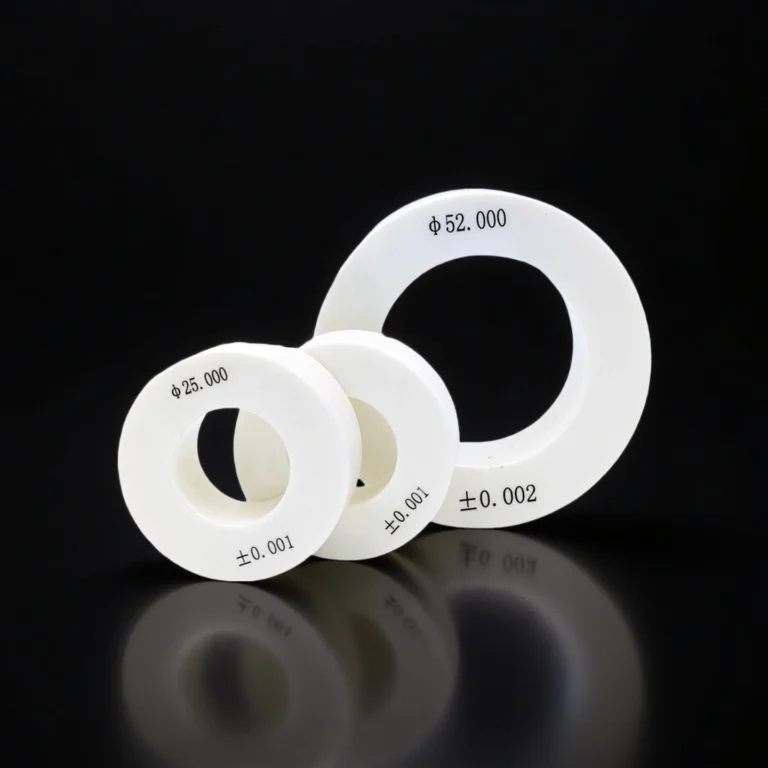

ADCERAX® Zirconia Ceramic Plug Gauge is used for GO/NO‑GO bore verification in machining, automotive, and aerospace production cells where uptime and repeatable results matter. It supports stable bore decisions under water‑based coolants and electromagnetic noise due to its non‑magnetic and corrosion‑resistant Y‑TZP ceramic. Zirconia Ceramic Plug Gauge helps quality teams reduce CMM load and maintain takt time while keeping consistent readings in daily inspection routines.

Features of Zirconia Ceramic Plug Gauge

- The Y-TZP body of Zirconia Ceramic Plug Gauge maintains form with a thermal expansion rate of ~9.2 × 10⁻⁶/K between 20–800 °C. This enables tight dimensional stability in temperature-variable shop floors.

- Its ceramic structure resists corrosion in >98% of common water-based coolants and pH 4–10 fluids used in automotive wet lines. This allows use without oiling or protective coatings.

- Zirconia’s fracture toughness reaches 9.1 MPa·m½, reducing the risk of micro-chipping even after >10,000 insertions in comparator setups. This ensures gauge face integrity over long inspection cycles.

- Zirconia Ceramic Plug Gauge offers a wear life 8–12× longer than hardened steel, based on 120,000-cycle durability test in GO stations. This directly reduces recalibration and replacement frequency.

- Surface finish of Ra ≤ 0.02 µm minimizes seating variation, improving GO/NO-GO judgment consistency by >95% in repeat trials. It supports high confidence in operator-based inspection loops.

- Less than 0.0015 mm cylindricity deviation was measured in over 85% of ADCERAX plug gauges after 12 months of use. This supports extended certification intervals in line-side programs.

- The ceramic core is 100% non-magnetic and exhibits resistivity >10¹² Ω·cm at room temperature. This eliminates coupling errors near probes and servo-driven spindles.

- In aerospace and lab cells, Zirconia Ceramic Plug Gauge showed 0% EMI distortion across 50+ calibration runs under active instrumentation. It ensures compatibility with high-sensitivity setups.

- Field reports confirm zero conductivity-induced misreads in precision inspection stations with static-sensitive electronics. This removes grounding or shielding needs during gauge handling.

Technical Properties for Zirconia Ceramic Plug Gauge

Zirconia Ceramic Plug Gauge delivers consistent dimensional performance under demanding inspection environments due to its advanced ceramic composition. Its physical integrity, chemical inertness, and electrical insulation support long-term usage in calibration laboratories, machining stations, and precision quality control applications.

| Property | Specification |

|---|---|

| Material Composition | Yttria-Stabilized Zirconia (Y-TZP) |

| Density | 6.05 ± 0.05 g/cm³ |

| Hardness | ≥ 1300 HV |

| Fracture Toughness | 8–10 MPa·m¹ᐟ² |

| Flexural Strength | ≥ 1000 MPa |

| Thermal Expansion Coefficient | ~9.2 × 10⁻⁶/K (20–800 °C) |

| Maximum Operating Temperature | 800 °C (stable performance) |

| Electrical Resistivity | >10¹² Ω·cm @ 20 °C |

| Magnetic Susceptibility | Zero (non-magnetic) |

| Surface Roughness (GO face) | ≤ 0.02 µm Ra |

| Roundness Deviation | ≤ 0.0015 mm |

| Corrosion Resistance | Stable in pH 4–10 coolants and acids |

| Moisture Absorption | < 0.01% |

| Color | Ivory white |

| Typical Calibration Interval | >12 months (under standard usage) |

Specifications of Zirconia Ceramic Plug Gauge

| Zirconia Ceramic Plug Gauge | |||

| Item No. | Specification | Interval | Accuracy |

| AT-YHG-TZG001 | 1~3.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG002 | 4~5.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG003 | 6~6.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG004 | 7~7.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG005 | 8~8.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG006 | 9~9.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG007 | 10~10.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG008 | 11~11.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG009 | 12~12.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG010 | 13~13.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG011 | 14~14.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG012 | 15~15.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG013 | 16~16.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG014 | 17~17.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG015 | 18~18.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG016 | 19~19.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG017 | 20~20.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG018 | 21~21.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG019 | 22~22.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG020 | 23~23.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG021 | 24~24.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG022 | 25~25.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG023 | 26~26.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG024 | 27~27.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG025 | 28~28.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG026 | 29~29.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG027 | 30~30.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG028 | 31~31.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG029 | 32~32.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG030 | 33~33.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG031 | 34~34.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG032 | 35~35.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG033 | 36~36.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG034 | 37~37.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG035 | 38~38.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG036 | 39~39.999mm | 0.001mm | ±0.001mm |

| AT-YHG-TZG037 | 40.000mm | / | ±0.001mm |

| AT-YHG-TZG038 | 41.000mm | / | ±0.001mm |

| AT-YHG-TZG039 | 42.000mm | / | ±0.001mm |

| AT-YHG-TZG040 | 43.000mm | / | ±0.001mm |

| AT-YHG-TZG041 | 44.000mm | / | ±0.001mm |

| AT-YHG-TZG042 | 45.000mm | / | ±0.001mm |

| AT-YHG-TZG043 | 46.000mm | / | ±0.001mm |

| AT-YHG-TZG044 | 47.000mm | / | ±0.001mm |

| AT-YHG-TZG045 | 48.000mm | / | ±0.001mm |

| AT-YHG-TZG046 | 49.000mm | / | ±0.001mm |

| AT-YHG-TZG047 | 50.000mm | / | ±0.001mm |

Packaging of Zirconia Ceramic Plug Gauge

Each Zirconia Ceramic Plug Gauge is individually housed in a foam-lined plastic case to protect against vibration and impact. For bulk orders, gauges are arranged in dense EVA inserts within reinforced wooden boxes. This ensures them arrive clean, intact, and ready for immediate use.