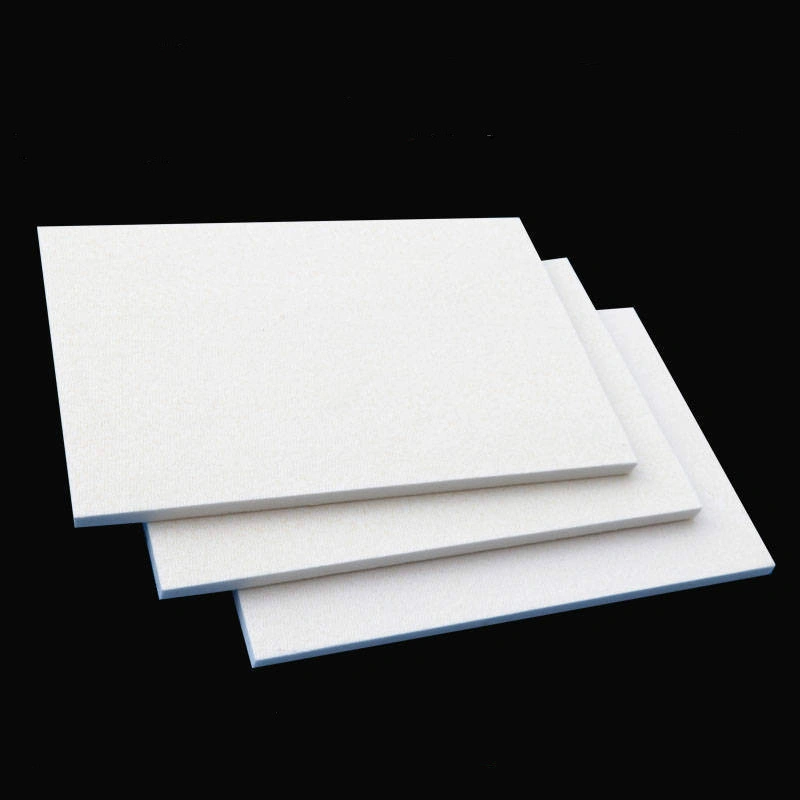

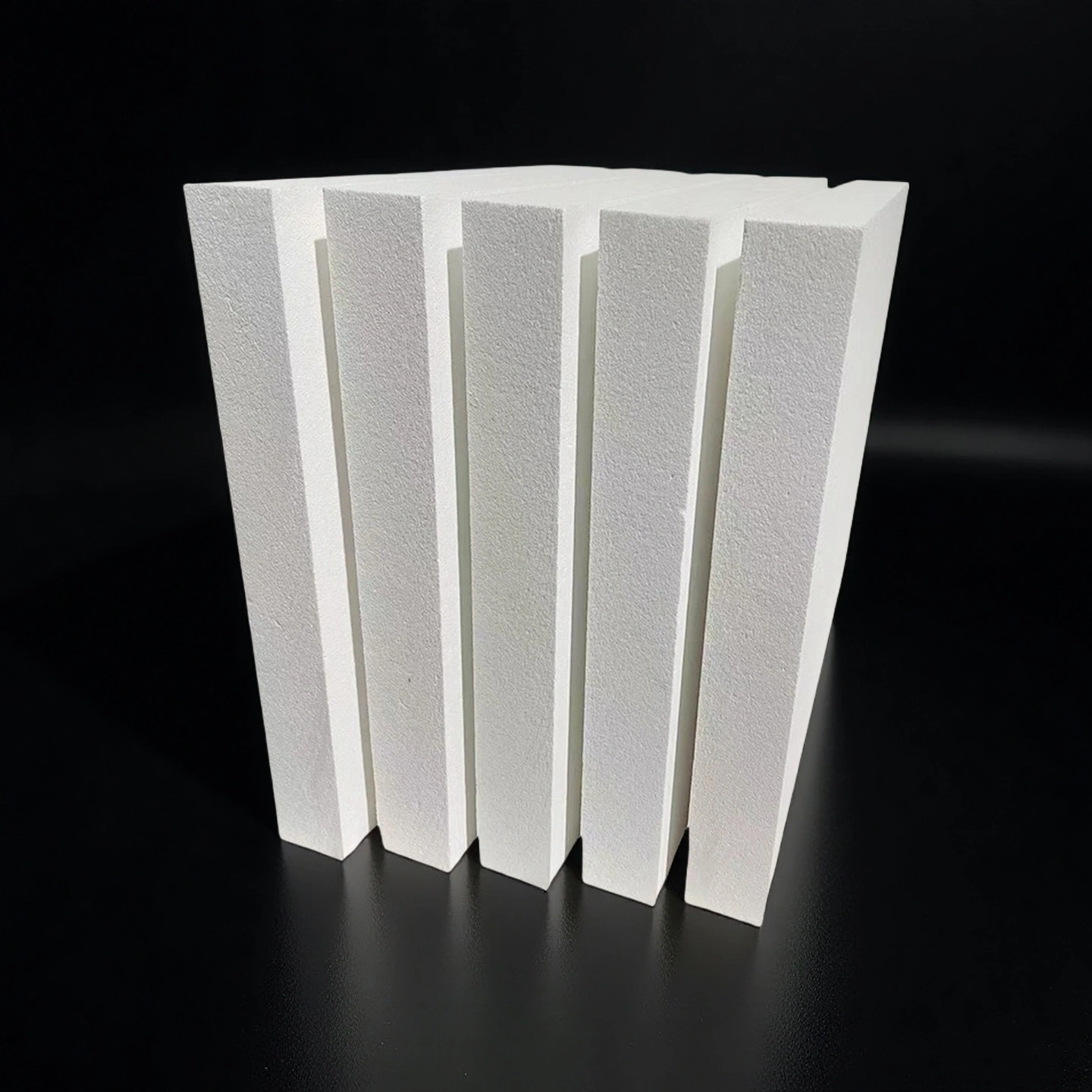

Alumina fiber board is a rigid, machinable high-temperature insulation board made from alumina (Al₂O₃) fibers and a small amount of inorganic binders. It combines the low thermal conductivity of ceramic fibers with the dimensional stability of a pressed board, so it can be cut, drilled, and anchored as a structural insulation layer in furnaces, kilns, and thermal processing equipment.

Alumina Fiber Board Benefits

- Low shrinkage at temperature: Helps maintain hot-face geometry and seal integrity during cycling.

- Stable low conductivity: Supports energy reduction and improved temperature uniformity at mid-to-high temperatures.

- Machinable rigid sheet: Slots, through-holes, and countersinks can be produced cleanly with controlled edge quality.

- Surface flatness & clean face: Reduces fiber fallout and supports cleaner hot-zone assemblies.

- Anchor/adhesive compatible: Works with stainless anchors or high-temperature bonding cements for reliable installation.

Alumina Ceramic Fiber Board Properties

|

Chemical Composition |

|

Item |

1000°C Fiber Blanket |

1260 °C Fiber Blanket |

1425°C Fiber Blanket |

1500°C Fiber Blanket |

1600°C Fiber Blanket |

|

AI2O3 |

42-44% |

45-47% |

34-36% |

41-43% |

72% |

|

SiO2 |

56-58% |

53-55% |

49-51% |

54-56% |

28% |

|

ZrO2 |

- |

- |

14-17% |

- |

- |

|

Cr2O3 |

- |

- |

- |

2-3% |

- |

|

Physical Properties |

|

Item |

1000 |

1260 |

1425 |

1500 |

1600 |

|

Classification Temperature (°C) |

1000 |

1260 |

1425 |

1500 |

1600 |

|

Melting Point (°C) |

1700 |

1760 |

1700 |

1760 |

- |

|

Color |

White |

White |

White |

Light Green |

White |

|

Average Fiber Diameter (mm) |

2.6 |

2.6 |

2.8 |

2.65 |

3.1 |

|

Fiber Length (mm) |

~200 |

~250 |

~250 |

~150 |

~100 |

|

Bulk Density(kg/m3) |

2600 |

2600 |

2800 |

2650 |

3100 |

|

Thermal Conductivity (W/m·K) 400℃ |

0.15 |

0.13 |

- |

- |

- |

|

Thermal Conductivity (W/m·K) 600℃ |

0.22 |

0.19 |

0.13 |

0.13 |

0.06 |

|

Thermal Conductivity (W/m·K) 800℃ |

0.31 |

0.25 |

0.2 |

0.19 |

0.1 |

|

Thermal Conductivity (W/m·K) 1000℃ |

- |

- |

0.29 |

0.26 |

0.14 |

Alumina Fibre Board Specifications

|

Alumina Ceramic Fiber Board |

|

Item No. |

Length(mm) |

Width (mm) |

Thickness (mm) |

Temperature℃ |

SiO2+Al2O3(%) |

|

AT-AO-XW1001 |

600 |

400 |

20-150 |

1000℃-1800℃ |

96%-99.8% |

|

AT-AO-XW1002 |

900 |

600 |

20—150 |

|

AT-AO-XW1003 |

1000 |

500 |

20-150 |

|

AT-AO-XW1004 |

1000 |

600 |

20-150 |

|

AT-AO-XW1005 |

1100 |

700 |

10-150 |

|

AT-AO-XW1006 |

1200 |

1000 |

10—150 |

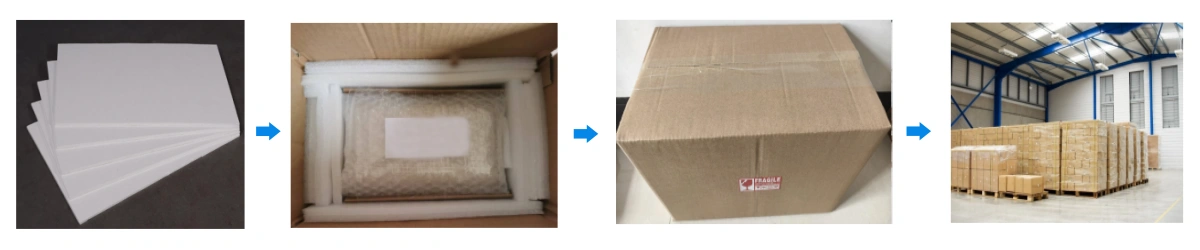

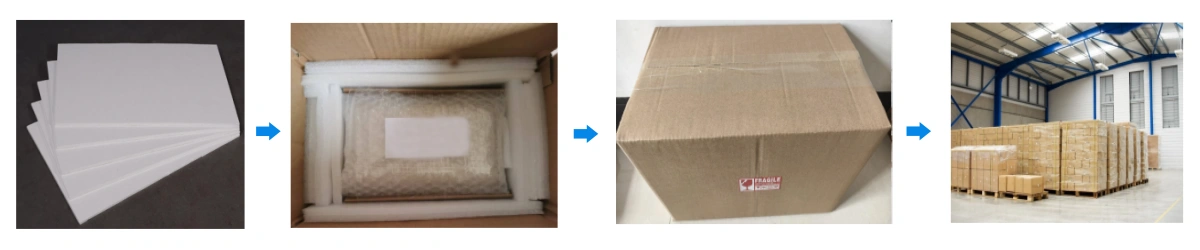

Alumina Fibre Board Packaging

- Boards are packed in moisture-proof cartons with foam protection

Alumina Fibre Board Applications

These cases show that alumina fiber boards improve energy efficiency, process stability, and equipment reliability across a wide range of high-temperature industries, demonstrating their value in real applications.

-

Industrial Furnaces — Hot-Face & Back-Up Panels

✅Key Advantages

1. Low shrinkage at temperature: Holds seal lines during cycling, minimizing heat leaks.

2. Stable conductivity at mid/high-temp: Supports tighter temperature bands for process consistency.

3. Rigid & machinable: Clean slots/holes ensure fast fit with existing anchors and carriers.

✅ Problem Solved

Retrofitting a mixed-load heat-treat line required maintaining ±10 °C uniformity at 900–1050 °C while cutting energy use. Replacing aged boards with high-alumina sheets plus a 25 mm back-up layer reduced burner duty, improved side-to-center delta by ~8–12 °C, and shortened ramp-up by ~10–15 min per cycle. The line avoided unscheduled downtime and brought maintenance intervals back on plan.

-

Advanced Materials & Powder Metallurgy — Sintering Cells

✅Key Advantages

1. Clean surface & low particulates: Helps protect sensitive green parts and fixtures.

2. Flatness control: Supports repeatable stack-ups and fixture alignment.

3. Thermal stability: Reduces dimensional drift across long holds and multiple cycles.

✅ Problem Solved

A sintering cell handling fragile compacts saw edge erosion on the hot-face. Switching to flatness-controlled alumina fiberboard sheets with sealed hot-face reduced debris accumulation, cut fixture re-shimming time by ~30–40%, and stabilized length change across batches.

-

Industry: Kiln Energy Retrofit — Back-Up & Baffle Panels

✅Key Advantages

1. Lower heat loss: Reduced wall flux improves energy balance at steady state.

2. Easy machining: Large pass-throughs and baffles shaped without complex tooling.

3. Fast install: Rigid sheets anchor cleanly, enabling phased upgrades during short outages.

✅ Problem Solved

A periodic kiln targets energy savings without extending downtime. Installing 50 mm alumina insulation ceramic fibre boards behind the hot face lowered fuel consumption per firing cycle by a measured single-digit percentage and kept product profiles within spec, avoiding post-firing rework.