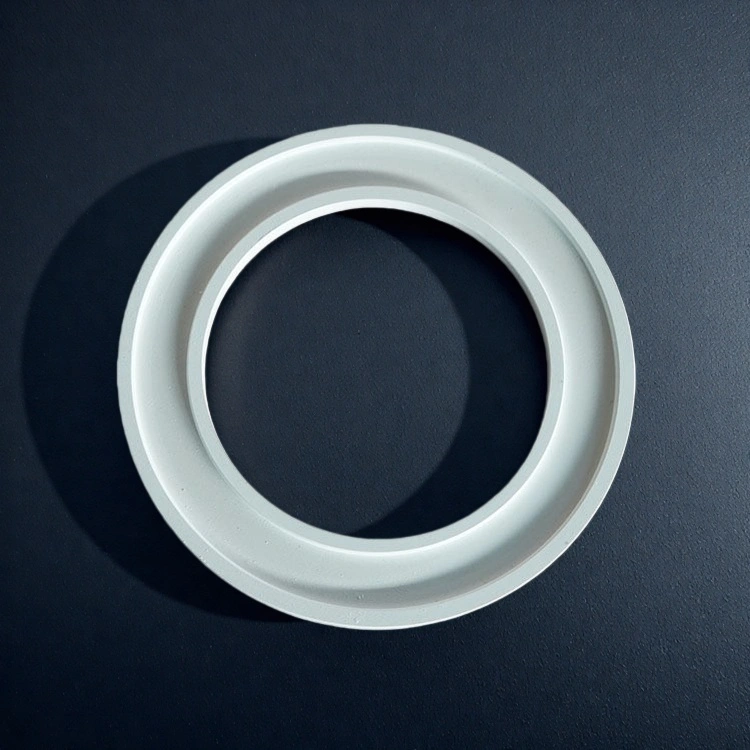

The boron nitride ring (BN ring) is a precision-engineered ceramic component crafted from hexagonal boron nitride (h-BN) — a material valued for its exceptional thermal endurance, electrical insulation, and clean, non-wetting interaction with molten metals.

Boron Nitride Ring Benefits

- Non-wetting to molten aluminum and many alloys, reducing build-up on ring surfaces and cleaning time.

- Low thermal conductivity helps maintain thermal gradients and minimize heat loss across joints.

- Stable electrical insulation at elevated temperature for fixtures near power feeds or heating elements.

- Precise machinability enables tight OD/ID concentricity and repeatable fit in housings.

- Surface options (raw, polished, micro-finished) support sealing or sliding interfaces.

Boron Nitride (BN) Rings Properties

|

Property |

Unit |

Pyrolytic Boron Nitride |

Hot Pressed Boron Nitride |

|

Purity |

|

99.99% |

99.50% |

|

Density |

g/cm3 |

2.15-2.19 |

1.96-2 |

|

Hardness |

HV0.5 |

651 |

62 |

|

Volume resistivity |

Ohm*cm |

2*1014 |

1.2*1014 |

|

Dielectric strength |

kV/mm |

55 |

76 |

|

Maximum working temperature |

℃ |

1000 (air), 2300 (vacuum) |

900 (air), 1850 (vacuum) |

|

Bending strength |

MPa |

173 (A direction) |

310 |

|

Thermal conductivity |

W/m*K |

60 (A direction) |

55 |

|

Tensile strength |

MPa |

112 (A direction) |

110 |

|

Thermal expansion coefficient |

/℃ |

6*10-7 |

1.8*10-6 |

|

Compressive strength |

MPa |

154 (A direction) |

120 |

Boron Nitride Ring Specifications

|

Item No. |

Diameter (mm) |

Thickness (mm) |

|

AT-BNC-H1001 |

Customize |

Boron Nitride Ring Packaging

- Each ring is individually packed in anti-static foam and sealed for protection.

Boron Nitride (BN) Ring Usage Instructions

Proper handling and operation of boron nitride rings (BN rings) ensure maximum service life, stable performance, and reliable alignment across thermal or vacuum processes. Follow the guidelines below to reduce wear, chipping, and contamination during installation and operation.

-

Installation

1. Inspect components carefully

Verify OD/ID dimensions, thickness, and tolerance accuracy against the drawing. Check for chips, cracks, or contamination on both faces before installation.

2. Confirm concentricity and markings

Ensure that the marked side or flow direction aligns with the intended assembly orientation to maintain system balance.

3. Prepare the housing or seat

Clean the groove or fixture pocket to remove metal debris or burrs. Avoid point loads or uneven pressure across thin ring sections.

4. Use controlled torque or clamping pressure

Apply fastening torque gradually and evenly to avoid localized stress. For polished faces, confirm full surface contact using feeler or blue-fit inspection.

5. Temperature alignment before seating

For large assemblies, preheat both the ring and housing to within ±20 °C to minimize thermal stress during startup.

-

Use

1. Operate within rated conditions

Follow the specified temperature (up to 1800 °C in vacuum/inert gas) and avoid prolonged exposure to air at high heat, as oxidation may reduce strength.

2. Avoid thermal shock

Maintain heating and cooling ramp rates below 5 °C/sec for thick sections and below 3 °C/sec for thin-wall rings to prevent microcracking.

3. Check alloy compatibility

For metal contact applications (e.g., molten Al, Mg, Cu), verify non-wetting performance; a light BN coating may further enhance separation.

4. Control the environmental atmosphere

Use in argon or nitrogen environments when possible; avoid water vapor or oxygen contamination that could alter the surface chemistry.

5. Monitor wear periodically

Inspect rings after every 10–20 cycles to track dimensional drift or discoloration, which may indicate local overheating.

-

Storage

1. Keep in original protective pouch

Store the BN ring inside its sealed clean pouch and foam cavity to prevent edge chipping or dust accumulation.

2. Control storage environment

Maintain ambient humidity below 60%, avoid prolonged exposure to direct sunlight, and keep away from corrosive vapors.

3. Segregate by lot and size

Maintain lot identification and dimensional labels for traceability and quick pairing with matched components.

4. Avoid stacking

Do not stack bare rings directly; always separate them with foam or clean interleaf paper to prevent face abrasion.

-

Cleaning

1. Cool down before handling

Always allow the ring to reach room temperature naturally before cleaning; thermal shock at this stage can cause invisible microcracks.

2. Use non-abrasive tools

For build-up removal, use soft nylon brushes, lint-free wipes, or compressed dry air. Avoid grinding or sanding on sealing or polished faces.

3. Surface maintenance

For polished BN rings, use isopropyl alcohol or a neutral solvent for surface cleaning. Do not use water-based cleaning that may trap moisture before reheating.

4. Inspection after cleaning

Check for discoloration, erosion, or flaking; replace rings if structural degradation or dimensional loss exceeds tolerance limits.