High Purity Boron Nitride Plate is a hot-pressed hexagonal boron nitride (h-BN) ceramic plate used as a machinable, electrically insulating, and non-wetting interface in high-temperature and vacuum systems. It is typically fabricated by hot-pressing h-BN powders (often with ceramic binders) into dense plates that can be CNC-machined into holes, slots, countersinks, and complex outlines with tight tolerances.

High Purity Boron Nitride Sheet & Plate Benefits

-

Stable at very high temperatures

High-purity BN plate maintains structure and insulation in vacuum or inert atmospheres up to around 2000 °C, where many alumina components already reach their limits.

-

Consistent flatness and tight thickness tolerance

Hot-pressed BN plates can be ground to tight thickness and flatness tolerances, enabling precise stacking in hot zones and uniform temperature fields.

-

High thermal conductivity with electrical insulation

With thermal conductivity typically in the 30–60 W/m·K range and volume resistivity above 10¹² Ω·cm, a high-purity boron nitride plate can conduct heat while electrically isolating components.

-

Non-wetting to many molten metals and glass

High-purity BN plate resists wetting and chemical attack from molten aluminium, zinc, and many glasses, helping reduce sticking and easing demoulding and cleaning.

-

Machinable to complex plate geometries

Compared with many dense ceramics, hot-pressed BN can be machined into slots, pockets, countersinks and stepped plates with detailed profiles, reducing the need for multi-part assemblies.

High Purity Boron Nitride Plate Properties

|

Property |

Unit |

Pyrolytic Boron Nitride |

Hot Pressed Boron Nitride |

|

Purity |

|

99.99% |

99.50% |

|

Density |

g/cm3 |

2.15-2.19 |

1.96-2 |

|

Hardness |

HV0.5 |

651 |

62 |

|

Volume resistivity |

Ohm*cm |

2*1014 |

1.2*1014 |

|

Dielectric strength |

kV/mm |

55 |

76 |

|

Maximum working temperature |

℃ |

1000 (air), 2300 (vacuum) |

900 (air), 1850 (vacuum) |

|

Bending strength |

MPa |

173 (A direction) |

310 |

|

Thermal conductivity |

W/m*K |

60 (A direction) |

55 |

|

Tensile strength |

MPa |

112 (A direction) |

110 |

|

Thermal expansion coefficient |

/℃ |

6*10-7 |

1.8*10-6 |

|

Compressive strength |

MPa |

154 (A direction) |

120 |

High Purity Boron Nitride Sheet Specifications

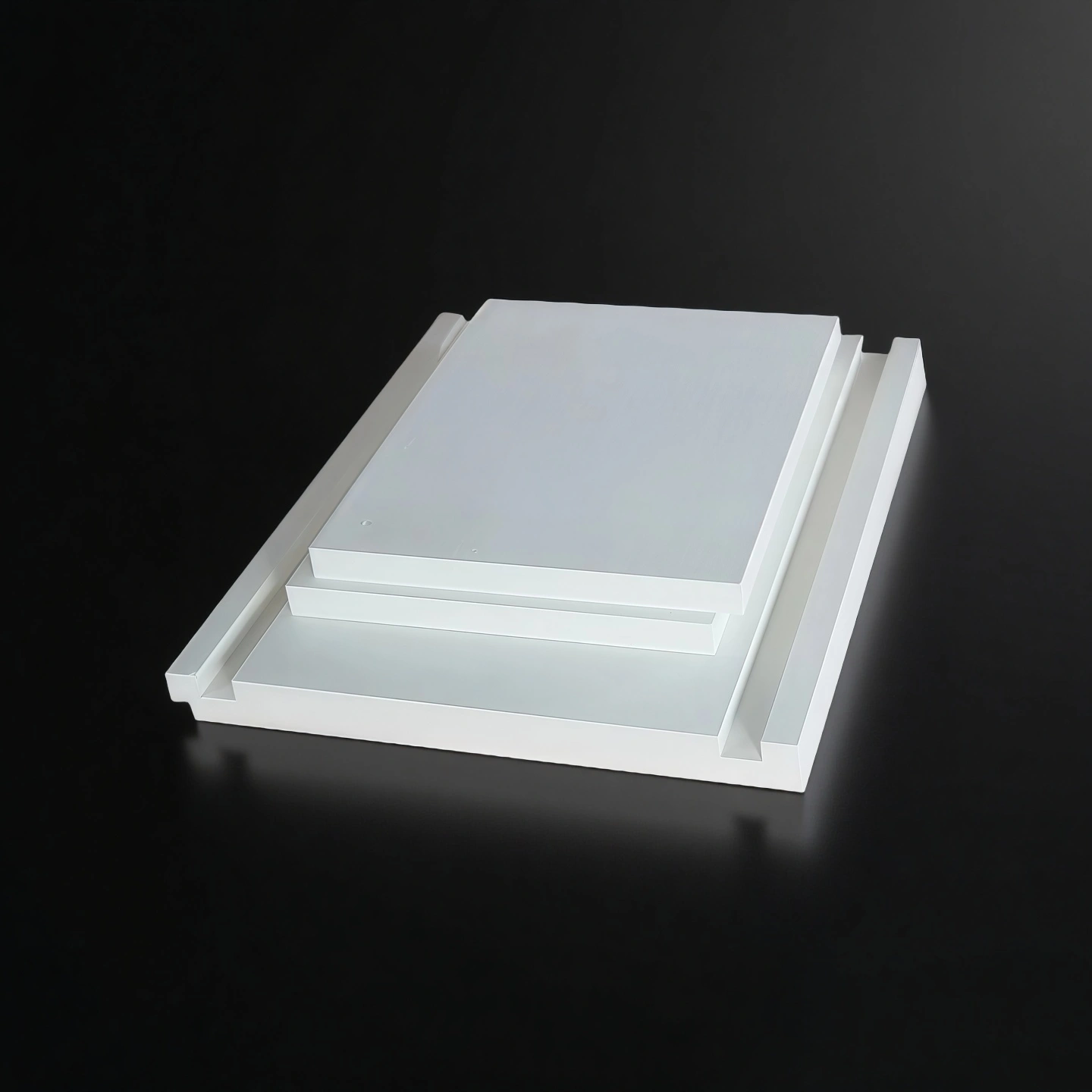

Type 1: Square High Purity Boron Nitride Plate

Type 2: Round High Purity Boron Nitride Plate

High Purity Boron Nitride Plate Packaging

- Each sheet is individually packed in anti-static foam and sealed for protection.

High Purity Boron Nitride (BN) Plates Applications

High Purity Boron Nitride Plates serve as structural and functional components across high-temperature, vacuum, and non-wetting environments where electrical isolation, dimensional precision, and chemical inertness are essential. Their combination of machinability, dielectric strength, and low thermal expansion makes them suitable for both custom-engineered assemblies and standard replacement parts in industrial systems.

-

Vacuum Brazing & Heat Treatment Equipment

✅Key Advantages

1. Dimensional stability under thermal cycling: Low CTE (≈1.5–2.5×10⁻⁶ /K) minimizes deformation during multiple heat cycles.

2. Electrical insulation for heater assemblies: Dielectric strength in the 2–3 kV/mm range supports use as isolation backers and standoffs.

3. Machinable integration: Holes, slots, and alignment pockets enable fixture simplification and improved repeatability.

✅ Problem Solved

In vacuum brazing operations, traditional alumina spacers often crack under thermal mismatch. Replacing them with BN plates allowed a European heat-treat service to reduce fixture failure rates by over 25%, ensuring stable component alignment during continuous brazing cycles up to 950 °C.

-

PVD/CVD Coating Systems & Thin-Film Equipment

✅Key Advantages

1. Non-wetting, low-particle surfaces: BN resists coating buildup and simplifies post-process cleaning.

2. Controlled flatness for chamber sealing: Ground-face BN plates maintain uniform contact, reducing vacuum leaks.

3. Clean machining compatibility: Plates can include precision holes and recesses for thermocouple or clamp fittings.

✅ Problem Solved

A Japanese coating system integrator standardized fine-ground BN isolation plates in their TiN and DLC deposition chambers. The change eliminated metallic contamination issues and shortened chamber maintenance downtime by 15–20 %, improving uptime across multiple coating lines.

-

Molten Metal, Glass, and Composite Processing

✅Key Advantages

1. Non-wetting to molten aluminum and alloys: Prevents adhesion, allowing clean release and reduced contamination.

2. Thermal-shock resistance: Withstands rapid temperature gradients during casting or forming cycles.

3. Ease of custom shaping: Machinability enables contoured liners, troughs, or mold interfaces.

✅ Problem Solved

An aluminum extrusion die manufacturer replaced graphite liners with BN ceramic plates for contact surfaces. After three months, die cleaning frequency dropped from every 8 hours to 24 hours, and surface finish consistency improved by 12 %, lowering scrap rates and energy consumption.

High Purity BN Plates Usage Instructions

Proper handling and installation of high-purity BN plates are essential to ensure their long-term dimensional stability, insulation performance, and clean operation in high-temperature or vacuum environments. Follow the guidelines below for reliable use and reduced maintenance downtime.

-

Installation

1. Surface preparation: Ensure the mounting base is flat, clean, and free from debris before positioning the high purity BN plate. Even small particulates may cause local stress or uneven clamping.

2. Orientation marks: Align according to the engraved or ink-marked reference side (when provided) to match drawing orientation and surface finish requirements.

3. Thermal compliance: Use compliant washers, mica spacers, or ceramic isolation bushings in assemblies where differential thermal expansion occurs between metal components and high purity BN plates.

4. Clamping method: Avoid point-loading or over-tightening bolts. Apply uniform pressure using flat clamps or distributed fasteners to preserve flatness and minimize bowing.

5. Joint design: Where plates contact other materials (e.g., graphite, alumina, or stainless steel), incorporate intermediate insulating pads to reduce mechanical stress and prevent fracture at thermal gradients.

-

Operation

1. Temperature range:

a. In air, maintain continuous use at ≤ 900–1000 °C to prevent surface oxidation.

b. In vacuum or inert atmospheres (argon, nitrogen), service temperatures can reach ~1800–2000 °C depending on grade.

2. Heating rate: Limit ramp-up to ≤ 5 °C/s to minimize thermal shock; follow process soak times recommended for even temperature distribution.

3. Flame contact: Avoid direct flame impingement or concentrated IR radiation on thin sections (< 5 mm).

4. Clean contact surfaces: For non-wetting or vacuum applications, ensure all faces remain free from oils, fingerprints, or oxide residues to maintain insulation resistance and cleanliness.

5. Process compatibility: BN plates should not be exposed to strong oxidizers, fluorine-bearing gases, or molten alkali metals, which can degrade the ceramic.

-

Storage

1. Dry environment: Store plates in sealed, dry pouches to prevent moisture adsorption, which can temporarily lower electrical resistivity.

2. Mechanical protection: Place plates horizontally on foam or soft pads; avoid edge contact with hard surfaces.

3. Stacking precautions: Do not stack more than three plates without separators; avoid heavy items over thin (< 5 mm) plates to prevent warping.

4. Temperature & humidity: Recommended storage conditions: 15–35 °C, < 60 % relative humidity.

-

Cleaning

1. Routine cleaning: Wipe gently using lint-free cloths or cleanroom wipes. Use dry compressed air or nitrogen blow-off to remove particulates before assembly.

2. Deep cleaning: For contamination or metal deposition, use a soft brush and ethanol/acetone rinse; ensure complete drying before reinstallation.

3. Surface maintenance: Avoid aggressive abrasive papers or blasting; if surface reconditioning is required, perform fine grinding or lapping as per the specified Ra or flatness tolerance on the drawing.

4. Inspection: After each maintenance cycle, check edges and corners for chips or microcracks. Replace or re-machine damaged parts to maintain consistent dielectric performance.

-

Common Misuse & Remedies

1. Over-tight clamping causing bowing or warping

Symptom: Plate deformation or uneven heating during operation.

Remedy: Reduce torque, use wider washers, distribute clamping evenly, and re-verify flatness per GD&T spec.

Oxidation marks after prolonged exposure above 1000 °C in air

2. Symptom: Surface discoloration or localized powdering.

Remedy: Operate under inert/vacuum atmosphere or reduce temperature setpoint; select high-purity BN grade with improved oxidation resistance.

Edge chipping during maintenance or handling

3. Symptom: Local cracks, small chips along corners or mounting holes.

Remedy: Add edge radius (R 0.5–1.0 mm) or chamfer to design; use foam carriers or lined trays for transport and inspection stages.

Surface contamination is causing coating defects

4. Symptom: Poor adhesion or arcing in PVD/CVD chambers.

Remedy: Handle with clean gloves; re-clean surface with solvent wipe; apply protective film until final installation.

Thermal mismatch cracks in mixed-material assemblies

5. Symptom: Radial or corner fractures near fasteners.

Remedy: Use flexible interlayers or isolation pads between the BN plate and metallic supports; adjust preheat sequence.