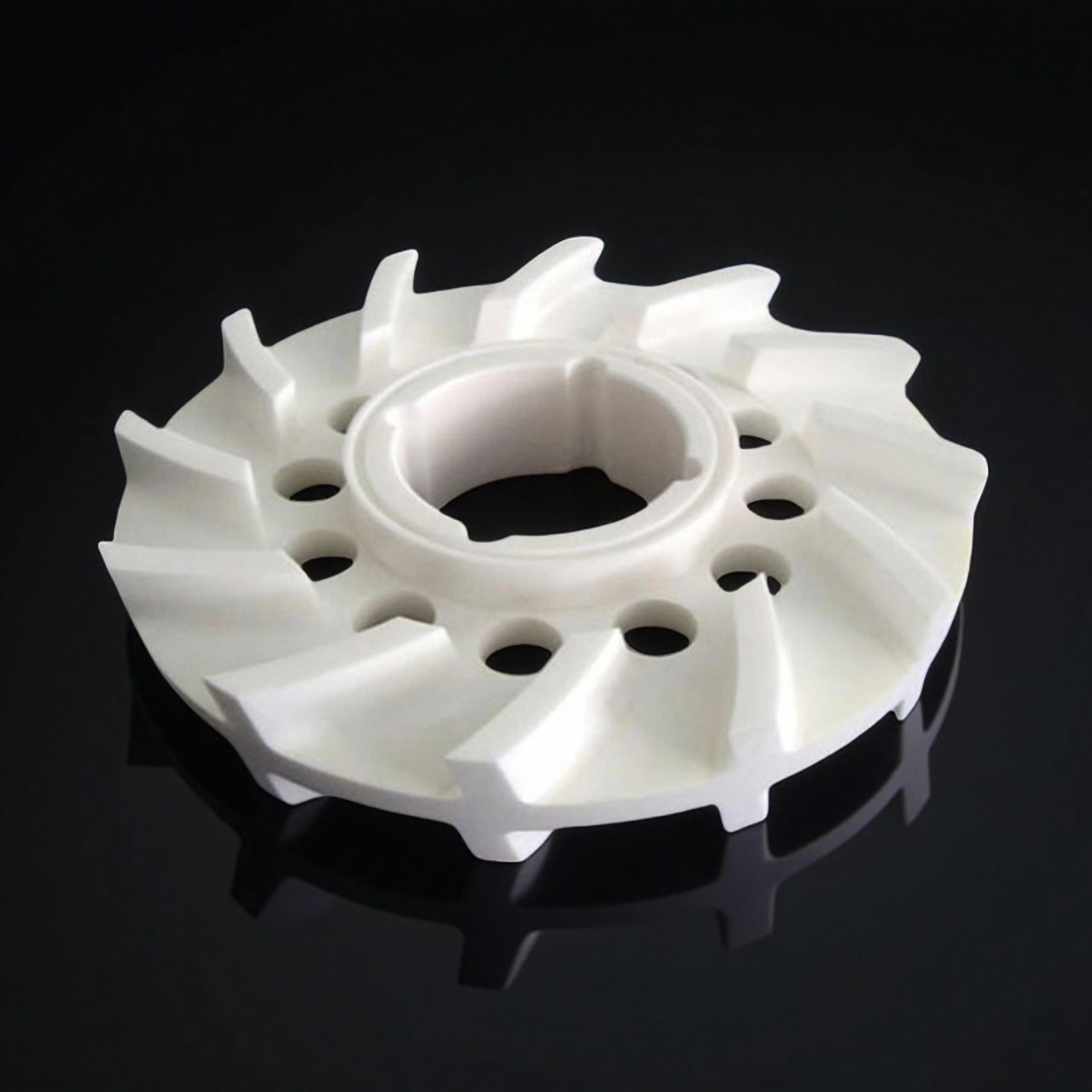

ADCERAX® Zirconia Ceramic Flange is produced from yttria‑stabilized zirconia through forming and controlled sintering, providing a dense and stable ceramic structure suitable for demanding pipeline connections. Its high mechanical strength and resistance to heat and corrosive media allow stable operation in chemical processing, metallurgical systems, and high‑temperature gas or exhaust pathways. The material’s inherent chemical inertness and electrical insulation characteristics support long‑term reliability in environments where metallic components experience degradation or contamination.

High-Temperature and Chemical Stability Advantages of Zirconia Ceramic Flange

-

Operates Reliably Above 1000 °C

Designed for continuous operation at temperatures exceeding 1000 °C, this flange maintains its mechanical integrity in kilns, furnaces, and thermal oxidizer systems. Its thermal endurance is supported by a flexural strength of over 900 MPa, ensuring no loss of stability during cyclic thermal loads.

-

Maintains Stability Under Thermal Cycling

The material resists damage from abrupt ΔT ≈ 250 °C changes without cracking, outperforming alumina or metal flanges in burner pipe and preheater applications. Laboratory trials confirm zero microcrack propagation after 50+ rapid thermal shock cycles.

-

Low Thermal Conductivity Performance

With a thermal conductivity of just 2.5 W/m·K, heat transfer to adjacent assemblies is minimized. This helps protect sensitive seals or gaskets near heat source transitions, ensuring longer system service life in high-flux applications.

-

Acid and Alkali Compatibility

The flange exhibits full chemical stability in pH 1 to 14 environments, making it suitable for sulfuric acid scrubbers, chlor-alkali reactors, and caustic recovery systems. After 72-hour exposure to H₂SO₄ at 80 °C, it showed a mass loss under 0.05 mg/cm².

-

Zero Metal Ion Leaching

Zirconia’s ceramic matrix structure prevents any ionic diffusion or oxidation, a critical factor in high-purity chemical lines. Long-term tests confirm no detectable contamination in ultrapure nitric acid systems.

-

Long-Term Hydrothermal Stability

After prolonged exposure to 200 °C steam at 95% RH, the flange retains both surface hardness and dimensional precision. This performance ensures stable sealing in superheated vapor lines and autoclave conduits for more than 5 years.

Technical Properties of Zirconia Ceramic Flange

The Zirconia Ceramic Flange is engineered from yttria-stabilized zirconia to deliver outstanding resistance to mechanical stress, aggressive chemicals, and thermal extremes. Its dense microstructure, high fracture toughness, and dielectric strength make it suitable for continuous operation in corrosive and high-temperature industrial environments.

| Property |

Specification |

| Material Composition |

Y₂O₃-Stabilized Zirconia (≥ 94%) |

| Density |

6.0 g/cm³ |

| Flexural Strength |

≥ 900 MPa |

| Compressive Strength |

≥ 2000 MPa |

| Fracture Toughness |

8–10 MPa·m¹ᐟ² |

| Hardness |

1250 HV 0.5 |

| Thermal Conductivity |

2.5 W/m·K |

| Coefficient of Thermal Expansion |

10.5 × 10⁻⁶ /K |

| Electrical Resistivity |

> 10¹² Ω·cm at room temperature |

| Chemical Stability (pH) |

Stable in pH 1–14 |

| Mass Loss (H₂SO₄, 72h, 80 °C) |

< 0.05 mg/cm² |

| Thermal Shock Resistance |

ΔT ≥ 250 °C |

Specifications of Zirconia Ceramic Flange

|

Zirconia Ceramic Flange |

|

Item No. |

Outer Diameter(mm) |

Length(mm) |

|

AT-YHG-FL1001 |

Customize |

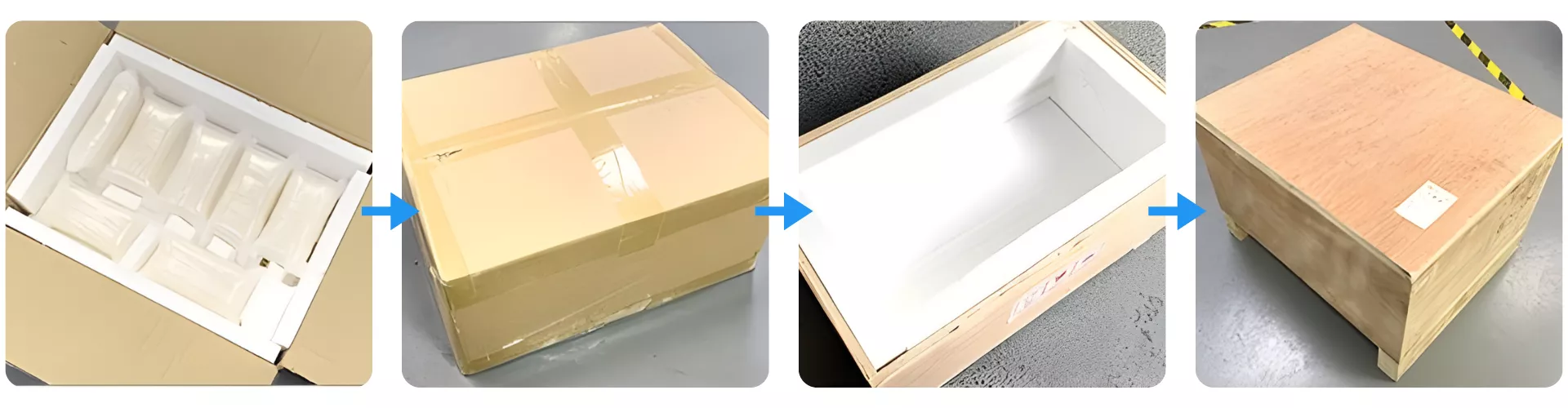

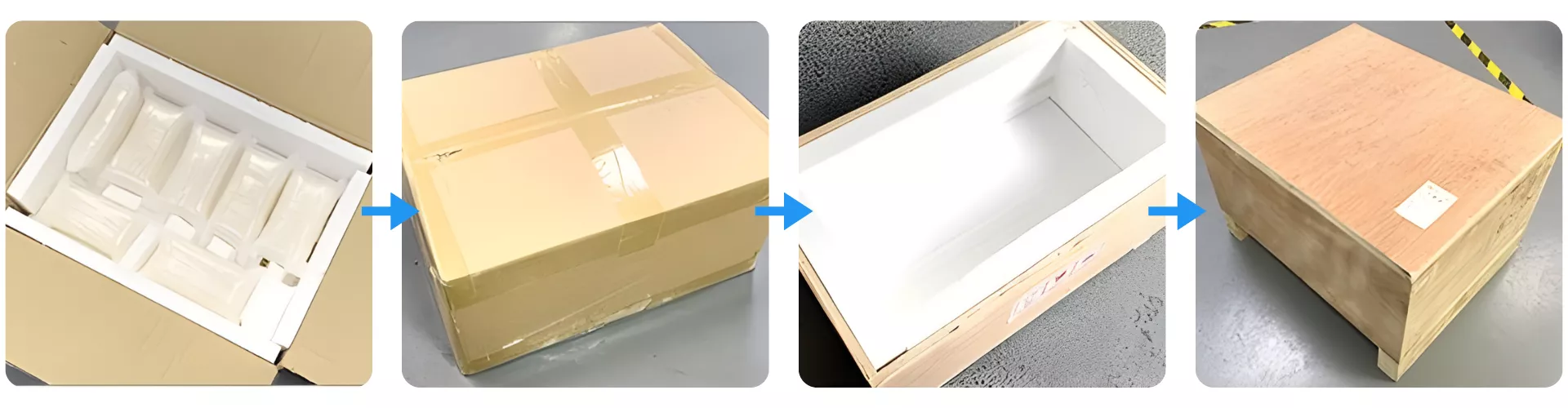

Packaging of Zirconia Ceramic Flange

Zirconia Ceramic Flange is carefully packed using molded foam inserts to prevent vibration and impact during international transit. Each unit is double-boxed and sealed in moisture-resistant outer cartons before being secured in reinforced plywood crates. This multi-layer protection ensures product integrity from factory to end-user site.

Enhancing Reliability in Harsh Pipeline Systems with ADCERAX® Zirconia Ceramic Flange Solutions

The Zirconia Ceramic Flange from ADCERAX® provides a long-life, contamination-free, and structurally stable solution for pipeline connectivity in extreme conditions. Its mechanical strength, chemical inertness, and thermal insulation properties directly address the failure points seen in conventional metallic flanges under corrosive and high-temperature operations. The following real-world applications illustrate how ADCERAX® resolves the most critical operational challenges across demanding industrial sectors.

-

Zirconia Ceramic Flange Use in Chlor-Alkali Plant Brine Recirculation Systems

✅Key Advantages

1. Chloride-Induced Corrosion Immunity

Zirconia remains dimensionally stable in hot brine streams exceeding 90 °C where duplex steel and nickel alloys show pitting initiation.

Its non‑metallic lattice prevents Cl₂-driven oxidation, maintaining seal load over long operating cycles.

2. No Ionic Leaching into Electrolytic Circuits

Under continuous NaCl/Cl₂ exposure, leaching tests show undetectable cation release (<0.1 ppm), avoiding conductivity drift in electrolyzer systems.

This enables stable product concentration control and prevents contamination of downstream brine purification stages.

3. Maintains Seal Compression Under Pressure Cycling

Zirconia maintains >900 MPa flexural strength, preventing face bowing or bolt-load decay across repeated recirculation pump starts.

This ensures stable gasket seating and eliminates frequent retightening intervals common with polymer-lined joints.

✅ ️Problem Solved

In a chlor-alkali plant brine loop operating at 92–98 °C and high Cl⁻ activity, stainless flanges required replacement every 4–6 weeks due to pitting and gasket embrittlement. Polymer-lined versions deformed under continuous recirculation pressure, causing recurrent leakage points and process contamination. After replacing junction points with ADCERAX® Zirconia Ceramic Flange, the line operated 12 consecutive months with zero flange retorque and no detectable electrolyte contamination, reducing unplanned shutdown frequency by >60%.

-

Zirconia Ceramic Flange Integration in High-Temperature Flue Gas Scrubbing Columns

✅Key Advantages

1. Oxidation Stability in SO₂/SO₃ Atmospheres

Zirconia surface integrity remains unchanged at 800 °C exposure, unlike steel which forms scale and loses flatness.

This ensures sealing surfaces remain geometrically reliable for long-term absorber tower operation.

2. No Thermal Cold‑Flow or Deformation

Zirconia’s rigid crystalline structure prevents cold‑flow creep seen in PTFE-lined assemblies under thermal cycling.

This preserves gasket compression balance, preventing radial seal displacement.

3. Maintains Flatness Through Condensation–Evaporation Cycles

With thermal shock resistance ΔT ≥ 250 °C, zirconia prevents warping during alternating dry/wet flue contact.

This avoids re-torque events and reduces maintenance scheduling interruptions.

✅ ️Problem Solved

A steel-and-PTFE hybrid flange assembly in a SO₂ scrubber exhibited surface oxidation and liner cold-flow, requiring bolt tightening every 2–3 weeks to prevent leakage. These alignment losses also increased tower backpressure and threatened emissions compliance. After installation of ADCERAX® Zirconia Ceramic Flange, flatness remained stable over 9 months of inspection intervals, eliminating retorque events and reducing maintenance labor time by ~45%, while maintaining consistent backpressure profiles.

-

ADCERAX® Zirconia Ceramic Flange Performance in Furnace Burner Feedlines

✅Key Advantages

1. CTE Compatibility for Hybrid Steel–Refractory Piping

With a thermal expansion coefficient of 10.5 × 10⁻⁶/K, zirconia minimizes differential stress against steel manifolds and refractory-lined tubes.

This eliminates flange face distortion during 1000 °C → ambient cooldown cycles.

2. Resistance to Thermal Shock During Rapid Firing Cycles

Zirconia withstands ΔT > 250 °C without micro-cracking, unlike alumina-based ceramics that fracture under abrupt flame exposure.

This ensures stable flange sealing during burner ignition sequences and daily cycling.

3. Structural Strength Maintained Under Radiant Heat Load

At 900+ MPa flexural strength, zirconia supports burner assembly vibration and mounting stresses without creep deformation.

This helps preserve burner feed alignment across long service intervals.

✅ ️Problem Solved

In a multi-burner steel reheating furnace, metal flanges warped during startup/shutdown cycling, causing misalignment and gasket fatigue that led to combustion variability and flame instability. Trial ceramic flanges made from lower-toughness materials cracked under thermal shock. After upgrading to ADCERAX® Zirconia Ceramic Flange, burner feedlines maintained alignment across 50+ thermal cycles, stabilizing flame geometry and reducing tuning adjustments by >30%, while eliminating flange deformation incidents entirely.

ADCERAX® Zirconia Ceramic Flange Handling and Maintenance Guidelines for Optimal Field Performance

To maximize long-term reliability and functional stability, Zirconia Ceramic Flange users must consider a range of practical handling, installation, and maintenance practices. This guide from ADCERAX® outlines the critical do's and don’ts to ensure safe operation, prevent assembly damage, and prolong sealing integrity across all supported application environments.

-

Pre-Installation Inspection and Preparation

1. Surface condition must be visually checked before assembly to ensure no chips, cracks, or contamination are present on the flange sealing face or bolt interface. Any visible defect could compromise sealing performance or introduce stress risers.

2. Verify flange compatibility with adjacent components, including bolt circle, face type, and sealing configuration. Pay special attention when mating ceramic-to-metal interfaces to avoid CTE mismatch-induced strain.

3. Clean contact surfaces with isopropyl alcohol or lint-free cloths to remove oil, dust, or packing residue. Avoid abrasive cleaning methods or metallic scrapers that may cause micro-surface damage.

-

Mounting and Mechanical Fastening Guidelines

1. Torque must be applied evenly using a calibrated cross-pattern sequence to prevent point loading or deformation across the flange face. Recommended torque values should align with the gasket type and size class.

2. Use soft gaskets such as graphite or PTFE, which conform to ceramic surfaces without exerting excessive stress. Avoid hard metal gaskets which could induce fracture under load.

3. Never hammer or force ceramic flanges into position; misalignment must be corrected at the support or coupling level, not through mechanical leverage that could compromise the ceramic structure.

-

Operational Environment and In-Service Monitoring

1. Avoid sudden pressure or temperature changes that exceed the recommended thermal shock threshold (ΔT > 250 °C). Allow controlled ramp-up and ramp-down cycles to minimize expansion-related stress.

2. Monitor bolt tension and sealing condition during the first 72 hours of thermal or chemical exposure, as slight settling may occur depending on gasket compressibility.

3. Inspect for discoloration, leaks, or mechanical stress marks around the flange perimeter regularly, especially in systems handling chlorinated media, to detect early signs of seal degradation.

-

Disassembly, Cleaning, and Reuse Considerations

1. Use appropriate non-metallic tools (e.g., polymer wedges, nylon scrapers) during disassembly to avoid chipping the sealing surfaces or mounting holes.

2. Never reuse damaged or thermally fatigued flanges, even if cracking is not visibly apparent. Microcracks may propagate during reinstallation, especially under bolt preload.

3. After removal, store flanges in clean, dry, foam-padded containers to prevent dust contamination or impact during transit or temporary inventory holding.