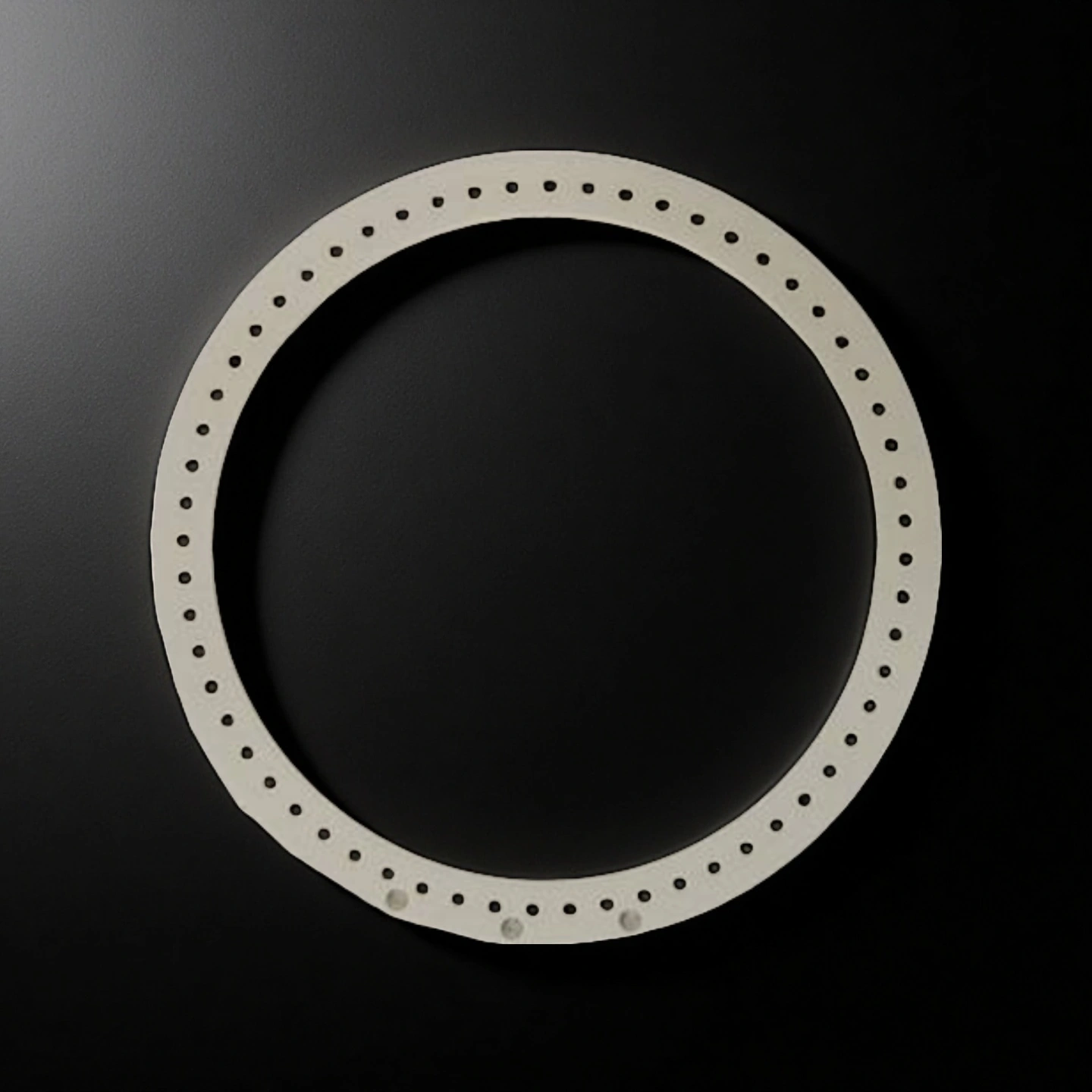

PBN rings are precision-engineered ceramic components used in high-temperature and high-vacuum applications. Their unique combination of thermal, electrical, and chemical properties makes them suitable for demanding environments such as GaN/SiC crystal growth, MOCVD reactors, and vacuum evaporation chambers.

PBN Ring Benefits

- High Purity: Manufactured from ≥99.99% BN to ensure minimal contamination in sensitive environments.

- Thermal Stability: Operates reliably up to 1800°C in vacuum without deformation or degradation.

- Electrical Insulation: Dielectric strength >10⁶ Ω·cm, suitable for high-voltage applications.

- Machinability: Precision CNC-machined to meet tight tolerances for integration into complex assemblies.

- Chemical Inertness: Resistant to most acids and alkalis, ensuring long-term stability in reactive environments.

Pyrolytic Boron Nitride Ring Specifications

Packing

- Each ring is individually packed in anti-static foam and sealed for protection.

Applications for PBN Ring

- Scenario 1: Crystal Growth Furnaces

In GaN or SiC crystal growth systems, PBN rings serve as thermal insulation and structural support components. Their high purity prevents contamination of the growing crystal, while their thermal stability ensures dimensional integrity under extreme temperatures.

- Scenario 2: MOCVD Equipment

PBN rings are used in the hot zone of MOCVD reactors to maintain uniform temperature distribution and electrical insulation. Their machinability allows integration into complex reactor geometries.

- Scenario 3: Vacuum Evaporation Sources

In high-vacuum evaporation systems, PBN rings are used to support crucibles and isolate heating elements. Their non-wetting surface and chemical inertness prevent material buildup and contamination.

PBN Ring Usage Instructions

- Installation: Handle with clean gloves to avoid contamination. Align with mating components using precision tools.

- Cleaning: Use isopropyl alcohol or deionized water. Avoid ultrasonic cleaning to prevent microcracks.

- Storage: Store in a dry, dust-free environment. Avoid direct sunlight and mechanical stress.

- Maintenance: Inspect for cracks or deformation after each use. Replace if structural integrity is compromised.

Common Mistakes to Avoid:

- Over-tightening during installation may cause cracking.

- Exposure to open flames or air above 1000°C may cause degradation of the material.

- Using incompatible chemicals (e.g., fluorine compounds) may reduce lifespan.