Silicon nitride thermocouple protection tube is a closed-end Si₃N₄ sleeve used to protect the thermocouple sensor when measuring molten aluminum, zinc, or magnesium. Its dense, non-wetting ceramic structure resists corrosion, thermal shock, and metal infiltration, keeping temperature readings stable. Compared with graphite or alumina tubes, it offers longer service life and lower risk of melt contamination.

Silicon Nitride Thermocouple Protection Tube Benefits

-

Non-wetting to Molten Aluminum and Alloys

The Si₃N₄ surface exhibits <5° wetting angle with Al-Si melts, which prevents molten metal adhesion, oxide buildup, and slag bridging around the thermocouple tip. This minimizes temperature drift and eliminates metal infiltration that could short the hot junction or contaminate the melt. -

Closed-End Mechanical and Chemical Integrity

The integrally sintered or precision-machined tip provides uniform wall thickness and dense, gas-tight structure (open porosity <1%). This resists erosion from high-flow melt zones and prevents aluminum ingress into the sensor cavity—critical for accurate response at 680–750 °C operating ranges. -

Dimensional Stability and Batch Repeatability

OD/ID tolerance can be controlled within ±0.1 mm on request, and straightness deviation remains <0.5 mm per 1000 mm length. This ensures consistent sealing with thermocouple seats and maintains the same immersion depth across multiple furnaces, reducing recalibration and installation variability. -

Thermal-Shock and Cycling Resistance

Silicon nitride withstands >300 °C instantaneous temperature gradients and supports repeated insertion/removal cycles between ambient and molten metal temperatures without cracking. Thermal shock resistance is achieved through low CTE (~3 × 10⁻⁶ /K) and high fracture toughness (>6 MPa·m¹ᐟ²). -

System and Sensor Compatibility

The tube interfaces seamlessly with ISO-standard K-type or N-type thermocouple cartridges, metal/ceramic seats, compression fittings, and flange geometries used in LPDC/HPDC and holding furnaces. The optimized ID matches sensor diameters to maintain response time without increasing thermal lag.

Silicon Nitride Thermocouple Tube Properties

| Si3N4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

| Density (g/cm3) | 3.2 | 3.3 | 3.25 |

| Flexture strength (MPa) | 700 | 900 | 600~800 |

| Young Modulus (GPa) | 300 | 300 | 300~320 |

| Poisson's ratio | 0.25 | 0.28 | 0.25 |

| Compressive strength (MPa) | 2500 | 3000 | 2500 |

| Hardness (GPa) | 15 | 16 | 15 |

| Fracture toughness (MPa*m1/2) | 5~7 | 6~8 | 6~7 |

| Maximum working temperature (℃) | 1100 | 1300 | 1100 |

| Thermal conductivity (W/m*K) | 20 | 25 | 80~100 |

| Thermal expansion coefficient (/℃) | 3*10-6 | 3.1*10-6 | 3*10-6 |

| Thermal shock resistance (ΔT ℃) | 550 | 800 | / |

Si3N4 Thermocouple Protection Tube Specifications

| Si3N4 Thermocouple Protection Tube | |||

| Item No. | Outer Diameter (mm) | Inner Diameter (mm) | Length (mm) |

| AT-DHG-G1001 | 16 | 8 | 300-1200 |

| AT-DHG-G1002 | 22 | 12 | 300-1200 |

| AT-DHG-G1003 | 28 | 16 | 300-1200 |

| AT-DHG-G1004 | 30 | 18 | 300-1200 |

| AT-DHG-G1005 | 45 | 25 | 300-1200 |

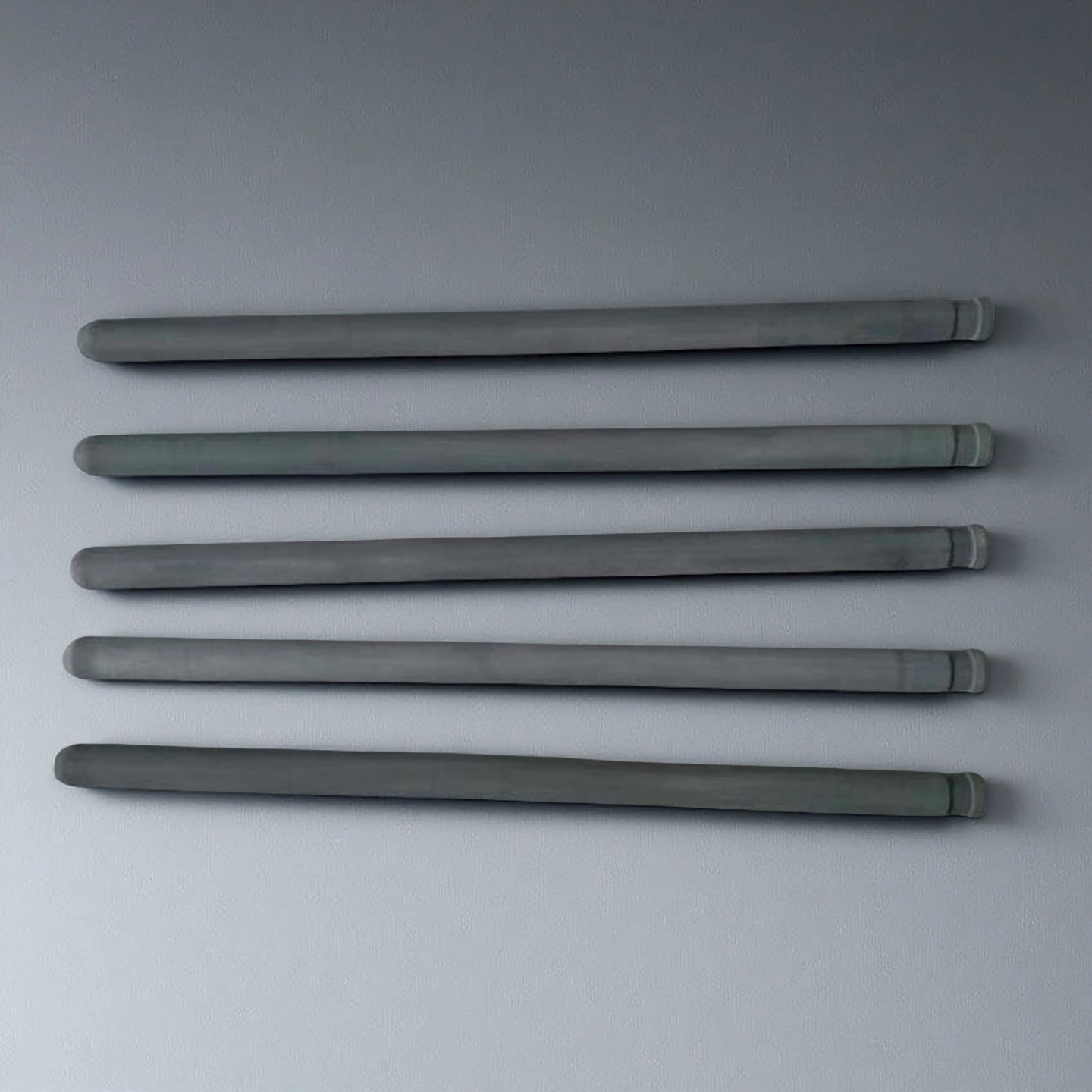

Silicon Nitride Thermocouple Tube Packaging

- Each tube is individually packed in foam-lined cartons

![]()