Boron nitride tube (BN tube) is a precision-engineered ceramic component made from hexagonal boron nitride (h-BN) or pyrolytic boron nitride (PBN). It combines high thermal conductivity, excellent electrical insulation, and chemical inertness—a rare combination that allows it to perform reliably under high temperature, high vacuum, and corrosive environments.

Boron Nitride Tubes Benefits

- Metal Non-wetting Behaviour — Reduces adhesion and contamination in molten aluminum/copper handling.

- Low CTE + Good Thermal Conductivity — Minimizes stress and temperature lag in hot-zone sleeves.

- Clean, Machinable Surfaces — Precise ID/OD control for coaxial alignment and leak-tight assemblies.

- High Electrical Insulation — Maintains isolation near heaters and power feeds at elevated temperatures.

- PBN Option for Ultra-Clean Tools — CVD microstructure for evaporation and MBE source lines.

BN Tube Properties

| Property | Unit | Pyrolytic Boron Nitride | Hot Pressed Boron Nitride |

| Purity | 99.99% | 99.50% | |

| Density | g/cm3 | 2.15-2.19 | 1.96-2 |

| Hardness | HV0.5 | 651 | 62 |

| Volume resistivity | Ohm*cm | 2*1014 | 1.2*1014 |

| Dielectric strength | kV/mm | 55 | 76 |

| Maximum working temperature | ℃ | 1000 (air), 2300 (vacuum) | 900 (air), 1850 (vacuum) |

| Bending strength | MPa | 173 (A direction) | 310 |

| Thermal conductivity | W/m*K | 60 (A direction) | 55 |

| Tensile strength | MPa | 112 (A direction) | 110 |

| Thermal expansion coefficient | /℃ | 6*10-7 | 1.8*10-6 |

| Compressive strength | MPa | 154 (A direction) | 120 |

Boron Nitride Tube Specifications

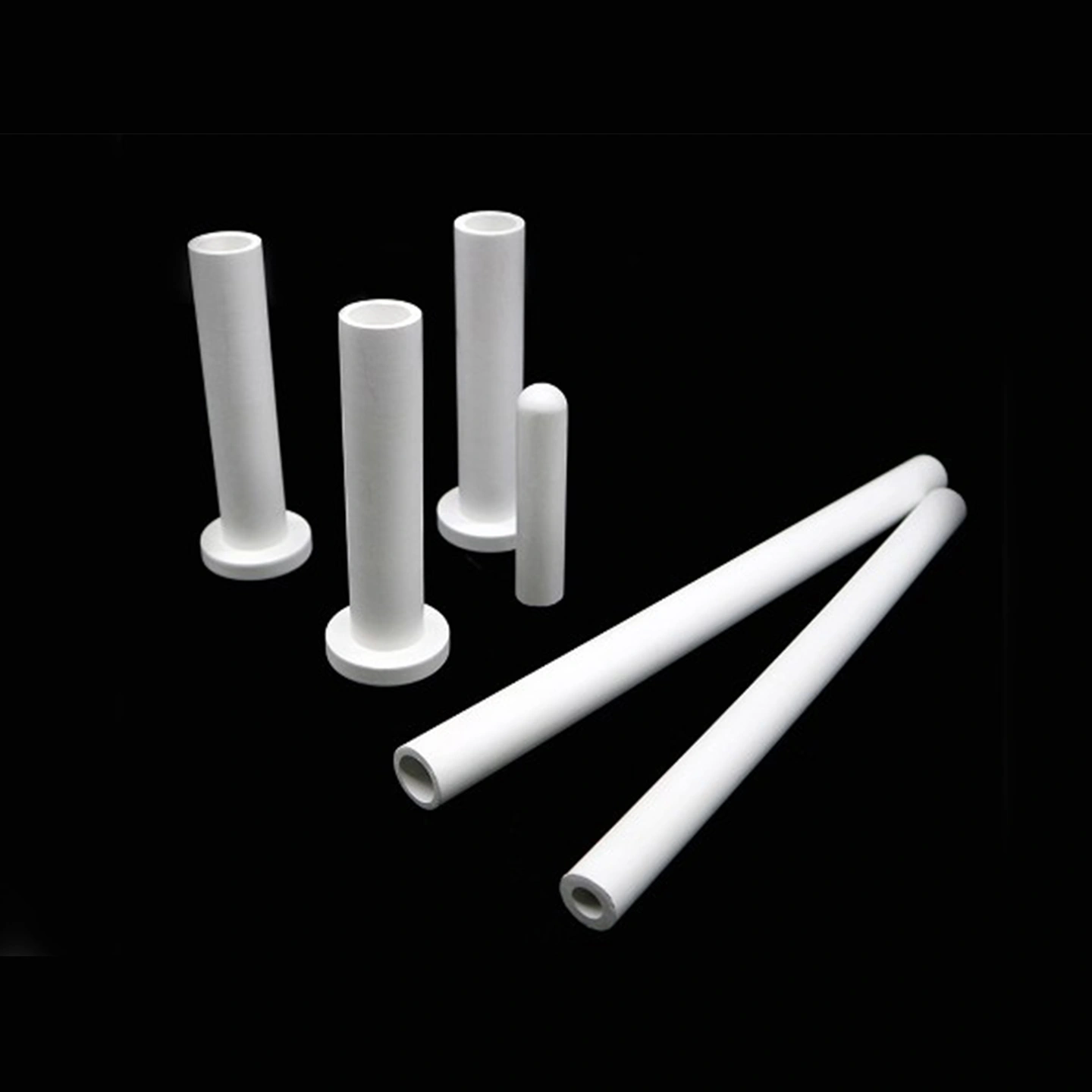

Type 1: BN Ceramic One End Closed Tube

| BN Ceramic One End Closed Tube | |||

| Item No. | Outer Diameter(mm) | Inner Diameter(mm) | Length(mm) |

| AT-BN-G1001 | 10 | 8.4 | 35 |

| AT-BN-G1002 | 10 | 6 | ≤200 |

| AT-BN-G1003 | 15 | 10 | |

| AT-BN-G1004 | 20 | 14 | |

| AT-BN-G1005 | 25 | 18 | |

| AT-BN-G1006 | 30 | 20 | |

Type 2: Boron Nitride Tube with Both End Open

| Boron Nitride Tube with Both End Open | |||

| Item No. | Outer Diameter(mm) | Inner Diameter(mm) | Length(mm) |

| AT-BN-G2001 | 6.5 | 1.7 | 50 |

| AT-BN-G2002 | 8 | 5 | 50 |

| AT-BN-G2003 | 4 | 2.3 | 7 |

| AT-BN-G2004 | 4 | 2.3 | 8 |

| AT-BN-G2005 | 5 | 3 | 10 |

| AT-BN-G2006 | 8 | 5 | 100 |

| AT-BN-G2007 | 8 | 6 | 100 |

| AT-BN-G2008 | 10 | 5 | 80 |

| AT-BN-G2009 | 10 | 5 | 100 |

| AT-BN-G2010 | 12 | 8 | 100 |

| AT-BN-G2011 | 15 | 10 | 100 |

| AT-BN-G2012 | 15 | 10 | 150 |

| AT-BN-G2013 | 20 | 10 | 100 |

| AT-BN-G2014 | 20 | 10 | 150 |

| AT-BN-G2015 | 20 | 10 | 200 |

| AT-BN-G2016 | 20 | 15 | 100 |

| AT-BN-G2017 | 20 | 15 | 200 |

| AT-BN-G2018 | 40 | 32 | 30 |

Type 3: Boron Nitride Tube with Two Bores

| Boron Nitride Tube with Two Bores | |||

| Item No. | Outer Diameter(mm) | Inner Diameter(mm) | Length(mm) |

| AT-BN-G3001 | 3 | 0.7 | 25 |

| AT-BN-G3002 | 4 | 0.7 | 20 |

| AT-BN-G3003 | 4 | 1 | 20 |

| AT-BN-G3004 | 5 | 1 | 25 |

| AT-BN-G3005 | 6 | 1.5 | 30 |

Type 4: Boron Nitride Step Tube

| Boron Nitride Step Tube | |||

| Item No. | Outer Diameter(mm) | Inner Diameter(mm) | Length(mm) |

| AT-BN-G5001 | Customize | ≤300 | |

Boron Nitride Ceramic Tube Packaging

- Individually packed in anti-static foam boxes