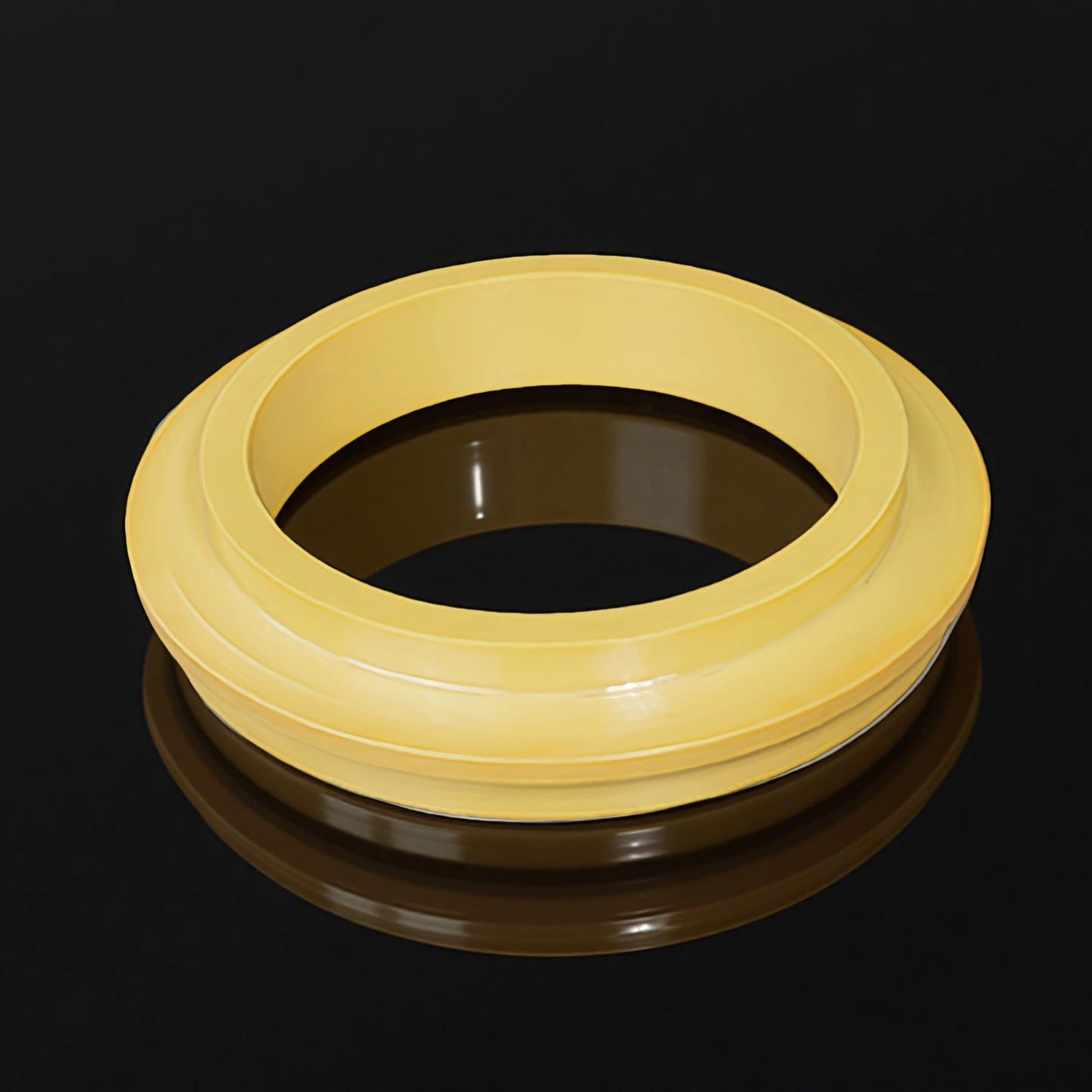

ADCERAX® MSZ Ceramic Seal Ring is engineered from magnesia‑stabilized zirconia to deliver stable mechanical performance under demanding thermal and chemical conditions. Its multi‑phase microstructure provides improved resistance to thermal shock and surface degradation, enabling reliable sealing in pumps, valves, and fluid‑handling assemblies exposed to corrosive or abrasive media. This material stability supports long operating cycles, minimizes leakage risk, and maintains sealing integrity across a wide range of industrial environments.

Key Performance Features of MSZ Ceramic Seal Ring

-

Strong acid–alkali durability

Withstands continuous exposure to HCl, NaOH, and chloride solutions without visible surface degradation.

Chemical structure remains stable after 1000-hour immersion in pH<3 or pH>11 media.

-

Minimal ion leaching

Ensures surface purity in contact with solvents, saltwater, and chemical reagents.

Typical ionic release levels are below 0.1 ppm after extended testing.

-

Stable microstructure under corrosive stress

Prevents pitting or phase breakdown in long-term chemical exposure.

Material retains over 95% strength after 60-day immersion in sulfuric acid at 80 °C.

-

High hardness surface

Achieves Vickers Hardness of 1100–1200 HV, effectively reducing surface abrasion.

Maintains seal geometry even under rotational speeds >10,000 RPM.

-

Extended wear life under friction

Sustains low wear rate of ≤1×10⁻⁶ mm³/N·m in ball-on-disc testing.

Lasts 3–5× longer than alumina or carbon-based seals in slurry pumps.

-

Resistance to particle-laden media

Performs reliably in applications with silica, alumina, or catalyst particulates.

Erosion loss remains under 0.01 mm/year in simulated slurry circulation.

-

Thermal stability up to 1000 °C

No structural deformation observed in cyclic furnace tests at 950–1000 °C.

Phase composition remains unchanged after 200 thermal cycles between 25 °C and 950 °C.

-

Low thermal conductivity

Reduces heat transfer to adjacent components, rated at 2–3 W/m·K.

Ideal for use in pumps or valves handling steam or superheated fluids.

-

Resistance to rapid temperature swings

Withstands direct exposure to >300 °C temperature gradient changes without crack formation.

Maintains seal integrity during CIP/SIP or cold start scenarios.

Technical Specifications of MSZ Ceramic Seal Ring

ADCERAX® MSZ Ceramic Seal Ring exhibits a dense polycrystalline structure with multi-phase toughness, engineered to maintain mechanical reliability, thermal resilience, and chemical inertness under demanding sealing environments.

| Property |

Specification |

| Material Composition |

MgO‑Partially Stabilized Zirconia |

| Density |

5.7 ± 0.05 g/cm³ |

| Flexural Strength |

500–620 MPa |

| Compressive Strength |

2000–2500 MPa |

| Vickers Hardness |

1100–1200 HV |

| Fracture Toughness |

6–12 MPa·m1/2 |

| Maximum Operating Temperature |

~1000 °C |

| Thermal Expansion Coefficient |

~10 × 10⁻⁶ K⁻¹ |

| Thermal Conductivity |

2–3 W/m·K |

| Corrosion Resistance |

Stable in pH 1–13 acids and bases |

| Ionic Leaching |

<0.1 ppm (Na+, K+) |

| Surface Finish Capability |

Sub-micron Ra achievable |

Dimensions of MSZ Ceramic Seal Ring

Packaging for MSZ Ceramic Seal Ring

MSZ Ceramic Seal Ring is securely packed using a multi-layer protection method to prevent damage during international transportation. Each unit is first boxed with shock-absorbing inner lining, then consolidated into reinforced cartons and sealed in moisture-proof wooden crates. The final palletized packaging ensures stability and integrity throughout handling and delivery.

ADCERAX® MSZ Ceramic Seal Ring Addresses Critical Sealing Challenges in Corrosive and Thermal-Intensive Equipment

The MSZ Ceramic Seal Ring by ADCERAX® is engineered to enhance sealing reliability in highly demanding fluid and mechanical systems. From high-chloride process pumps to CIP-exposed food systems, this advanced zirconia-based component plays a vital role in preventing leakage, resisting chemical attack, and stabilizing performance under thermal shock and rotational stress.

-

High-Chloride Slurry Pumps in Chemical Desulfurization Systems

✅Key Advantages

1. Chloride‑Rich Corrosion Stability

The MSZ microstructure retains >95% flexural strength after 60‑day exposure in chloride concentrations above 20,000 ppm.

This prevents the pitting and surface roughening commonly observed on SiC and carbon rings under the same conditions.

2. Slurry Erosion Resistance

Material loss remains below 0.01 mm/year when tested against limestone slurry at 1200–1500 mg/L solid concentration.

This allows the sealing face to maintain flatness even under continuous abrasive circulation.

3. Thermal‑Shock Endurance During Steam Cleaning

The ring withstands >200 rapid steam‑flush cycles with ΔT > 300 °C without edge chipping or microcracking.

This ensures sealing stability during routine desulfurization tower cleaning and hot–cold transitions.

✅ ️Problem Solved

A European FGD plant previously experienced seal failures every 4–6 months when using carbon and SiC components due to chloride‑driven pitting and abrasive wear from limestone slurry. Each leakage event triggered a forced pump shutdown costing an estimated USD 8,000–12,000 per incident, including cleanup and lost throughput. After switching to ADCERAX® MSZ Ceramic Seal Ring, the service interval increased to 18+ months, and no thermal‑shock cracks were detected after routine steam purging. The operational data demonstrated a >60% reduction in unscheduled stoppages, directly linked to MSZ’s corrosion–erosion–thermal stability synergy.

-

High-Pressure Feed Pumps in Industrial Water Reuse Facilities

✅Key Advantages

1. High Compressive Strength Under Pressure Cycling

With compressive strength at 2000–2500 MPa, the ring maintains sealing‑face integrity during rapid pressure rise in feed lines.

This prevents micro‑deformation commonly seen in polymer‑reinforced seals under repeated high‑pressure pulses.

2. Oxidant‑Resistant Ceramic Stability

Ionic leaching remains below 0.1 ppm when exposed to sodium hypochlorite and ozone sterilization cycles.

The chemical inertness prevents surface embrittlement that leads to premature cracking in metal‑backed seals.

3. CIP Thermal‑Cycle Fatigue Resistance

The MSZ structure withstands >150 CIP/SIP cycles involving temperature changes from 20 °C to 95 °C without phase degradation.

This ensures long‑term dimensional stability despite aggressive disinfection routines.

✅ ️Problem Solved

A North American water‑reuse facility reported recurring leakage in their feed pumps due to polymer‑based seals degrading under hypochlorite exposure and pressure surges. Failures typically occurred within 2–3 months, causing disruptive depressurization and emergency shutdowns. After adopting ADCERAX® MSZ Ceramic Seal Ring, the operating life extended beyond 12 months, even under daily CIP thermal cycling and continuous oxidant contact. System inspections showed zero surface pitting and no sealing‑face distortion, resulting in a 75% drop in pressure‑related shutdown incidents and more predictable maintenance scheduling.

-

Food-Grade Dosing Pumps with Frequent Hot Water Sterilization

✅Key Advantages

1. Hygienic Surface Integrity

The polished MSZ surface consistently achieves Ra < 0.2 μm, preventing residue adhesion of syrups, sugars, and concentrates.

This ensures smooth flushing during washdowns and reduces microbial retention risk.

2. Acidic Ingredient Corrosion Resistance

The ceramic maintains full structural integrity after 1000-hour exposure to common food acids such as citric and malic acid.

This avoids the surface softening or discoloration frequently seen in composite seal materials.

3. Hot‑Water Sterilization Stability

MSZ endures repeated 90–95 °C sterilization cycles without swelling, microcracking, or dimensional drift.

This allows uninterrupted dosing accuracy during daily cleaning operations.

✅ ️Problem Solved

A beverage concentrate line experienced seal deformation and contamination issues caused by elastomer and composite rings failing after 40–60 hot-water wash cycles. Sugar crystals caused scoring on the sealing face, degrading dosing accuracy and forcing batch rejections costing USD 15,000–20,000 per occurrence. Upon switching to ADCERAX® MSZ Ceramic Seal Ring, the system maintained tight sealing and hygienic contact surfaces for 300+ sterilization cycles with no detectable wear. This resulted in zero contamination incidents and significantly improved consistency in high-viscosity fluid dosing.

ADCERAX® MSZ Ceramic Seal Ring Usage Guide for Long-Term Stability and Lifecycle Integrity

Proper handling and usage of MSZ Ceramic Seal Ring are essential to achieving optimal sealing performance under demanding chemical, thermal, and mechanical environments. This guide outlines key practices for installation, operational settings, maintenance protocols, and storage to help ensure consistent sealing reliability across industrial systems.

-

Installation Best Practices

1. Clean all sealing surfaces before assembly

Any residual particles or moisture may cause misalignment or micro-gaps.

Use non-abrasive solvents and lint-free wipes during pre-cleaning.

2. Align concentricity and avoid forced fitting

Do not hammer or apply uneven force during positioning.

Ensure parallel contact surfaces for full-face sealing without stress.

3. Follow directional mounting based on sealing face orientation

Improper direction may result in early-stage leakage or uneven wear.

Confirm groove design and loading sequence before assembly.

-

Environmental Conditions to Monitor During Operation

1. Avoid exposure to temperature beyond 1000 °C

Prolonged overheating can alter microstructure and reduce fracture toughness.

For thermal cycling applications, gradual ramp-up/down is strongly recommended.

2. Minimize sudden pressure surges exceeding system rating

Excessive pressure spikes can crack the sealing interface.

Use pulsation dampeners in reciprocating pump systems.

3. Limit contact with particles >100 μm in high-speed applications

Hard solids can induce abrasion at seal faces under dynamic load.

Install upstream filters to prevent particulate entry into sealing zones.

-

Cleaning, Inspection, and Preventive Maintenance

1. Inspect seal faces for wear lines or micro-chips every 3–6 months

Early identification helps reduce unexpected system failures.

Use optical magnification for surface evaluation if necessary.

2. Avoid high-pressure jet cleaning directly onto sealing surfaces

Focused water impact may introduce thermal shock or edge erosion.

Use soft-flow rinse and controlled temperature gradients during cleaning.

3. Re-lubricate or inspect adjoining soft sealing elements

Dehydrated or compressed elastomers can compromise ceramic ring efficiency.

Replace aged or chemically degraded backup seals regularly.

-

Storage and Transportation Guidelines

1. Keep MSZ Ceramic Seal Ring in its original multi-layer protective packaging

Factory packaging is designed to prevent chipping, dust ingress, and humidity exposure.

Avoid repacking with abrasive or acidic materials.

2. Store in dry, vibration-free areas at ambient temperature

Exposure to condensation or mechanical shock may introduce micro-cracks.

Maintain storage shelves with padded trays and desiccant packs.

3. Avoid stacking crates beyond maximum load rating

Overloading can stress packaging and compromise internal structural safety.

Use labeled orientation signs to prevent misplacement during transport.