A Yttrium Oxide Crucible is a high-temperature Y₂O₃ ceramic crucible used mainly for melting titanium alloys and other oxygen-sensitive metals at about 2000–2100 °C in vacuum or inert atmospheres, where it helps reduce container-to-melt reactions and improve melt purity.

Yttrium Oxide Crucible Benefits

-

Low reactivity with titanium and active metals

Yttria crucibles show low chemical reactivity with Ti, TiAl and other active alloys at temperatures above 1600 °C, helping to limit oxygen pick-up and unwanted reactions compared with conventional oxide crucibles. -

High working temperature window

With a base material melting point above 2400 °C, the Yttrium Oxide Crucible can support furnace set-points up to around 2100 °C in vacuum or inert gas, providing headroom for demanding alloy and materials processing. -

Dense microstructure for erosion resistance

Sintered Y₂O₃ crucibles with a bulk density of around 3.5 g/cm³ provide a relatively dense structure, improving resistance against slag and melt erosion in repeated high-temperature cycles. -

Stable thermal and dielectric behaviour

Yttrium oxide ceramics combine low thermal conductivity among oxide-based engineering ceramics with stable dielectric behaviour, which is useful in high-frequency induction environments. -

Geometry adaptable to furnace design

Y₂O₃ crucibles can be produced as straight-wall cylinders, deep types or optimized shapes to match existing coils and support structures, enabling gradual upgrades from alumina or zirconia crucibles without redesigning the furnace.

Yttrium Oxide Ceramic Crucible Properties

| Category | Property | Value |

| Chemical & Physical | Main Composition | 99% Y₂O₃ |

| Color | White | |

| Density | 4.9 g/cm³ | |

| Hardness (Mohs) | 6 | |

| Mechanical | Flexural Strength | 130 MPa |

| Compressive Strength | 508 MPa | |

| Thermal | Thermal Expansion Coefficient (25°C → 400°C) | 7.2 × 10⁻⁶ /°C |

| Long-Term Service Temperature | 800°C | |

| Thermal Conductivity (25°C) | 1.71 W/m·K | |

| Electrical | Dielectric Strength (5 mm) | 10 kV/mm |

| Volume Resistivity | > 10¹³ Ω·cm | |

| Dielectric Loss (25°C @ MHz) | Not specified | |

| Dielectric Constant (25°C @ MHz) | Not specified |

Y2O3 Crucible Specifications

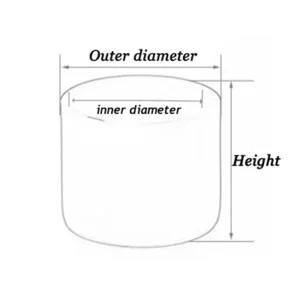

Type 1: Cylinder Y2O3 Crucible

| Item No. | Capacity(ml) | Outer Diameter(mm) | Inner Diameter(mm) | Height(mm) | Purity(%) |

| AT-YOC-Y0001 | 18 | 23 | 20 | 60 | 99.5 |

| AT-YOC-Y0002 | 52 | 40 | 30 | 80 | 99.5 |

| AT-YOC-Y0003 | 80 | 50 | 40 | 70 | 99.5 |

| AT-YOC-Y0004 | 507 | 85 | 75 | 120 | 99.5 |

| AT-YOC-Y0005 | 480 | 93 | 81 | 100 | 99.5 |

| AT-YOC-Y0006 | 700 | 100 | 80 | 150 | 99.5 |

| AT-YOC-Y0007 | 1100 | 120 | 100 | 160 | 99.5 |

| AT-YOC-Y0008 | 2900 | 160 | 140 | 200 | 99.5 |

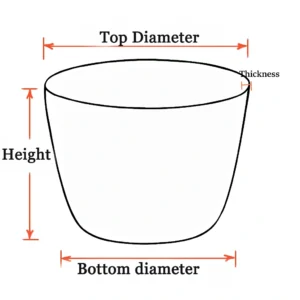

Type 2: Arc-shaped Y2O3 Crucible

| Item No. | Capacity(ml) | Top Diameter(mm) | Bottom Diameter(mm) | Height(mm) | Thickness (mm) | Purity(%) |

| AT-YOC-H0001 | 10 | 28 | 20 | 32 | 2 | 99.5 |

| AT-YOC-H0002 | 15 | 32 | 21 | 35 | 2 | 99.5 |

| AT-YOC-H0003 | 25 | 39 | 24 | 35 | 2.5 | 99.5 |

| AT-YOC-H0004 | 40 | 46 | 30 | 40 | 3 | 99.5 |

| AT-YOC-H0005 | 50 | 48 | 30 | 52 | 3 | 99.5 |

| AT-YOC-H0006 | 100 | 58 | 35 | 68 | 3.5 | 99.5 |

| AT-YOC-H0007 | 150 | 67 | 42 | 78 | 3.5 | 99.5 |

| AT-YOC-H0008 | 200 | 73 | 48 | 86 | 4 | 99.5 |

| AT-YOC-H0009 | 300 | 83 | 52 | 106 | 4 | 99.5 |

| AT-YOC-H0010 | 350 | 87 | 54 | 102 | 4 | 99.5 |

| AT-YOC-H0011 | 500 | 100 | 60 | 118 | 5 | 99.5 |

| AT-YOC-H0012 | 750 | 112 | 70 | 132 | 5.5 | 99.5 |

| AT-YOC-H0013 | 100 | 125 | 80 | 146 | 5.5 | 99.5 |

| AT-YOC-H0014 | 1300 | 130 | 90 | 152 | 5.5 | 99.5 |

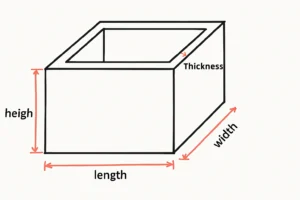

Type 3: Rectangular Y2O3 Crucible

| Item No. | Capacity(ml) | Length(mm) | Width(mm) | Height(mm) | Purity(%) |

| AT-YOC-F0001 | 50 | 50 | 50 | 25 | 99.5 |

| AT-YOC-F0002 | 34 | 55 | 40 | 20 | 99.5 |

| AT-YOC-F0003 | 18 | 60 | 30 | 15 | 99.5 |

| AT-YOC-F0004 | 78 | 65 | 65 | 25 | 99.5 |

| AT-YOC-F0005 | 100 | 65 | 65 | 35 | 99.5 |

| AT-YOC-F0006 | 150 | 70 | 70 | 30 | 99.5 |

| AT-YOC-F0007 | 44 | 70 | 30 | 30 | 99.5 |

| AT-YOC-F0008 | 18 | 70 | 30 | 15 | 99.5 |

| AT-YOC-F0009 | 180 | 80 | 80 | 40 | 99.5 |

| AT-YOC-F0010 | 65 | 85 | 30 | 37 | 99.5 |

| AT-YOC-F0011 | 220 | 85 | 85 | 40 | 99.5 |

| AT-YOC-F0012 | 180 | 90 | 90 | 30 | 99.5 |

| AT-YOC-F0013 | 280 | 90 | 90 | 45 | 99.5 |

| AT-YOC-F0014 | 173 | 90 | 60 | 40 | 99.5 |

| AT-YOC-F0015 | 197 | 90 | 60 | 45 | 99.5 |

| AT-YOC-F0016 | 28 | 100 | 20 | 20 | 99.5 |

| AT-YOC-F0017 | 44 | 100 | 30 | 20 | 99.5 |

| AT-YOC-F0018 | 70 | 100 | 30 | 30 | 99.5 |

| AT-YOC-F0019 | 61 | 100 | 40 | 20 | 99.5 |

| AT-YOC-F0020 | 284 | 115 | 65 | 45 | 99.5 |

| AT-YOC-F0021 | 255 | 115 | 90 | 30 | 99.5 |

| AT-YOC-F0022 | 350 | 115 | 115 | 35 | 99.5 |

| AT-YOC-F0023 | 38 | 120 | 30 | 15 | 99.5 |

| AT-YOC-F0024 | 233 | 120 | 60 | 40 | 99.5 |

| AT-YOC-F0025 | 450 | 120 | 110 | 50 | 99.5 |

| AT-YOC-F0026 | 1273 | 120 | 120 | 100 | 99.5 |

| AT-YOC-F0027 | 550 | 140 | 140 | 37 | 99.5 |

| AT-YOC-F0028 | 758 | 140 | 140 | 45 | 99.5 |

| AT-YOC-F0029 | 300 | 200 | 90 | 25 | 99.5 |

| AT-YOC-F0030 | 700 | 200 | 100 | 50 | 99.5 |

| AT-YOC-F0031 | 1500 | 200 | 200 | 50 | 99.5 |

| AT-YOC-F0032 | 3300 | 200 | 200 | 100 | 99.5 |

| AT-YOC-F0033 | 2400 | 220 | 220 | 70 | 99.5 |

| AT-YOC-F0034 | 3200 | 220 | 220 | 80 | 99.5 |

| AT-YOC-F0035 | 7465 | 330 | 330 | 80 | 99.5 |

| AT-YOC-F0036 | 15760 | 330 | 330 | 160 | 99.5 |

| AT-YOC-F0037 | 2000 | 400 | 80 | 80 | 99.5 |

Y2O3 Crucible Packaging

- Sealed in anti-static bags, foam-protected, and packed in export-grade cartons