Alumina Ceramic is increasingly selected when electronic systems demand long-term stability rather than short-term performance. However, insulation failure heat accumulation and dimensional drift still threaten reliability. Consequently, material choice becomes a foundational engineering decision.

Alumina Ceramic plays a central role in electrical and electronic engineering by providing stable insulation controlled thermal behavior and dimensional consistency. This article examines how alumina ceramic supports reliability across assemblies interfaces and operating environments, with emphasis on predictable performance over extended service life.

To evaluate why Alumina Ceramic underpins electronic reliability, it is necessary to begin with its functional roles inside real electrical and electronic assemblies. Moreover, these roles reveal how material properties translate directly into system-level performance.

Before examining stability mechanisms and service conditions, the following section outlines how Alumina Ceramic functions within electrical and electronic assemblies. Furthermore, it establishes the connection between material capability and component-level responsibility.

Functional Roles of Alumina Ceramic in Electrical and Electronic Assemblies

Alumina Ceramic is not a passive insulator in electronic systems. Instead, it performs multiple functional roles that combine electrical isolation thermal management and structural support. Therefore, understanding these roles clarifies why alumina ceramic is engineered into critical electronic assemblies.

Electrical Insulation and Structural Support Components

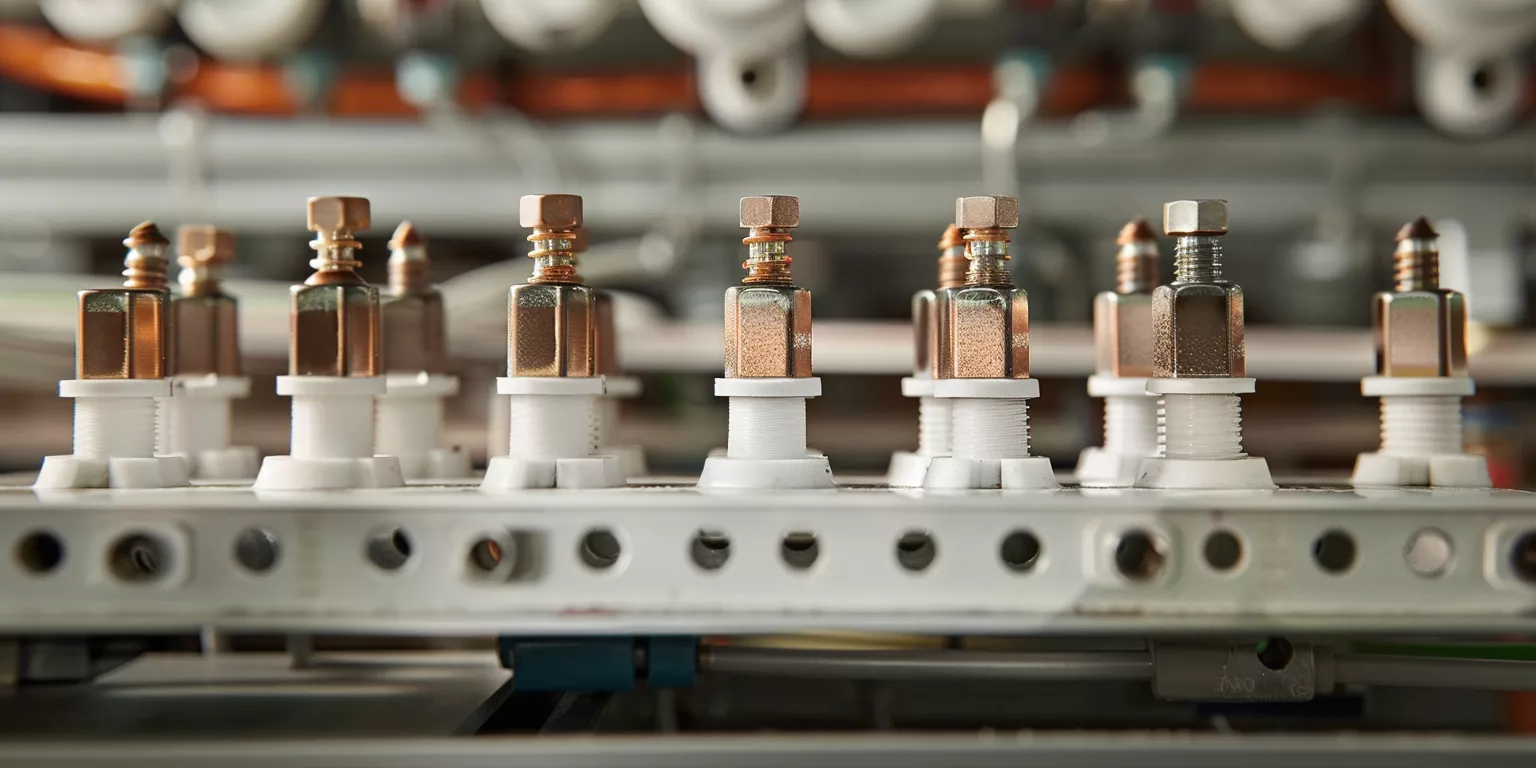

Electrical insulation components made from Alumina Ceramic are widely used as substrates terminal separators and high-voltage isolators. In practice, these parts operate continuously under electric field stress while supporting mechanical loads from mounted components. Consequently, insulation stability must be maintained over thousands of operating hours.

In industrial control panels operating at 3–10 kV, alumina ceramic substrates retained volume resistivity above 10¹⁴ Ω·cm after 20 000 hours of service. By contrast, polymer-based insulators exhibited gradual resistivity reduction due to thermal aging and moisture absorption. As a result, ceramic components preserved electrical safety margins over extended lifetimes.

From an engineering standpoint, dielectric strength exceeding 15 kV/mm combined with compressive strength above 2000 MPa allows Alumina Ceramic to function as both insulator and load-bearing support. Therefore, it reduces component count while improving reliability.

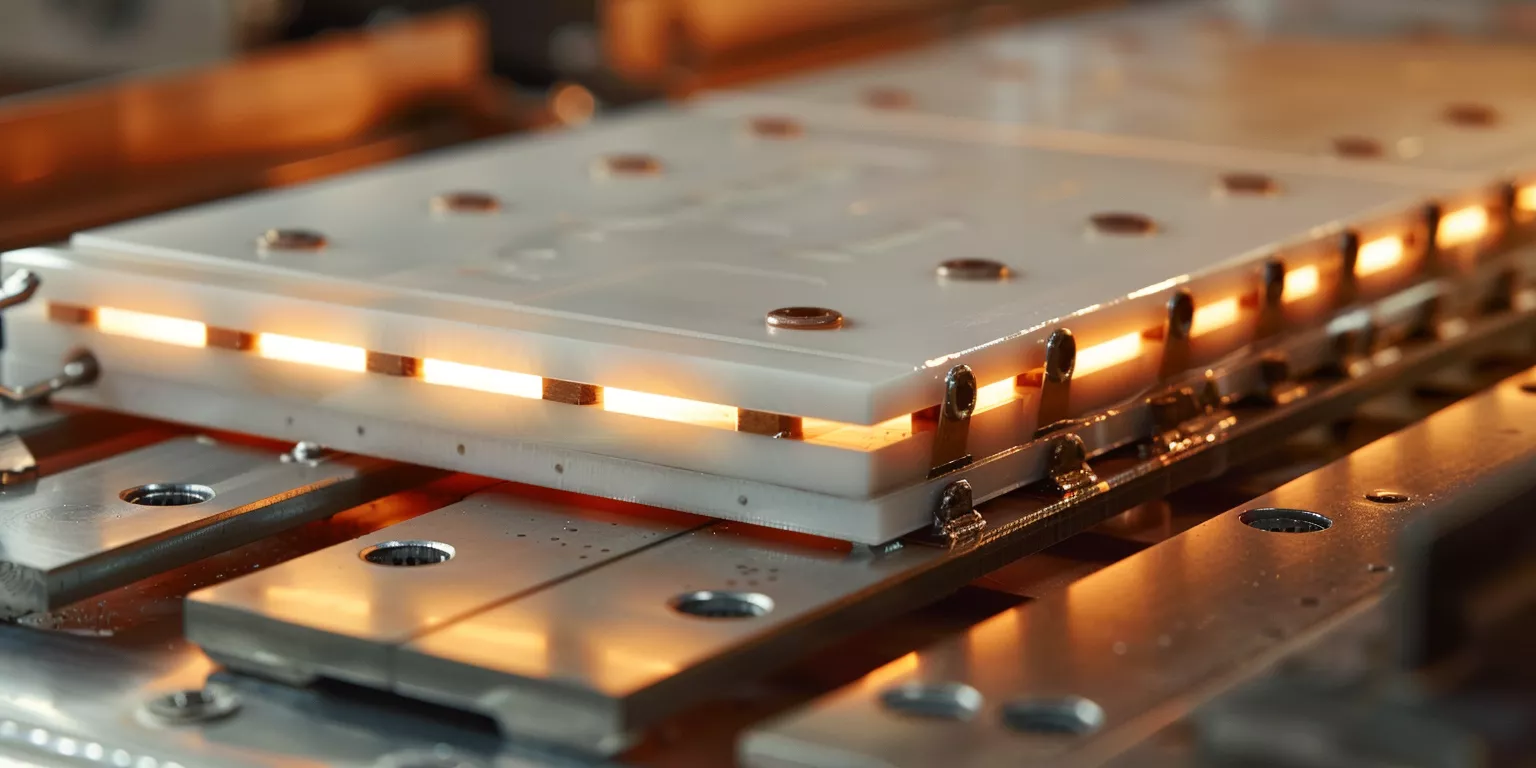

Thermal Management Interfaces and Heat Distribution Parts

Alumina Ceramic is also widely used in thermal management interfaces where electrical insulation and heat dissipation must coexist. In power electronics and LED systems, ceramic substrates spread heat away from active devices while preventing electrical conduction. Thus, thermal performance directly influences device longevity.

In a power module operating at junction temperatures near 180 °C, alumina ceramic substrates with thermal conductivity of 24–30 W/m·K reduced hotspot temperature by approximately 12 °C compared to epoxy-based boards. Moreover, temperature gradients across the substrate remained below 18 °C during steady-state operation. Consequently, thermal stress on solder joints was significantly reduced.

Practically, the balance between moderate thermal conductivity and strong electrical insulation enables Alumina Ceramic to outperform both metals and polymers in hybrid thermal-electrical roles. As a result, it becomes a preferred solution for high-power-density assemblies.

Precision Positioning and Protective Housing Components

Precision positioning and protective housing components represent another critical application of Alumina Ceramic. These parts ensure alignment protection and dimensional accuracy in sensors relays and switching devices. Therefore, dimensional stability becomes a key performance metric.

In sensor housings exposed to continuous vibration and temperature variation between 40 °C and 160 °C, alumina ceramic components maintained dimensional deviation below 0.05 %. Meanwhile, metal housings experienced measurable expansion-induced misalignment. As a consequence, signal accuracy and calibration stability improved when ceramic housings were adopted.

From a system perspective, low thermal expansion around 7–8 ×10⁻⁶/K allows Alumina Ceramic to preserve geometry under combined thermal and mechanical loads. Thus, it supports precision assemblies where alignment tolerance is critical.

Summary of Functional Roles in Electrical and Electronic Assemblies

| Component Role | Typical Electrical Stress (kV/mm) | Operating Temperature (°C) | Primary Engineering Function |

|---|---|---|---|

| Insulating substrates | 5–15 | 80–200 | Electrical isolation |

| Thermal interface parts | <5 | 120–250 | Heat distribution |

| Precision housings | <3 | 40–160 | Dimensional control |

Before moving from functional roles to reliability outcomes, it is necessary to clarify how material selection governs the long-term behavior of electrical systems. Moreover, stability in electronics is rarely defined by peak ratings alone but by performance retention under continuous operation.

How Material Selection Governs Electrical System Stability

Material selection in electrical and electronic systems directly governs insulation reliability thermal consistency and dimensional control. Furthermore, small deviations in material properties often amplify into system-level instability over time. Therefore, understanding how Alumina Ceramic behaves under prolonged electrical and thermal loading is essential.

Retention of Dielectric Strength Over Extended Operation

Dielectric strength retention1 is a primary requirement for electronic materials operating under continuous voltage stress. In practice, insulation failure seldom occurs as an immediate breakdown but develops gradually through leakage path formation. Consequently, long-term dielectric margin preservation becomes critical.

In high-voltage control modules operating at 6–12 kV, Alumina Ceramic substrates maintained dielectric strength above 90 % of initial values after 15 000 operational hours. Meanwhile, organic insulation materials showed measurable degradation within 4000 hours due to thermal and electrical aging. As a result, ceramic-based assemblies sustained stable insulation performance across their intended service life.

From an engineering viewpoint, low dielectric loss (tan δ < 0.001 at 1 MHz) and stable crystal structure allow Alumina Ceramic to resist gradual insulation decay. Therefore, it supports predictable electrical behavior in long-running systems.

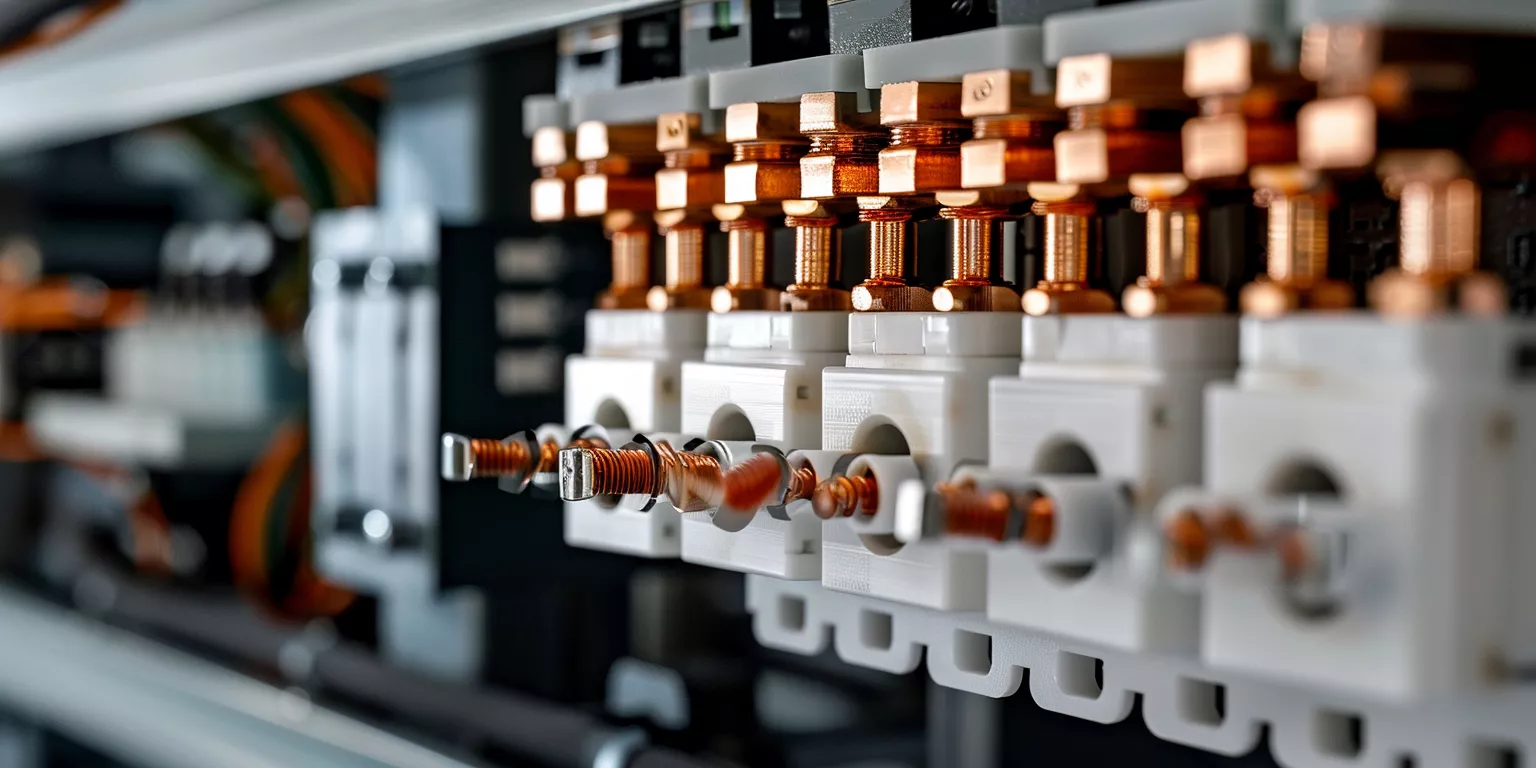

Thermal Expansion Compatibility at Ceramic Metal Interfaces

Thermal expansion compatibility plays a decisive role at interfaces between ceramic components and metallic conductors or housings. During operation, repeated temperature changes generate cyclic stress at these junctions. Thus, mismatch in thermal expansion coefficients can initiate microcracking.

In power electronics assemblies subjected to 1000 thermal cycles between 40 °C and 180 °C, alumina ceramic interfaces with matched CTE metals exhibited crack initiation rates below 5 %. By contrast, poorly matched interfaces showed microcrack formation exceeding 25 % of inspected joints. Consequently, interface integrity directly affected system reliability.

Practically, the thermal expansion coefficient of Alumina Ceramic2 around 7–8 ×10⁻⁶/K aligns well with common electronic metals. As a result, stress accumulation remains manageable under repeated thermal cycling.

Manufacturing Consistency in High-Volume Electronics

High-volume electronic manufacturing requires materials with consistent properties across large production batches. Variability in thickness flatness or dielectric behavior can reduce yield and complicate quality control. Therefore, consistency becomes as important as absolute performance.

In automated assembly lines producing over 50 000 units per month, alumina ceramic substrates demonstrated thickness variation below ±0.03 mm and dielectric constant dispersion under 2 %. Conversely, polymer-based alternatives showed greater batch-to-batch variability. As a result, ceramic substrates enabled tighter process control and higher assembly yield.

Thus, manufacturing consistency inherent to Alumina Ceramic supports stable large-scale production. Consequently, it contributes to predictable system performance across product lifecycles.

Summary of Material Selection Impact on Electrical Stability

| Material Property | Typical Value | Stability Contribution | Affected System Aspect |

|---|---|---|---|

| Dielectric strength (kV/mm) | >15 | Insulation margin | Electrical safety |

| Thermal expansion (×10⁻⁶/K) | 7–8 | Interface integrity | Joint reliability |

| Thickness tolerance (mm) | ±0.03 | Assembly consistency | Production yield |

Before examining how failures emerge, it is essential to understand the service environments that continuously shape material behavior in electronic systems. Moreover, these environments define long-term performance far more than nominal design ratings.

Service Environments That Define Electronic Material Performance

Electrical and electronic components operate within service environments characterized by sustained electrical loading localized heating and subtle mechanical stress. Furthermore, these conditions act concurrently over long durations, making gradual degradation more relevant than instantaneous overload. Therefore, realistic operating environments must be considered when evaluating Alumina Ceramic performance.

Continuous Electrical Loading and Field Exposure

Continuous electrical loading subjects insulating materials to persistent electric fields that can drive slow degradation. In practice, leakage paths form progressively under sustained voltage stress rather than through immediate breakdown. Consequently, resistance to long-term field exposure is critical.

In industrial power distribution modules operating at 4–8 kV, alumina ceramic insulators maintained surface resistivity above 10¹³ Ω/sq after 12 000 hours of continuous operation. Meanwhile, polymer insulators showed localized resistivity drops near electrode edges. As a result, Alumina Ceramic preserved electrical margins under constant field exposure.

From an engineering perspective, stable lattice structure and low ionic mobility reduce charge migration in Alumina Ceramic. Therefore, it withstands prolonged electrical stress without significant performance drift.

Localized Thermal Gradients and Hot Spot Formation

Localized heating is common in electronic assemblies where power density is concentrated. Although average operating temperatures may appear moderate, hot spots introduce thermal gradients that challenge material stability. Thus, resistance to uneven heating becomes essential.

In power converters with localized junction temperatures reaching 200 °C, alumina ceramic substrates limited in-plane temperature gradients to below 20 °C. By contrast, glass-filled polymer boards exhibited gradients exceeding 35 °C. Consequently, ceramic substrates reduced thermal stress at solder joints.

Practically, thermal conductivity around 24–30 W/m·K enables Alumina Ceramic to spread heat effectively without sacrificing insulation. As a result, it mitigates hot spot induced damage.

Environmental Aging and Assembly-Induced Micro Stress

Electronic components are also exposed to environmental aging factors such as humidity vibration and assembly stress. Over time, these factors interact with thermal and electrical loads. Therefore, materials must resist cumulative micro stress.

In outdoor control units exposed to 85 % relative humidity and temperature cycling between 30 °C and 140 °C, alumina ceramic supports showed no measurable swelling or warpage after 18 months. Conversely, polymer supports absorbed moisture and deformed. As a consequence, ceramic components maintained alignment stability.

Thus, Alumina Ceramic demonstrates resilience against environmental aging and assembly-induced stress. Consequently, it supports long service life in demanding electronic environments.

Summary of Service Environments and Material Response

| Service Condition | Typical Range | Material Response | Performance Outcome |

|---|---|---|---|

| Electric field stress | 4–12 kV | Stable resistivity | Insulation reliability |

| Local hot spots (°C) | 150–220 | Controlled gradients | Thermal stress reduction |

| Humidity exposure (%) | up to 85 | No swelling | Dimensional stability |

Before defining mitigation strategies, it is necessary to recognize how failure mechanisms manifest in real electronic applications. Moreover, most failures reflect boundary conditions rather than intrinsic material limitations.

Failure Mechanisms Observed in Alumina Ceramic Electronic Components

Alumina Ceramic used in electronic components rarely fails abruptly; instead, degradation typically accumulates under combined electrical thermal and mechanical influences. Therefore, understanding typical failure manifestations helps engineers set realistic design and handling boundaries.

-

Electrical Overstress Induced Surface Tracking

Surface tracking can occur when localized contamination combines with high electric fields over extended periods. In practice, microscopic conductive paths gradually form along the ceramic surface, especially near sharp electrode edges. Consequently, insulation resistance may decline even though bulk dielectric strength remains intact. -

Thermal Cycling Induced Microcrack Formation

Repeated temperature fluctuations introduce cyclic tensile and compressive stress within ceramic structures. Over thousands of cycles, microcracks may initiate at corners or mounting interfaces and slowly propagate. As a result, mechanical robustness can decline despite stable electrical performance. -

Assembly and Handling Related Edge Damage

Mechanical damage most often arises during assembly rather than operation. Small edge chips introduced by improper fixturing or overtightening fasteners concentrate stress locally. Therefore, handling discipline directly affects long-term reliability.

Overall, these failure mechanisms emphasize that Alumina Ceramic performance is closely linked to system-level integration practices. Consequently, failure prevention focuses more on design and process control than material substitution.

Before applying alumina ceramic in electronic assemblies, design-oriented integration must be addressed to avoid preventable interface and handling failures. Moreover, disciplined specification transforms Alumina Ceramic from a generic material into a predictable engineering element.

Design-Oriented Approaches to Integrating Alumina Ceramic in Electronics

Alumina Ceramic integration in electronics succeeds when purity geometry and interfaces are treated as design variables rather than procurement details. Furthermore, electronic assemblies amplify small deviations in flatness bonding quality and stress distribution. Therefore, integration should be planned as an engineering process from specification to assembly.

Alumina Purity Selection for Electrical Stability

Alumina purity selection influences dielectric stability and resistance to environmental aging in electronic service. In practice, higher purity reduces glassy phases and limits ionic conduction pathways under electrical stress. Consequently, purity impacts long-term insulation margins more than short-term dielectric strength.

In industrial control electronics exposed to 85 % humidity, alumina parts at 96 % purity showed measurable surface resistivity drops of roughly 1 order of magnitude after 1500 hours. By contrast, ≥99 % alumina maintained surface resistivity above 10¹³ Ω/sq under similar exposure. As a result, higher purity ceramics preserved insulation stability in moisture-sensitive environments.

From an engineering standpoint, purity selection should be tied to field stress and contamination risk rather than to temperature rating alone. Therefore, specifying ≥99 % alumina is often justified for high-voltage or high-reliability assemblies.

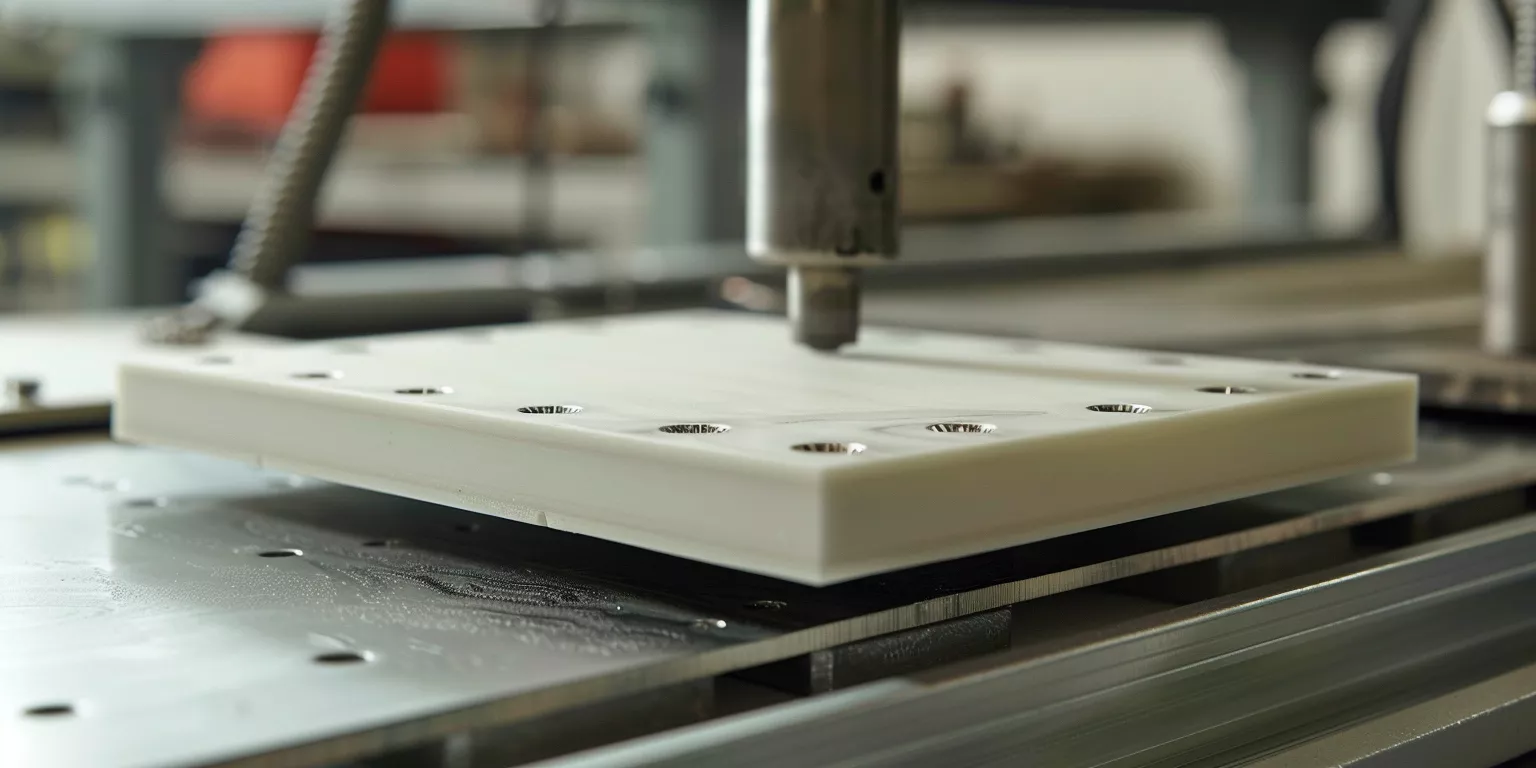

Geometry Thickness and Surface Condition Control

Geometry and surface condition determine how Alumina Ceramic distributes stress and how reliably it interfaces with metallization and bonding layers. In practice, electronic substrates are limited not by bulk strength but by flatness and edge integrity. Thus, thickness and surface finish become reliability controls.

In automated assembly lines, alumina substrates with flatness deviation under 50 µm across 100 mm panels showed solder joint defect rates below 1.5 %. Conversely, substrates with flatness deviation near 120 µm produced defect rates above 6 % due to uneven wetting and localized stress. Consequently, controlling flatness directly improved yield and long-term joint stability.

Practically, surface roughness in the range of Ra 0.2–0.8 µm is often selected to balance metallization adhesion and stress concentration avoidance. As a result, geometry and finish specifications should be treated as functional requirements rather than cosmetic tolerances.

Interface Engineering and Assembly Methodology

Interface engineering is frequently the decisive factor in alumina ceramic electronic reliability. During operation, differential thermal expansion and localized heating generate cyclic stresses at joints. Therefore, assembly methodology must minimize stress concentration and prevent edge damage.

In power assemblies cycling between 40 °C and 180 °C, alumina components bonded with well-matched metallization and controlled solder thickness exhibited joint survival rates above 95 % after 1000 cycles. By contrast, joints with uneven bondline thickness showed microcrack initiation in over 20 % of samples. As a result, bondline control proved more important than changing ceramic grade.

From a process perspective, fixture design torque control and edge protection reduce chipping incidence below 0.5 % in production runs exceeding 10 000 units. Consequently, interface discipline and handling control should be built into manufacturing plans rather than treated as post-failure corrections.

Summary of Design-Oriented Integration Controls

| Design Variable | Typical Control Target | Measurable Indicator | Reliability Outcome |

|---|---|---|---|

| Alumina purity (%) | ≥99 | Surface resistivity (Ω/sq) >10¹³ | Stable insulation margin |

| Flatness (µm) | <50 per 100 mm | Assembly defect rate (%) <1.5 | Higher yield stability |

| Thermal cycling range (°C) | 40–180 | Joint survival (%) >95 after 1000 cycles | Interface durability |

| Edge damage rate (%) | <0.5 | Chipping occurrence per batch | Lower stress concentration |

Why Alumina Ceramic Continues to Anchor Electronic Material Standards

Alumina Ceramic remains widely adopted in electronic systems because it consistently satisfies multiple engineering constraints simultaneously. Therefore, its continued relevance reflects system-level compatibility rather than isolated material excellence.

-

Balanced Electrical and Thermal Performance

Alumina Ceramic provides a rare balance between dielectric strength and thermal conductivity. In practice, it maintains insulation performance while dissipating localized heat without introducing electrical noise. Consequently, it supports stable operation across power electronics and control assemblies. -

Manufacturing Maturity and Process Compatibility

Decades of industrial use have established robust forming sintering and machining processes for Alumina Ceramic. As a result, dimensional tolerances and surface finishes are predictable across suppliers and production volumes. Therefore, integration risk remains low for high-volume electronic manufacturing. -

Defined Performance Boundaries and Reliability History

Alumina Ceramic exhibits well-documented performance limits under electrical thermal and environmental loading. Engineers can therefore design within known safety margins rather than relying on uncertain long-term behavior. As a consequence, reliability assessments become more accurate and defensible.

Overall, Alumina Ceramic continues to anchor electronic material standards because it minimizes uncertainty across design production and operation. Subsequently, selection decisions remain driven by proven system stability rather than novelty.

Before concluding the discussion, an engineering-level perspective helps align material selection with real electrical system constraints. Moreover, this perspective bridges theoretical material properties and practical deployment decisions.

Engineering Perspective on Alumina Ceramic Selection for Electrical Systems

Alumina Ceramic selection in electrical systems is best approached as a boundary-definition exercise rather than a material comparison exercise. Therefore, engineers evaluate where ceramic properties stabilize system behavior and where alternative materials may introduce uncertainty.

-

System-Level Risk Reduction Through Material Predictability

Alumina Ceramic offers predictable dielectric thermal and mechanical behavior across long operating periods. In practice, this predictability simplifies failure mode analysis and reduces cascading system risk. Consequently, it is frequently chosen for critical insulation and support roles rather than secondary components. -

Design for Margin Rather Than Maximum Rating

Electrical systems benefit more from stable safety margins than extreme performance limits. Alumina Ceramic enables conservative design by maintaining consistent properties under combined stressors. As a result, engineers can avoid overcompensation through excessive cooling or insulation redundancy. -

Integration Discipline Over Material Substitution

Most performance issues attributed to ceramic components originate from interface design handling or assembly practices. Therefore, successful implementation depends more on integration discipline than on changing materials. This reinforces Alumina Ceramic as a reliable baseline rather than a limiting factor.

Ultimately, Alumina Ceramic fits electrical systems where long-term stability and controlled degradation outweigh short-term optimization. Consequently, its role persists across evolving electronic architectures.

Conclusion

Alumina Ceramic continues to support electrical and electronic systems by delivering stable insulation thermal control and dimensional reliability under prolonged operational stress.

If your electrical assemblies require predictable insulation performance and long-term stability, Alumina Ceramic components can be evaluated against your specific operating conditions and design constraints.

FAQ

What electrical voltage ranges are suitable for Alumina Ceramic components

Alumina Ceramic is commonly used in systems ranging from low-voltage control circuits to high-voltage modules exceeding 10 kV when properly designed.

How does Alumina Ceramic compare to polymer insulators in electronics

Ceramics provide superior thermal stability and long-term dielectric retention, whereas polymers may degrade faster under combined heat and electrical stress.

Can Alumina Ceramic handle frequent thermal cycling in electronics

Yes, when designed with proper geometry and interface matching, Alumina Ceramic tolerates thousands of thermal cycles with minimal degradation.

Is Alumina Ceramic suitable for high-volume electronic manufacturing

Its mature processing routes and dimensional consistency make it well suited for automated high-volume electronic production.

References: