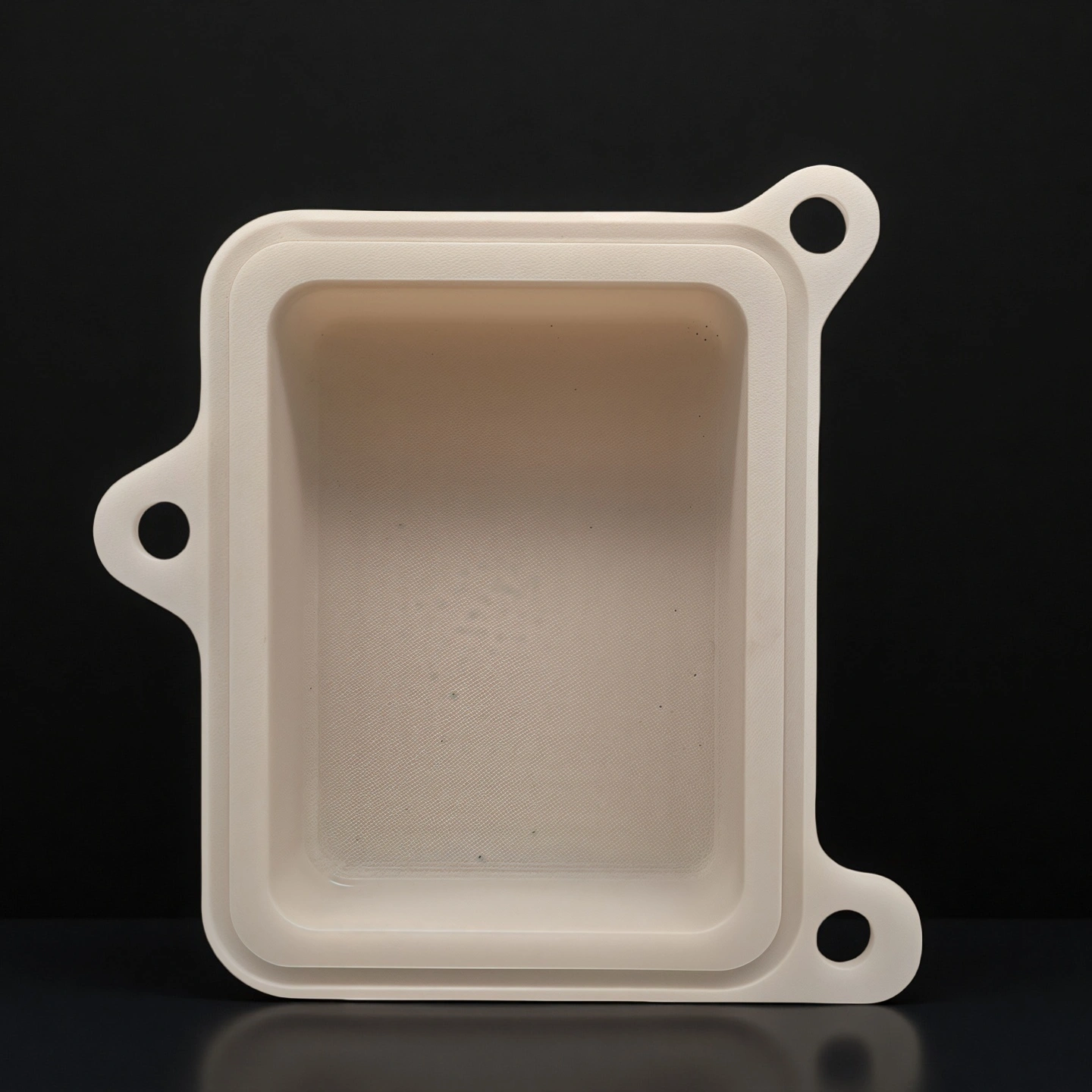

Aluminum nitride crucible is a high-temperature ceramic vessel made from dense sintered AlN, engineered for applications that require both high thermal conductivity and electrical insulation in a compact container. Compared with common alumina crucibles, aluminum nitride crucibles transfer heat much more efficiently, helping achieve more uniform temperature profiles in laboratory furnaces, evaporation sources, and material research processes. Their low impurity level, stable geometry, and resistance to thermal cycling make them suitable for melting small metal charges, evaporating functional materials, and conducting controlled thermal analysis in inert or vacuum atmospheres.

Aluminum Nitride Crucible Benefits

-

High heat transfer across thin walls

Thin-wall aluminum nitride crucible design allows fast and uniform heat distribution across the melt or sample, which helps reduce radial temperature gradients compared with typical alumina crucibles. -

Electrical insulation with high thermal conductivity

The crucible combines ceramic-level electrical insulation with a thermal conductivity commonly one order of magnitude higher than alumina, making it suitable for induction-assisted or high-power-density heating zones. -

Stable performance at elevated temperature

The material structure and wall thickness are optimized for repeated heating cycles up to around 1700°C in inert or controlled atmospheres, while limiting deformation and microcracking under normal furnace ramp rates. -

Low contamination for sensitive samples

The dense AlN microstructure and controlled impurity levels help reduce chemical interaction with molten metals, alloys, and functional powder systems, which is important for thin-film precursors and material property measurements. -

Geometries aligned with equipment fixtures

The crucible shapes can be matched to common sample holders, evaporation sources, and furnace carriers, including stepped profiles or deep chambers where filling height and view port geometry are critical.

Aluminium Nitride Ceramic Crucible Properties

| Property Content | Unit | Unit | ALN-170 | ALN-200 | ALN-230 |

| Basic Properties | Color | gray | light yellow | light yellow | |

| Density | g/cm³ | 3.2-3.3 | 3.2-3.3 | 3.2-3.3 | |

| Surface Roughness | μm | 0.2-0.75 | 0.2-0.75 | 0.2-0.8 | |

| Camber | length ‰ | ≤3‰ | ≤3‰ | ≤3‰ | |

| Hardness | HV | 1100 | 1100 | 1100 | |

| Thermal Properties | Max Operating Temperature | °C | 1100 | 1100 | 1100 |

| Thermal Conductivity | W/m·K | 170-190 | 190-220 | 220-230 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(20-400°c) | 4-5 | 4-5 | 4-5 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(400-800°c) | 5-6 | 5-6 | 5-6 | |

| Mechanical Properties | Flexural Strength | MPa | 300-400 | 350-450 | 400-500 |

| Tensile Strength | MPa | 200-300 | 250-350 | 280-380 | |

| Compressive Strength | MPa | 2000-3000 | 2200-3200 | 2500-3500 | |

| Electrical properties | Dielectric Constant | at 1MHz | 8-9 | 8-9 | 8-9 |

| Dielectric strength | KV/mm | ≥15 | ≥15 | ≥15 | |

| Volume resistivity | 20℃ Ω.cm | ≥1014 | ≥1014 | ≥1014 |

Aluminium Nitride Crucible Specifications

| Aluminum Nitride Crucible | ||

| Item No. | Diameter (mm) | Height (mm) |

| AT-AIN-GG1001 | Customize | |

Aluminum Nitride Melting Crucible Packaging

- Each aluminum nitride crucible is individually wrapped in soft cushioning material to protect edges and rims from chipping.