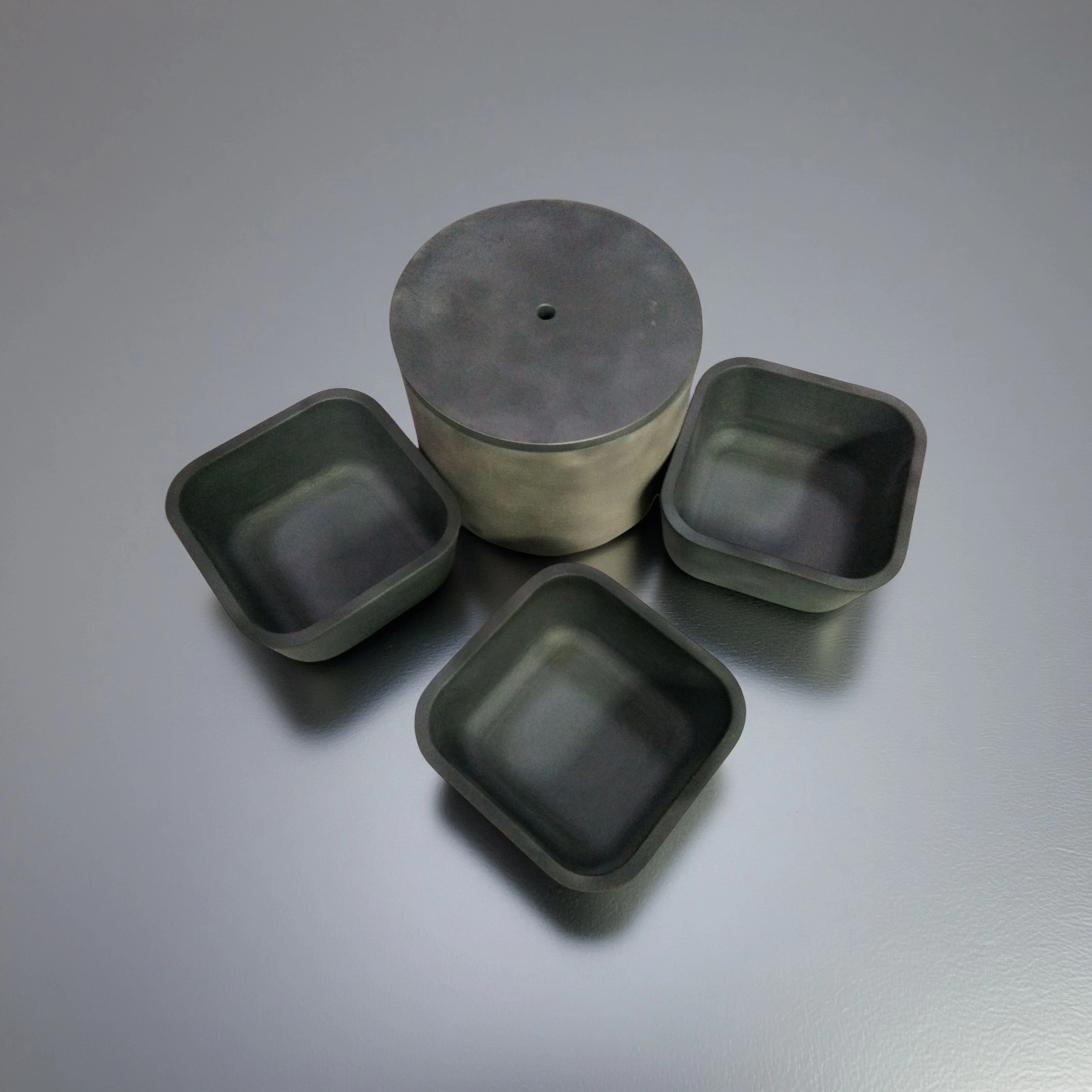

Silicon nitride crucible is a technical ceramic vessel developed for melting, holding or sampling aluminum, magnesium and zinc alloys where conventional graphite or alumina crucibles fail due to oxidation, short service life or alloy contamination. Unlike traditional crucibles, it combines low wettability to molten metals, resistance to thermal shock and stable geometry over repeated heating cycles, which makes it preferred in foundries, vacuum furnace systems and metal research labs.

Silicon Nitride Crucible Benefits

-

Low wettability to molten Al/Mg reduces buildup and cleaning time.

Silicon nitride forms a chemically stable surface that resists adhesion of aluminum and magnesium dross. This lowers metal loss, minimizes contamination and shortens manual cleaning intervals between casts. -

Dimensional accuracy (typically ±0.2 mm on ID/OD) improves furnace fit and automation.

Consistent geometry allows the crucible to sit securely in the furnace pocket or mechanical holder. It also prevents robotic misalignment and reduces downtime caused by improper seating or excessive movement. -

Low thermal expansion (2.8–3.2 × 10⁻⁶/K) and dense microstructure reduce cracking.

The material can withstand rapid heating and cooling if pre-heated correctly. This stabilizes cycle life in foundries or labs where temperature changes are frequent and helps prevent premature fracture. -

Polished inner surface (Ra ≤ 1.6 μm) supports clean metal flow and sampling.

A smoother inner wall reduces trapped oxides and prevents alloy residues from sticking to the crucible. This is particularly useful in alloy research, casting samples and molten metal transfer operations. -

Batch-to-batch uniformity simplifies OEM standardization and repeat orders.

Controlled sintering and machining processes keep each crucible consistent in density, wall thickness and roundness. Furnace manufacturers and high-volume users can reorder the same geometry without adjusting fixtures or tools.

Silicon Nitride Crucible Properties

| Si3N4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

| Density (g/cm3) | 3.2 | 3.3 | 3.25 |

| Flexture strength (MPa) | 700 | 900 | 600~800 |

| Young Modulus (GPa) | 300 | 300 | 300~320 |

| Poisson's ratio | 0.25 | 0.28 | 0.25 |

| Compressive strength (MPa) | 2500 | 3000 | 2500 |

| Hardness (GPa) | 15 | 16 | 15 |

| Fracture toughness (MPa*m1/2) | 5~7 | 6~8 | 6~7 |

| Maximum working temperature (℃) | 1100 | 1300 | 1100 |

| Thermal conductivity (W/m*K) | 20 | 25 | 80~100 |

| Thermal expansion coefficient (/℃) | 3*10-6 | 3.1*10-6 | 3*10-6 |

| Thermal shock resistance (ΔT ℃) | 550 | 800 | / |

Si3N4 Crucible Specifications

Type 1: Silicon Nitride Crucible Cylinder

![]()

| Silicon Nitride Crucible Cylinder | ||||

| Item No. | Outer Diameter(mm) | Inner Diameter(mm) | Height(mm) | Thickness(mm) |

| AT-DHG-GG001 | 61 | 50 | 65 | 5.5 |

| AT-DHG-GG002 | 58.0 | 50.0 | 70.0 | 4.0 |

| AT-DHG-GG003 | 58.0 | 52.0 | 90.0 | 3.0 |

| AT-DHG-GG004 | 72.0 | 65.0 | 95.0 | 3.5 |

| AT-DHG-GG005 | 81.5 | 70.0 | 90.0 | 5.5 |

| AT-DHG-GG006 | 81.0 | 72.0 | 100.0 | 4.5 |

| AT-DHG-GG007 | 85.0 | 75.0 | 105.0 | 5.0 |

| AT-DHG-GG008 | 87.0 | 75.0 | 108.0 | 6.0 |

| AT-DHG-GG009 | 87.0 | 78.0 | 112.0 | 4.5 |

| AT-DHG-GG010 | 88.0 | 80.0 | 115.0 | 4.0 |

| AT-DHG-GG011 | 93.0 | 85.0 | 125.0 | 4.0 |

| AT-DHG-GG012 | 99.0 | 90.0 | 125.0 | 4.5 |

| AT-DHG-GG013 | 104.0 | 95.0 | 130.0 | 4.5 |

| AT-DHG-GG014 | 110.0 | 100.0 | 135.0 | 5.0 |

| AT-DHG-GG015 | 131.0 | 120.0 | 150.0 | 5.5 |

| AT-DHG-GG016 | 136.0 | 125.0 | 165.0 | 5.5 |

| AT-DHG-GG017 | 172.0 | 150.0 | 190.0 | 6.0 |

Type 2: Silicon Nitride Crucible Arc-Shaped

![]()

| Silicon Nitride Crucible Arc-Shaped | ||||

| Item No. | Top Outer Diameter(mm) | Bottom Outer Diameter (mm) | Height(mm) | Thickness(mm) |

| AT-DHG-GG018 | 58 | 33 | 66 | 3 |

| AT-DHG-GG019 | 58 | 35 | 68 | 5 |

| AT-DHG-GG020 | 59 | 35 | 71 | 4 |

| AT-DHG-GG021 | 67 | 42 | 78 | 4.5 |

| AT-DHG-GG022 | 73 | 44 | 86 | 5 |

| AT-DHG-GG023 | 75 | 46 | 78 | 4.5 |

| AT-DHG-GG024 | 79 | 46 | 96 | 5 |

| AT-DHG-GG025 | 80 | 70 | 78 | 4.8 |

| AT-DHG-GG026 | 83 | 50 | 106 | 6 |

| AT-DHG-GG027 | 91 | 56 | 108 | 6 |

| AT-DHG-GG028 | 100 | 65 | 110 | 5.5 |

| AT-DHG-GG029 | 100 | 60 | 118 | 7 |

| AT-DHG-GG030 | 100 | 60 | 70 | 4 |

Type 3: Silicon Nitride Crucible Lid

![]()

| Silicon Nitride Crucible Lid | ||

| Item No. | Diameter (mm) | Thickness(mm) |

| AT-DHG-GG031 | 50 | 5.5 |

| AT-DHG-GG032 | 60 | 5 |

| AT-DHG-GG033 | 68 | 4.7 |

| AT-DHG-GG034 | 73 | 5 |

| AT-DHG-GG035 | 80 | 5 |

| AT-DHG-GG036 | 84 | 5 |

Silicon Nitride Crucible Packaging

- Multi-layer foam fit with anti-shock corners; bagged for dust control

- Individual lid packed separately or pre-mated per request

![]()