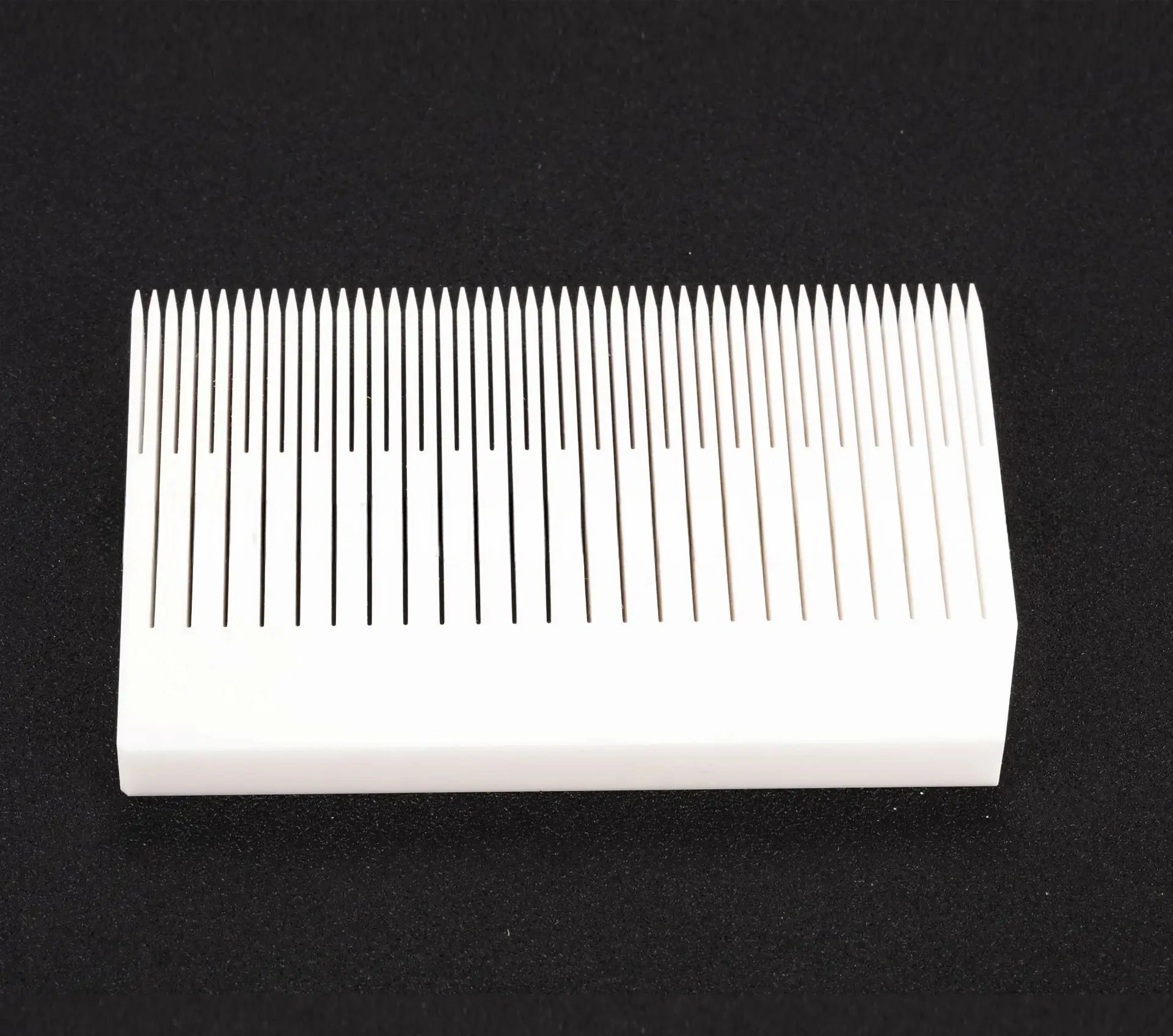

ADCERAX® Zirconia Ceramic Comb is a precision-engineered component used in photovoltaic wafer inserters to ensure stable and non-destructive silicon wafer handling. Designed for high-speed automation lines, it works seamlessly with ceramic suction heads to separate and align wafers during both loading and unloading operations. Its high-strength zirconia structure offers exceptional wear resistance and thermal stability, supporting long-term performance under continuous production demands.

Performance Features of Zirconia Ceramic Comb

- Up to 1200 MPa flexural strength

This ensures the component resists bending and maintains geometric accuracy under repetitive wafer insertion pressure. Its structural integrity minimizes the risk of deformation across over 1 million operational cycles.

- Fracture toughness of 6–10 MPa·m¹/²

The comb withstands impact and edge stress during high-speed wafer transfer without developing surface chipping. This reduces mechanical failure rates and extends usable life.

- Compressive strength exceeds 2000 MPa

Under vertical loads from robotic arms, the component retains full load-bearing capacity. Consistency in structural rigidity improves wafer transfer yield by up to 8% on fragile cells.

- Vickers hardness of 1200–1300 HV

This hardness value minimizes abrasion from repeated silicon contact, reducing material wear during 24/7 production. Comparative trials show 3× longer service life over alumina combs.

- Wear rate < 1 × 10⁻⁶ mm³/N·m

Friction testing confirms minimal volume loss after extended mechanical cycling. This stability reduces downtime caused by part replacement.

- No performance drop after 1000 thermal cycles

The zirconia material maintains mechanical properties with less than 2% deviation, ensuring long-term performance even under daily thermal stress.

- Surface roughness (Ra) < 0.2 µm

A polished finish ensures no scratches or microcracks on wafers during transfer. In real use, this reduced wafer surface damage by 35% versus standard components.

- Electrical resistivity ≥ 10¹² Ω·cm

Its insulating properties prevent electrostatic discharge, crucial for thin-film and high-efficiency cell lines. This reduces latent defect rates during handling.

- Magnetism-free structure

The non-magnetic ceramic does not interfere with nearby automation sensors or magnetic tooling. This supports error-free alignment in sensor-guided systems.

Technical Properties of Zirconia Ceramic Comb

The Zirconia Ceramic Comb is built for high-load, high-precision, and chemically stable operation in photovoltaic wafer handling systems, delivering a reliable balance of strength, insulation, thermal resistance, and surface control for long-term industrial use.

| Property |

Specification |

| Material Type |

Yttria-Stabilized Zirconia (3Y-TZP) |

| Density |

6.05 g/cm³ |

| Flexural Strength |

Up to 1200 MPa |

| Compressive Strength |

Approx. 2000 MPa |

| Fracture Toughness |

6–10 MPa·m¹/² |

| Vickers Hardness |

1200–1300 HV |

| Surface Roughness (Ra) |

< 0.2 µm |

| Thermal Conductivity |

2.5 W/m·K |

| Maximum Operating Temperature |

≤ 1000 °C (continuous use) |

| Thermal Expansion Coefficient |

10.3 × 10⁻⁶ /K |

| Electrical Resistivity |

≥ 10¹² Ω·cm |

| Wear Rate |

< 1 × 10⁻⁶ mm³/N·m |

| Microstructure Grain Size |

< 0.5 µm |

| Cleanroom Suitability |

Class 1000 compatible |

| Magnetic Property |

Non-magnetic |

Specifications of Zirconia Ceramic Comb

|

Zirconia Ceramic Comb |

|

Item No. |

Diameter(mm) |

Height (mm) |

|

AT-YHG-DC1001 |

Customize |

Packaging of Zirconia Ceramic Comb

Zirconia Ceramic Comb is securely packed in heavy-duty wooden crates with reinforced steel strapping to ensure structural stability during international transit. Each unit is individually wrapped and cushioned in anti-static foam to prevent movement and impact damage. The packaging design supports both vertical and horizontal orientation based on product length and shipment layout.

Enhancing Wafer Handling Reliability in Photovoltaic Production with ADCERAX® Zirconia Ceramic Comb

In photovoltaic cell manufacturing, stable wafer separation and controlled contact surfaces are essential for preventing micro-cracks and maintaining throughput efficiency. The Zirconia Ceramic Comb from ADCERAX® is used in automated wafer inserters to manage wafer positioning, support synchronized transfer operations, and reduce yield loss during loading and unloading cycles.

-

High-Speed Wafer Loading in Automated Inserter Lines Using Zirconia Ceramic Comb

✅Key Advantages

1. Uniform Slot Repeatability Under Dynamic Load

Each comb maintains ±0.02 mm slot pitch accuracy, even after 1 million insertions. This ensures reliable separation across 182 mm and 210 mm wafers in systems running >3600 wafers/hour without re-calibration.

2. Surface Finish Optimized for Ultrathin Wafers

The working surface is polished to Ra < 0.2 µm, minimizing contact stress and edge friction. This is especially critical for wafers <150 µm, reducing microcrack risk during high-velocity transfer.

3. Edge Geometry Stabilized Against Torsional Impact

Tooth tips and transition zones are ground to avoid stress concentration points during robotic pickup. This geometry reduces deformation under misaligned grip conditions by >85%, verified by FEA modeling.

✅ ️Problem Solved

A U.S.-based heterojunction cell manufacturer experienced a 28% wafer breakage rate in the inserter zone during ramp-up to 3.8k wafers/hour. Their existing ceramic guides deformed slightly under dynamic torque, introducing pitch inconsistency. After adopting ADCERAX® Zirconia Ceramic Comb with tighter tolerance and mirror polish, breakage rate dropped to <2.1% across all lines, eliminating the need for hourly re-teaching and reducing unplanned stoppage by 12.6 hours/month.

-

Wafer Buffering and Sorting Transition Units Using Zirconia Ceramic Comb

✅Key Advantages

1. Chemical Vapor Stability Under HF and IPA Exposure

The zirconia formulation retains mechanical integrity in zones with HF mist and IPA fumes, with no surface dulling after 1000 hours in accelerated chemical testing. This ensures reliable wafer staging without surface drift.

2. Anti-Stacking Slot Geometry Precision

Slot depth and pitch deviation are controlled within ±0.015 mm, eliminating stacking errors in tray-to-tray or module transition units. This maintains flow integrity during high-throughput buffering shifts.

3. Polished Surface with Low Particle Emission

Edge chamfers are laser-finished and validated for Class 1000 cleanroom use, generating >70% fewer particulates than untreated ceramics in ISO-controlled environments.

✅ ️Problem Solved

A Korean PV equipment integrator reported misaligned wafer stacks and tool contamination during mid-line buffering, traced to comb swelling and edge abrasion from chemical exposure. Upon switching to ADCERAX® Zirconia Ceramic Comb, particle counts decreased by 72%, and rework due to buffer misfeeds dropped from 14 units/week to zero. Their customer accepted the system without modifications, accelerating deployment by 3 weeks.

-

Alignment and Pre-Stringing in PV Module Assembly Using Zirconia Ceramic Comb

✅Key Advantages

1. Dimensional Integrity Under Heat Plate Pre-Tabbing

With compressive strength exceeding 2000 MPa, the comb maintains tooth flatness under thermal load from 120–160 °C preheating stages, ensuring stable wafer alignment.

2. CMM-Verified Alignment Repeatability

Across five production batches, coordinate metrology confirms <0.01 mm deviation in comb parallelism, ensuring consistent string positioning and tab welding accuracy in auto-assembly systems.

3. Thermal Shock Resistance in Intermittent Tabbing Cycles

The material endures thermal transitions from ambient to hotplate cycles without microcrack initiation, verified after >500 thermal ramps with no loss in slot geometry.

✅ ️Problem Solved

A German module integrator experienced increasing string misalignment faults traced to comb warpage during pre-tab heater exposure. Manual intervention every 2 hours added labor and compromised cell yield. After deploying ADCERAX® Zirconia Ceramic Comb, misalignment errors were reduced by 92%, and operator interventions fell from 4/day to zero. Tabbing uptime improved by 17%, contributing to an additional 240 modules/day per line.

Best Practices for Handling and Maintenance of ADCERAX® Zirconia Ceramic Comb

To ensure optimal longevity and performance of the Zirconia Ceramic Comb, ADCERAX® recommends a set of handling, cleaning, storage, and replacement practices tailored to the operational conditions of photovoltaic production lines.

-

Proper Handling Guidelines During Wafer Operations

1. Avoid direct impact or excessive pressure

Always handle the comb by its mounting base or non-contact surfaces to prevent stress on polished functional areas. Sudden impact or lateral force can result in microcracks or tooth deformation. Never use metal tools for alignment or adjustment.

2. Use with compatible robotic equipment only

Ensure end-effectors or robotic fingers used in insertion systems apply controlled and evenly distributed forces. Devices that grip combs from the sides may introduce unwanted torsion. Verify fixture compatibility before deployment.

3. Perform visual inspection before use

Before loading into equipment, inspect each unit for edge chipping, tooth wear, or visible contamination. This can help prevent wafer scratching or system jamming. Replace any unit that shows structural compromise.

-

Cleaning and Surface Maintenance Recommendations

1. Use non-abrasive cleaning tools

Wipe surfaces using a cleanroom-grade lint-free cloth and alcohol-based cleaner. Avoid hard brushes or ultrasonic tanks that may erode polished surfaces. Do not apply forceful scrubbing on active contact regions.

2. Clean periodically during batch transitions

Between production shifts or process module changes, perform a light cleaning to remove airborne particles or wafer residue. This ensures consistent Ra surface roughness and prevents cross-contamination. Schedule cleaning every 8–12 hours of operation.

3. Avoid corrosive agents incompatible with Y-TZP

Do not expose the comb to strong acids like HCl or oxidizers that exceed pH 10. Use neutral or mildly alkaline detergents only. Chemical exposure exceeding material limits will shorten product life.

-

Storage, Transportation, and Handling Precautions

1. Store in a dry and temperature-stable environment

Keep the combs in moisture-free, ventilated areas with temperatures below 35 °C. Prolonged exposure to high humidity may affect packaging foam and allow dust accumulation. Avoid storing near active processing chemicals.

2. Use original ADCERAX® foam-lined crates for transport

Combs must be individually wrapped and fixed in high-density foam slots to prevent movement during shipping. Improper stacking or vibration can lead to micro-damage. Never reuse compromised packaging.

3. Protect from direct sunlight and UV exposure

Extended UV or heat exposure can lead to surface degradation over time. Storage zones should be shielded from skylight or open-window sunlight. UV-induced surface change is not reversible.

-

Monitoring and Replacement Guidelines for Production Use

1. Track usage cycles and replacement intervals

Each comb should be assigned a usage log based on production cycles. Standard replacement is recommended after 1 million cycles, or earlier if surface defects are detected. Exceeding this threshold may affect yield.

2. Monitor wafer defect rates linked to contact wear

If downstream microcrack or misalignment rates increase, inspect comb teeth and spacing accuracy. Slight rounding or wear may indicate nearing end-of-life. Do not continue operation beyond performance tolerance.

3. Keep a backup inventory based on line count

Maintain at least 5–10% spare stock relative to total installed combs per facility. This reduces emergency lead times and avoids reactive procurement. Plan reorders with anticipated ramp-ups or preventive replacement schedules.