause crack propagation within the ceramic layer.

2. Temperature Range: Operate within 5–80°C for typical aqueous solutions. Higher temperatures may accelerate thermal expansion mismatch with housing materials.

3. pH Compatibility: Zirconia membranes tolerate pH 3–10 continuously. For extreme pH cycles, monitor seal degradation and replace accordingly.

-

Storage and Handling

1. Protective Packaging: Always store the membrane in its original foam-lined crate. Avoid unprotected contact with hard objects during handling.

2. Moisture Prevention: Keep in a dry, ventilated environment to prevent microbial growth inside pores. Use desiccant packs if humidity >60%.

3. Inventory Rotation: Follow FIFO (First-In, First-Out) principle to minimize long-term storage exposure, especially in coastal or high-humidity areas.