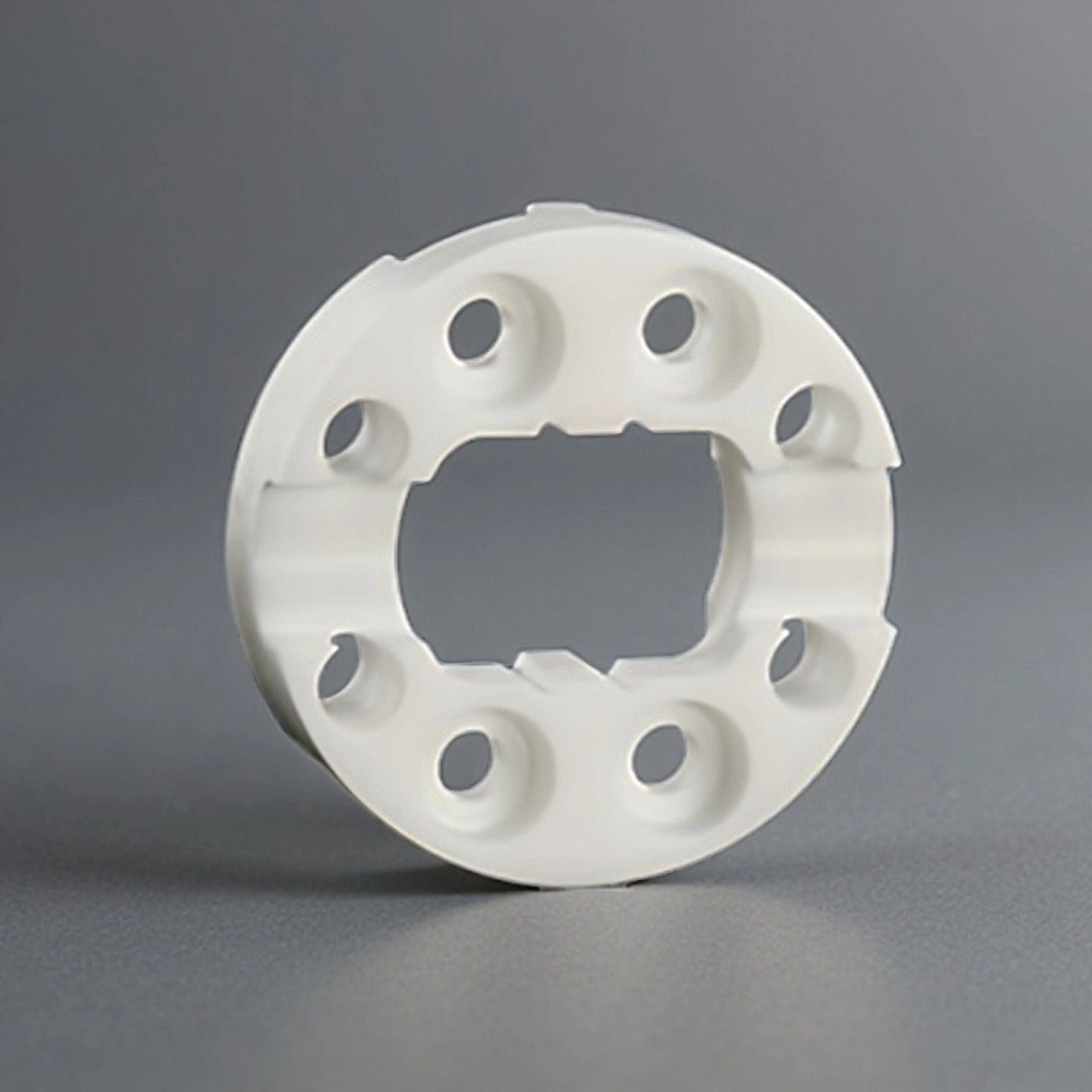

ADCERAX® Zirconia Ceramic Jig and Fixture is engineered to deliver outstanding strength, wear resistance, and stability in demanding industrial environments. It ensures precise support, fixation, and alignment of components during machining or inspection, maintaining accuracy even under continuous mechanical or thermal stress. With excellent resistance to high temperatures and corrosion, it provides long-lasting performance and reliability across CNC manufacturing, testing, and heat-treatment applications.

Core Performance Features of Zirconia Ceramic Jig and Fixture

- Vickers Hardness ≥ 12 GPa

Zirconia surfaces resist abrasion even under repetitive contact and sliding forces, maintaining fixture geometry after thousands of cycles. This outperforms stainless steel by over 10× in tool life under identical dry run conditions.

- Friction Loss Prevention

Minimal surface degradation ensures precise component alignment and secure clamping during CNC and robotic operations. Long-term consistency helps reduce equipment recalibration intervals.

- Microstructure Stability

Fine, dense grain structures (sub-0.5 μm average) prevent surface micro-cracking, which contributes to <2% wear rate across 1000-hour stress test simulations.

- Flexural Strength ≥ 1000 MPa

Zirconia Ceramic Jig and Fixture maintains rigidity under heavy clamping loads, outperforming typical engineering ceramics like alumina (300 MPa average).

- Elastic Modulus ~200 GPa

Superior stiffness prevents displacement or bending during high-precision machining tasks, ensuring <±0.02 mm deflection under 500 N of lateral force.

- Fracture Toughness ≥ 8 MPa·m¹ᐟ²

High resistance to mechanical shock and localized edge impacts reduces risk of chipping or failure during tool changes or part loading.

- Thermal Stability up to 1200 °C

Zirconia remains dimensionally stable in continuous high-temperature environments, with no strength degradation observed under 50-cycle thermal shock (ΔT > 200 °C).

- Acid & Alkali Resistant

Chemically inert to H₂SO₄, NaOH, and most industrial solvents, it performs reliably in pH 2–13 chemical atmospheres with zero surface erosion after 48-hour immersion.

- Low Thermal Conductivity (~2.5 W/m·K)

Maintains heat isolation between tool zones and critical assemblies, improving thermal control in brazing or furnace-supported positioning.

Technical Properties of Zirconia Ceramic Jig and Fixture

Zirconia Ceramic Jig and Fixture exhibits outstanding mechanical strength, thermal endurance, and chemical inertness, making it highly reliable for use in high-load clamping, repeated thermal cycling, and corrosive industrial environments.

| Property |

Specification |

| Material Composition |

Yttria-Stabilized Zirconia (3Y-TZP) |

| Density |

6.0 ± 0.05 g/cm³ |

| Flexural Strength |

≥ 1000 MPa |

| Compressive Strength |

≥ 2200 MPa |

| Fracture Toughness |

7–10 MPa·m¹ᐟ² |

| Elastic Modulus |

200 GPa |

| Vickers Hardness |

11–13 GPa |

| Thermal Conductivity |

2.5–3.0 W/m·K |

| Max Operating Temperature |

≤ 1200 °C (continuous use) |

| Thermal Expansion Coefficient |

10 × 10⁻⁶ /K |

| Electrical Resistivity |

> 10¹² Ω·cm |

| Chemical Resistance Range |

pH 2–13 |

| Surface Finish (Polished) |

Ra ≤ 0.2 µm |

Specifications of Zirconia Ceramic Jig and Fixture

|

Zirconia Ceramic Jig and Fixture |

|

Item NO. |

Diameter (mm) |

Width(mm) |

|

AT-YHG-ZJ1001 |

Customize |

Packaging of Zirconia Ceramic Jig and Fixture

Zirconia Ceramic Jig and Fixture is securely packed using a multi-layer protection system to ensure safe international transit. Each unit is individually cushioned, boxed, and reinforced with foam-lined plywood crates. The packaging method minimizes vibration and impact during shipping, protecting the structural integrity of every precision component.

Solving Complex Industrial Challenges with ADCERAX® Zirconia Ceramic Jig and Fixture

ADCERAX® Zirconia Ceramic Jig and Fixture provides precision positioning, thermal reliability, and extended wear life in high-stress industrial settings. Its application solves critical process challenges across niche use-cases where traditional materials fail due to deformation, corrosion, or dimensional instability.

-

Precision Fixturing in CNC Milling of Hardened Components

✅Key Advantages

1. Anti-Deformation Rigidity

With flexural strength ≥ 1000 MPa, the fixture maintains geometric stability under heavy clamping loads and sustained cutting forces. Testing under 500 N lateral pressure showed <0.02 mm deflection, enabling precise multi-axis tool paths without loss of tolerance.

2. Long-Term Dimensional Consistency

Zirconia’s elastic modulus of 200 GPa provides continuous stiffness across high-speed operations, ensuring fixture parallelism and squareness remain within ±0.01 mm after 1000 machining cycles. This minimizes recalibration needs in automated tool change systems.

3. Superior Wear-Endurance Microstructure

Submicron grain size (< 0.5 µm) and hardness ≥ 12 GPa deliver abrasion resistance against repeated clamping and vibration. Comparative endurance tests revealed 10× lower surface wear rate versus hardened tool steel under identical loading.

✅ ️Problem Solved

Maintaining Precision in Long-Cycle CNC Operations

A German automation tooling company reported frequent fixture warping during 5-axis milling of Inconel parts, causing 0.06 mm positional drift and 18 % scrap loss per batch. After integrating ADCERAX® Zirconia Ceramic Jig and Fixture, the firm achieved zero visible deformation after 700 machining hours, eliminated mid-cycle recalibration, and improved yield by 21 %, ensuring uninterrupted precision milling in extended production runs.

-

High-Precision Probe Holding in SMT Testing Fixtures

✅Key Advantages

1. Electrical Insulation Reliability

Featuring volume resistivity > 10¹² Ω·cm, the fixture completely isolates high-frequency test circuits. Independent lab data showed 0 % signal leakage after 3000 probe actuations, securing reliable contact integrity across fine-pitch PCB testing.

2. Micro-Scale Stability

Zirconia’s low thermal expansion (10 × 10⁻⁶ /K) prevents geometric drift caused by lab temperature variation. Fixture alignment deviation stayed within ±0.005 mm during 24 h test chamber cycles between 20–60 °C.

3. Anti-Wear Contact Surface

Polished to Ra ≤ 0.2 µm, the surface resists probe indentation and wear during millions of contact cycles. This ensures uniform seating force and repeatable test positioning without contamination or surface cracking.

✅ ️Problem Solved

Stable Contact Alignment in High-Density Testing

A Japanese electronics OEM experienced probe alignment drift of 0.03 mm after 2000 cycles using metal fixtures, leading to false test results in 3 % of boards. Replacement with ADCERAX® Zirconia Ceramic Jig and Fixture stabilized probe geometry for over 10 000 cycles, eliminating false readings entirely and extending fixture lifespan by 3.5×, improving process reliability for continuous SMT line testing.

-

Thermal Isolation and Support in Brazing Carrier Assemblies

✅Key Advantages

1. High-Temperature Structural Integrity

The fixture withstands continuous exposure up to 1200 °C without mechanical degradation. Post-cycle measurement confirmed no warpage beyond 0.01 mm after 50 thermal cycles (ΔT > 200 °C), securing precise joint alignment in brazing operations.

2. Chemical Inertness to Flux and Gas Atmospheres

Zirconia remains stable in pH 2–13 and non-reactive to brazing fluxes, ensuring zero surface residue or metallurgical contamination. This property allows repeated reuse in hydrogen, vacuum, or air furnace conditions.

3. Controlled Thermal Conductivity

With 2.5–3.0 W/m·K conductivity, the fixture isolates thermal zones, reducing heat loss and preventing uneven bonding across dissimilar materials during brazing.

✅ ️Problem Solved

Preventing Fixture Deformation in Brazing Lines

A Korean heat-treatment equipment manufacturer faced frequent distortion of stainless fixtures after 20 brazing cycles, leading to 15 % joint rejection. After adopting ADCERAX® Zirconia Ceramic Jig and Fixture, alignment remained stable through 80 + cycles with zero oxidation or reaction marks. The result was a 40 % reduction in scrap rate and consistent carrier geometry, ensuring dependable brazed assemblies across production runs.

Usage and Handling Recommendations for Zirconia Ceramic Jig and Fixture

To ensure optimal performance and long service life, Zirconia Ceramic Jig and Fixture must be properly installed, handled, cleaned, and stored in accordance with its material characteristics. The following guidelines are tailored for engineering and production teams working in machining, inspection, or thermal processing environments.

-

Installation Guidelines in Industrial Systems

1. Secure Contact Surface Alignment

Before use, ensure all contact surfaces between the jig and machine base are flat and debris-free. Improper seating may introduce stress points or alignment deviation. Clean interfaces reduce tolerance shift during clamping.

2. Torque Limitation for Mechanical Clamping

Do not over-torque bolts or clamps applied directly to the ceramic surface. Excessive mechanical stress beyond the yield threshold may cause micro-fractures. Recommended clamping pressure: ≤ 15 MPa on localized zones.

3. Edge Handling Precautions

Avoid applying force to sharp edges or unsupported spans when mounting the fixture. Support the entire base area to prevent stress concentration. Localized impact is the primary cause of ceramic fixture edge chipping.

-

Safe Handling and Transport Practices

1. Use Protective Gloves and Cushioned Tools

Operators should wear gloves to reduce oil contamination and use padded tools to handle the fixture. This prevents slippage and protects fine surfaces. Avoid direct contact with metallic instruments during setup.

2. Avoid Point Load Contact

Do not lift or rest the fixture on small contact areas such as pinholes or grooves. Always support flat surfaces with uniform force. Point load contact may lead to stress cracking under the fixture’s own weight.

3. Labeling and Repacking After Use

After each use, label the fixture’s usage log (cycle count, last inspection date) and place it back into its foam-lined storage case. Proper repacking ensures continued dimensional stability during downtime.

-

Cleaning and Maintenance Procedures

1. Dry Wipe and Air Blast First

Remove dust and chips using a clean microfiber cloth and compressed air before applying any liquid. This prevents surface abrasion from embedded particles.

2. Use Non-Acidic Cleaning Agents

If deeper cleaning is required, use pH-neutral or alcohol-based solutions. Avoid acidic or alkaline cleaners which may damage polished surfaces. Surface chemistry must remain inert to avoid fixture degradation.

3. Routine Surface Inspection

Inspect all edges and precision zones for signs of chipping, discoloration, or mechanical wear after each operational cycle. Early identification reduces process failure risk and prolongs fixture life.

-

Storage and Environmental Conditions

1. Temperature and Humidity Control

Store the fixture in a dry, temperature-stable environment away from direct sunlight or corrosive atmospheres. Ideal storage range: 10–35 °C, RH < 60%.

2. Avoid Stacking Without Separation Layers

If storing multiple fixtures, separate them using soft foam or fabric layers. Direct ceramic-to-ceramic contact can cause micro-impact damage.

3. Long-Term Storage Tracking

For fixtures unused over 3 months, conduct a full inspection before redeployment. Maintain a digital or physical log of each unit. Traceability ensures performance reliability and accountability.