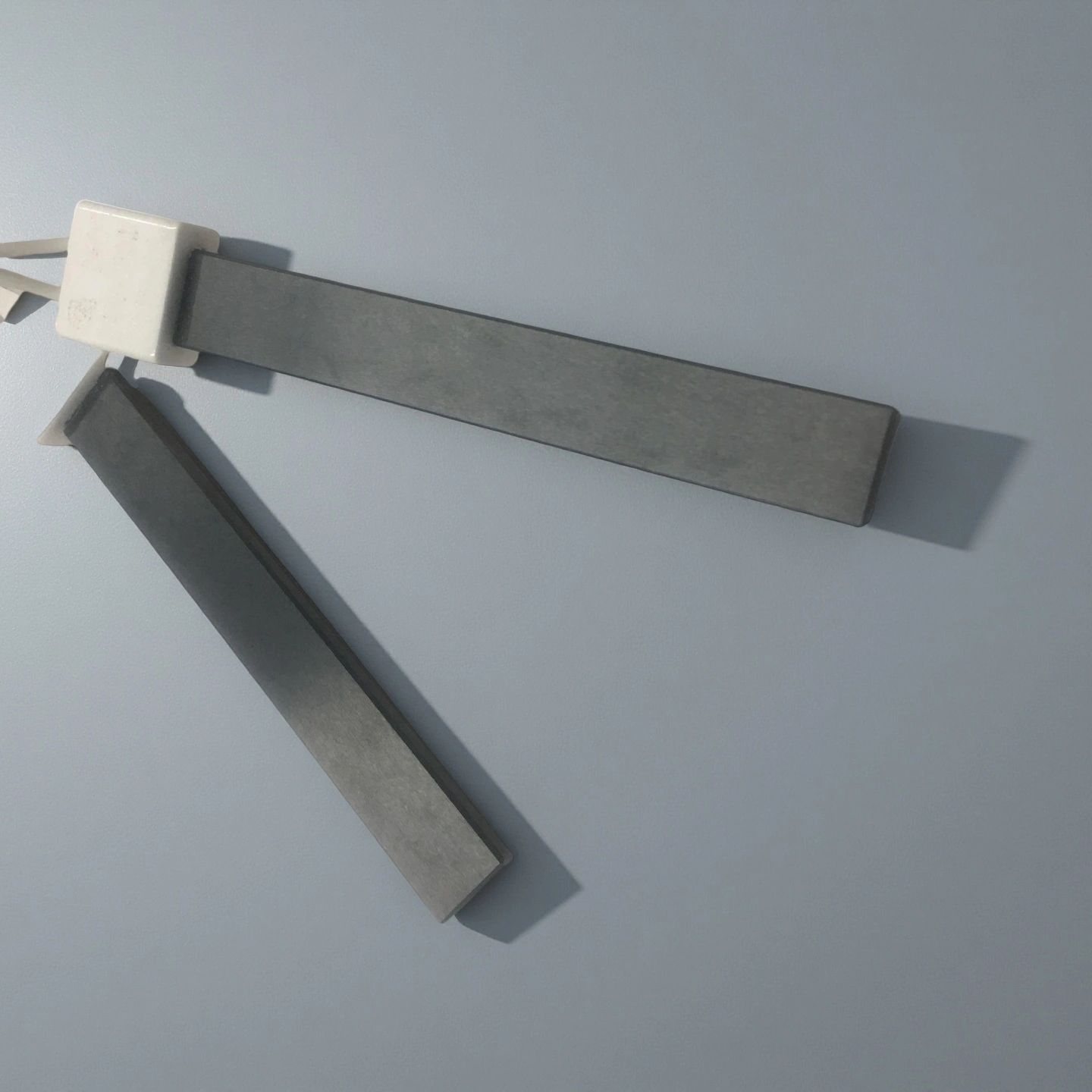

The silicon nitride ignitor is a Si₃N₄ ceramic hot surface element for automatic ignition of gas and solid fuels in boilers, pellet stoves, biomass burners and compact industrial furnaces, combining a slim rod geometry with rapid heating to ignition temperature in a controlled time window.

Silicon Nitride Ignitor Benefits

-

Controlled ignition time

The silicon nitride hot surface ignitor is designed to reach ignition temperature within a predictable 60–90 s window, matching combustion controller timing for boiler and burner start-up. -

Extended service life vs. metal elements

The Si₃N₄ ceramic body and hot surface design support a high number of on–off cycles, which helps many heating systems align ignitor replacement with planned service intervals rather than reacting to early failures. -

Compact geometry for tight combustion heads

The slim rod shape and focused hot zone allow the silicon nitride ignitor to fit in modern compact burner heads, condensing boilers and pellet burners with limited space around the flame port. -

Stable performance at high surface temperature

The ceramic element operates in the high-temperature range needed to ignite gas and solid fuel streams while maintaining a consistent hot zone profile over repeated heating cycles. -

Designed for intermittent ignition systems

The silicon nitride ignitor is intended to work with intermittent ignition control, being energized only during start-up and re-ignition sequences, which supports energy-saving burner designs without permanent pilot flames.

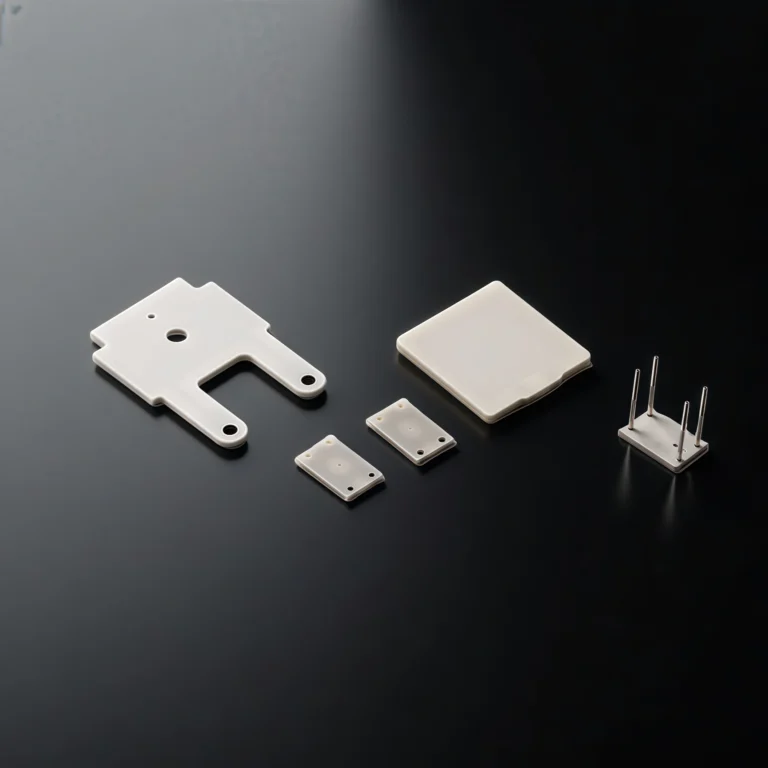

Silicon Nitride Ceramic Ignitors

| Si3N4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

| Density (g/cm3) | 3.2 | 3.3 | 3.25 |

| Flexture strength (MPa) | 700 | 900 | 600~800 |

| Young Modulus (GPa) | 300 | 300 | 300~320 |

| Poisson's ratio | 0.25 | 0.28 | 0.25 |

| Compressive strength (MPa) | 2500 | 3000 | 2500 |

| Hardness (GPa) | 15 | 16 | 15 |

| Fracture toughness (MPa*m1/2) | 5~7 | 6~8 | 6~7 |

| Maximum working temperature (℃) | 1100 | 1300 | 1100 |

| Thermal conductivity (W/m*K) | 20 | 25 | 80~100 |

| Thermal expansion coefficient (/℃) | 3*10-6 | 3.1*10-6 | 3*10-6 |

| Thermal shock resistance (ΔT ℃) | 550 | 800 | / |

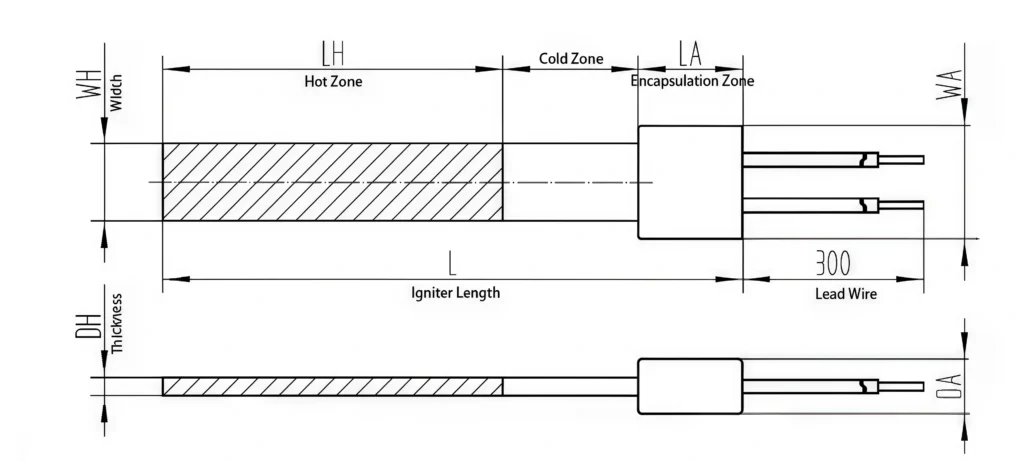

Si3N4 Ignitor Specifications

| Silicon Nitride Ignitor | |||||||||

| Item No. | Ignitor Size(mm) | Heating Area Size | Package Area Size | Value | |||||

| L | LH | WH | LA | WA | DA | DH | voltage (V) | power (W) | |

| AT-DHG-JR138 | 138 | 94 | 17 | 23 | 25 | 12 | 4 | AC220-240 | 700/450 |

| AT-DHG-JR128 | 128 | 84 | 17 | 23 | 25 | 12 | 4 | AC220-240 | 600/400 |

| AT-DHG-JR95 | 95 | 58 | 17 | 23 | 25 | 12 | 4 | AC220-240 | 400 |

| AT-DHG-JR52 | 52 | 15 | 17 | 23 | 25 | 12 | 4 | AC110 | 100 |

| AT-DHG-JR135 | 135 | 98 | 23 | 23 | 31 | 12 | 4 | AC220-240 | 900/600 |

| AT-DHG-JR115 | 115 | 76 | 30 | 25 | 38 | 12 | 4 | AC220-240 | 900/600 |

Silicon Nitride Ignitor Packaging

- Each silicon nitride ignitor is placed in a shock-absorbing inner sleeve or tray to protect the ceramic element and lead wires during transport.

![]()