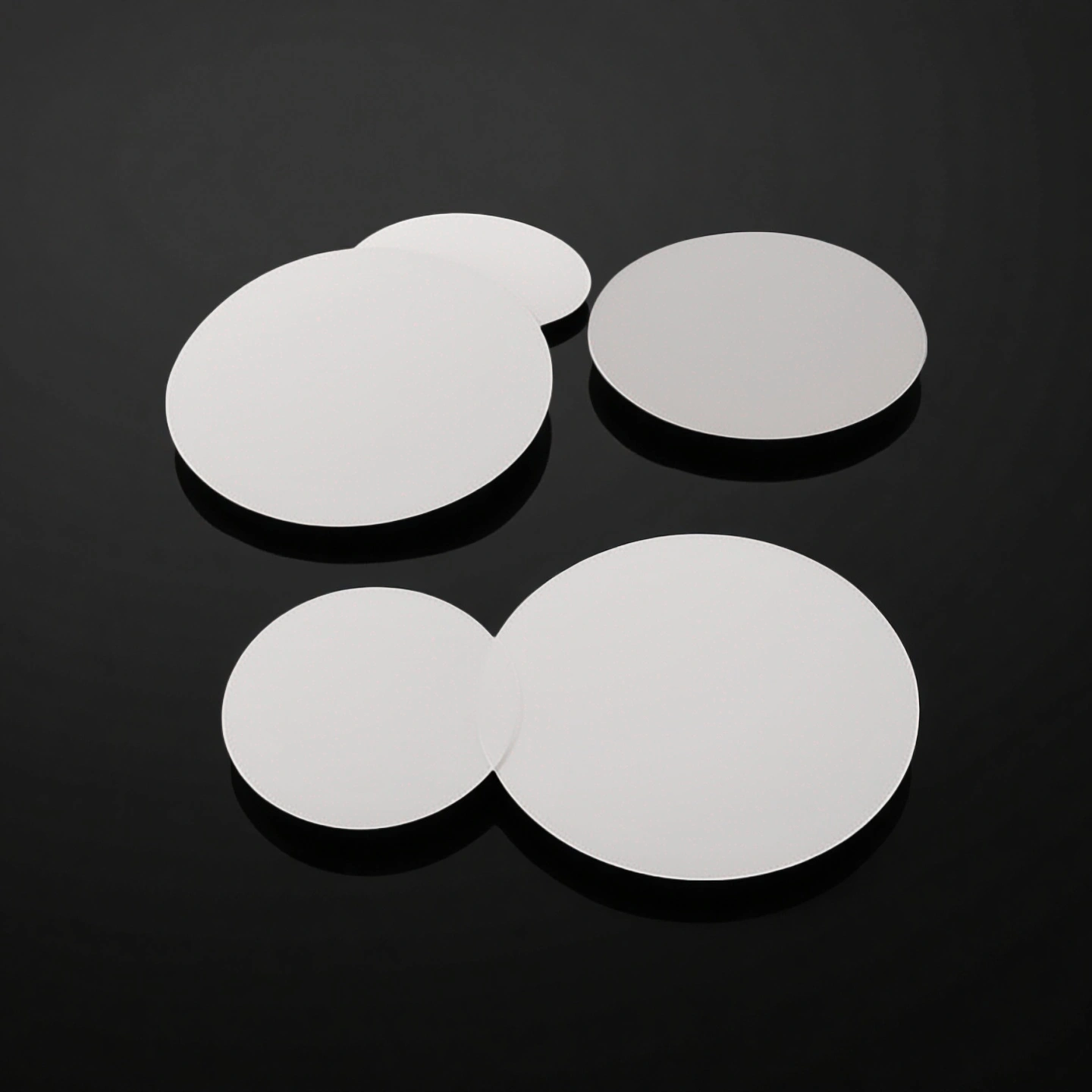

Pyrolytic boron nitride plate (PBN plate) is a high-purity boron nitride sheet produced by chemical vapor deposition, forming a dense, binder-free, layered microstructure with anisotropic thermal conductivity, low outgassing, and strong stability in vacuum or inert atmospheres up to around 2000 °C. It is commonly used as an insulation board, support plate, or structural element inside high-temperature vacuum, evaporation, and semiconductor-related equipment where material cleanliness and thermal control are critical.

Pyrolytic Boron Nitride Sheet Benefits

-

Anisotropic Thermal Management

In-plane thermal conductivity is significantly higher than through-thickness, enabling efficient lateral heat spreading while keeping the backside thermally insulated. -

High Purity and Low Outgassing

CVD-deposited pyrolytic boron nitride contains no binders or glassy phases, which helps maintain low contamination and stable vacuum levels in high-vacuum and UHV equipment. -

High-Temperature Stability in Vacuum

PBN plates maintain mechanical integrity and electrical insulation at temperatures up to around 2000 °C in vacuum or inert gas, which is suitable for many high-temperature heater assemblies and shields. -

Electrical Insulation with Good Dielectric Properties

Pyrolytic boron nitride combines high volume resistivity with low dielectric loss, allowing PBN plates to function as electrical insulators close to hot zones and power elements. -

Predictable Machining and Surface Quality

PBN plates can be machined to tight dimensional tolerances and controlled surface roughness, allowing close fit to graphite, metal or ceramic assemblies in heater modules and fixtures.

Pyrolytic Boron Nitride Sheet Properties

| Property | Unit | Pyrolytic Boron Nitride | Hot Pressed Boron Nitride |

| Purity | 99.99% | 99.50% | |

| Density | g/cm3 | 2.15-2.19 | 1.96-2 |

| Hardness | HV0.5 | 651 | 62 |

| Volume resistivity | Ohm*cm | 2*1014 | 1.2*1014 |

| Dielectric strength | kV/mm | 55 | 76 |

| Maximum working temperature | ℃ | 1000 (air), 2300 (vacuum) | 900 (air), 1850 (vacuum) |

| Bending strength | MPa | 173 (A direction) | 310 |

| Thermal conductivity | W/m*K | 60 (A direction) | 55 |

| Tensile strength | MPa | 112 (A direction) | 110 |

| Thermal expansion coefficient | /℃ | 6*10-7 | 1.8*10-6 |

| Compressive strength | MPa | 154 (A direction) | 120 |

Pyrolytic Boron Nitride Sheet Function

- Electrical Insulation — Maintains dielectric strength ≥ 10 kV/mm under vacuum or inert gas, ensuring stable isolation of heating elements and conductive components.

- Thermal Barrier — Low thermal expansion (2–4 × 10⁻⁶ /K) and high temperature tolerance (≈ 1000 °C) reduce stress and deformation during repeated heating cycles.

- Non-Wetting Separation Layer — Chemically inert to molten aluminum, magnesium, and zinc alloys, preventing adhesion, metal buildup, and contamination of furnace parts.

PBN Sheet Specifications

| PBN Sheet | ||

| Item No. | Diameter(mm) | Height (mm) |

| AT-PBN-BC001 | Customize | |

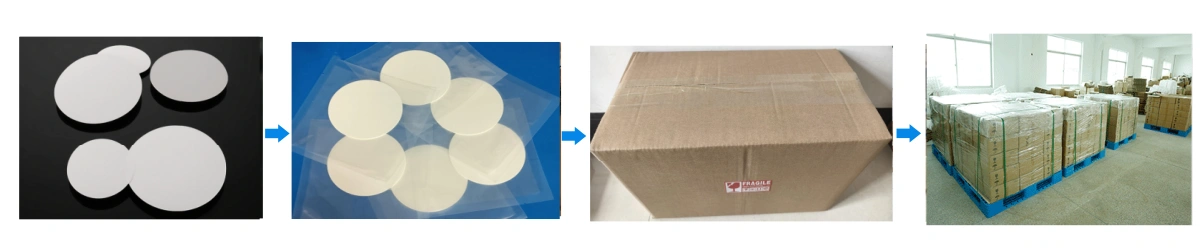

Pyrolytic Boron Nitride Sheet Packaging

- Each sheet is sealed in anti-static polyethene bags

- Foam-padded inner box to prevent edge chipping