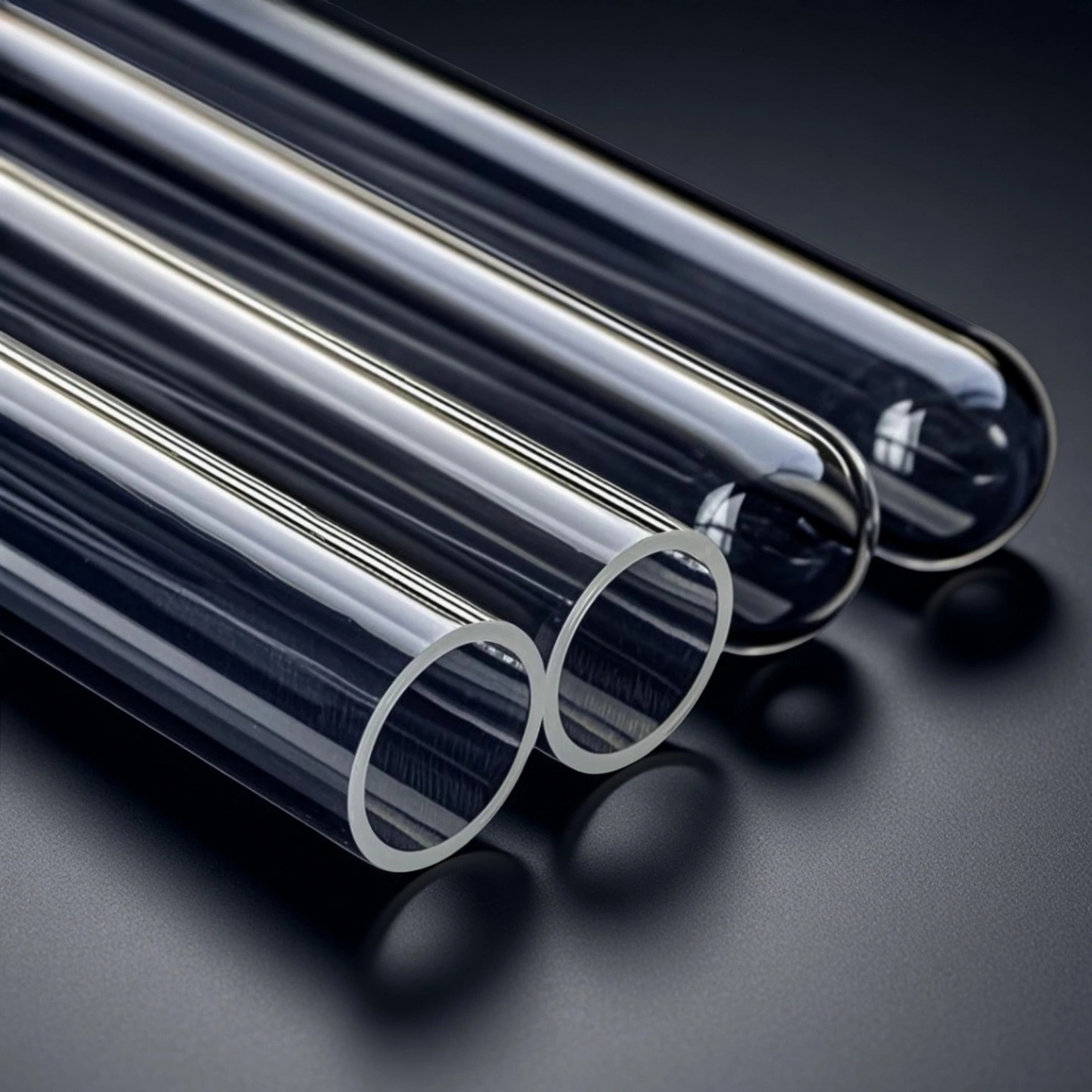

Sapphire tube is a hollow component made from single-crystal aluminum oxide (Al₂O₃). It functions as a protective sleeve, optical path, or sight tube in equipment that requires deep-UV to near-IR transmission, high hardness, chemical stability, and dimensional integrity at elevated temperature. Sapphire tubing is typically produced from C-plane single crystal and then machined and polished to the required OD/ID, wall thickness, straightness, and end-face geometry.

Sapphire Tube Benefits

- Concentricity over length — stable OD/ID axis alignment to reduce lamp fit and seal stress.

- End-face geometry options — square, bevel, or micro-chamfer to lower chipping risk and improve sealing.

- Thin-wall capability — enables lower optical loss and weight without compromising straightness.

- Low-scatter finish — optional end polishing to improve UV throughput and imaging consistency.

- Dimensional repeatability — drawing-matched batches for easier replacement and interchange.

Sapphire Tubing Properties

| Property | Value |

| Material | Al2O3 (monocrystalline structure) |

| Purity | 99.999% |

| Max. Working Temperature | 1950℃ |

| Transmissivity | >86% (280-3500nm) |

| Refractive Index (λ ≈ 546 nm) | 1.76 |

| Density | 3.98-4.1g/cm3 |

| Hardness | 1700Hv |

| Compressive Strength | 2100MPa |

| Tensile Strength | 200MPa |

| Bending Strength | 445MPa |

| Elasticity Modulus | 380GPa |

| Poisson's Ratio | 0.28 |

| Thermal Conductivity | 28-32W/m*K |

| Thermal Expansion Coefficient | 6*10-6/K |

| Refractive Index | 1.76 |

| Volume Resistivity | >1.5*1016Ohm*cm |

| Dielectric Strength | 48KV/mm |

| Lattice Constant (a, c) | a = 4.758 Å, c = 12.991 Å |

| Double-Side Polished Surface | Ra < 0.5 nm |

| Decomposition Point | > 2000 °C (in air) |

Sapphire Tube Specifications

| Type 1 ——Sapphire Tube Open at Both Ends | |||

| Item No. | Outer Diameter(mm) | Thickness(mm) | Length (mm) |

| AT-BS-G2001 | 5~10mm | 1~4mm | 0~1400mm |

| AT-BS-G2002 | 10~20mm | 1~8mm | 0~1400mm |

| AT-BS-G2003 | 20~30mm | 1~10mm | 0~1400mm |

| AT-BS-G2004 | 30~50mm | 1~15mm | 0~1400mm |

| AT-BS-G2005 | 50~70mm | 1~15mm | 0~400mm |

| AT-BS-G2006 | 1~3mm | Inner hole 0.3~1mm | 0~150mm |

| AT-BS-G2007 | 5-200mm | Inner hole0.3-180mm | 5-1400mm (Customize) |

| Type 2 ——Sapphire Tube One End Sealed | |||

| Item No. | Outer Diameter(mm) | Inner Diameter(mm) | Length (mm) |

| AT-BS-G2008 | 20-70 | 16 | 800 |

| AT-BS-G2009 | 20-70 | 16 | 900 |

| AT-BS-G2010 | 20-70 | 16 | 1000 |

| AT-BS-G2011 | 20-70 | 16 | 1450 |

| Type 3 ——Sapphire Thermocouple Protection Tubes | |||

| Item No. | Outer Diameter(mm) | Inner Diameter(mm) | Length (mm) |

| AT-BS-G2012 | 6 | 4 | 5-1500 |

| AT-BS-G2013 | 8 | 5 | 5-1500 |

| AT-BS-G2014 | 10 | 5 | 5-1500 |

| AT-BS-G2015 | 5-80 | 2-70 | 5-1500 (Customize) |

| Type 4 ——Sapphire Capillary Tube | |||

| Item No. | Outer Diameter(mm) | Inner Diameter(mm) | Length (mm) |

| AT-BS-G2016 | 1.57 | 0.5 | 280 |

Sapphire Tube vs. Quartz/Borosilicate

- Durability: Sapphire outperforms in hardness and abrasion resistance; quartz/borosilicate are more prone to scratching.

- Optics: Sapphire supports deep-UV and high-energy environments with polished, low-scatter ends; quartz also transmits UV but scratches more easily.

- Temperature & strength: Sapphire maintains geometry at heat with lower CTE; borosilicate is cheapest but least suitable for harsh UV/thermal duty.

- Cost & machining: Sapphire is higher cost and requires diamond machining; quartz/borosilicate are easier to form and cheaper for non-critical use.

| Property | Sapphire Tube | Quartz Tube |

|---|---|---|

| Hardness | Mohs 9 (very high) | Mohs 7 |

| Thermal Shock Resistance | Excellent (up to 1000 °C ramp tolerance) | Moderate (≤800 °C) |

| UV Transmission | Deep-UV (190 nm) | UV (220 nm limit) |

| Chemical Resistance | Excellent to acids/alkalis/plasma | Limited in fluorine/chlorine plasma |

| Cost | Higher, but longer service life | Lower initial cost |

In summary: sapphire is chosen where lifetime stability, deep UV throughput, or dimensional precision is critical.

Sapphire Sleeves Packing

- Each sapphire tube is individually packed in anti-static foam-lined boxes